Sharp AR-LC5 (serv.man3) Service Manual ▷ View online

AR-LC5 EXPLANATION OF THE CIRCUITS 11 - 1

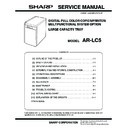

[11] EXPLANATION OF THE CIRCUITS

Block diagram

1. Operation

(1) Communication buffer circuit

On the communication buffer circuit, signals are input and output by the transistor array TD62504 (IC02).

RXD-

TXD-

DSR-

DTR-

RES-

VCC

GND2

+24V

GND1

FG

24V

10V

8MHz

Xtal

CPU(H8/3294)

24V

10V

LLED

Copier

Communication

buffer circuit

Power supply

monitoring unit

monitoring unit

Power supply

10 V circuit

10 V circuit

Operation unit

Large-capacity tray control PWB

Large-capacity tray

Lift motor drive

circuit

circuit

Solenoid drive

circuit

circuit

LED lighting circuit

Sensor input

circuit

circuit

Transfer moto

Clutch drive circuit

r

drive circuit

Upper limit sw (LLSW)

Lift motor (LLM)

Paper amount detection

sensor (LRE)

sensor (LRE)

Paper feed clutch (LPFC)

Paper feed solenoid (LPFS)

Cassette detection line (LCD)

Transfer motor (LPFM)

Upper limit detection sensor (LUD)

Lower limit detection sensor (LDD)

Paper detection sensor (LPED)

Paper delivery detection sensor

(LPFD)

Paper delivery detection sensor

(LPFD)

Copier connection sensor (LTOD)

Door open switch (LDSW)

7

5

8

6

2

1

3

4

3

1

2

3

1

2

C24

0.1u

TXD-LCC/

CN-B-1

DTR-LCC/

CN-B-3

RES-LCC/

CN-B-5

LRE/

CN-A-24

C25

0.1u

BR13

1.2kX4

D11

MC2836

D12

MC2838

+5V

Signal name

Logic

DSR-LCC

H: Request for communication

L: No request for communication

DTR-LCC

H: Communication allowed

L: Communication inhibited

TXD-LCC

H: Normal

L: Start bit

L: Start bit

RXD-LCC

H: Normal

L: Start bit

AR-LC5 EXPLANATION OF THE CIRCUITS 11 - 2

(2) Sensor input circuit

The sensor signals used by LCC are connected directly to the input port of the IC02. LPFD is provided with a static electricity noise protective diode

which protects against static electricity from the paper transport section. The other sensors has the same circuit configuration as the LPED.

which protects against static electricity from the paper transport section. The other sensors has the same circuit configuration as the LPED.

(3) Upper limit switch

A limit switch is provided to protect the LCC If it fails to operate normally. If the tray exceeds the upper limit sensor (LUD) position, the switch is turned

on to shut off the power of the lift motor.

on to shut off the power of the lift motor.

(4) Solenoid and clutch drive circuit

The solenoids and clutches are driven by a Darlington transistor array TD62004AP with 7-circuit clamp diode. LPFS is turned on when the CPU's port

output is at H. LPFC has the same circuit.

output is at H. LPFC has the same circuit.

1000p X7

1

3

4

1

6

5

5

7

7

5

8

6

3

1

8

LDD

/LDSW

LTOD

LTOD

LUD

/24VM

LCD

LPFD

LPED

3

1

2

3

1

2

LPED

LDD

LCD

CN-A-28

R15

22k

C9

C6

C10

C11

LUD

CN-A-11

LTOD

CN-A-18

R16

22k

D9

MC2838

MC2838

D10

MC2836

MC2836

LPFD

BR1

4.7kX4

R7

4.7k

4.7k

CN-A-27

C5

R10

4.7k

4.7k

R11

22k

22k

10kX4

BR2

+24V

+5V

+5V

24V

24V(LLSW)

LLM+

LLM-

Upper limit switch

Lift motor

LCC control PWB

Lift motor

drive circuit

drive circuit

B

C

E

B

C

E

LTRC/

CN-D-2

DTD114EK

Q3

D1

1SS133

Q2

DTD114GK

DTD114GK

10k

+24V

AR-LC5 EXPLANATION OF THE CIRCUITS 11 - 3

(5) Lift motor drive circuit

The tray height is adjusted according to the size of the paper mounted on the paper feed tray. The lift motor controls the rotational direction (CW/CCW)

with the control signals (LLMU, LLMD) from the CPU. The circuit forms a bridge circuit with STA457C to allow the CW/CCW control.

with the control signals (LLMU, LLMD) from the CPU. The circuit forms a bridge circuit with STA457C to allow the CW/CCW control.

