|

|

MX-M266N MX-M316N MX-M356N (serv.man3)

NOTE Service Manual for models with the V suffix.

Service Manual

|

127

|

47.11 MB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man4)

NOTE Installation Manual for models with the V suffix.

Service Manual

|

76

|

26.56 MB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man5)

Installation Manual (Revised December 2016).

Service Manual

|

74

|

26.04 MB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man7)

Circuit Diagram (Revised to include New Model MX-M356N).

Service Manual

|

127

|

12.1 MB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man8)

NOTE Parts Guide for models with the V suffix.

Service Manual / Parts Guide

|

104

|

161.53 MB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man9)

Parts Guide Includes RP19 20, TR18 HD14 15. (Revised June 2016).

Service Manual / Parts Guide

|

121

|

108.49 MB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man10)

PWB Parts Guide (Revised January 2016).

Service Manual / Parts Guide

|

33

|

633.8 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man19)

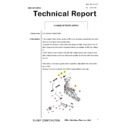

Change of Connector (Revision)

Service Manual / Technical Bulletin

|

5

|

350.94 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man20)

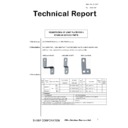

Change In 1st Delivery Unit

Service Manual / Technical Bulletin

|

4

|

480.15 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man21)

Parts Change For Productivity Improvement.

Service Manual / Technical Bulletin

|

3

|

292.09 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man22)

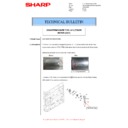

CHANGE OF QUANTITY OF FOLLOWER HOLDER FIXING SCREW.

Service Manual / Technical Bulletin

|

2

|

281.77 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man23)

Removal of OP harness plate.

Service Manual / Technical Bulletin

|

2

|

192.1 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man24)

Change of MG roller and bearing.

Service Manual / Technical Bulletin

|

3

|

243.08 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man25)

Disuse of Delivery cabinet support fixing screw.

Service Manual / Technical Bulletin

|

2

|

210.46 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man26)

CCE 1790 CHANGE OF WAVEGUIDE STICK CLEANING METHOD (Optics)

Service Manual / Technical Bulletin

|

4

|

272.05 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man27)

Quantity change of FD slide collar on shifter unit.

Service Manual / Technical Bulletin

|

2

|

241.12 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man28)

Discontinuation of Radio Wave absorbtion Sheet.

Service Manual / Technical Bulletin

|

2

|

233.49 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man29)

Change of cleaning blade.

Service Manual / Technical Bulletin

|

2

|

143.42 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man30)

Parts change for productivity improvement.

Service Manual / Technical Bulletin

|

3

|

291.51 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man31)

Discontinuation of side door reinforce plate.

Service Manual / Technical Bulletin

|

3

|

295.96 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man32)

Notes when replacing the LED PWB unit.

Service Manual / Technical Bulletin

|

1

|

293.31 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man33)

Parts change for productivity improvement.

Service Manual / Technical Bulletin

|

2

|

275.65 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man34)

Removal of touch pen holder.

Service Manual / Technical Bulletin

|

1

|

176.63 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man35)

Quantity change of rear cover sub fixing screw.

Service Manual / Technical Bulletin

|

2

|

184.11 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man36)

Change of Parts Supply.

Service Manual / Technical Bulletin

|

2

|

243.87 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man37)

Discontinuation of Screw.

Service Manual / Technical Bulletin

|

2

|

182.39 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man38)

Change of 1st Delivery Transport Follower Collar.

Service Manual / Technical Bulletin

|

2

|

291.96 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man39)

Change of Power Supply PWB.

Service Manual / Technical Bulletin

|

4

|

275.51 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man40)

Elimination of HV PWB support plate change in shape of lift fixing plate.

Service Manual / Technical Bulletin

|

2

|

259.89 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man41)

Change of belt idle bearing on 1st 2nd delivery unit's.

Service Manual / Technical Bulletin

|

2

|

168.46 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man42)

Removal of DV cover F Change in shape of cartridge guide lower.

Service Manual / Technical Bulletin

|

3

|

290.37 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man43)

Registration of joint plate for the stand as a service part. (DS19 20).

Service Manual / Technical Bulletin

|

1

|

146.76 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man44)

Parts change for productivity improvement.

Service Manual / Technical Bulletin

|

3

|

311.8 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man45)

Change of power supply.

Service Manual / Technical Bulletin

|

4

|

274.33 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man46)

Design change of paper guide at right door section.

Service Manual / Technical Bulletin

|

5

|

343.3 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man47)

Parts change for productivity improvement.

Service Manual / Technical Bulletin

|

2

|

273.34 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man48)

Change of clutch and modification of clutch related parts.

Service Manual / Technical Bulletin

|

3

|

205.14 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man49)

Change in material of winder pulley in scanner unit.

