Sharp VC-ME80HM Service Manual ▷ View online

5

VC-ME80GM

VC-ME80HM

VC-ME80HM

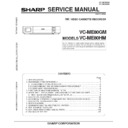

2-2 DISASSEMBLING THE MECHANISM/MAIN PWB ASSEMBLY

1. When removing the mechanism from the main PWB,

remove 1 screw

1

, and remove the antenna cover.

Remove 1 screw

2

.

Remove the FFC cable (AA, AD, AH)

3

which connects

the PWB and the mechanism.

Take out vertically the mechanism so that it does not

damage the adjacent parts.

Take out vertically the mechanism so that it does not

damage the adjacent parts.

2. Removing the mechanism and cassette controller

Remove 2 screws

4

fixing the cassette controller to the

mechanism, and remove the cassette controller.

2

4

1

3

CASSETTE

HOUSING

HOUSING

MAIN PWB

MECHANISM CHASSIS

6

VC-ME80GM

VC-ME80HM

VC-ME80HM

END SENSOR

AC CONNECTOR

2-3 CARES WHEN REASSEMBLING

INSTALLING THE CASSETTE CONTROLLER

When the cassette controller is installed on the mecha-

nism, the initial setting is essential condition.

There are two initial setting methods, namely electrical and

mechanical.

1. Electrical initial setting

So as to perform initial setting of mechanism execute the

Step 1 of Installation of cassette housing. After ascertaining

the return to the initial setting position (*1) install the

cassette controller. (Conditions: When mechanism and

PWB have been installed)

When the cassette controller is installed on the mecha-

nism, the initial setting is essential condition.

There are two initial setting methods, namely electrical and

mechanical.

1. Electrical initial setting

So as to perform initial setting of mechanism execute the

Step 1 of Installation of cassette housing. After ascertaining

the return to the initial setting position (*1) install the

cassette controller. (Conditions: When mechanism and

PWB have been installed)

AE CONNECTOR

INSTALLING THE MECHANISM ON PWB

Lower vertically the mechanism, paying attention to the

mechanism edge, and install the mechanism with due care

so that the parts are not damaged. So as to fix the mecha-

nism to the main PWB install two housings. (Fit the antenna

cover to one of them. For other, fix the vicinity of loading

motor and solder joint side of main PWB.) Connect again

the FFC cable (AA-MH, AD-ME, AH-MH) between the

mechanism and the main PWB.

Lower vertically the mechanism, paying attention to the

mechanism edge, and install the mechanism with due care

so that the parts are not damaged. So as to fix the mecha-

nism to the main PWB install two housings. (Fit the antenna

cover to one of them. For other, fix the vicinity of loading

motor and solder joint side of main PWB.) Connect again

the FFC cable (AA-MH, AD-ME, AH-MH) between the

mechanism and the main PWB.

PARTS WHICH NEED PARTICULAR CARE

When installing the mechanism chassis on the PWB unit,

take care so as to prevent deformation due to contact of

mechanism chassis with REC TIP SW.

When installing the mechanism chassis on the PWB unit,

take care so as to prevent deformation due to contact of

mechanism chassis with REC TIP SW.

Pulley feed gear

Screwdriver

Tilt mark (*1)

Casecon

drive gear

drive gear

Drive angle of

cassette control

cassette control

2. Mechanical initial setting

Feed the pulley feed gear of loading motor with screw

driver. After ascertaining the return to the initial set position

(*1) install the cassette controller in the specified position.

(This method is applied only for the mechanism.)

Feed the pulley feed gear of loading motor with screw

driver. After ascertaining the return to the initial set position

(*1) install the cassette controller in the specified position.

(This method is applied only for the mechanism.)

START SENSOR

AL CONNECTOR

REC TIP SW

7

VC-ME80GM

VC-ME80HM

VC-ME80HM

3. FUNCTION OF MAJOR MECHANICAL PARTS (TOP VIEW)

17

15

10

27

11

5

9

14

12

8

16

13

4

2

7

3

1

18

28

6

No.

Function

No.

Function

1

Full erase head

2

Supply pole base ass’y

3

Tension arm ass’y

4

Idler wheel ass’y

5

Pinch drive lever ass’y

6

Supply reel disk

7

Supply main brake ass’y

8

Take-up main brake ass’y

9

Pinch drive cam

10

A/C head ass’y

11

Reverse guide lever ass’y

12

Casecon drive gear

13

Take-up reel disk

14

Pinch roller lever ass’y

15

Drum ass’y

16

Loading motor

17

Drum drive motor

18

Take-up pole base ass’y

27

Fixing guide

28

Rack lever ass'y

8

VC-ME80GM

VC-ME80HM

VC-ME80HM

FUNCTION OF MAJOR MECHANICAL PARTS (BOTTOM VIEW)

No.

Function

No.

Function

19

Slow brake lever

20

Master cam

21

Capstan D.D. motor

22

Reel belt

23

Clutch lever

24

Limitter pulley ass'y

12

Casecon drive gear

26

Shifter

29

Sub-chassis ass'y

26

24

29

21

22

19

20

12

23

Click on the first or last page to see other VC-ME80HM service manuals if exist.