Sharp AR-M550 (serv.man12) Service Manual ▷ View online

AR-M550/M620 DETAILS OF EACH SECTION 6 - 80

a-7. Process adsorption plate

1) Remove the drum unit.

2) Remove the cover to remove the adsorption plate.

a-8. Drum separation pawl solenoid

1) Disconnect the connector, and remove the harness guide unit.

2) Remove the drum separation pawl solenoid.

a-9. OPC drum cleaner temperature sensor

1) Remove the upper cover.

2) Remove the OPC drum cleaner temperature sensor.

a-10. Discharge lamp

1) Remove the upper cover. (See “a-9. OPC drum cleaner tempera-

ture sensor” in this section)

2) Remove the discharge lamp.

AR-M550/M620 DETAILS OF EACH SECTION 6 - 81

a-11. Image density sensor

1) Remove the upper cover. (See “a-9. OPC drum cleaner tempera-

ture sensor” in this section)

2) Disconnect the connector.

3) Remove the OPC drum unit. (See “a-1. OPC drum” in this section)

4) Remove the image density sensor.

a-12. OPC drum marking sensor

1) Remove the OPC drum unit. (See “a-1. OPC drum” in this section)

2) Remove the OPC drum marking sensor.

AR-M550/M620 DETAILS OF EACH SECTION 6 - 82

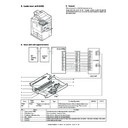

[Transfer section]

A. General

In this section, toner images on the OPC drum are transferred to

paper.

paper.

B. Major parts and signal functions

Code

Signal

name

Name

Function/Operation

Type

Note

DM

DM

OPC drum motor

Drives the OPC drum and the

transfer section.

transfer section.

DC brushless motor

TURM

TURM

Transfer separation motor

Drives and separates the transfer

belt.

belt.

DC brush motor

The transfer belt is pressed on

the OPC drum only during

printing.

the OPC drum only during

printing.

THPS2

THPS2

Transfer belt contact/separation

home position sensor 2

home position sensor 2

Transfer belt separation home

position detection 2

position detection 2

Transmission type

Not used.

THV

THV

Transfer high voltage

High voltage for transfer

HUS-TC

HUS-TC

Process humidity sensor

Process peripheral humidity

detection

detection

Humidity sensor

Analog detector

(Not used)

(Not used)

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

13

14

15

16

17

18

14

15

16

17

18

PCU

PWB

PWB

GND2

/DM

DMCLK

DM-T

DM-T

S5B-PH-K-S

+5V2

2

1 +38V

B2PS-VH

GND1

B1v8B-PHDSS-B

CN-6

GND2

/DM

DMCLK

DM-T

+5V2

GND2

/DVM

DVMCLK

DVM-T

+5V2

GND2

+5V2

/FUM

FUMCLK

FUM-T

+24V1

GND2

/VFM-BKR

AC PWB

11

10

12

14

15

16

14

15

16

+38V

+38V

GND1

GND1

+38V

GND1

CN-5

B16B-PADSS-1

DM

CN-8

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1 PCS-LED

PCS

DMS-LED

DMS

/DL

/PTDL

/PTDL

/PSPS

HUS-TC

GND2

TH-CL

GND2

TLS

GND2

B20B-PHDSS-B

(NC)

+24V1

+5V2

+24V1

+12V2

+12V2

+24V-DL

+12V2

+24V-DL

10

9

8

7 MHV-T

/THV+PWM

/CHV-PWM

THV+REM

CN-15

B34B-PHDSS-B

B34B-PHDSS-B

9

8

7

6

THV

HV

CN-1

B16B-PH-K-S

MHV-T

/THV+PWM

/THV+PWM

/CHV-PWM

THV+REM

FPS-187(WH)

1

2

4

3

1

8

4

5

6

7

3

2

6

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

1

9

8

7

6

5

4

3

2

25

26

27

28

29

30

31

32

26

27

28

29

30

31

32

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

10

20

19

18

17

16

15

14

13

12

11

10

24

23

22

21

24

23

22

21

25

26

27

28

29

30

31

32

26

27

28

29

30

31

32

25

26

27

28

29

30

31

32

26

27

28

29

30

31

32

B32B-PHDSS-B

+24V1

GND2

+24V1

/RRC

(NC)

+24V(DSW)

+24V1

+5V-APPD1

+5V-APPD2

+5V-PFD2

+5V-DSWD

+5V-AINPD

+5V-THPS1

+5V-THPS2

PFD2

THPS1

THPS2

TURM

/SFM

APPD1

APPD2

AINPD

/CFM-AM1

DSWD

/DGS

(NC)

DSW-L

DSW-L

CN-7

GND2

GND2

GND2

(NC)

(NC)

