Sharp AR-FN5 (serv.man2) Service Manual ▷ View online

C. Rear edge plate solenoid

Refer to Fig.(7-3).

8-3

8-4

D. Shutter drive solenoid

Refer to Fig.(7-3).

8-5

E. Transport switch gate solenoid

Refer to Fig.(1-A-1) to (1-A-5).

Refer to Fig.(6-1) to (6-2).

Refer to Fig.(6-1) to (6-2).

8-7

[6] ADJUSTMENTS

Adjustments are required when replacing the following parts:

A. Rear edge plate unit

B. Side guide plate

C. Gate solenoid right

D. Gate solenoid left

E. Upper alignment solenoid

F. Shutter solenoid

G. Rear edge plate solenoid

H. Paper holding solenoid

A. Rear edge plate unit

1. Staple 5 sheets of A4 or LT paper, and check the slide shift of the

paper bundle in the transport direction (Y-axis).

2. When the shift of the paper bundle is within 1mm, there is no need

to adjust.

3. If the shift of the paper bundle is greater than 1mm, execute SIM

3-6-3 to adjust the rear edge plate position.

B. Side guide plate

1. Staple 5 sheets of A4 or LT paper, and check the slide shift of the

paper bundle in the vertical direction (X-axis) to the transport direc-

tion.

tion.

2. When the shift of the paper bundle is within 1mm, there is no need

to adjust.

3. If the shift of the paper bundle is greater than 1mm, execute SIM

3-6-2 to adjust the side guide plate position. Also check that the

paper bundle is in parallel with the alignment reference wall of the

side guide plate.

paper bundle is in parallel with the alignment reference wall of the

side guide plate.

SIM 3-6 Finisher alignment member adjustment

When a sub code is entered, the above display is shown.

1. In SIM 3-6-1, press [OK] and select [1] - [10] to specify the paper

size.

2. Enter SIM 3-6-2 Jogger pos X (side guide plate) or SIM 3-6-3

Jogger pos Y (rear edge plate) and press [OK]. The alignment

section (rear edge plate unit), side guide plate) will be operated.

During the load operation, the [OK] key is highlighted.

section (rear edge plate unit), side guide plate) will be operated.

During the load operation, the [OK] key is highlighted.

3. Keep the alignment member at the paper alignment position, and

open the alignment section. Insert paper of the same size into the

alignment member and check that the tightness is proper. 1~2 mm

smaller (tight) than the paper size is O.K.

alignment member and check that the tightness is proper. 1~2 mm

smaller (tight) than the paper size is O.K.

4. When the adjustment value of the simulation is decreased by 1,

the clearance between paper and the side guide plate is de-

creased by 0.41mm, and between paper and the rear edge plate

0.83mm, and vice versa.

creased by 0.41mm, and between paper and the rear edge plate

0.83mm, and vice versa.

1)

2)

4)

3)

5)

1)

2)

1)

2)

3)

4)

1)

2)

Sim3-6 JOGGER ADJ.

1:PAPER SIZE

2:JOGGER POS X

3:JOGGER POS Y

1

(Initial screen)

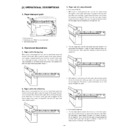

C. Gate solenoid right

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

one to the marked position.

After fixing, press the plunger with your finger to adjust so that the

lead edge of the gate right is in a position 16.5mm ~ 17mm apart from

the alignment tray transport surface. Release the finger and check

that it returns smoothly by the spring and that the lead edge of the

gate right is in a position 36mm apart from the transport surface.

lead edge of the gate right is in a position 16.5mm ~ 17mm apart from

the alignment tray transport surface. Release the finger and check

that it returns smoothly by the spring and that the lead edge of the

gate right is in a position 36mm apart from the transport surface.

D. Gate solenoid left

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

one to the marked position.

After fixing the solenoid, check and adjust so that the gate left edge is

in contact with the transport surface on the transport PG with the

plunger released, and so that the gate left edge is 6.5 - 7mm from the

transport surface.

in contact with the transport surface on the transport PG with the

plunger released, and so that the gate left edge is 6.5 - 7mm from the

transport surface.

E. Upper alignment solenoid

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

one to the marked position.

After fixing, pull the plunger with your finger and check that the upper

alignment holding plate is in contact with the alignment tray. Then

release the finger and check that the plunger returns smoothly by the

spring.

alignment holding plate is in contact with the alignment tray. Then

release the finger and check that the plunger returns smoothly by the

spring.

F. Shutter solenoid

Mark the solenoid installing position before replacement, and fix a new

one to the marked position.

one to the marked position.

