Sharp AR-FN5 (serv.man2) Service Manual ▷ View online

[4] OPERATIONAL DESCRIPTIONS

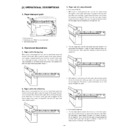

1. Paper transport path

a. Tray 1 paper exit

b. Tray 2 paper exit (Offset function selectable)

c. Tray 2 staple paper exit

b. Tray 2 paper exit (Offset function selectable)

c. Tray 2 staple paper exit

2. Operational descriptions

1. Paper exit to the top tray

When paper is discharged from the machine, the finisher lowers the

direction switch gate right to pass the paper to the upper transport

path (escape transport section) and lowers the direction switch gate

left to discharge the paper to the top tray. The direction switch gate

right is triggered by the finisher paper entry sensor and operated only

when the paper lead edge passes through it.

direction switch gate right to pass the paper to the upper transport

path (escape transport section) and lowers the direction switch gate

left to discharge the paper to the top tray. The direction switch gate

right is triggered by the finisher paper entry sensor and operated only

when the paper lead edge passes through it.

2. Paper exit to the offset tray

When paper is discharged from the machine, the finisher lowers the

direction switch gate right to pass the paper to the upper transport

path, and lowers the direction switch gate left to discharge the paper

to the offset tray. The direction switch gate right is triggered by the

finisher paper entry sensor and operated only when the paper lead

edge passes through it.

direction switch gate right to pass the paper to the upper transport

path, and lowers the direction switch gate left to discharge the paper

to the offset tray. The direction switch gate right is triggered by the

finisher paper entry sensor and operated only when the paper lead

edge passes through it.

3. Paper exit of a stapled bundle

·

In the case of A3, WL

a. When paper is discharged from the machine, the finisher raises

the direction switch gate right to pass the paper to the alignment

tray. When the read edge of paper passes the paper entry sensor,

the operation is triggered. That is, when the rear edge of paper

passes the direction switch gate right, the gate is lowered to store

the rear edge of paper completely in the alignment tray.

tray. When the read edge of paper passes the paper entry sensor,

the operation is triggered. That is, when the rear edge of paper

passes the direction switch gate right, the gate is lowered to store

the rear edge of paper completely in the alignment tray.

b. The rear edge plate and the side guide plate are moved in the

paper alignment direction to lower the upper alignment plate, per-

forming alignment. After alignment, stapling is performed by the

staple unit.

forming alignment. After alignment, stapling is performed by the

staple unit.

c. After alignment and stapling, the side guide plate is loosened and

the shutter is lowered to discharge paper to the paper exit roller by

the rear edge plate. The bundle of paper is discharged to the offset

tray by the paper exit roller.

the rear edge plate. The bundle of paper is discharged to the offset

tray by the paper exit roller.

·

In the case of small size

a. The rear edge plate is moved to the center and the direction switch

gate right is raises to pass the paper to the alignment tray. When

the read edge of paper passes the paper entry sensor, the opera-

tion is triggered. That is, when the rear edge of paper passes the

direction switch gate right, the gate is lowered to store the rear

edge of paper completely in the alignment tray.

the read edge of paper passes the paper entry sensor, the opera-

tion is triggered. That is, when the rear edge of paper passes the

direction switch gate right, the gate is lowered to store the rear

edge of paper completely in the alignment tray.

b. When the second last paper is passed, the rear edge plate (1) is

lowered and passed under the paper bundle (2) to the rear edge of

the paper bundle (3). Then the rear edge plate is raised. (HP

position)

the paper bundle (3). Then the rear edge plate is raised. (HP

position)

c. When the last paper from the machine passes the direction switch

gate right, it lowers the gate.

d. The paper bundle is moved in the paper exit direction by the rear

edge plate.

e. The rear edge plate and the side guide plate are moved in the

paper guiding direction and the upper guide plate is lowered to

perform the last alignment. Then stapling is performed by the sta-

ple unit.

perform the last alignment. Then stapling is performed by the sta-

ple unit.

f.

After alignment and stapling by the stapler unit, the side guide

plate is loosened and the shutter is lowered. The paper is moved

to the paper exit roller by the rear edge plate, and discharged to

the offset tray by the paper exit roller.

plate is loosened and the shutter is lowered. The paper is moved

to the paper exit roller by the rear edge plate, and discharged to

the offset tray by the paper exit roller.

3. Descriptions on each section

This machine is composed of the paper exit unit and the alignment

unit. The paper exit unit includes the paper exit tray 1 and 2. The

paper exit tray 2 is provided with the offset function and the lift-up

function.

unit. The paper exit unit includes the paper exit tray 1 and 2. The

paper exit tray 2 is provided with the offset function and the lift-up

function.

The alignment unit includes the paper transport section used for the

non-staple mode, the paper alignment section for the staple mode,

and the staple unit.

non-staple mode, the paper alignment section for the staple mode,

and the staple unit.

a. Paper exit unit section

(1) Paper transport (Main motor)

By rotating the main drive motor, the paper exit unit and the all trans-

port rollers of the alignment unit are driven.

port rollers of the alignment unit are driven.

(2) Tray 1 full detection

The top of paper bundle on the tray is detected by the combination of

the lever and the photo sensor to judge paper full on Tray 1.

the lever and the photo sensor to judge paper full on Tray 1.

(3) Lift-up section

·

Lift-up motor

In order to discharge paper always at a fixed position regardless of

paper load on the tray 2, the lift-up motor is driven, the pulley is

rotated normally or in reverse, and the timing belt is driven to move

the tray 2 up and down.

paper load on the tray 2, the lift-up motor is driven, the pulley is

rotated normally or in reverse, and the timing belt is driven to move

the tray 2 up and down.

