Sharp MX-5050N / MX-5050V / MX-5070N / MX-5070V / MX-6050N / MX-6050V / MX-6070N / MX-6070V (serv.man6) Service Manual ▷ View online

MX-6070N SIMULATION 6 – 18

6-2

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of each fan

motor and its control circuit.

motor and its control circuit.

Section

Others

Operation/Procedure

1) Select the item to be operation checked with the touch panel

1) Select the item to be operation checked with the touch panel

key.

2) Press [EXECUTE] key.

The selected load performs the operation.

When [EXECUTE] key is pressed, the operation is terminated.

Press [ALL] key to select all the fans collectively.

When [EXECUTE] key is pressed, the operation is terminated.

Press [ALL] key to select all the fans collectively.

Load operation check method:

The load operation is checked by the operation sound. However,

there are some loads which cannot be checked with the operation

sound.

The load operation is checked by the operation sound. However,

there are some loads which cannot be checked with the operation

sound.

6-3

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the trans-

port unit and the control circuit.

port unit and the control circuit.

Section

Process (Transport)

Operation/Procedure

1) Select the operation mode with the mode select button.

1) Select the operation mode with the mode select button.

2) When [EXECUTE] key is pressed, the operation of the mode

selected in 1) is performed.

6-4

Purpose

Operation test/check

Function (Purpose)

Used to check the cleaning operation of the

main charger

main charger

Section

Process

Operation/Procedure

1)

1)

Select the items to be checked with the touch panel key

2)

Press [EXECUTE] key

6-6

Purpose

Operation test/check

Function (Purpose)

Used to perform fusing pressure release

and applying, and to check the operations

of the control circuits.

and applying, and to check the operations

of the control circuits.

Section

Fusing

Operation/Procedure

1)

1)

Press [FUSER] key to highlight it.

2)

Press [EXECUTE] key, and fusing pressure applying and fus-

ing pressure release are repeated.

ing pressure release are repeated.

During this period, the status of the fusing roller pressure is dis-

played.

played.

6-90

Purpose

Setting

Function (Purpose)

Used to reset the machine to the factory

setting. (The scanner is set to the lock

enable position)

setting. (The scanner is set to the lock

enable position)

Section

Scanner

Operation/Procedure

1)

1)

Press [EXECUTE] key.

The scanner is shifted to the lock enable position and stopped.

The scanner is shifted to the lock enable position and stopped.

7

7-1

Purpose

Setting

Function (Purpose)

Used to set the operating conditions of

aging.

aging.

Section

Others

Operation/Procedure

1)

1)

Select an item to be set with the touch panel key.

2)

Press [EXECUTE] key.

The machine is rebooted in the aging mode.

The machine is rebooted in the aging mode.

The aging operation condition set by this mode is maintained here-

after unless the power is turned off or the setting is changed.

after unless the power is turned off or the setting is changed.

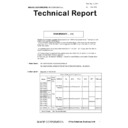

Display

Content

FUFM

Fusing cooling fan

POFM2

Paper exit cooling fan

PROFM1

Process fan 1

PROFM2

Process fan 2

PSFM

Power cooling fan

Mode select button

Content

TC1

Primary transfer (normal rotation)

TC1_R

Primary transfer (reverse rotation)

TC2

Secondary transfer

Mode

select

button

Mode

display

Content

NOTE

TC1

BLACK

Monochrome

mode position

mode position

Black mode position -> Color

mode position -> Drum

separation position -> (Black

mode position)

(Repeated in this sequence.)

mode position -> Drum

separation position -> (Black

mode position)

(Repeated in this sequence.)

COLOR

Color mode

position

position

FREE

Non-transport

position

position

TC1_R

BLACK

Monochrome

mode position

mode position

Black mode position -> Drum

separation position -> Color

mode position -> (Black mode

position) (Repeated in this

sequence.)

separation position -> Color

mode position -> (Black mode

position) (Repeated in this

sequence.)

FREE

Non-transport

position

position

COLOR

Color mode

position

position

TC2

PRINT

Print position

Print position -> Drum

separation position

(Repeated in this sequence)

separation position

(Repeated in this sequence)

FREE

Non-transport

position

position

MC (K) COUNT

Main charger cleaner operation check

MC (C) COUNT

MC (M) COUNT

MC (Y) COUNT

ALL

MC (M) COUNT

MC (Y) COUNT

ALL

All color

PRINT

Fusing pressure

applying

applying

Fusing pressure applying -> Fusing

pressure release -> (Fusing pressure

applying) The operation is repeated.

pressure release -> (Fusing pressure

applying) The operation is repeated.