A fuse (F01) is provided to protect the motor against shorting or overload.

Suppose that both LLMD and LLMU become H level at the above circuit. If LLMU becomes H first, the STA457C pin 3 become H, IC04 pin 13 through

IC07 pin 6 become H due to diode D20. Even if LLMU is at H and LLMD at H on the port, STA457C pin 1 is at L and pin 6 at H, thus no conduction of

STA457C is achieved.

IC07 pin 6 become H due to diode D20. Even if LLMU is at H and LLMD at H on the port, STA457C pin 1 is at L and pin 6 at H, thus no conduction of

STA457C is achieved.

(6) Transport motor drive circuit

The motor drive circuit is composed of IC05 motor ICs (IC12, IC04 and IC06). When the PWM signal output from the CPU made at H level, the tran-

sistor inside the IC06 turns on to supply current to the motor to start the motor. As the motor is started, hole signals (Hu, Hv, Hw) inside the motor

switch the input of IC05, while the output switches the transistor inside IC06. The motor thus starts rotating under non-control state.

sistor inside the IC06 turns on to supply current to the motor to start the motor. As the motor is started, hole signals (Hu, Hv, Hw) inside the motor

switch the input of IC05, while the output switches the transistor inside IC06. The motor thus starts rotating under non-control state.

When the motor rotates, the speed signal (RE) is output from the motor. The signal is taken into the CPU. If the motor speed is slow, the RWM signal

On duty is increased to increase the speed; if the motor speed is high, the PWM signal On duty is decreased to maintain the required speed.

On duty is increased to increase the speed; if the motor speed is high, the PWM signal On duty is decreased to maintain the required speed.

As the current flowing to the motor becomes large, the input voltage at the minus side of the IC09 rises. If the voltage exceeds the plus-side input volt-

age, output voltage at IC09 becomes at L level, leading in the PWM signal to turn off the transistor of IC07 so that the current to the motor is cut off.

(setting: 3A).

age, output voltage at IC09 becomes at L level, leading in the PWM signal to turn off the transistor of IC07 so that the current to the motor is cut off.

(setting: 3A).

Lift motor

CPU port

LLMD

LLMU

Forward rotation (UP)

L

H

Forward rotation (DOWN)

H

L

OFF

L

L

1-D2

1-D2

1.25A/120V

T1.0A/250V

T1.0A/250V

LLM+

LLM-LLM-

1

1

6

6

5

10

9

9

4

4

8

3

3

2

2

7

7

4

13

3

14

D3

1SS133x2

R20 1k

IC3

STA457C

R17

10k

10k

R19

10k

R3

C13

0.1u

CN-A-3

CN-A-4

R18 1k

D2

R22

1k

IC2D

M63823P

IC2C

M63823P

F1

R21 1k

+24V(LLSW)

LLMU

LLMD

0.1u X3

U

V

W

5

12

6

11

7

10

2

IB1

IC1

IC1

9

VCC

1

5

IA2

IC2E

M63823P

IC2F

IC2G

D6

D7

D8

R25

2.2K

R23

2.2K

R39

R38

R37

R38

R37

CN-C-9

R41

2.7k

1k

R27

1k

1k

C15

C

C18

100U/35V

IC5

SLA6012

Q8

Q7

RT1N141C

Q6

RT1N141C

+24V

+10V

AR-LC5 EXPLANATION OF THE CIRCUITS 11 - 4

(7) 24V power detection line

The line monitors 24V power. If the 24V power fed from the copier is not 24V, the level becomes L and the 24V power error is sent to the copier.

(8) LED lighting circuit

This is the LED lighting circuit for the cassette door switch.

When the CPU outputs the L signal, the LED comes on.

D4

RD11EB

RD11EB

C31

0.1u

R6

1k(1/4W)

FR1

100(1/4W)

Q1

2SC1472K

C30

0.1u

D5

RD18FB1

RD18FB1

R5

1k(1/4W)

+10V

+24V

B

C

E

LLED

CN-A-29

R1

220(1/4W)

R8

4.7k

4.7k

R9

4.7k

Q4

DTD114GK

DTD114GK

+5V

Click on the first or last page to see other AR-LC5 (serv.man3) service manuals if exist.