Sharp AL-1000 / AL-1010 (serv.man12) Service Manual ▷ View online

Main code

Sub code

Contents

50

1

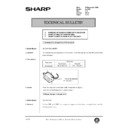

Lead edge position and paper lead edge/rear edge void adjustment

Used to adjust the copy image position on copy paper and the lead edge/rear edge void amounts. Performed by

adjusting the scanning start position and print start position (resist roller ON timing) in 100%.

(Operation/Procedure)

1. When this simulation is executed, the current set value is displayed in two digits. (Center value: 50)

2. When the copy mode select key is pressed, the setting mode and the setting display are changed sequentially.

* The selected adjustment mode is indicated by the lamps as follows.

3. Enter the adjustment value with the 10-key and press the START key. Then the set value is stored and copy is

made. (An increase of 1 in the set value corresponds to 0.1mm shift.)

4. Press the clear key to store the set value and exit the simulation.

Used to adjust the copy image position on copy paper and the lead edge/rear edge void amounts. Performed by

adjusting the scanning start position and print start position (resist roller ON timing) in 100%.

(Operation/Procedure)

1. When this simulation is executed, the current set value is displayed in two digits. (Center value: 50)

2. When the copy mode select key is pressed, the setting mode and the setting display are changed sequentially.

* The selected adjustment mode is indicated by the lamps as follows.

3. Enter the adjustment value with the 10-key and press the START key. Then the set value is stored and copy is

made. (An increase of 1 in the set value corresponds to 0.1mm shift.)

4. Press the clear key to store the set value and exit the simulation.

Adjustment mode

Lamps ON

Print start position

AE lamp

Image lead edge void amount

TEXT lamp

Image scanning start position (Scanner)

PHOTO lamp

Image rear edge void amount

AE, TEXT, PHOTO lamps

10

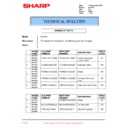

Center offset adjustment

(Outline)

Used to adjust the copy image position on copy paper and the center offset position in scanning an original.

Performed by changing the set values of the SCAN LEFT MARGIN register and the PRINT LEFT MARGIN

register of ASIC.

(Operation/Procedure)

1. When this simulation is executed, the current set value is displayed.

2. In a machine with the multi paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

In a machine with the single paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

* The selected adjustment mode is indicated by the lamps as follows:

3. Enter the adjustment value with the 10-key and press the SORT key. Then the set value is stored and a copy

is made. (An increase of 1 in the set value corresponds to 0.1mm shift.)

4. Press the clear key to store the set value and exit the simulation.

(Outline)

Used to adjust the copy image position on copy paper and the center offset position in scanning an original.

Performed by changing the set values of the SCAN LEFT MARGIN register and the PRINT LEFT MARGIN

register of ASIC.

(Operation/Procedure)

1. When this simulation is executed, the current set value is displayed.

2. In a machine with the multi paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

In a machine with the single paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

* The selected adjustment mode is indicated by the lamps as follows:

3. Enter the adjustment value with the 10-key and press the SORT key. Then the set value is stored and a copy

is made. (An increase of 1 in the set value corresponds to 0.1mm shift.)

4. Press the clear key to store the set value and exit the simulation.

* Machine with the multi manual paper feed unit installed

Adjustment mode

Lamps ON

Print center offset (main cassette paper feed)

AE, main cassette lamp

Print center offset (2nd cassette paper feed)

AE, 2nd cassette lamp

Print center offset (Manual paper feed)

AE, manual feed lamp

OC/original center offset

AE, TEXT lamp

SPF/Original center offset

AE, TEXT, PHOTO lamp

* Machine with the single manual paper feed unit installed

Adjustment mode

Lamps ON

Print center offset (main cassette paper feed)

AE, main cassette lamp

Print center offset (Manual paper feed)

AE (Blink)

OC/original center offset

AE, TEXT lamp

SPF/Original center offset

AE, TEXT, PHOTO lamp

51

2

Resist amount adjustment

(Outline)

Used to adjust the contact pressure of paper onto the copier resist roller and the SPF resist roller.

(Operation/Procedure)

1. When this simulation is executed, the currently set value is displayed.

2. In a machine with the multi paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

In a machine with the single paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

* The selected adjustment mode is indicated by the lamps as follows:

3. Enter the adjustment value with the 10-key and press the SORT key. Then the set value is stored and a copy

is made.

4. Press the clear key to store the set value and exit the simulation.

(Outline)

Used to adjust the contact pressure of paper onto the copier resist roller and the SPF resist roller.

(Operation/Procedure)

1. When this simulation is executed, the currently set value is displayed.

2. In a machine with the multi paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

In a machine with the single paper feed unit installed, press the copy mode select key, and each setting mode

and display are changed sequentially.