FREE

Fusing pressure

release

release

AGING

Aging operation setup

INTERVAL

Intermittent operation setting

MX-6070N SIMULATION 6 – 19

7-6

Purpose

Setting

Function (Purpose)

Used to set the operating intermittent aging

cycle.

cycle.

Section

Operation/Procedure

1) Enter the intermittent aging operation cycle (unit: sec) with 10-

1) Enter the intermittent aging operation cycle (unit: sec) with 10-

key.

2) Press [OK] key.

The time entered in procedure 1) is set.

* The interval time that can be set is 1 to 900 (sec).

* The interval time that can be set is 1 to 900 (sec).

The aging operation condition set by this mode is maintained here-

after unless the power is turned off or the setting is changed.

after unless the power is turned off or the setting is changed.

7-8

Purpose

Operation display

Function (Purpose)

Used to display the warm-up time.

Section

Operation/Procedure

Press [EXECUTE] key.

Counting of the warm-up time is started and the time required for

warm-up is displayed

* Interruption of counting by pressing [EXECUTE] key is inhibited.

Press [EXECUTE] key.

Counting of the warm-up time is started and the time required for

warm-up is displayed

* Interruption of counting by pressing [EXECUTE] key is inhibited.

7-9

Purpose

Operation test/check

Function (Purpose)

Color setting in the color copy test mode

(Used to check the copy operation and the

image quality for each color).

(Used to check the copy operation and the

image quality for each color).

Section

Operation/Procedure

1) Select the copy color with the touch panel key.

1) Select the copy color with the touch panel key.

(Two or more colors can be selected.)

The key of the selected color is highlighted.

The key of the selected color is highlighted.

2) Press [EXECUTE] key.

Copying is performed with the selected color.

When [CLOSE] key is pressed, the display goes into the copy oper-

ation menu in the simulation mode.

ation menu in the simulation mode.

7-12

Purpose

Operation test/check

Function (Purpose)

The document reading number of sheets

setting (for aging operation)

setting (for aging operation)

Section

SPF

Operation/Procedure

1)

1)

Set document reading quantity with 10-key.

(Setting range:0 - 255)

(Setting range:0 - 255)

2)

Press [OK] key. The set value is saved.

The aging operation condition set by this mode is maintained here-

after unless the power is turned off or the setting is changed.

after unless the power is turned off or the setting is changed.

8

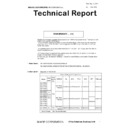

8-1

Purpose

Operation test/check/adjustment

Function (Purpose)

Used to check and adjust the operations of

the developing voltage in each print mode

and the control circuit.

* When the middle speed is adjusted, the

low speed are also adjusted simultane-

ously.

the developing voltage in each print mode

and the control circuit.

* When the middle speed is adjusted, the

low speed are also adjusted simultane-

ously.

Section

Process (Developing)

Operation/Procedure

1)

1)

Select a speed with [MIDDLE] and [LOW] keys on the touch

panel.

panel.

2)

Select a target item to be adjusted with scroll keys.

3)

Enter the setting value with 10-key. (The value specified on the

label of the high voltage PWB must be entered.)

* When the r s key is pressed, the setting value of each item

label of the high voltage PWB must be entered.)

* When the r s key is pressed, the setting value of each item

can be changed with 1up (1down) collectively.

4)

Press [OK] key. Press [OK] key. The set value is saved.

MISFEED DISABLE

JAM detection ignoring setting

FUSING DISABLE

Fusing unit ignoring setting

WARMUP DISABLE

Warming up ignoring setting

DV CHECK DISABLE

Developing unit ignoring setting

SHADING DISABLE

Shading correction operation omitting setting

CCD GAIN FREE

CCD gain adjustment omitting setting

K

Setup/cancel of black

C

Setup/cancel of cyan

M

Setup/cancel of magenta

Y

Setup/cancel of yellow

Item/Display (Mode)

Content

Adjustment

range

Actual

voltage

MIDDLE

A

MIDDLE

SPEED

DVB_K

SPEED

DVB_K

Developing

bias voltage

(Middle

speed mode)

bias voltage

(Middle

speed mode)

K

0 - 600

–450V

+/- 5V

B

MIDDLE

SPEED

DVB_C

SPEED

DVB_C

Developing

bias voltage

(Middle

speed mode)

bias voltage

(Middle

speed mode)

