Sharp AR-CF2 (serv.man2) Service Manual ▷ View online

: Jan. 9 2004

1

AR-CF2 OPERATIONAL DESCRIPTION 4 - 1

[4] OPERATIONAL DESCRIPTION

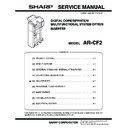

1. Structure

A. Cross-sectional view (Main body)

B. Drive system

[List of actuators]

2. Function outline

A. Operation mode

(1)

Normal (online mode)

• Through (horizontal transport)

• Straight mode (normal paper feeding from inserter)

• Reverse mode (reverse paper feeding from inserter)

(2)

Offline mode

• Punching mode (inserter operation = normal paper feeding)

• Stapling mode (inserter operation = normal paper feeding)

B. Delivery speed

(1)

Delivery speed

3. Operational description

A. Through-mode operation of inserter (Online)

Step 01: The inserter receives an operation command sent by the

main unit.

Step 02: The transport motor rotates at a speed specified by the main

unit.

Horizontal transport rollers 1 (inlet rollers) and horizontal

transport rollers 2 (paper exit rollers) rotate.

transport rollers 2 (paper exit rollers) rotate.

Step 03: A sheet exits from the main unit.

Step 04: The paper exit sensor detects the leading edge of the sheet.

Step 05: The paper exit sensor detects the trailing edge the sheet.

Step 06: The transport motor stops.

Horizontal transport rollers 1 and horizontal transport rollers

2 stop.

2 stop.

Actuator

Components to be driven

Description

Type

Paper feed

motor

motor

Pulse motor

Pickup roller, feed rollers,

separation rollers, registration

rollers, vertical transport rollers

separation rollers, registration

rollers, vertical transport rollers

Transport motor

Pulse motor

Inlet rollers (horizontal

transport rollers 1), paper exit

rollers (horizontal transport

rollers 2)

transport rollers 1), paper exit

rollers (horizontal transport

rollers 2)

Reverse motor

Pulse motor

Reverse rollers

Reverse flapper

solenoid

solenoid

Solenoid

Switch-over flapper in reverse

section

section

Registration

clutch

clutch

Electromagnetic

clutch

clutch

Registration roller lock clutch

• Straight mode:

800 mm/sec

• Saddle mode (reverse): 420 mm/sec

Pickup roller

Paper feed roller

Separation roller

Registration roller

Vertical

transport roller

transport roller

Horizontal

transport roller 1

transport roller 1

Reverse roller

Empty sensor

Registration sensor

Timing sensor

Horizontal

transport roller 2

transport roller 2

Reverse sensor

Paper exit sensor

1

AR-CF2 OPERATIONAL DESCRIPTION 4 - 2

B. Normal paper feed operation of inserter (online/

offline)

[Paper loading]

Step 01: A sheet is placed in the paper feed tray of the inserter.

Step 02: The START LED lights up in blue on the operator panel of

the inserter.

Step 03: An operation command is sent by the main unit, or a user

presses the START switch on the operator panel of the

inserter.

inserter.

Step 04: The registration clutch is turned ON to lock the registration

rollers.

[Separation]

Step 05: The paper feed motor reverses to lower the pickup roller,

thereby taking in the sheet from the paper feed tray.

Step 06: The registration sensor detects the leading edge of the

sheet.

Step 07: The sheet makes contact with the registration rollers to form

a loop, thereby stopping the paper feed motor.

Step 08: The registration clutch is turned OFF.

[Leading-edge registration]

Step 09: The paper feed motor starts to rotate in the forward direction.

The registration rollers and vertical transport rollers rotate.

Step 10: The timing sensor detects the leading edge of the sheet.

Step 11: The leading edge of the sheet passes between the vertical

transport rollers.

Step 12: When sheet transport needs to be suspended for adjusting

the space between sheets, the paper feed motor stops to

stop the sheet.

stop the sheet.

[Transport]

Step 13: When a predetermined waiting time period has passed, The

paper feed motor restarts.

(If the transport motor has stopped, it is started.)

Step 14: The paper exit sensor is turned ON, and detects the leading

edge of the sheet.

Step 15: The timing sensor is turned OFF, and the trailing edge of the

sheet is detected.

Step 16: When the trailing edge of the sheet leaves the vertical trans-

port rollers, the paper feed motor stops.

(When there is a next sheet to be inserted, the paper feed

motor reverses to take it in.

motor reverses to take it in.

[Paper exit]

Step 17: The paper exit sensor is turned OFF, and the trailing edge of

the sheet is detected.

Step 18: When there is no next sheet to be inserted, the transport

motor stops.

Note: While the transport motor (horizontal transport rollers 1 and

horizontal transport rollers 2) rotates at a speed specified by

the main unit in the online mode, it rotates at either of the

speeds shown below in the offline mode.

the main unit in the online mode, it rotates at either of the

speeds shown below in the offline mode.

∗

Transport speed in offline mode

Small-sized sheet (of which length detected in the tray is 216 mm or

less): 1000 mm/sec

Large-sized sheet (of which length detected in the tray is more than

216 mm): 800 mm/sec

Small-sized sheet (of which length detected in the tray is 216 mm or

less): 1000 mm/sec

Large-sized sheet (of which length detected in the tray is more than

216 mm): 800 mm/sec

: Jan. 9 2004

1

AR-CF2 OPERATIONAL DESCRIPTION 4 - 3

[Paper loading]

Step 01: A sheet is placed in the paper feed tray of the inserter.

Step 02: The START LED lights up in blue on the operator panel of

the inserter.

Step 03: The inserter reserves an operation command sent by the

main unit.

