Sharp XG-NV4SE (serv.man4) Service Manual ▷ View online

25

XG-NV4SE/SM

XG-NV40SA

XG-NV40SA

No.

Adjusting point

Adjusting conditions

Adjusting procedure

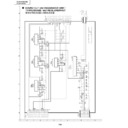

8

RGB counter-

voltage

adjustment

voltage

adjustment

1. Feed the black-and-red

(25%) stripe signal (S-

VGA).

VGA).

2. Make the following choice:

Group : OUTPUT 3

Subject : RC (R)

Subject : RC (R)

»

Using the control switches or the remote controller

buttons, adjust the data in order to minimize the

flicker.

buttons, adjust the data in order to minimize the

flicker.

»

Make the same adjustment for BC (B) and GC (G).

»

See if the image is equally adjusted at the center

and both sides of the screen. If not, readjust the

setting to have the image equal at right and left.

and both sides of the screen. If not, readjust the

setting to have the image equal at right and left.

10

RGB white

balance

balance

1. Feed the 32-step gray scale

signal (S-VGA).

Group : OUTPUT 1

Subject : R1-BLK (R)

Group : OUTPUT 1

Subject : R1-BLK (R)

B1-BLK (B)

»

Choose the subjects R1-BLK and B1-BLK and

adjust the black balance of the gradation.

adjust the black balance of the gradation.

1

2

9

RGB gradation

regeneration

adjustment

regeneration

adjustment

1. F e e d t h e g r e e n - o n l y

SMPTE pattern signal.

Group : OUTPUT 1

Subject : G1-BLK

Group : OUTPUT 1

Subject : G1-BLK

»

Adjust the G-GAIN data until the gradation of the

portion

portion

1

(95% and 100% white) shown below can

be slightly recognized. Make sure also that the

gradation of the portion

gradation of the portion

2

(0% and 5% black) is

visible.

12

Video picture

adjustment

adjustment

1. Feed the split colour bar

signal.

Group : VIDEO 1

Subject : PICTURE

Group : VIDEO 1

Subject : PICTURE

2. Connect the oscilloscope

between pin (2) of P801

and GND.

and GND.

»

Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 2.2 ±0.02 Vp-p.

buttons, adjust the black-to-white (100%) level

difference to 2.2 ±0.02 Vp-p.

11

Horizontal

center

center

1. Feed the NTSC mono-

scope pattern signal.

2. Group : VIDEO 2

Subject : N358-DLY (4)

N443-DLY (0)

PAL-DLY (0)

SECAM-DLY (0)

PAL-DLY (0)

SECAM-DLY (0)

Make sure the settings are

as above.

3. Group : VIDEO 1

Subject : NTSC-H

»

Using the control switches or the remote controller

buttons, adjust the data to have the same overscan.

buttons, adjust the data to have the same overscan.

2.2Vp-p

26

XG-NV4SE/SM

XG-NV40SA

XG-NV40SA

No.

Adjusting point

Adjusting conditions

Adjusting procedure

13

Video AGC

1. Feed the split colour bar

signal.

Group : VIDEO 1

Subject : AGC

Group : VIDEO 1

Subject : AGC

2. Connect the oscilloscope

between pin (2) of P801

and GND.

and GND.

»

Using the control switches or the remote controller

buttons, adjust the black-to-white (100%) level

difference to 1.65 ±0.02 Vp-p.

buttons, adjust the black-to-white (100%) level

difference to 1.65 ±0.02 Vp-p.

14

Video

brightness

adjustment

brightness

adjustment

1. Feed the baseband (split

colour bar) signal. (The ON-

AIR signal is not accepted

because of its too much

noise.)

Group : VIDEO 1

Subject : BRIGHT

AIR signal is not accepted

because of its too much

noise.)

Group : VIDEO 1

Subject : BRIGHT

2. Press the control switch or

the remote control’s mute

button (to set the gamma

correction to the process

setting).

button (to set the gamma

correction to the process

setting).

»

Using the control switches or the remote controller

buttons, adjust the setting until the black signal

becomes bit-less and set to -2 point of value.

buttons, adjust the setting until the black signal

becomes bit-less and set to -2 point of value.

16

NTSC colour

saturation level

saturation level

1. Feed the split colour bar

signal.

Group : VIDEO 1

Subject : N-COLOR

Group : VIDEO 1

Subject : N-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

»

Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.28 ±0.02 Vp-p.

buttons, adjust the difference between the 100%

white portion and the red portion to 0.28 ±0.02 Vp-p.

(same as 100% white)

15

Tint

1. Feed the split colour bar

signal.

Group : VIDEO 1

Subject : TINT

Group : VIDEO 1

Subject : TINT

2. Connect the oscilloscope to

pin (5) of P801.