C

0 - 600

–450V

+/- 5V

C

MIDDLE

SPEED

DVB_M

SPEED

DVB_M

Developing

bias voltage

(Middle

speed mode)

bias voltage

(Middle

speed mode)

M

0 - 600

–450V

+/- 5V

D

MIDDLE

SPEED

DVB_Y

SPEED

DVB_Y

Developing

bias voltage

(Middle

speed mode)

bias voltage

(Middle

speed mode)

Y

0 - 600

–450V

+/- 5V

LOW

A

LOW

SPEED

DVB_K

SPEED

DVB_K

Developing

bias voltage

(Low speed

mode)

bias voltage

(Low speed

mode)

K

0 - 600

–450V

+/- 5V

B

LOW

SPEED

DVB_C

SPEED

DVB_C

Developing

bias voltage

(Low speed

mode)

bias voltage

(Low speed

mode)

C

0 - 600

-450V

±5V

C

LOW

SPEED

DVB_M

SPEED

DVB_M

Developing

bias voltage

(Low speed

mode)

bias voltage

(Low speed

mode)

M

0 - 600

-450V

±5V

D

LOW

SPEED

DVB_Y

SPEED

DVB_Y

Developing

bias voltage

(Low speed

mode)

bias voltage

(Low speed

mode)

Y

0 - 600

-450V

±5V

MX-6070N SIMULATION 6 – 20

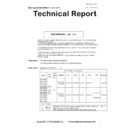

8-2

Purpose

Operation test/check/adjustment

Function (Purpose)

Used to check and adjust the operation of

the main charger grid voltage in each

printer mode and the control circuit.

* When the middle speed is adjusted, the

low speed are also adjusted simultane-

ously.

the main charger grid voltage in each

printer mode and the control circuit.

* When the middle speed is adjusted, the

low speed are also adjusted simultane-

ously.

Section

Process (Charging)

Operation/Procedure

1) Select a speed with [MIDDLE] and [LOW] keys on the touch

1) Select a speed with [MIDDLE] and [LOW] keys on the touch

panel.

2) Select a target item to be adjusted with scroll keys.

3) Enter the adjustment value with 10-key. (The value specified

3) Enter the adjustment value with 10-key. (The value specified

on the label of the high voltage PWB must be entered.)

* When the r s key is pressed, the setting value of each item

* When the r s key is pressed, the setting value of each item

can be changed with 1up (1down) collectively.

4) Press [OK] key. The set value is saved.

8-6

Purpose

Operation test/check/adjustment

Function (Purpose)

Used to check and adjust the operation of

the transport voltage and the control circuit.

the transport voltage and the control circuit.

Section

Process (Transport)

Operation/Procedure

1) Select a target item to be adjusted with scroll keys.

2) Enter the set value with 10-key.

1) Select a target item to be adjusted with scroll keys.

2) Enter the set value with 10-key.

Enter the default value specified on the following list.

3) Press [OK] key. The set value is saved.

Item/Display (Mode)

Content

Adjustment

range

Actual

voltage

MIDDLE

A

MIDDLE

SPEED

GB_K

SPEED

GB_K

Main charger

grid voltage

(Middle

speed mode)

grid voltage

(Middle

speed mode)

K

50 - 850

-630V

±5V

B

MIDDLE

SPEED

GB_C

SPEED

GB_C

Main charger

grid voltage

(Middle

speed mode)

grid voltage

(Middle

speed mode)

C

50 - 850

-630V

±5V

C

MIDDLE

SPEED

GB_M

SPEED

GB_M

Main charger

grid voltage

(Middle

speed mode)

grid voltage

(Middle

speed mode)

M

50 - 850

-630V

±5V

D

MIDDLE

SPEED

GB_Y

SPEED

GB_Y

Main charger

grid voltage

(Middle

speed mode)

grid voltage

(Middle

speed mode)

Y

50 - 850

-630V

±5V

LOW

A

LOW

SPEED

GB_K

SPEED

GB_K

Main charger

grid voltage

(Low speed

mode)

grid voltage

(Low speed

mode)

K

50 - 850

-598V

±5V

B

LOW

SPEED

GB_C

SPEED

GB_C

Main charger

grid voltage

(Low speed

mode)

grid voltage

(Low speed

mode)

C

50 - 850

-598V

±5V

C

LOW

SPEED

GB_M

SPEED

GB_M

Main charger

grid voltage

(Low speed

mode)

grid voltage

(Low speed

mode)

