Sharp AR-FN1 (serv.man10) Service Manual ▷ View online

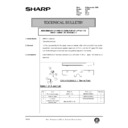

13. 10V power generating circuit

The 10V power generating circuit generates

+

10V which is supplied

to the power supply of the transfer motor IC uPD1246C (IC10) and

comparator BA10393F (IC15). The circuit consists of a Zener diode

RD11EB (ZD7), transistor 2SC1472 (Q5), other peripheral resis-

tances and capacitors.

comparator BA10393F (IC15). The circuit consists of a Zener diode

RD11EB (ZD7), transistor 2SC1472 (Q5), other peripheral resis-

tances and capacitors.

+

24V is reduced to about

+

11V by the Zener

diode ZD7 and passed through the emitter follower circuit of the

transistor Q5 to become about

transistor Q5 to become about

+

10V for outputting.

14. Transfer motor drive circuit

The transfer motor drive circuit consists of a motor IC yP1246C

(IC10), transistor array TD62503F (IC16), motor driver IC SLA6023

(IC20) and peripheral circuits.

(IC10), transistor array TD62503F (IC16), motor driver IC SLA6023

(IC20) and peripheral circuits.

When the transfer motor control signal (FMPWM) from the CPU be-

comes at L level, the transistor inside the IC20 turns on to let the

motor current flow to start the motor. When the motor is started, the

transfer motor hole signal (HU, HV, HW) input to the IC10 is changed

over to switch over the drive of the transistor inside the IC20 so that

the motor begins to rotate under non-controlled state.

comes at L level, the transistor inside the IC20 turns on to let the

motor current flow to start the motor. When the motor is started, the

transfer motor hole signal (HU, HV, HW) input to the IC10 is changed

over to switch over the drive of the transistor inside the IC20 so that

the motor begins to rotate under non-controlled state.

As the transfer motor rotates, the speed signal (FMRE) is output from

the motor. The CPU incorporates the signal. It reduces the ON duty

of the FMPWM signal to increase the speed when the motor speed is

slow; it increases the ON duty of the FMPWM signal to reduce the

speed when the motor speed is high. The motor speed is thus main-

tained at a constant speed. As the current flowing into the motor

becomes large, the current flowing to the R25 also becomes large,

thus raising the voltage at the negative side of the comparator

BA10393F (IC15). When this voltage becomes greater than the refer-

ence voltage (about 1.1V) preset at the plus side, the output of IC15

becomes at L level, thus turning off the IC20 transistor to restrict the

current flowing to the motor (current limit setting: about 5A).

the motor. The CPU incorporates the signal. It reduces the ON duty

of the FMPWM signal to increase the speed when the motor speed is

slow; it increases the ON duty of the FMPWM signal to reduce the

speed when the motor speed is high. The motor speed is thus main-

tained at a constant speed. As the current flowing into the motor

becomes large, the current flowing to the R25 also becomes large,

thus raising the voltage at the negative side of the comparator

BA10393F (IC15). When this voltage becomes greater than the refer-

ence voltage (about 1.1V) preset at the plus side, the output of IC15

becomes at L level, thus turning off the IC20 transistor to restrict the

current flowing to the motor (current limit setting: about 5A).

+24V

R22

1K(1/4W)

1K(1/4W)

R24

1K(1/4W)

R23

100(1/4W)

100(1/4W)

ZD07

RD11EB

C169

0.1U

0.1U

0.1U

C168

C10

47U/35V

ZD01

RD18FB1

Q05

2SC1472

+10V

CPU

PA4

PA7

(IC02)

TD62503F

IC13E

TD62503F

IC16G

IC20

SLA6023

IA1

IB1

IC2

IB2

IA2

GND

Vcc

GND

OA

OB

OC

IC1

3

7

10

D19

TD62503F

IC16A

TD62503F

IC16D

TD62503F

IC16B

TD62503F

IC16C

TD62503F

IC16F

TD62503F

IC16E

BR13

1Kx3

R186

680

680

680

R185

R184

R174

R173

R172

10K

10K

10K

IC10

IN1

IN2

IN3

IN4

IN5

VCC

IN6

VREF

UPC1246C

OUT1

OUT3

OUT5

OUT6

OUT4

OUT2

REVERSE

GND

C163

0.1U

0.1U

C164

0.1U

+5V

5

6

R194

680

R187

2.4K

2.4K

R195

200

R25

0.22

(1W)