»

Using the control switches or the remote controller

buttons, adjust the data to have the -(B-Y) wave-

form downhill straight.

buttons, adjust the data to have the -(B-Y) wave-

form downhill straight.

1.65Vp-p

100% White Red

27

XG-NV4SE/SM

XG-NV40SA

XG-NV40SA

No.

Adjusting point

Adjusting conditions

Adjusting procedure

19

Video white

balance

balance

1. Feed the NTSC mono-

scope pattern signal

Group : VIDEO 2

Subject : R1-GAIN

Group : VIDEO 2

Subject : R1-GAIN

B1-GAIN

»

Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colourless.

buttons, adjust so that the entire screen looks

evenly colourless.

18

SECAM colour

saturation level

saturation level

1. Feed the SECAM colour

bar signal.

Group : VIDEO 1

Subject : S-COLOR

Group : VIDEO 1

Subject : S-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

»

Using the control switches or the remote controller

buttons, adjust the data to have a level difference of

0.28 ±0.02 Vp-p between the 100% white portion

and the red portion.

buttons, adjust the data to have a level difference of

0.28 ±0.02 Vp-p between the 100% white portion

and the red portion.

20

Colour system

performance

check

performance

check

1. Receive the colour bar sig-

nal.

»

In the process mode and select L1. Check the colour

and tint.

and tint.

21

Video system

performance

check

performance

check

1. Receive the monoscope

pattern signal.

»

In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

ture, brightness and sharpness.

17

PAL colour

saturation level

saturation level

1. Feed the PAL colour bar

signal.

Group : VIDEO 1

Subject : P-COLOR

Group : VIDEO 1

Subject : P-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

»

Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.28±0.02 Vp-p.

buttons, adjust the difference between the 100%

white portion and the red portion to 0.28±0.02 Vp-p.

100% White Red

100% White Red

22

Audio system

performance

check

performance

check

»

In the process mode nad select L3. Check the bass,

treble.

treble.

28

XG-NV4SE/SM

XG-NV40SA

XG-NV40SA

No.

Adjusting point

Adjusting conditions

Adjusting procedure

23

RGB

performance

check

performance

check

1. Receive the RGB signal.

»

In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

24

Off-timer

performance

check

performance

check

»

In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

25

Thermistor

performance

check

performance

check

1. Heat the thermistor using a

dryer.

»

Make sure the “TEMP” is displayed.

S4

“Factory setting 4”

Remote controller

setting

setting

Process

adjustment

adjustment

»

Make the following settings.

26

Factory settings

27

Automatic

synchronization

synchronization

1. Receive the PHASE check

pattern signal.

»

Call the VGA/S-VGA/XGA mode and make sure

that the clock, phase, horizontal and vertical posi-

tions can be automatically adjusted.

that the clock, phase, horizontal and vertical posi-

tions can be automatically adjusted.

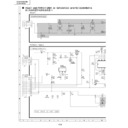

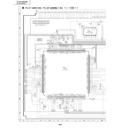

ADJUSTING THE PC BOARD (CPCi-0029CE01/02. PC I/F Unit)

1. Initializing the EEPROM

1)

Press the S5001 key to call the process mode.

2)

2. Adjusting the level settings

2-1. Oscilloscope range setting

Set the range to DC 1V/div. and 5µs/div.

2-2. Input signal

Feed the SVGA 800x600 60Hz gradation waveform signal.

2-3. Adjusting and checking the level settings

1)

Press the S5001 key to call the process mode.

2)

Adjust the SH-PHASE setting on the "OUTPUT 3" menu until the "OUTPUT 3" characters are not blurry any

longer.

longer.

3)

Connect a oscilloscope to TP2. Adjust the BRIGHT setting of "OUTPUT 2" to have the black level of the signal

at 1.7V.

at 1.7V.

4)

Adjust the ROS setting on the A/D menu until the voltage at the positive pole of C64 or pin (2) of IC11 becomes

1.7V.

1.7V.

5)

Adjust the GOS setting on the A/D menu until the voltage at the positive pole of C57 or pin (2) of IC10 becomes

1.7V.

1.7V.

6)

Adjust the BOS setting on the A/D menu until the voltage at the positive pole of C50 or pin (2) of IC9 becomes

1.7V.

1.7V.

7)

Make sure the GAIN setting on the A/D menu is 163.

8)

Connect the oscilloscope to TP1. Adjust the R-D setting on the A/D menu until the white top level of the signal

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

9)

Connect the oscilloscope to TP3. Adjust the B-D setting on the A/D menu until the white top level of the signal

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

10) Connect the oscilloscope to TP2. Adjust the G-D setting on the A/D menu until the white top level of the signal

becomes 3.6V. (Make sure that both the black and white graduations are visible clearly.)

11) Increase the brightness level of OUTPUT 2 by 10 points.

12) Press the S5001 key to exit from the process mode.

12) Press the S5001 key to exit from the process mode.