Service Manual / Technical Bulletin

|

6

|

1009.2 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man50)

Design change of paper guide inner.

Service Manual / Technical Bulletin

|

5

|

354.5 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man51)

Design change of right door.

Service Manual / Technical Bulletin

|

3

|

255.18 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man52)

Change of transport follower roller.

Service Manual / Technical Bulletin

|

2

|

272.05 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man53)

Change of POSD Sensor.

Service Manual / Technical Bulletin

|

2

|

159.78 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man54)

Change of Mylar for sealing dispersion.

Service Manual / Technical Bulletin

|

2

|

143.01 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man55)

Countermeasure for L4-70.

Service Manual / Technical Bulletin

|

2

|

93.9 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man56)

Design change of fusing rear paper detect lever.

Service Manual / Technical Bulletin

|

2

|

123.99 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man57)

Reinforcement of lift coupling.

Service Manual / Technical Bulletin

|

2

|

83.07 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man58)

Change in quantity of screw for fixing support plate.

Service Manual / Technical Bulletin

|

2

|

128.37 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man59)

Parts change for productivity improvement.

Service Manual / Technical Bulletin

|

3

|

430.59 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man60)

Change of lift up unit for common use with other models.

Service Manual / Technical Bulletin

|

2

|

85.54 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man61)

Change of flywheel fixing screw.

Service Manual / Technical Bulletin

|

2

|

106.35 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man62)

Change of cassette baseplate.

Service Manual / Technical Bulletin

|

2

|

199.82 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man63)

Change of Flywheel.

Service Manual / Technical Bulletin

|

2

|

158.25 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man64)

Disuse of cassette handle fixing screw.

Service Manual / Technical Bulletin

|

2

|

150.08 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man65)

Disuse of screw for right rail upper paper guide reinforce plate.

Service Manual / Technical Bulletin

|

2

|

145.21 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man66)

Discontinuing painting on MG spring.

Service Manual / Technical Bulletin

|

2

|

91.26 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man67)

Change in quantity of LSU fixing screws.

Service Manual / Technical Bulletin

|

2

|

175.66 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man68)

Modification of paper feed.

Service Manual / Technical Bulletin

|

3

|

272.92 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man69)

Changes of parts in M F paper guide.

Service Manual / Technical Bulletin

|

3

|

147.3 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man70)

Change in shape of lower fusing frame.

Service Manual / Technical Bulletin

|

2

|

73.54 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man71)

Full detect actuator manufacturer change.

Service Manual / Technical Bulletin

|

2

|

106.72 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man72)

Change in shape of Pin-Spring.

Service Manual / Technical Bulletin

|

2

|

207.25 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man73)

Design change of front inner frame.

Service Manual / Technical Bulletin

|

2

|

178.03 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man74)

Change of Photo Sensor.

Service Manual / Technical Bulletin

|

2

|

220.32 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man75)

Change in shape of transfer bearing R.

Service Manual / Technical Bulletin

|

2

|

141.63 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man76)

Removal of rear cabinet fixing plate.

Service Manual / Technical Bulletin

|

2

|

71.83 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man77)

Handling problem with locking rotation plate on manual paper feed tray.

Service Manual / Technical Bulletin

|

2

|

148.5 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man78)

Service parts setup - Desk Unit Field Support Parts.

Service Manual / Technical Bulletin

|

3

|

283.54 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man79)

Improvement of paper transport capability.

Service Manual / Technical Bulletin

|

3

|

172.29 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man80)

Improvement to prevent right door unit arm dislocating.

Service Manual / Technical Bulletin

|

2

|

263.48 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man81)

Design change of transfer high voltage spring.

Service Manual / Technical Bulletin

|

2

|

87.42 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man82)

Modification of TN drive cover.

Service Manual / Technical Bulletin

|

2

|

136.53 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man83)

Rom upgrade..(2) ICU u201v1 PCU 0202v1.

Service Manual / Technical Bulletin

|

2

|

61.74 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man84)

CCE 1549 COUNTERMEASURE FOR NOISE FROM RSPF

Service Manual / Technical Bulletin

|

2

|

235.86 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man85)

Discontinuation of E type ring on PS roller.

Service Manual / Technical Bulletin

|

3

|

153.38 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man86)

Discontinuation of clamp.

Service Manual / Technical Bulletin

|

2

|

130.41 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man87)

Change of ATC sensor harness.

Service Manual / Technical Bulletin

|

2

|

244 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man88)

Change in manual paper feed clutch harness.

Service Manual / Technical Bulletin

|

2

|

156.62 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man89)

Change in outer diameter of transfer roller collar.

Service Manual / Technical Bulletin

|

2

|

136.63 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man90)

Improvement in locking of MF unit.