DRAWER

QR/P4-32S-C(01)/QR/P4-32P-C(01)

/CFM-DV

TURM

THPS2

/ADUM2/A

/ADUM2A

/ADUM2B

/ADUM2/B

/ADUM2A

/ADUM2B

/ADUM2/B

/ADUM1/A

/ADUM1A

/ADUM1B

/ADUM1/B

/ADUM1A

/ADUM1B

/ADUM1/B

+5V-APPD1

+5V-APPD2

+5V-APPD2

+5V-AINPD

GND2

APPD1

APPD2

AINPD

APPD1

APPD2

AINPD

/DGS

+24V2

+24V2

+24V(DSW)

(NC)

+24V1

GND2

TURM

DSW-L

+5V-PFD2

+5V-THPS2

PFD2

THPS2

/TCB-PWM

DSW-ADU

+5V-DSW

/CFM-ADU

/TCBIAS

LEFT DOOR UNIT

8

7

6

5

4

3

2

1

9

10

11

12

11

12

8

7

6

5

4

3

2

1

9

10

11

12

11

12

3

2

1

SMR-12V-N/SMP-12V-NC

GND2

179228-3

THPS2

+5V-THPS2

2

1

GND2

PHR-2

TURM

+5V-PFD2

THPS2

PFD2

+5V-THPS2

+5V-THPS2

DSW-L

DSW-L

DSW-L

+24V1

GND2

TURM

TURM

/TCB-PWM

/CFM-ADU

/TCBIAS

7

5

4

3

2

1

6

B6B-PH-K-S

DSW-L

DSW-L

DSW-L

GND2

F-GND

F-GND

/TCB-PWM

Bias

FPS-187

TB PWB

/TCBIAS

No.

Name

Operation

1

Transfer roller (Drive)

Drives the transfer belt.

2

Transfer cleaning roller

Cleans the transfer belt.

3

Transfer belt

Transfers toner images from the OPC drum to paper.

4

Transfer tension roller

Applies a proper tension to the transfer belt.

5

Transfer belt discharge brush

Connects the transfer belt to the chassis ground.

6

Transfer roller

Applies a transfer voltage to the transfer belt.

7

Transfer roller (Idle)

Helps to stretch the transfer belt.

8

Transfer (TCCL) bias high voltage PWB

Generates a bias voltage for the transfer cleaning roller in cleaning or in the print mode.

AR-M550/M620 DETAILS OF EACH SECTION 6 - 83

C. Operational descriptions

1) Toner image transfer

Toner images formed on the drum by the developing roller are trans-

ferred to paper by the transfer belt.

ferred to paper by the transfer belt.

Toner on the drum is negatively charged by stirring in the developing

unit. By applying a positive voltage to the transfer roller, the transfer

belt and paper on the transfer belt are positively charged to transfer

negatively charged toner images to paper.

unit. By applying a positive voltage to the transfer roller, the transfer

belt and paper on the transfer belt are positively charged to transfer

negatively charged toner images to paper.

2) Transfer belt cleaning

During the job, a positive voltage is applied to the transfer cleaning

roller so that negatively charged toner on the transfer belt is attracted

to the cleaning roller.

roller so that negatively charged toner on the transfer belt is attracted

to the cleaning roller.

(The brush on the back of the transfer belt is provided for increasing

the cleaning effect.)

the cleaning effect.)

After completion of the job, the applied voltage to the transfer cleaning

roller is switched to negative, and toner is returned from the transfer

cleaning roller to the transfer belt, and toner on the transfer belt is

attracted to the drum and cleaned by the cleaning blade.

roller is switched to negative, and toner is returned from the transfer

cleaning roller to the transfer belt, and toner on the transfer belt is

attracted to the drum and cleaned by the cleaning blade.

Cleaning timing:

• After completion of the job,

• When warming-up.

• After canceling a jam

• After execution of process control

3) Transfer belt separation/contact

Transfer belt is separated by the transfer separation motor.

The transfer belt is in contact with the drum except for the following

cases:

cases:

• When executing process control (to prevent against breakage of

toner patch on the drum)

• When a jam occurs (Protection of the drum, left door open/close)

• When shipping (Protection of the drum. Separate with the simulation

6-1 (7).)

-2.0kv

Cleaning roller

cleaning mode

cleaning mode

Cleaning mode

Transfer belt

cleaning mode

cleaning mode

Transfer

mode

mode

2.0kv

10

Ω

8

-100v

AC4.5kv

(35

µ

A)

1.5~2.0kv

-2.0kv

2.0kv

-2.0kv

-100v

AC4.5kv

2.0kv

(35 A)

1.5~2.0kv

10

Ω

8

Click on the first or last page to see other AR-M550 (serv.man12) service manuals if exist.