Sharp AR-C250 (serv.man41) Service Manual / Technical Bulletin ▷ View online

GMA050702

Sharp Electronics (UK) Ltd., Technical Services Group

If acceptable and within specification, exit Test Simulation 50-22.

If out of specification, place the check pattern on the platen glass with the

arrow pointing left, placing 5 sheets of blank paper on top.

Press “EXECUTE”.

The pattern will be scanned, and the display will show a result of “EXACT”,

“ROUGH”, or “ERROR”. Exit the simulation by using C/A.

“Recheck and “Fine Tune” the Registration by using Test Simulation 50-20

(Main scan) and 50-21 (Sub scan).

Copy Exposure

Test Simulation 46-01 & 46-02

Prior to adjusting colour balance, adjust all Colour and B/W exposure settings

back to the default value of 50 :-

Half Tone Correction

Test Simulation 44-27

Ensure Half Tone Correction is reset back to default ONLY when either Drum(s) or

Developer are replaced.

Calibration:

Engine

Calibration

Test Simulation 46-24

Select A3 paper and press “EXECUTE” to print a half tone test pattern (This

should be printed on recommended colour paper). Place this pattern onto the

platen glass so that the darkest density patches are toward the left or exit side of

the copier. Place 5 sheets of blank paper on top of the test pattern for greater

accuracy.

should be printed on recommended colour paper). Place this pattern onto the

platen glass so that the darkest density patches are toward the left or exit side of

the copier. Place 5 sheets of blank paper on top of the test pattern for greater

accuracy.

GMA050702

Sharp Electronics (UK) Ltd., Technical Services Group

Select “SERVICE” and then “EXECUTE”.

The colour test pattern will be scanned, and a reference patch image will be printed.

Examine the image and determine the following:

Examine the image and determine the following:

1) The maximum density area is not blurred or distorted.

2) Patch “A” of Y, C, M, and K is not visible.

3) Patches “B through E” are very faint. (“B” & “C” not visible is acceptable)

4) The patch density for each colour should change gradually from high

density (left) to low density (right).

GMA050702

Sharp Electronics (UK) Ltd., Technical Services Group

If the colour patch is judged to be abnormal, select “Repeat” to reprint the test

pattern.

pattern.

Once the test pattern is rescanned and the colour patch is judged to be normal,

press OK. Wait until the message “Please Quit This Mode” is displayed before

exiting the test simulation.

After completion of this command, make test copies using the Sharp Colour Test

Chart (UKOG-0283FCZZ) and confirm copy quality. If the customer is satisfied with

the quality, calibration is complete.

If the copy quality is not acceptable, perform Manual Colour Balance adjustment:-

Manual Colour Balance

Test command 46-21:

This adjustment needs to be performed if:-

a) You are unable to get a satisfactory result from the automatic adjustment.

b) To suit individual customer needs.

a) You are unable to get a satisfactory result from the automatic adjustment.

b) To suit individual customer needs.

Enter Test Simulation 46-21, select “A3” paper, and verify that all values are set to

500.

500.

(After completion of TC 46-24, this is done automatically).

Press “EXECUTE”.

A colour patch image will be printed. Examine the printout, and determine the

following:

following:

1) Patch “A” of Y, C, M, and K is not visible.

2) Patches “B through E” are very faint. (“B” & “C” not visible is acceptable).

3) The patch density for each colour should change gradually from high

density (left) to low density (right).

4) Each colour should be roughly equal in density. For example, Cyan should

not be noticeably darker than Magenta, or vice- versa.

Note: If the four colour “gamuts” are too intense between “G” and “A”,

background may result. A noticeable “drop-off” in intensity should occur near

“G”.

background may result. A noticeable “drop-off” in intensity should occur near

“G”.

Cont’d

GMA050702

Sharp Electronics (UK) Ltd., Technical Services Group

If any of the above conditions are not met, adjust the density of each colour’s gamut

by using the up and down arrows. This changes all 15 squares simultaneously.

(each colour’ “gamut” is represented by 15 squares. - Letters “A” through “O”.)

The next objective is to adjust the individual patch to get the composite black

strip (CMY mixed) to match the process black strip (Bk) as closely as possible.

1)

by using the up and down arrows. This changes all 15 squares simultaneously.

(each colour’ “gamut” is represented by 15 squares. - Letters “A” through “O”.)

The next objective is to adjust the individual patch to get the composite black

strip (CMY mixed) to match the process black strip (Bk) as closely as possible.

1)

With the first process black strip facing you, label the process black strip from

left to right, MAX, O, N, M, L, K, J, I, H, G, F, E, D, C, B, and A. (16 squares) This

will be your reference sheet.

2)

will be your reference sheet.

2)

In order to manipulate the composite black strip so it resembles the process

black strip as closely as possible, highlight the colour you wish to adjust (C, M, Y, or

K). Choose the square you wish to adjust, (letter A through O) ,use the ten keys to

increase or decrease the value, and press “OK”.

K). Choose the square you wish to adjust, (letter A through O) ,use the ten keys to

increase or decrease the value, and press “OK”.

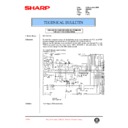

Select Colour

to be adjusted

Either Select 1 point to adjust

1 point at a time or use the up

and down arrows to adjust all

15 points simultaneously