Service Manual / Technical Bulletin

|

2

|

267.3 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man91)

Improvement of paper transport capability.

Service Manual / Technical Bulletin

|

3

|

172.21 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man92)

Design change of upper cover.

Service Manual / Technical Bulletin

|

2

|

108.97 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man93)

CCE 1557 CHANGE OF SILENCE MOQUETTE ON RSPF

Service Manual / Technical Bulletin

|

2

|

203.99 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man94)

Remedy for Dog Earing on reverse side when duplex printing.

Service Manual / Technical Bulletin

|

2

|

133.39 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man95)

Removal of motor fixing screw.

Service Manual / Technical Bulletin

|

2

|

188.2 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man96)

Change in shape of open close lock pawl.

Service Manual / Technical Bulletin

|

3

|

97.28 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man97)

Change of PCU PWB for productivity improvement.

Service Manual / Technical Bulletin

|

2

|

452.38 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man98)

Countermeasure for operation of change gate solenoid.

Service Manual / Technical Bulletin

|

2

|

132.3 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man99)

Modification of key interface harness.

Service Manual / Technical Bulletin

|

2

|

123.13 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man100)

Change in shape of tension plate R for DSPF RSPF.

Service Manual / Technical Bulletin

|

3

|

217.95 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man101)

Change to RSPF hinge.

Service Manual / Technical Bulletin

|

2

|

62.41 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man102)

Change in design of PS frame.

Service Manual / Technical Bulletin

|

2

|

117.2 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man103)

Remedy for toner dispersion.

Service Manual / Technical Bulletin

|

3

|

392.61 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man104)

Addition of discharge brush to manual feed tray.

Service Manual / Technical Bulletin

|

3

|

418.18 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man105)

Change in design of PS right lower guide.

Service Manual / Technical Bulletin

|

2

|

156.85 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man106)

Improvement in separation of paper in the paper feed unit.

Service Manual / Technical Bulletin

|

3

|

188.75 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man107)

Improvement in locking of MF unit.

Service Manual / Technical Bulletin

|

2

|

249.1 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man108)

Discontinuation of MX-HD14.

Service Manual / Technical Bulletin

|

1

|

37.7 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man109)

Countermeasure for noise from main drive.

Service Manual / Technical Bulletin

|

2

|

93.65 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man110)

Preventative measures for mismounting of cassette.

Service Manual / Technical Bulletin

|

2

|

136.31 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man111)

Improvement for paper feeding from manual paper feed unit.

Service Manual / Technical Bulletin

|

2

|

153.65 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man112)

Improvement for banding and blur.

Service Manual / Technical Bulletin

|

2

|

103.08 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man113)

Improvement for paper feed release lever becoming detached.

Service Manual / Technical Bulletin

|

3

|

294.88 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man114)

Change to fuser upper HR bearings.

Service Manual / Technical Bulletin

|

2

|

65.6 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man115)

PCQ (water droplet shaped marks on copies).

Service Manual / Technical Bulletin

|

2

|

135.39 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man116)

Design change of toner motor coupling.

Service Manual / Technical Bulletin

|

2

|

391.26 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man117)

COUNTERMEASURE FOR 500 CASSETTE PAPER FEED RELEASE LEVER OF MAIN UNIT COMING OFF AND CAUSING AN A5R JAM

Service Manual / Technical Bulletin

|

3

|

163.48 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man118)

MODIFICATION OF PS FOLLOWER COLLAR

Service Manual / Technical Bulletin

|

2

|

104.9 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man119)

Countermeasure for Scan Lamp Unit.

Service Manual / Technical Bulletin

|

3

|

259.13 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man120)

Rom upgrade..(1) ICU u200v1 PCU 0200v1.

Service Manual / Technical Bulletin

|

1

|

21.31 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man121)

Addition of DV cover.

Service Manual / Technical Bulletin

|

2

|

140.45 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man122)

Countermeasure for noise from 1st delivery gate.

Service Manual / Technical Bulletin

|

3

|

246.4 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man123)

Countermeasure for dog earing paper when using the Manual Feeder.

Service Manual / Technical Bulletin

|

3

|

228.37 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man124)

Remedy for operating sound of duplex motor.

Service Manual / Technical Bulletin

|

2

|

87.67 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man125)

Change in shape of Reactle (Transformer)and base plate

Service Manual / Technical Bulletin

|

2

|

155.23 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man126)

Starting Powder List (This list takes priority over information in Service Manuals).

Service Manual / Technical Bulletin

|

4

|

66.25 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man127)

Image rubbing at rear side of printed surface of paper.

Service Manual / Technical Bulletin

|

3

|

126.29 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man128)

CAUTION ILLUSTRATIONS ADDED TO PACKING BOX.

Service Manual / Technical Bulletin

|

1

|

83.72 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man129)

OPERABILITY IMPROVEMENT OF MF EXTENSION TRAY LOWER.

