Sharp MX-FNX2 (serv.man7) Service Manual ▷ View online

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 17

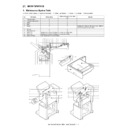

H. Power Supply System

(1) Finisher/Saddle Assembly

a. Outline

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

b. Protective Mechanisms

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

(2) Punch Unit (option)

a. Outline

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

b. Protective Mechanisms

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

Finisher

controller PCB

controller PCB

Punch controller PCB

(punch unit; option)

(punch unit; option)

Relay interface PCB

Host

machine

Circuit Breaker

(CB1)

Circuit protector

(CP2)

24VC

5VDC

5V

5V

24V

24V

24V

Clutch

Motor

Motor

Joint switch

(FJSW)

Front door switch

(FFDDW)

Stapler safety switch

(FSSSW)

Sensor

24 V

5 V

Finisher

controller

PCB

controller

PCB

24 V

5 V

5 V

Punch controller PCB

Motors

Sensors

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 17

H. Power Supply System

(1) Finisher/Saddle Assembly

a. Outline

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

b. Protective Mechanisms

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

(2) Punch Unit (option)

a. Outline

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

b. Protective Mechanisms

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

Finisher

controller PCB

controller PCB

Punch controller PCB

(punch unit; option)

(punch unit; option)

Relay interface PCB

Host

machine

Circuit Breaker

(CB1)

Circuit protector

(CP2)

24VC

5VDC

5V

5V

24V

24V

24V

Clutch

Motor

Motor

Joint switch

(FJSW)

Front door switch

(FFDDW)

Stapler safety switch

(FSSSW)

Sensor

24 V

5 V

Finisher

controller

PCB

controller

PCB

24 V

5 V

5 V

Punch controller PCB

Motors

Sensors

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 17

H. Power Supply System

(1) Finisher/Saddle Assembly

a. Outline

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

b. Protective Mechanisms

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

(2) Punch Unit (option)

a. Outline

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

b. Protective Mechanisms

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

Finisher

controller PCB

controller PCB

Punch controller PCB

(punch unit; option)

(punch unit; option)

Relay interface PCB

Host

machine

Circuit Breaker

(CB1)

Circuit protector

(CP2)

24VC

5VDC

5V

5V

24V

24V

24V

Clutch

Motor

Motor

Joint switch

(FJSW)

Front door switch

(FFDDW)

Stapler safety switch

(FSSSW)

Sensor

24 V

5 V

Finisher

controller

PCB

controller

PCB

24 V

5 V

5 V

Punch controller PCB

Motors

Sensors

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 17

H. Power Supply System

(1) Finisher/Saddle Assembly

a. Outline

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

When the host machine is turned on, it supplies the finisher controller PCB with 24VDC and 5VDC. 24VDC is for the motors and clutches.

24VDC and 5VDC are also supplied as a relay pass drive, 5VDC is used to drive sensors and ICs on PCBs.

If a punch unit (option) is installed, power is also supplied to the punch controller PCB.

Some of 24 VDC used to drive motors is cut off when the joint switch (FJSW), front door switch (FFDDW), or stapler safety switch (FSSSW) is

open.

The block diagram of the power supply system is below.

b. Protective Mechanisms

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

A circuit breaker (CB1) is monitored to protect the 24 VDC system used to drive the motors against overcurrent. The 24-V system used to drive

the feed motor (FFM), paddle motor (FPM), and stack delivery motor (FAM) is equipped with a fuse which melts in the presence of overcurrent.

(2) Punch Unit (option)

a. Outline

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

When the host machine is turned on, the punch unit is supplied by the finisher controller PCB with 24-V and 5-V power.

The 24-V power is used to drive the motors, while the 5-V power is used by sensors and the ICs on the punch controller PCB.

The 24-V power to the motors will be cut off when the joint switch (FJSW) or the front door switch (FFDDW) of the finisher unit is open.

The following is a block diagram for the power supply system:

b. Protective Mechanisms

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

The 24-V system used to drive the punch motor (FPNM) and the punch horizontal registration motor (FPSM) is equipped with a built-in fuse

which melts in the presence of overcurrent.

Finisher

controller PCB

controller PCB

Punch controller PCB

(punch unit; option)

(punch unit; option)

Relay interface PCB

Host

machine

Circuit Breaker

(CB1)

Circuit protector

(CP2)

24VC

5VDC

5V

5V

24V

24V

24V

Clutch

Motor

Motor

Joint switch

(FJSW)

Front door switch

(FFDDW)

Stapler safety switch

(FSSSW)

Sensor

24 V

5 V

Finisher

controller

PCB

controller

PCB

24 V

5 V

5 V

Punch controller PCB

Motors

Sensors