2 3 4

4 3 2 BR15

1Kx3

+24V

U V W

1

2

8

9

5

12

11

6

4

D20

D21

1SR124-400

x3

+

-

BA10393F

7

IC15B

C160

C161

C162

0.1Ux3

+10V

+5V

R196

10K

10K

R171

4.7K

4.7K

+5V

+5V

2 3 4

BR11

2.2Kx3

2.2Kx3

+10V

R168

R169

1.2K

1.2K

1.2K

C151

C150

C149

1000Px3

C09

100U/35V

HW

HV

HU

97

99

FMDIR

FMPWM/

5

12

7

10

R193

2.2K

2.2K

2.2K

R192

R191

11

12

13

14

15

16

7

9

10

6

5

3

4

2

1

8

C148

0.1U

0.1U

R160

2.2K

2.2K

R167

2.2K

2.2K

R170

4

5

6

11

12

13

1

2

3

16

15

14

PA6

100

FMRE

R138

10K

R137

2.4K

2.4K

C130

1000P

FMRE

+5V

+5V

BR2-8

10K

FM

Transfer motor

speed signal

speed signal

Transfer motor

haul signal

haul signal

(1-point earth)

9 – 11

15. Stepping motor drive circuit

The control signal (STMA,B) from the expansion I/O expansion is

input through the driver TD62503F to the H driver circuit which con-

sists of a large-current driving transistors Q1

input through the driver TD62503F to the H driver circuit which con-

sists of a large-current driving transistors Q1

∼

4, thus driving the

staple motor which staples sheets.

The rotational direction (CW, CCW) of the staple motor is controlled b

signal locks STMA, STMB. The motor is braked to stop at the home

position.

signal locks STMA, STMB. The motor is braked to stop at the home

position.

TD62503 (IC15) is a driver to drive Q1

∼

4. A delay circuit is com-

posed of R163-R166, R176, R177, C152, C153, C156, C157, D3,

and D4 to prevent short current from flowing into the H driver circuit

which is formed by Q1

and D4 to prevent short current from flowing into the H driver circuit

which is formed by Q1

∼

4, when STMA and STMB are changed

over.

The staple motor has a large rush current. It thus has a current limit

circuit consisting of a voltage comparator BA10393F (IC15) and pe-

ripheral resistances and capacitors, to apply current limit at about

5.3A. To prevent the circuit from shorting or motor locking, a protec-

tive fuse (F2) is installed.

circuit consisting of a voltage comparator BA10393F (IC15) and pe-

ripheral resistances and capacitors, to apply current limit at about

5.3A. To prevent the circuit from shorting or motor locking, a protec-

tive fuse (F2) is installed.

16. Stapler unit

The stapler unit (EH-524S: Max Co., Ltd.) staples up to 50 sheets of

80-g paper. The unit consists of a driving DC motor (STM), home

position sensor (STHP), non-needle sensor (LSTS), cartridge sensor

(NCTS), and self-priming sensor which detects the stapling position of

needles (READY).

80-g paper. The unit consists of a driving DC motor (STM), home

position sensor (STHP), non-needle sensor (LSTS), cartridge sensor

(NCTS), and self-priming sensor which detects the stapling position of

needles (READY).

Item

Specification

Outside dimensions

H

×

W

×

L: 97 mm

×

80 mm

×

104 mm

Stapling capacity

52 g 2 sheets ~ 80 g 50 sheets, below 5

mm thick

mm thick

Stapling type

Bypass flat clinch

Stapling speed

400 msec or below

Needle cartridge

5000 needles

500

3K

2SB1431

Q04

150

5K

2SD1590

Q02

2.5A/125V

T1.6A/250V

T1.6A/250V

F02

+24V

I/O

PE4

PE5

8 STMA

9 STMB

+5V

R166

R165

R164

R163

D03

D04

R161

R162

4.7K

4.7K

200

200

1K

1K

1SS133

1SS133

(IC03)

