Sharp AR-FN5 Service Manual ▷ View online

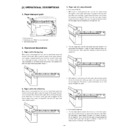

8. Attach the front and rear cabinets.

After hanging the ribs of the front and rear covers on the frames,

attach the front and rear cabinets using a screw (M4 x 10) respec-

tively.

At this time, paste the connection harness to the rear cabinet as

shown in the illustration.

attach the front and rear cabinets using a screw (M4 x 10) respec-

tively.

At this time, paste the connection harness to the rear cabinet as

shown in the illustration.

9. Attach the trays.

< 1 > Raise the paper holder lever, insert the two pawls on the rear

side of the offset tray unit to the mounting positions, and fix the

tray using the two screws (M4 x 10).

tray using the two screws (M4 x 10).

< 2 > Insert the bosses of the escape exit tray into the mounting holes

shown in the illustration and attach the tray.

[CAUTION]

When attaching the offset tray, make sure that part of the roller shaft

of the offset tray is not on the offset tray.

of the offset tray is not on the offset tray.

10. Mount the staple cartridge.

Remove protective paper from the cartridge.

Open the staple cover, insert the staple cartridge to the staple unit

until it clicks, and then close the staple cover.

Open the staple cover, insert the staple cartridge to the staple unit

until it clicks, and then close the staple cover.

11. Paste the staple position label.

Paste the staple position label to the document feeder.

Insert the power plug of the copier to the outlet and turn

on the main switch of the copier. Then, carry out the

following procedure.

on the main switch of the copier. Then, carry out the

following procedure.

12. Check for stapling operation.

Make three copies in the staple sort mode.

Check to see if stapling has been performed properly.

Check to see if stapling has been performed properly.

13. Check for paper delivery to the top tray.

Deliver two copies to the top tray.

If this equipment is installed together with a printer expansion kit or a

facsimile expansion kit, check the appendix of each operation manual

(key operator programs and index list output and setting).

facsimile expansion kit, check the appendix of each operation manual

(key operator programs and index list output and setting).

14. Check for paper delivery to the offset tray.

Deliver three sets from two originals to the offset tray.

Check to see if copies have been offset stacked properly.

Check to see if copies have been offset stacked properly.

Installation of staple sorter is now complete.

Screw (M4 x 10)

Screw (M4 x 10)

Front cabinet

Rear cabinet

Ribs

Ribs

Connection

harness

harness

Screw

(M4 x 10)

Top tray

Offset tray unit

Paper holder lever

pawls

Roller shaft

NG

NG

Protective paper

Staple cover

Staple cartridge

staple position label

Escape exit tray

Offset tray

Stapling position

[3] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

No.

Name

1

Upper tray

2

Lower tray

3

Alignment unit

1

2

3

2. Sensors, motors, solenoids, etc.

1

2

3

4

5

6

7

8

9

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

No.

Part name

Code

Function/Operation

Type

1

Upper tray paper exit sensor

T10D

Counts down the output page, detects JAM.

Photo sensor

2

JAM process PG open/close detection

switch

switch

TCSW

Interlocks when the open/close PG of the transport section in front of

the upper stage tray is open.

the upper stage tray is open.

Micro switch

3

Escape full sensor

T1PD

Detects paper full in the upper stage tray (ESC tray).

Photo sensor

4

Paper exit roller rotation control clutch

ORCLD

Used to select whether to slow the speed of the paper exit roller upper

for the speed of the paper exit roller lower or to make it as a normal

follower roller.

for the speed of the paper exit roller lower or to make it as a normal

follower roller.

Electromagnetic

clutch

clutch

5

Main drive motor

FMM

Drives the rollers for paper transport.

Pulse motor

6

Lower tray paper exit sensor

/T20D

Counts down the output page, detects JAM.

Photo sensor

7

Paper hold solenoid

OFSLD

Presses paper onto the paper shift prevention lever of the lower stage

tray upper.

tray upper.

Solenoid

8

Paper position sensor

/T2PD

Detects the top surface of discharged paper, and detects the upper

standby position of the lift-up tray.

standby position of the lift-up tray.

Photo sensor

9

Tray offset drive motor

OFM

(+, –)

Supplies drive power to separate paper and shift the tray to the front

and the rear.

and the rear.

DC motor

10

Tray position sensor (Upper)

T2UP

Detects the lift-up tray position in combination with the tray position

sensor (lower). (Upper limit detection in the case of erroneous detection

by the paper position sensor, intermediate position detection, and full

detection)

sensor (lower). (Upper limit detection in the case of erroneous detection

by the paper position sensor, intermediate position detection, and full

detection)

Photo sensor

11

Tray position sensor (Lower)

T2DN

Detects the lift-up tray position in combination with the tray position

sensor (upper). (Upper limit detection in the case of erroneous

detection by the paper position sensor, intermediate position detection,

and full detection)

sensor (upper). (Upper limit detection in the case of erroneous

detection by the paper position sensor, intermediate position detection,

and full detection)

Photo sensor

12

Offset home position sensor

OFHP

Detects the standby position of the offset tray.

