Panasonic AW-E800E Service Manual ▷ View online

– 2 –

Pin No.

Signal

Pin No.

Signal

1

Return Control

7

Iris Follow

2

Not Used

8

Auto/Remote Control

3

GND

9

Not Used

4

Auto/Manual Control

10

Not Used

5

Iris Control

11

Not Used

6

Lens Power

12

Not Used

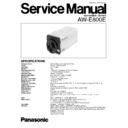

<Front View>

Iris Connector (IRIS)

o q

i

w

u

e

y

t

r

!2

!0

!1

8. NO/BAR Switch (NO/BAR/

−

)

The item just below can be selected by pressing this

switch while the Sub Menu is on the screen.

While the Sub Menu is displayed any setting can be

brought down to a lower value with this switch. When

the menu is not displayed or the camera is in shooting

mode, the color (colour) bar and the shooting conditions

are alternately indicated by pressing the switch.

switch while the Sub Menu is on the screen.

While the Sub Menu is displayed any setting can be

brought down to a lower value with this switch. When

the menu is not displayed or the camera is in shooting

mode, the color (colour) bar and the shooting conditions

are alternately indicated by pressing the switch.

9. Video Output Connector (VIDEO OUT)

A composite video signal is provided at this connector.

10.

Iris Connector (IRIS)

Input terminal for lens with an iris control function.

14. Cable Clamp

Clamp the DC Power Supply Cable (AW-CA4T1) con-

nected to the DC 12 V Input Connector to prevent it from

slipping out.

nected to the DC 12 V Input Connector to prevent it from

slipping out.

15. G/L Input Connector (G/L IN)

Signals synchronized with the reference signal are to be

supplied to this connector when the camera is to be syn-

chronized with the reference signal BB.

supplied to this connector when the camera is to be syn-

chronized with the reference signal BB.

16. Optional Card Slot

Slot for inserting an optional card. For details, refer to

the manual for optional cards.

the manual for optional cards.

11. I/F Remote Connector (I/F REMOTE)

Input terminal dedicated to control signals from the

optional Remote Control Box (RCB) (WV-CB700A) and

the RCU (WV-RC700A, WV-RC550) and the camera

pan/tilt unit (AW-PH300).

optional Remote Control Box (RCB) (WV-CB700A) and

the RCU (WV-RC700A, WV-RC550) and the camera

pan/tilt unit (AW-PH300).

* WV-CB700A is connected through the optional RCB

cable (AW-CA50T10/AW-CA50B10).

* WV-RC700A/WV-RC550 is connected through the

optional RCU cable (AW-CA50A26).

* AW-PH300 is connected through the optional pan/ tilt

unit cable (AW-CA50T15/AW-CA50A15).

12. Power Indicator

Red LED lamp lights to indicate that the specified DC

power is supplied to the camera.

power is supplied to the camera.

13. DC 12 V Input Connector (DC 12V IN)

12 V DC is supplied through the optional DC power sup-

ply cable (AW-CA4T1).

ply cable (AW-CA4T1).

1. Connect this to a DC 12 V class 2 power supply

only.

2. To prevent fire or shock, the UL listed wire VW-1,

style 1007 should be used as for the cable for DC

12 V Input Connector.

12 V Input Connector.

Cautions

– 3 –

1. Test Equipment Required

8

The following test Equipments are required for

adjustment of the Convertible Camera AW-

E800/AW-E800E.

8

Oscilloscope

8

Frequency Counter

8

Digital Voltmeter

8

Vectorscope

8

Waveform Monitor

8

Underscanned Color (Colour) Video Monitor (correspond

to Wide Picture)

8

High Resolution Black and White Video Monitor

(correspond to Wide Picture)

8

Signal Generator

8

12 V DC Power Supply Unit

8

Lux Meter

8

Lighting (200 footcandles (2,000 lx), Color (Colour)

Temperature 3,200 K)

8

Auto Iris Lens (2/3" Bayonet-Mount)

8

Camera Cables AW-CA50T6

8

Remote Control Box (WV-CB700A)

8

1/2 ND Filter (2 pieces)

8

RCB Cable (AW-CA50T10)

8

Logarithmic Gray Scale Chart (Part No. : YWV2310RB99)

8

Extension Board between Joint Board and Analog

Process or DSP Board (Part No. : 0E1A055A)

8

Extension Board between DSP Board and Encoder Board

(Part No. : 0E1A058A)

8

Extension Board between DSP Board and Drive Board

(Part No. : 0E1A056A)

ADJUSTMENT PROCEDURE

8

Extension Board between DSP Board and Encoder Board

(Part No. : 0E1A057A)

8

Extension Board between Gch of CCD and Analog

Process Board and Drive Board (Part No. : 0E1A059A)

This Extension Board including three boards.

Extension Board between Bch CCD and Gch CCD

Extension Board between Rch CCD and Gch CCD

Extension Board between Gch CCD and Drive Board

Extension Board between Gch of CCD and Drive Board

Extension Board between Gch of CCD and Analog

Process Board

2. Disassembling Procedure for

Adjustment

8

Referring to Fig. 2-1, remove four screws that secure the

Rear Panel and remove the Rear Panel.

Fig. 2-1

Remove four screws.

Rear Panel

P1

P2

P1

P3

P2

P4

P6

P5

P1

P2

P1

P2

– 4 –

3. Connection and Setting Up for

Adjustment

3.1. Connection

8

The Fig. 3-1 shows the connection diagram for the

adjustment procedure.

Fig. 3-1

8

Connect the Underscanned Color (Colour) Video Monitor

to the Video Output Connector on the Rear Panel of the

Convertible Camera AW-E800/AW-E800E through the

Waveform Monitor and the Vectorscope.