TD62503F

TD62503F

3

14

4

13

IC09D

IC09C

R176

C157

68000P

1K

IC09B

IC09A

TD62503F

TD62503F

15

2

1

16

R16

R17

2.4K(1/4W)

2.4K(1/4W)

R177

C156

68000P

C152

10000P

C153

10000P

500

3K

2SB1431

Q03

150

5K

2SD1590

Q01

D01 D02

STM+

STM-

STM

1SR124-400•~2

1K

+5V

R190

+

-

100

C155

0.1U

0.1U

C154

0.1U

0.1U

R175

1.2K

1.2K

R18

0.22

(1W)

(1W)

R188

3.9K

3.9K

+5V

+10V

+5V

R189

2.2K

2.2K

BA10393F

C165

0.1U

0.1U

8

1

3

2

4

IC15A

5

12

11

6

TD62503F

TD62503F

IC09E

IC09F

STHP

STM

LSTS

NCTS

READY

+5V

GND

Finisher

main PWB

Stapler unit

9 – 12

15. Stepping motor drive circuit

The control signal (STMA,B) from the expansion I/O expansion is

input through the driver TD62503F to the H driver circuit which con-

sists of a large-current driving transistors Q1

input through the driver TD62503F to the H driver circuit which con-

sists of a large-current driving transistors Q1

∼

4, thus driving the

staple motor which staples sheets.

The rotational direction (CW, CCW) of the staple motor is controlled b

signal locks STMA, STMB. The motor is braked to stop at the home

position.

signal locks STMA, STMB. The motor is braked to stop at the home

position.

TD62503 (IC15) is a driver to drive Q1

∼

4. A delay circuit is com-

posed of R163-R166, R176, R177, C152, C153, C156, C157, D3,

and D4 to prevent short current from flowing into the H driver circuit

which is formed by Q1

and D4 to prevent short current from flowing into the H driver circuit

which is formed by Q1

∼

4, when STMA and STMB are changed

over.

The staple motor has a large rush current. It thus has a current limit

circuit consisting of a voltage comparator BA10393F (IC15) and pe-

ripheral resistances and capacitors, to apply current limit at about

5.3A. To prevent the circuit from shorting or motor locking, a protec-

tive fuse (F2) is installed.

circuit consisting of a voltage comparator BA10393F (IC15) and pe-

ripheral resistances and capacitors, to apply current limit at about

5.3A. To prevent the circuit from shorting or motor locking, a protec-

tive fuse (F2) is installed.

16. Stapler unit

The stapler unit (EH-524S: Max Co., Ltd.) staples up to 50 sheets of

80-g paper. The unit consists of a driving DC motor (STM), home

position sensor (STHP), non-needle sensor (LSTS), cartridge sensor

(NCTS), and self-priming sensor which detects the stapling position of

needles (READY).

80-g paper. The unit consists of a driving DC motor (STM), home

position sensor (STHP), non-needle sensor (LSTS), cartridge sensor

(NCTS), and self-priming sensor which detects the stapling position of

needles (READY).

Item

Specification

Outside dimensions

H

×

W

×

L: 97 mm

×

80 mm

×

104 mm

Stapling capacity

52 g 2 sheets ~ 80 g 50 sheets, below 5

mm thick

mm thick

Stapling type

Bypass flat clinch

Stapling speed

400 msec or below

Needle cartridge

5000 needles

500

3K

2SB1431

Q04

150

5K

2SD1590

Q02

2.5A/125V

T1.6A/250V

T1.6A/250V

F02

+24V

I/O

PE4

PE5

8 STMA

9 STMB

+5V

R166

R165

R164

R163

D03

D04

R161

R162

4.7K

4.7K

200

200

1K

1K

1SS133

1SS133

(IC03)

TD62503F

TD62503F

3

14

4

13

IC09D

IC09C

R176

C157

68000P

1K

IC09B

IC09A

TD62503F

TD62503F

15

2

1

16

R16

R17

2.4K(1/4W)

2.4K(1/4W)

R177

C156

68000P

C152

10000P

C153

10000P

500

3K

2SB1431

Q03

150

5K

2SD1590

Q01

D01 D02

STM+

STM-

STM

1SR124-400•~2

1K

+5V

R190

+

-

100

C155

0.1U

0.1U

C154

0.1U

0.1U

R175

1.2K

1.2K

R18

0.22

(1W)