(1)

(2)

(3)

·

Full detection

Paper full on the tray 2 is detected in combination between the

lower limit sensor ON and detection of the top of paper bundle on

the tray by the paper exit actuator.

lower limit sensor ON and detection of the top of paper bundle on

the tray by the paper exit actuator.

(4) Offset tray section

·

Offset motor

The offset motor moves the offset tray vertically to the paper exit

direction so that each bundle of paper discharged to the offset tray

is separately grouped.

direction so that each bundle of paper discharged to the offset tray

is separately grouped.

·

Paper exit clutch

This clutch is turned on when a stapled bundle of paper is dis-

charged so that the bundle of paper is warped by the difference

between the speeds of the upper and the lower paper exit rollers,

preventing the bundle from being caught by the preceding bundle’s

staple.

charged so that the bundle of paper is warped by the difference

between the speeds of the upper and the lower paper exit rollers,

preventing the bundle from being caught by the preceding bundle’s

staple.

b. Alignment unit section

(1) Transport switch gate right (gate right solenoid)

Selection between the transport section and the alignment section

in the alignment unit is made by the transport switch gate right.

This gate drops the rear edge of paper entering the alignment

section so that the rear edge is completely transported.

in the alignment unit is made by the transport switch gate right.

This gate drops the rear edge of paper entering the alignment

section so that the rear edge is completely transported.

(2) Rear edge plate unit

·

Rear edge plate motor

The motor is turned on at the timing when paper enters the align-

ment tray to drive the rear edge plate unit. Paper of A3 or WLT is

aligned to the shutter, and paper of a smaller size is aligned to the

right side of the alignment tray in the transport direction.

ment tray to drive the rear edge plate unit. Paper of A3 or WLT is

aligned to the shutter, and paper of a smaller size is aligned to the

right side of the alignment tray in the transport direction.

·

Rear edge plate solenoid

After provisional alignment of small size paper, this solenoid puts

down the rear edge plate of the rear edge unit to pass it under the

aligned paper. After returning to the home position, it is turned off

and the rear edge plate is put back and paper is transported to the

shutter.

down the rear edge plate of the rear edge unit to pass it under the

aligned paper. After returning to the home position, it is turned off

and the rear edge plate is put back and paper is transported to the

shutter.

(3) Side guide plate (Guide plate motor)

When paper enters the alignment tray, this plate is driven to align

paper vertically to the paper transport direction toward the fixed

wall of the alignment tray front side.

paper vertically to the paper transport direction toward the fixed

wall of the alignment tray front side.

(4) Shutter (Shutter solenoid)

The shutter solenoid drives the shutter which stops the lead edge

of paper for alignment. After stapling, the shutter is put down to

transport paper to the paper exit roller.

of paper for alignment. After stapling, the shutter is put down to

transport paper to the paper exit roller.

(5) Transport switch gate left (Gate left solenoid)

Paper passed through the escape transport path is sent to the tray

1 or to the tray 2.

1 or to the tray 2.

4. Basic operations

A. Flowchart of basic operations

The initialization (home positioning of each motor) is performed at the

following timing:

following timing:

1) When the power is turned on.

2) When the staple section door on the upper side of the finisher

paper exit unit is opened or closed.

3) When the alignment unit is opened or closed.

4) When the copy start key is pressed (JOB_START): Recovery op-

eration

5) When copying is completed (JOB_END).

6) When a jam occurs: Jogger saving

Job end operation

Initializing at power ON

Individual printing

operation (Offset tray)

operation (Offset tray)

Operation in case

of an error

of an error

Operation when the

door is closed

door is closed

Stapling operation

Job start operation

Transport operation

Offset paper exit operation

Power ON

B. Operations of each section when the power it turned on

Unit

No.

Operation

Remark

Alignment unit

Escape transport upper unit

1

Finisher paper entry detection

OP: Paper provided. JAM display

CL: Paper empty. Go to READY

CL: Paper empty. Go to READY

2

Paper width detection

3

Transport switch gate right drive

4

Transport switch gate left drive

Escape transport lower unit

5

Upper alignment plate drive

Alignment tray unit

6

Side guide plate alignment drive

7

Rear edge plate alignment drive

8

Rear edge plate drive

9

Side guide plate home position

10

Rear edge plate unit home position

11

Shutter drive

12

Tray paper empty detection

Staple unit

13

Staple empty detection

14

Cartridge empty detection

15

Stapling operation

16

Home position detection

17

Self priming

Others

18

Staple supply cover open/close detection

19

Tray JAM process detection

Paper exit tray unit

Escape tray

20

No. 1 tray paper exit detection

21

JAM process PG open/close detection

Lift-up tray

22

No. 2 tray paper exit detection

23

Lift-up drive

24

Lift-up drive rotation control

25

Tray position detection (upper)

26

Paper position detection

27

Tray position detection (lower)

28

Tray offset drive

29

Offset home position

Main drive system

30

Main rotation drive

31

Paper exit roller rotation control

5. Operational specifications of each section

(1) Operational specifications of side guide plate

Pulse motor specifications and control

·

1 step = 7.5 degrees

·

1-2 phase drive 1200pps

·

Reduction ratio 15P

®

40P = 24P (MXL tooth shape)

·

Side guide plate shift for an input of 1 pulse: 0.1905mm / pulse

·

Slow up/down control for tuning:

Basic operations of side guide plate

1. Moving to the standby position

·

The side guide plate is moved from the home position to the

standby position according to the paper size information supplied

by the main body.

standby position according to the paper size information supplied

by the main body.

Paper width (mm) Shift quantity (mm) Pulse number (pluse)

A3, A4

297

0

0

B4, B5

257

22.1

116

A4R

210

45.5

239

WLT, LT

279.4

12.4

65

RG, LTR,GLG

215.9

42.7

224