Photo sensor

13

Staple supply cover open/close

detection switch

detection switch

SCSW

Detects the staple supply cover open/close. When open, interlocks.

Micro switch

14

Lift-up motor

LUM

(+, –)

Drives the lift-up tray up and down.

DC motor

15

Lift-up drive control sensor

LUEN

Reads the encoder for control of the DC motor rotation.

Photo sensor

16

Stapler unit

17

Tray paper empty sensor

ATPD

Detects paper presence or empty on the alignment tray.

Photo sensor

18

Shutter drive solenoid

STSLD

When discharging a bundle of paper, shift the lead edge reference

plate in the paper transport direction.

plate in the paper transport direction.

Solenoid

19

Upper alignment plate drive solenoid

AJSLD

Holds paper on the alignment tray.

Solenoid

20

Side guide plate home position sensor

SDHP

Detects the home position of the width alignment members.

Photo sensor

21

Transport switch gate solenoid Right

GRSLD

Drive to sort paper into the escape transport section and the alignment

tray.

tray.

Solenoid

3. Rollers, gates, etc.

No.

Name

Function

1

Paper entry sensor

Detects paper transported from the machine.

2

Transport roller fin

Transports paper in combination with No. 8 roller.

3

Paper entry follower roller (Kick-out

sponge)

sponge)

Transports paper in combination with No. 2 roller.

4

Transport switch gate right

Selects between the escape transport (non-staple mode) and the alignment tray transport (staple

mode).

When selecting the alignment transport (staple mode), this gate drops the rear edge of paper.

mode).

When selecting the alignment transport (staple mode), this gate drops the rear edge of paper.

5

Side guide plate

Aligns paper vertically to the paper transport direction.

6

Upper alignment hold plate

Knocks paper when paper (5th page or later) comes on the alignment tray removing air or adjusting

curls.

curls.

7

Rear edge plate

Aligns paper in the paper transport direction.

8

PS upper roller (Common part)

Transports paper in combination with No. 2, 19, 20 rollers.

9

Paper empty sensor (1A71A)

Detects paper empty on the alignment tray.

10

Shutter

Serves as the paper lead edge reference for alignment of paper, and opens to allow a bundle of

paper to be transported to the paper exit port after stapling.

paper to be transported to the paper exit port after stapling.

11

Transport switch gate left

Selects between the escape tray transport and the offset tray transport.

12

PS upper roller (Common part)

Transports paper in combination with No. 13 roller.

13

Escape transport roller

Transports paper in combination with No. 12 (No. 8) roller.

14

Escape paper exit sensor

Detects paper transport to the escape tray.

15

Transports paper in combination with No. 16 roller.

16

Escape paper exit roller

Transports paper in combination with No. 15 roller.

17

Paper exit roller upper

Transports paper in combination with No. 18 roller. This roller normally follows No. 18 roller. When

discharging a stapled bundle of paper, the electromagnetic clutch turns on to make this roller a drive

roller. The bundle of paper is bent by the difference between this roller speed and the No. 18 roller

speed so that it is not caught by the preceding bundle staple.

discharging a stapled bundle of paper, the electromagnetic clutch turns on to make this roller a drive

roller. The bundle of paper is bent by the difference between this roller speed and the No. 18 roller

speed so that it is not caught by the preceding bundle staple.

18

Paper exit roller lower

Transports (discharges) paper in combination with No. 17 roller.

19

Transport drive roller fin

Transports paper in combination with No. 8 roller.

20

Paper entry roller fin

Transports paper in combination with No. 8 roller.

No.

Part name

Code

Function/Operation

Type

22

Transport switch gate solenoid Left

GLSL

Drive to sort paper into the escape paper exit port and the lift-up tray

paper exit port.

paper exit port.

Solenoid

23

Side guide plate alignment motor

SDM

Aligns paper vertically to the paper transport direction.

Pulse motor

24

Reciprocating alignment motor

BKM

Aligns paper in the paper transport direction.

Pulse motor

25

Paper entry sensor

INPD

Detects paper entry in the finisher and detects JAM. Switch trigger of

the transport switch gate right.

the transport switch gate right.

Photo sensor

26

Paper width sensor

WDPD

Make a distinction between A4 and A5R, LT and INVR. If the paper

entry sensor is ON and this sensor is OFF, it is A5R or INVR.

entry sensor is ON and this sensor is OFF, it is A5R or INVR.

Photo sensor

27

Rear edge plate drive solenoid

BKSLD

Drives the rear edge plate.

Solenoid

28

Rear edge plate home position sensor

BKHP

Detects the home position of the rear edge alignment members.

Photo sensor

29

Tray JAM process detection switch

PGSW

Interlocks when the alignment tray is opened downward in a JAM

process.

process.

Micro switch

1

2

3

20

4

5

6

2

19

7

11

9

10

16

15

14

12

13

17

18

8

8

8

Display