(1W)

R188

3.9K

3.9K

+5V

+10V

+5V

R189

2.2K

2.2K

BA10393F

C165

0.1U

0.1U

8

1

3

2

4

IC15A

5

12

11

6

TD62503F

TD62503F

IC09E

IC09F

STHP

STM

LSTS

NCTS

READY

+5V

GND

Finisher

main PWB

Stapler unit

9 – 12

15. Stepping motor drive circuit

The control signal (STMA,B) from the expansion I/O expansion is

input through the driver TD62503F to the H driver circuit which con-

sists of a large-current driving transistors Q1

input through the driver TD62503F to the H driver circuit which con-

sists of a large-current driving transistors Q1

∼

4, thus driving the

staple motor which staples sheets.

The rotational direction (CW, CCW) of the staple motor is controlled b

signal locks STMA, STMB. The motor is braked to stop at the home

position.

signal locks STMA, STMB. The motor is braked to stop at the home

position.

TD62503 (IC15) is a driver to drive Q1

∼

4. A delay circuit is com-

posed of R163-R166, R176, R177, C152, C153, C156, C157, D3,

and D4 to prevent short current from flowing into the H driver circuit

which is formed by Q1

and D4 to prevent short current from flowing into the H driver circuit

which is formed by Q1

∼

4, when STMA and STMB are changed

over.

The staple motor has a large rush current. It thus has a current limit

circuit consisting of a voltage comparator BA10393F (IC15) and pe-

ripheral resistances and capacitors, to apply current limit at about

5.3A. To prevent the circuit from shorting or motor locking, a protec-

tive fuse (F2) is installed.

circuit consisting of a voltage comparator BA10393F (IC15) and pe-

ripheral resistances and capacitors, to apply current limit at about

5.3A. To prevent the circuit from shorting or motor locking, a protec-

tive fuse (F2) is installed.

16. Stapler unit

The stapler unit (EH-524S: Max Co., Ltd.) staples up to 50 sheets of

80-g paper. The unit consists of a driving DC motor (STM), home

position sensor (STHP), non-needle sensor (LSTS), cartridge sensor

(NCTS), and self-priming sensor which detects the stapling position of

needles (READY).

80-g paper. The unit consists of a driving DC motor (STM), home

position sensor (STHP), non-needle sensor (LSTS), cartridge sensor

(NCTS), and self-priming sensor which detects the stapling position of

needles (READY).

Item

Specification

Outside dimensions

H

×

W

×

L: 97 mm

×

80 mm

×

104 mm

Stapling capacity

52 g 2 sheets ~ 80 g 50 sheets, below 5

mm thick

mm thick

Stapling type

Bypass flat clinch

Stapling speed

400 msec or below

Needle cartridge

5000 needles

500

3K

2SB1431

Q04

150

5K

2SD1590

Q02

2.5A/125V

T1.6A/250V

T1.6A/250V

F02

+24V

I/O

PE4

PE5

8 STMA

9 STMB

+5V

R166

R165

R164

R163

D03

D04

R161

R162

4.7K

4.7K

200

200

1K

1K

1SS133

1SS133

(IC03)

TD62503F

TD62503F

3

14

4

13

IC09D

IC09C

R176

C157

68000P

1K

IC09B

IC09A

TD62503F

TD62503F

15

2

1

16

R16

R17

2.4K(1/4W)

2.4K(1/4W)

R177

C156

68000P

C152

10000P

C153

10000P

500

3K

2SB1431

Q03

150

5K

2SD1590

Q01

D01 D02

STM+

STM-

STM

1SR124-400•~2

1K

+5V

R190

+

-

100

C155

0.1U

0.1U

C154

0.1U

0.1U

R175

1.2K

1.2K

R18

0.22

(1W)

(1W)

R188

3.9K

3.9K

+5V

+10V

+5V

R189

2.2K

2.2K

BA10393F

C165

0.1U

0.1U

8

1

3

2

4

IC15A

5

12

11

6

TD62503F

TD62503F

IC09E

IC09F

STHP

STM

LSTS

NCTS

READY

+5V

GND

Finisher

main PWB

Stapler unit

9 – 12