Step 04: The registration clutch is turned ON to lock the registration

rollers.

[Separation]

Step 05: The paper feed motor reverses to lower the pickup roller,

thereby taking in the sheet from the paper feed tray.

Step 06: The registration sensor detects the leading edge of the

sheet.

Step 07: The sheet makes contact with the registration rollers to form

a loop, thereby stopping the paper feed motor.

Step 08: The registration clutch is turned OFF.

[Leading-edge registration]

Step 09: The paper feed motor starts to rotate in the forward direction.

The registration rollers and vertical transport rollers rotate. If

the sheet is the first sheet, the flapper solenoid in the reverse

section is turned ON at this point of time.

the sheet is the first sheet, the flapper solenoid in the reverse

section is turned ON at this point of time.

Step 10: The timing sensor detects the leading edge of the sheet.

Step 11: The leading edge of the sheet passes between the vertical

transport rollers.

Step 12: When sheet transport needs to be suspended for adjusting

the space between sheets, the paper feed motor stops to

stop the sheet.

stop the sheet.

[Entering reverse section]

Step 13: When a predetermined waiting time period has passed, the

flapper solenoid is turned ON, the paper feed motor restarts,

and the reverse motor starts to rotate in the forward direction.

and the reverse motor starts to rotate in the forward direction.

Step 14: The reverse sensor is turned ON, and detects the leading

edge of the sheet.

Step 15: When the trailing edge of the sheet leaves the timing sensor,

the paper feed motor starts to slow down to stop.

(After the paper feed motor has completely stopped, if there

is a next sheet to be inserted, the paper feed motor starts to

reverse to take it in.)

(After the paper feed motor has completely stopped, if there

is a next sheet to be inserted, the paper feed motor starts to

reverse to take it in.)

Step 16: The reverse sensor is turned OFF. The trailing edge of the

sheet is detected, and the flapper solenoid in the reverse

section is turned OFF. When the sheet travels a predeter-

mined distance, the reverse motor stops.

section is turned OFF. When the sheet travels a predeter-

mined distance, the reverse motor stops.

C. Reverse paper feeding operation of inserter

1

AR-CF2 OPERATIONAL DESCRIPTION 4 - 4

[Exiting from reverse section]

Step 17: When the reverse motor has completely stopped, the reverse

motor starts to reverse, and the transport motor starts.

Step 18: The reverse sensor is turned ON, and detects the leading

edge of the sheet.

Step 19: The paper exit sensor is turned ON, and detects the leading

edge of the sheet.

Step 20: The reverse sensor is turned OFF. When the sheet travels a

predetermined distance after its trailing edge is detected, the

reverse motor stops.

(If the next sheet waits at the leading-edge registration posi-

tion, the flapper solenoid in the reverse section is turned ON,

the paper feed motor starts to rotate in the forward direction,

and the reverse motor starts to rotate in the forward direc-

tion.)

reverse motor stops.

(If the next sheet waits at the leading-edge registration posi-

tion, the flapper solenoid in the reverse section is turned ON,

the paper feed motor starts to rotate in the forward direction,

and the reverse motor starts to rotate in the forward direc-

tion.)

[Paper exit]

Step 21: The paper exit sensor is turned OFF, and the trailing edge of

the sheet is detected.

Step 22: If there is no next sheet to be inserted, the transport motor

stops.

4. Offline mode setting

A. How to set punching mode

The figure below shows the operator panel.

Setting procedure:

Step 01: Place a sheet in the tray.

Step 02: Press the PUNCH switch on the operator panel.

Step 03: The PUNCH LED lights up to indicate that setting has been

completed.

Step 04: Press the START switch to start operation.

Canceling procedure:

Step 01: Press the PUNCH switch on the operator panel.

Step 02: The PUNCH LED goes out to indicate that setting has been

canceled.

Note: If you cannot make or cancel setting by following the respective

procedures above, refer to "5. LED indication on operation

panel" shown later. When no LEDs are lit, check the setting

made by the main unit and the inserter status.

panel" shown later. When no LEDs are lit, check the setting

made by the main unit and the inserter status.

B. How to set stapling mode

Setting procedure:

Step 01: Place a sheet in the tray.

Step 02: Press the STAPLE MODE switch on the operator panel.

Step 03: Each time you press the switch, the STAPLE MODE LEDs

light up by turns in the following order: 1

→

2

→

3

→

4

→

All

LEDs OFF

→

1

→

... (When the saddle mode is cannot be

used, the order is: 1

→

2

→

3

→

All LEDs OFF

→

1

→

...)

Step 04: When the desired LED lights up, press the START switch to

start operation.

(Refer to the correspondence between the stapling modes and LEDs

shown later.)

shown later.)

Canceling procedure:

Step 01: Press the STAPLE MODE switch on the operator panel.

Step 02: All the STAPLE MODE LEDs go out to indicate that setting

has been canceled.

Note 1:

If you cannot make or cancel setting by following the respec-

tive procedures above, refer to "5. LED indication on opera-

tion panel" shown later. When no LEDs are lit, check the

setting made by the main unit and the inserter status.

tive procedures above, refer to "5. LED indication on opera-

tion panel" shown later. When no LEDs are lit, check the

setting made by the main unit and the inserter status.

Note 2:

The punching mode and saddle mode cannot be used at the

same time.

same time.

Punch switch

Punch LED

Start switch

Start LED

Start switch

Staple mode switch

Start switch

Staple mode LED 4

Staple mode LED 3

Staple mode LED 2

Staple mode LED 1

Click on the first or last page to see other AR-CF2 (serv.man2) service manuals if exist.