M

50 - 850

-598V

±5V

D

LOW

SPEED

GB_Y

SPEED

GB_Y

Main charger

grid voltage

(Low speed

mode)

grid voltage

(Low speed

mode)

Y

50 - 850

-598V

±5V

Item/Display

Content

Setting

range

Default

value

A

TC1 LOW SPEED CL K

Primary transfer bias

adjustment value

adjustment value

Color

K

Low speed

0 - 255

85

B

TC1 MIDDLE SPEED CL K

Middle speed

0 - 255

106

C

TC1 LOW SPEED CL C

C

Low speed

0 - 255

85

D

TC1 MIDDLE SPEED CL C

Middle speed

0 - 255

106

E

TC1 LOW SPEED CL M

M

Low speed

0 - 255

85

F

TC1 MIDDLE SPEED CL M

Middle speed

0 - 255

106

G

TC1 LOW SPEED CL Y

Y

Low speed

0 - 255

85

H

TC1 MIDDLE SPEED CL Y

Middle speed

0 - 255

106

I

TC1 LOW SPEED BW K

Monochrome

K

Low speed

0 - 255

85

J

TC1 MIDDLE SPEED BW K

Middle speed

0 - 255

106

K

TC2 PLAIN CL SPX

Secondary transfer bias

adjustment value

adjustment value

Color

Standard

paper

<Middle speed>

paper

<Middle speed>

Front surface

0 - 255

96

L

TC2 PLAIN CL DPX

Back surface

0 - 255

96

M

TC2 PLAIN BW SPX

Monochrome

Front surface

0 - 255

96

N

TC2 PLAIN BW DPX

Back surface

0 - 255

96

O

TC2 HEAVY1 CL SPX

Color

Heavy paper

1<106 -176g/m

1<106 -176g/m

2

>

<Low speed >

Front surface

0 - 255

90

P

TC2 HEAVY1 CL DPX

Back surface

0 - 255

96

Q

TC2 HEAVY1 BW SPX

Monochrome

Front surface

0 - 255

90

R

TC2 HEAVY1 BW DPX

Back surface

0 - 255

96

S

TC2 HEAVY2 CL SPX

Color

Heavy paper 2

<177 - 220g/m

<177 - 220g/m

2

>

<Low speed >

Front surface

0 - 255

90

T

TC2 HEAVY2 CL DPX

Back surface

0 - 255

96

U

TC2 HEAVY2 BW SPX

Monochrome

Front surface

0 - 255

90

V

TC2 HEAVY2 BW DPX

Back surface

0 - 255

96

MX-6070N SIMULATION 6 – 21

8-10

Purpose

Operation test/check/adjustment

Function (Purpose)

Used to check and adjust the operation of

the main charger total current output in

each printer mode and the control circuit.

the main charger total current output in

each printer mode and the control circuit.

Section

Process (Charging)

Operation/Procedure

1) Select a target item of setting with scroll key on the touch

1) Select a target item of setting with scroll key on the touch

panel.

2) Enter the set value with 10-key.

3) Press [OK] key. (The set value is saved.)

3) Press [OK] key. (The set value is saved.)