* The selected adjustment mode is indicated by the lamps as follows:

3. Enter the adjustment value with the 10-key and press the SORT key. Then the set value is stored and a copy

is made.

4. Press the clear key to store the set value and exit the simulation.

AL-1000/1010

10-9

Main code

Sub code

Contents

51

2

* Machine with the multi manual paper feed unit installed

Adjustment mode

Lamps ON

Main cassette paper feed

AE, main cassette lamp

2nd cassette paper feed

AE, 2nd cassette lamp

Manual paper feed

AE, manual feed lamp

SPF/Resist

AE, TEXT, PHOTO lamp

* Machine with the single manual paper feed unit installed

Adjustment mode

Lamps ON

Main cassette paper feed

AE, main cassette lamp

Manual paper feed

AE (Blink)

SPF/Resist

AE, TEXT, PHOTO lamp

61

3

Polygon motor (HSYNC output) check

(Operation/Procedure)

When the START key is pressed, HSYNC is performed and the polygon motor is rotated for 30 sec.

At that time, the Zoom lamp is lighted for 100msec e3very time when HSYNC is detected.

(Operation/Procedure)

When the START key is pressed, HSYNC is performed and the polygon motor is rotated for 30 sec.

At that time, the Zoom lamp is lighted for 100msec e3very time when HSYNC is detected.

63

1

Shading check

(Outline)

Used to display the detection level of the white plate for shading. (Vref of AD conversion IC is fixed.)

(Operation/Procedure)

When the START key is pressed, the mirror base unit moves to the white plate for shading and Vref+ voltage of

AD conversion IC is set to 4.5V and Vref- voltage to 0.5V, and the copy lamp is lighted.

This state is kept for 10 sec, and the level of one pixel at the center is detected every second to display on the

value display section.

(Outline)

Used to display the detection level of the white plate for shading. (Vref of AD conversion IC is fixed.)

(Operation/Procedure)

When the START key is pressed, the mirror base unit moves to the white plate for shading and Vref+ voltage of

AD conversion IC is set to 4.5V and Vref- voltage to 0.5V, and the copy lamp is lighted.

This state is kept for 10 sec, and the level of one pixel at the center is detected every second to display on the

value display section.

64

1

Self print by engine only (1 by 2 mode)

(Outline)

Used to print the set quantity in 1 by 2 mode ignoring the optical system state.

(Operation/Procedure)

1. When this simulation is executed, warming up is performed and the ready lamp is lighted.

2. Enter the copy quantity with the 10-key, select the cassette with the cassette select key, and press the START

key. Paper is fed from the cassette and printing is performed.

In 1 by 2 print mode, one line is printed and the following two lines are not printed.

(Outline)

Used to print the set quantity in 1 by 2 mode ignoring the optical system state.

(Operation/Procedure)

1. When this simulation is executed, warming up is performed and the ready lamp is lighted.

2. Enter the copy quantity with the 10-key, select the cassette with the cassette select key, and press the START

key. Paper is fed from the cassette and printing is performed.

In 1 by 2 print mode, one line is printed and the following two lines are not printed.

AL-1000/1010

10-10

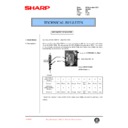

4. Trouble Codes

Main code

Sub code

Trouble content

Detail of trouble

E7

03

HSYNC cannot be

detected.

detected.

LSU (laser diode, reception element, APC circuit) trouble

LSU drive circuit (ASIC) trouble

LSU drive circuit (ASIC) trouble

E7

04

CCD white level trouble

CCD drive circuit (CCD PWB, ASIC harness) trouble

Copy lamp lighting trouble (Copy lamp, invertor PWB)

Copy lamp lighting trouble (Copy lamp, invertor PWB)

E7

05

CD black level trouble

CCD drive circuit (CCD PWB, ASIC, harness) trouble

E7

12

Shading trouble

(white correction)

(white correction)

Dirt on white plate for scanning white level

E7

14

ASIC connection trouble

Improper connection between CPU and ASIC (pattern cut, improper connection

of lead pin)

of lead pin)

E7

15

Copy lamp OFF trouble

Copy lamp or copy lamp drive circuit (invertor PWB) trouble Copy lamp

disconnection

disconnection

L1

00

Feed is not completed

within the specified time.

within the specified time.

When the mirror base is returned for the specified time (6 sec) in mirror initializing

after turning on the power, the mirror home position sensor (MHPS) does not

turn OFF. Or when the mirror base is fed for the specified time (about 6 sec)

after start of copy return, the mirror home position sensor (MHPS) does not turn

OFF.

after turning on the power, the mirror home position sensor (MHPS) does not

turn OFF. Or when the mirror base is fed for the specified time (about 6 sec)

after start of copy return, the mirror home position sensor (MHPS) does not turn

OFF.