Service Manual / Technical Bulletin

|

2

|

228.61 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man130)

CHANGE OF UNDER SEPARATOR PAWL FOR PRODUCTIVITY IMPROVEMENT.

Service Manual / Technical Bulletin

|

2

|

62.8 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man131)

IMPROVEMENT OF HEAT RESISTANCE OF ADU ENTER EXIT PAPER ACTUATOR.

Service Manual / Technical Bulletin

|

2

|

85.29 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man132)

IMPROVEMENT OF HEAT RESISTANCE OF ADU ENTER EXIT PAPER ACTUATOR.

Service Manual / Technical Bulletin

|

2

|

75.47 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man133)

COUNTERMEASURE FOR DOUBLE FEED AND REVERSE OF B5 B5R SIZED PAPER.

Service Manual / Technical Bulletin

|

3

|

277.81 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man134)

Change of PCU PWB for productivity improvement.

Service Manual / Technical Bulletin

|

2

|

127.57 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man135)

Countermeasure for failure of change gate solenoid.

Service Manual / Technical Bulletin

|

2

|

131.77 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man136)

Countermeasure for noise from exteriors and manual paper feed unit when duplexing.

Service Manual / Technical Bulletin

|

2

|

120.81 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man137)

Discontinuance of cassette detect mylar.

Service Manual / Technical Bulletin

|

2

|

80.71 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man138)

Change of tray arm for colour tone integration.

Service Manual / Technical Bulletin

|

2

|

156.95 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man139)

Addition of a short harness due to the removal of the Reactle. Note INFORMATION ONLY AS THIS DOES NOT EFFECT EUROPEAN MACHINES.

Service Manual / Technical Bulletin

|

2

|

205.69 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man140)

Improvement in rotation performance of delivery guide collar.

Service Manual / Technical Bulletin

|

2

|

190.77 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man141)

Additional steps when attaching or removing paper exit options.

Service Manual / Technical Bulletin

|

3

|

318.89 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man142)

Improvement of earth spring for right door.

Service Manual / Technical Bulletin

|

2

|

91.34 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man143)

Countermeasure to prevent lower separation pawl falling off during paper jam removal.

Service Manual / Technical Bulletin

|

2

|

89.81 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man144)

Change to Manual Paper Feed Guide Sheet.

Service Manual / Technical Bulletin

|

2

|

154.69 KB

|

|

MX-M266N MX-M316N MX-M356N (serv.man11)

Rom upgrade for Machines fitted with DSK..(2) ICU u201v1 PCU 0202v1 Includes Technical Bulletin DCE996. For Models WITH HDD and MXFR50U DSK Option.

Driver / Update

|

|

44.12 MB

|

|

MX-M266N MX-M316N MX-M356N (serv.man12)

Rom upgrade..(2) ICU u201v1 PCU 0202v1 Includes Technical Bulletin DCE996. For Models WITHOUT HDD.

Driver / Update

|

|

42.85 MB

|

|

MX-M266N MX-M316N MX-M356N (serv.man13)

Rom upgrade..(2) ICU u201v1 PCU 0202v1 Includes Technical Bulletin DCE996. For Models WITH HDD.

Driver / Update

|

|

43.69 MB

|

|

MX-M266N MX-M316N MX-M356N (serv.man14)

Rom upgrade..(1) ICU u200v1 PCU 0200v1 Includes Technical Bulletin DCE960. For Models WITHOUT HDD.

Driver / Update

|

|

41.32 MB

|

|

MX-M266N MX-M316N MX-M356N (serv.man15)

Rom upgrade..(1) ICU u200v1 PCU 0200v1 Includes Technical Bulletin DCE960. For Models WITH HDD.

Driver / Update

|

|

42.16 MB

|

|

MX-M266N MX-M316N MX-M356N (serv.man16)

Initial production release firmware for models with the HDD option fitted.

Driver / Update

|

|

42.11 MB

|

|

MX-M266N MX-M316N MX-M356N (serv.man17)

Initial production release firmware for models without the HDD option fitted.

Driver / Update

|

|

41.28 MB

|

|

MX-M266N MX-M316N MX-M356N (serv.man18)

Watermark Data Version 01.00.00.00

Driver / Update

|

|

6.32 MB

|

|

|

MX-M266N MX-M316N MX-M356N

Handy Guide.

Handy Guide

|

52

|

2.32 MB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man2)

EEPROM Programming Procedure

Handy Guide

|

4

|

772.27 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man145)

MSDS for MX-312GT.

Regulatory Data

|

5

|

61.63 KB

|

|

|

MX-M266N MX-M316N MX-M356N (serv.man146)

MSDS for MX-312GV.

Regulatory Data

|

5

|

66.26 KB

|