W

TC2 HEAVY3 CL SPX

Secondary transfer bias

adjustment value

adjustment value

Color

Heavy paper 3

<221- 256g/ m

<221- 256g/ m

2

>

<Low speed>

Front surface

0 - 255

90

X

TC2 HEAVY3 CL DPX

Back surface

0 - 255

96

Y

TC2 HEAVY3 BW SPX

Monochrome

Front surface

0 - 255

90

Z

TC2 HEAVY3 BW DPX

Back surface

0 - 255

96

AA

TC2 HEAVY4 CL

Color

Heavy paper 4 <257 - 300g/m

2

>

<Low speed >

0 - 255

90

AB

TC2 HEAVY4 BW

Monochrome

0 - 255

90

AC

TC2 OHP CL

Color

OHP <Low speed >

0 - 255

103

AD

TC2 OHP BW

Monochrome

0 - 255

103

AE

TC2 ENVELOPE CL

Color

Envelope <Low speed >

0 - 255

90

AF

TC2 ENVELOPE BW

Monochrome

0 - 255

90

AG

TC2 THIN CL

Color

Thin paper <Low speed >

0 - 255

96

AH

TC2 THIN BW

Monochrome

0 - 255

96

AI

TC2 GLOSSY PAPER CL

Color

Gross paper <Low speed >

0 - 255

90

AJ

TC2 GLOSSY PAPER BW

Monochrome

0 - 255

90

AK

TC2 EMBOSS CL

Color

Embossed paper <Low speed >

0 - 255

90

AL

TC2 EMBOSS BW

Monochrome

0 - 255

90

AM

TC2 LABEL CL

Color

Label <Low speed >

0 - 255

90

AN

TC2 LABEL BW

Monochrome

0 - 255

90

AO

TC2 FRONT EDGE LOW SPX

Front edge bias adjustment

value

value

In low speed front surface print

0 - 255

76

AP

TC2 FRONT EDGE LOW DPX

In low speed back surface print

0 - 255

69

AQ

TC2 FRONT EDGE MIDDLE SPX

In middle speed front surface print

0 - 255

83

AR

TC2 FRONT EDGE MIDDLE DPX

In middle speed back surface print

0 - 255

83

AS

TC2 BACKEND LOW SPX

Rear edge bias adjustment

value

value

In low speed front surface print

0 - 255

76

AT

TC2 BACKEND LOW DPX

In low speed back surface print

0 - 255

69

AU

TC2 BACKEND MIDDLE SPX

In middle speed front surface print

0 - 255

0

AV

TC2 BACKEND MIDDLE DPX

In middle speed back surface print

0 - 255

0

AW

TC2 INTERVAL LOW SPEED

Bias reference value between

papers

papers

In low speed print (+ pole)

0 - 255

66

AX

TC2 INTERVAL MIDDLE SPEED

In middle speed print (+ pole)

0 - 255

109

AY

TC2 CLEANING MINUS LOW SPEED

Cleaning negative bias

adjustment value

adjustment value

In low speed print (- pole)

0 - 255

54

AZ

TC2 CLEANING MINUS MIDDLE SPEED

In middle speed print (- pole)

0 - 255

62

BA

TC2 CLEANING PLUS LOW SPEED

Cleaning negative bias

adjustment value

adjustment value

In low speed print (+ pole)

0 - 255

66

BB

TC2 CLEANING PLUS MIDDLE SPEED

In middle speed print (+ pole)

0 - 255

109

BC

PTC LOW SPEED CL

PTC current adjustment value

Color

Low speed

0 - 255

109

BD

PTC MIDDLE SPEED CL

Middle speed

0 - 255

206

BE

PTC LOW SPEED BW

Monochrome

Low speed

0 - 255

109

BF

PTC MIDDLE SPEED BW

Middle speed

0 - 255

206

BG

CASE VOLT LOW CL

PTC case voltage adjustment

value

value

Color

Low speed

0 - 255

0

BH

CASE VOLT MIDDLE CL

Middle speed

0 - 255

0

BI

CASE VOLT LOW BW

Monochrome

Low speed

0 - 255

0

BJ

CASE VOLT MIDDLE BW

Middle speed

0 - 255

0

BK

DHV LOW SPEED CL SPX

Separation bias reference

value

value

Color

Low speed

Front surface

0 - 255

80

BL

DHV LOW SPEED CL DPX

Back surface

0 - 255

109

BM

DHV LOW SPEED BW SPX

Monochrome

Front surface

0 - 255

80

BN

DHV LOW SPEED BW DPX

Back surface

0 - 255

109

BO

DHV MIDLLE SPEED CL SPX

Color

Middle speed

Front surface

0 - 255

226

BP

DHV MIDLLE SPEED CL DPX

Back surface

0 - 255

226

BQ

DHV MIDLLE SPEED BW SPX

Monochrome

Front surface

0 - 255

226

BR

DHV MIDLLE SPEED BW DPX

Back surface

0 - 255

226

Item/Display

Content

Setting

range

Default

value

Item/Display

Contents

Setting

range

Default

value

Changeabl

e range

MI

DD

LE

DD

LE

A

MIDDLE

SPEED

MC_K

SPEED

MC_K

Main charger

total current K

total current K

50 - 100

70

-500 -

-1000μA

B

MIDDLE

SPEED

MC_C

SPEED

MC_C

Main charger

total current C

total current C

50 - 100

70

-500 -

-1000μA

C

MIDDLE

SPEED

MC_M

SPEED

MC_M

Main charger

total current M

total current M

50 - 100

70

-500 -

-1000μA

D

MIDDLE

SPEED

MC_Y

SPEED

MC_Y

Main charger

total current Y

total current Y

50 - 100

70

-500 -

-1000μA