L3

00

Return is not completed

within the specified time.

within the specified time.

When the mirror base is returned for the specified time (6 sec) in mirror

initializing after turning on the power, the mirror home position sensor (MHPS)

does not turn ON.Or when the mirror base is returned for the specified time

(about 6 sec) after start of copy return, the mirror home position sensor (MHPS)

does not turn ON.

initializing after turning on the power, the mirror home position sensor (MHPS)

does not turn ON.Or when the mirror base is returned for the specified time

(about 6 sec) after start of copy return, the mirror home position sensor (MHPS)

does not turn ON.

L4

01

Main motor lock

When the main motor encoder pulse is not detected for 100msec.

L6

10

Polygon motor lock

The lock signal (specified rpm signal) does not return within a certain time (about

20sec) from starting the polygon motor rotation

20sec) from starting the polygon motor rotation

H2

00

Thermistor open detection

The fusing thermistor is open.

H3

00

Heat roller abnormally high

temperature

temperature

The fusing temperature rises above 240°C.

H4

00

Heat roller abnormally low

temperature

temperature

The fusing temperature does not reach 185°C within 27 sec of turning on the

power, or the fusing temperature keeps at 140°C.

power, or the fusing temperature keeps at 140°C.

U2

01

Counter sum check error

U2

04

EEPROM serial

communication error

communication error

When a communication trouble occurs with the EEPROM.

CH

(Blinking)

-

TD cartridge not installed

Check if TD cartridge is installed.

AL-1000/1010

10-11

4. Trouble Codes

Main code

Sub code

Trouble content

Detail of trouble

E7

03

HSYNC cannot be

detected.

detected.

LSU (laser diode, reception element, APC circuit) trouble

LSU drive circuit (ASIC) trouble

LSU drive circuit (ASIC) trouble

E7

04

CCD white level trouble

CCD drive circuit (CCD PWB, ASIC harness) trouble

Copy lamp lighting trouble (Copy lamp, invertor PWB)

Copy lamp lighting trouble (Copy lamp, invertor PWB)

E7

05

CD black level trouble

CCD drive circuit (CCD PWB, ASIC, harness) trouble

E7

12

Shading trouble

(white correction)

(white correction)

Dirt on white plate for scanning white level

E7

14

ASIC connection trouble

Improper connection between CPU and ASIC (pattern cut, improper connection

of lead pin)

of lead pin)

E7

15

Copy lamp OFF trouble

Copy lamp or copy lamp drive circuit (invertor PWB) trouble Copy lamp

disconnection

disconnection

L1

00

Feed is not completed

within the specified time.

within the specified time.

When the mirror base is returned for the specified time (6 sec) in mirror initializing

after turning on the power, the mirror home position sensor (MHPS) does not

turn OFF. Or when the mirror base is fed for the specified time (about 6 sec)

after start of copy return, the mirror home position sensor (MHPS) does not turn

OFF.

after turning on the power, the mirror home position sensor (MHPS) does not

turn OFF. Or when the mirror base is fed for the specified time (about 6 sec)

after start of copy return, the mirror home position sensor (MHPS) does not turn

OFF.

L3

00

Return is not completed

within the specified time.

within the specified time.

When the mirror base is returned for the specified time (6 sec) in mirror

initializing after turning on the power, the mirror home position sensor (MHPS)

does not turn ON.Or when the mirror base is returned for the specified time

(about 6 sec) after start of copy return, the mirror home position sensor (MHPS)

does not turn ON.

initializing after turning on the power, the mirror home position sensor (MHPS)

does not turn ON.Or when the mirror base is returned for the specified time

(about 6 sec) after start of copy return, the mirror home position sensor (MHPS)

does not turn ON.

L4

01

Main motor lock

When the main motor encoder pulse is not detected for 100msec.

L6

10

Polygon motor lock

The lock signal (specified rpm signal) does not return within a certain time (about

20sec) from starting the polygon motor rotation

20sec) from starting the polygon motor rotation

H2

00

Thermistor open detection

The fusing thermistor is open.

H3

00

Heat roller abnormally high

temperature

temperature

The fusing temperature rises above 240°C.

H4

00

Heat roller abnormally low

temperature

temperature

The fusing temperature does not reach 185°C within 27 sec of turning on the

power, or the fusing temperature keeps at 140°C.

power, or the fusing temperature keeps at 140°C.

U2

01

Counter sum check error

U2

04

EEPROM serial

communication error

communication error

When a communication trouble occurs with the EEPROM.

CH

(Blinking)

-

TD cartridge not installed

Check if TD cartridge is installed.

AL-1000/1010

10-11