After fixing, pull the plunger with your finger and check that the shutter

rotates 90 degrees and makes contact with the tray. Then release the

finger and check that the shutter returns smoothly by the spring and

that it is vertical to the alignment tray after returning.

rotates 90 degrees and makes contact with the tray. Then release the

finger and check that the shutter returns smoothly by the spring and

that it is vertical to the alignment tray after returning.

16.5 17mm

36 mm

6.5 7mm

90

O

G. Rear edge plate solenoid

Mark the solenoid installing position before replacement, and fix a new

one to the marked position. (The solenoid and the installing plate

positions are determined by the round hole.)

one to the marked position. (The solenoid and the installing plate

positions are determined by the round hole.)

After fixing, pull the plunger with your finger and check that the rear

edge plate rotates 90 degrees and makes contact with the rear edge

plate slide. Then release the finger and check that the rear edge plate

returns smoothly by the spring and that it is vertical to the alignment

tray after returning.

edge plate rotates 90 degrees and makes contact with the rear edge

plate slide. Then release the finger and check that the rear edge plate

returns smoothly by the spring and that it is vertical to the alignment

tray after returning.

H. Paper holding solenoid

Fix the paper holding solenoid below the long fixing hole so that the

whole paper hold installing plate unit is in the lower limit of the adjust-

ment range.

whole paper hold installing plate unit is in the lower limit of the adjust-

ment range.

(The solenoid and the installing plate positions are determined by the

round hole.)

round hole.)

[7] MAINTENANCE

Note: Before maintenance, disconnect the power cable from the body.

Be sure to avoid communication during maintenance. It is very dangerous.

For maintenance, refer to the DISASSEMBLY AND ASSEMBLY and the Parts Guide.

The table below shows the maintenance parts and the work contents.

Part name

Work content

Condition of execution

Cycle

Transport rollers

Cleaning

Maintenance/Servicing

40K or 2 years

Paper guides

Cleaning

Maintenance/Servicing

40K or 2 years

Gears

Lubrication, greasing

Maintenance/Servicing

40K or 2 years

Belts

Check

Maintenance/Servicing

80K or 2 years

Staple unit

Replacement

Maintenance/Servicing

200K (Number of operations)

Reference: 65 ~ 66 times of staple replacement

Reference: 65 ~ 66 times of staple replacement

Sensors

Check

Maintenance/Servicing

40K or 2 years

OF roller cleaner

Cleaning

Maintenance service

When the lead edge or rear edge of paper is dirtied or at 20 - 25K

For maintenance of the OF roller cleaner, refer to the figure below.

G. Rear edge plate solenoid

Mark the solenoid installing position before replacement, and fix a new

one to the marked position. (The solenoid and the installing plate

positions are determined by the round hole.)

one to the marked position. (The solenoid and the installing plate

positions are determined by the round hole.)

After fixing, pull the plunger with your finger and check that the rear

edge plate rotates 90 degrees and makes contact with the rear edge

plate slide. Then release the finger and check that the rear edge plate

returns smoothly by the spring and that it is vertical to the alignment

tray after returning.

edge plate rotates 90 degrees and makes contact with the rear edge

plate slide. Then release the finger and check that the rear edge plate

returns smoothly by the spring and that it is vertical to the alignment

tray after returning.

H. Paper holding solenoid

Fix the paper holding solenoid below the long fixing hole so that the

whole paper hold installing plate unit is in the lower limit of the adjust-

ment range.

whole paper hold installing plate unit is in the lower limit of the adjust-

ment range.

(The solenoid and the installing plate positions are determined by the

round hole.)

round hole.)

[7] MAINTENANCE

Note: Before maintenance, disconnect the power cable from the body.

Be sure to avoid communication during maintenance. It is very dangerous.

For maintenance, refer to the DISASSEMBLY AND ASSEMBLY and the Parts Guide.

The table below shows the maintenance parts and the work contents.

Part name

Work content

Condition of execution

Cycle

Transport rollers

Cleaning

Maintenance/Servicing

40K or 2 years

Paper guides

Cleaning

Maintenance/Servicing

40K or 2 years

Gears

Lubrication, greasing

Maintenance/Servicing

40K or 2 years

Belts

Check

Maintenance/Servicing

80K or 2 years

Staple unit

Replacement

Maintenance/Servicing

200K (Number of operations)

Reference: 65 ~ 66 times of staple replacement

Reference: 65 ~ 66 times of staple replacement

Sensors

Check

Maintenance/Servicing

40K or 2 years

OF roller cleaner

Cleaning

Maintenance service

When the lead edge or rear edge of paper is dirtied or at 20 - 25K

For maintenance of the OF roller cleaner, refer to the figure below.