8

Terminate the input terminal of the Underscanned Color

(Colour) Video Monitor with 75

Ω

.

8

Mount the Auto Iris Lens to the AW-E800/AW-E800E.

8

Connect the Power Supply Unit to the DC 12 V Input

Connector on the Rear Panel of the AW-E800/AW-E800E.

8

For the Optional Card AW-PB301/AW-PB301E and AW-

PB302/AW-PB302E, connect the AW-CA50T6 to the I/F

Remote Connector on the Rear Panel of the AW-

E800/AW-E800E.

8

Terminate the Connectors of the AW-CA50T6 with 75

Ω

.

8

Connect the probe of the Digital Voltmeter, Oscilloscope

or Frequency Counter at the desired Test Point in each

adjustment step.

3.2. Setting Up for Standard Picture

8

The adjustment should be done after 10 minutes warm-up.

8

Set the Logarithmic Gray Scale Chart.

8

Incident light of 2,000 lx on the Logarithmic Gray Scale

Chart.

8

Aim the Camera at the Logarithmic Gray Scale Chart.

8

Set the Camera so that the Logarithmic Gray Scale Chart

becomes full picture on the Underscanned Color (Colour)

Video Monitor.

8

Connect the Oscilloscope to E301 (G-IN) on the Analog

Process Board.

8

Adjust the Lens Focus to obtain correct focal point.

Waveform

Monitor

Monitor

Vectorscope

Underscanned

Color (Colour)

Video Monitor

Color (Colour)

Video Monitor

75

Ω

AW-E800

AW-E800E

Signal Generator

Lens

Test Chart

Lcm

12V DC Power Supply

AW-CA50T6

I/F Remote

Video Out

G/L In

8

Set the Lens Iris so that the peak level of the Gray Scale

from the Blanking level becomes 270 mVp-p as shown in

Fig. 3-2.

Fig. 3-2

8

The adjustments should be done with this Standard

Picture, unless otherwise specified.

4. Adjustment Procedure

8

Refer to the Location of the Test Points and

Adjusting Controls on the page 10.

(1). Internal Frequency Adjustment

Test Point:

TP6 (INT 28M)

DSP Board

Adjust:

R140 (INT 28M)

Encoder Board

8

Connect the Frequency Counter to TP6.

8

Adjust R140 so that the Internal Frequency becomes

28.636364 MHz ± 10 Hz for AW-E800 (28.375 MHz for

AW-E800E).

(2). OG Voltage Adjustment

Test Point:

E16 (OG-R)

Drive Board

E15 (OG-G)

Drive Board

E14 (OG-B)

Drive Board

Adjust:

R119 (OG-R)

Drive Board

R116 (OG-G)

Drive Board

R113 (OG-B)

Drive Board

8

Connect the Oscilloscope to E16.

8

Adjust R119 so that the Rch OG level becomes 1.5 V.

8

Change the connection of the Oscilloscope to E15.

8

Adjust R116 so that the Gch OG level becomes 1.5 V.

8

Change the connection of the Oscilloscope to E14.

8

Adjust R113 so that the Bch OG level becomes 1.5 V.

270 mVp-p

– 5 –

8

Adjust R1 so that the blooming and noise of Bch on the

Video Monitor become minimum as shown in Fig. 4-2.

8

Adjust R2 so that the blooming and noise of Gch on the

Video Monitor become minimum as shown in Fig. 4-2.

8

Adjust R3 so that the blooming and noise of Rch on the

Video Monitor become minimum as shown in Fig. 4-2.

Fig. 4-2

8

Open the menu and turn off the electronic shutter.

(5). Preamp. Adjustment

Test Point:

E307 (G)

Analog Process Board

E507 (B)

Analog Process Board

E107 (R)

Analog Process Board

Adjust:

R323 (G-WC)

Analog Process Board

R123 (R-WC)

Analog Process Board

R523 (B-WC)

Analog Process Board

R446 (G-LEVEL)

Analog Process Board

R328 (G-DC)

Analog Process Board

R646 (B-LEVEL)

Analog Process Board

R528 (B-DC)

Analog Process Board

R246 (R-LEVEL)

Analog Process Board

R128 (R-DC)

Analog Process Board

8

Observe at E307, E507 and E107 by the Oscilloscope.

8

Turn R323, R523 and R123 so that the signals are not

clipped as shown in Fig. 4-3.

8

Turn R328, R528 and R128 so that the signals do not go

below the Blanking Level as shown in Fig. 4-3.

Fig. 4-3

8

Connect the Oscilloscope to E307.

8

Adjust R446 so that G-Level becomes 300 mVp-p as

shown in Fig. 4-4.

8

Adjust R328 so that the DC voltage at E307 becomes 0 V

as shown in Fig. 4-4.

8

Change the connection of the Oscilloscope to E507.

8

Adjust R646 so that B-Level becomes 300 mVp-p as

shown in Fig. 4-4.

(3). RG Voltage Adjustment

Test Point:

E301 (G-IN)

Analog Process Board

E101 (R-IN)

Analog Process Board

E501 (B-IN)

Analog Process Board

Adjust:

R59 (RG-G)

Drive Board

R61 (RG-R)

Drive Board

R57 (RG-B)

Drive Board

8

Open the Lens Iris.

8

Connect the Oscilloscope to E301.

8

Adjust R59 so that the saturation level of Gch becomes

maximum and the distortion in the circle area becomes

minimum as shown in Fig. 4-1.

8

Change the connection of the Oscilloscope to E101.

8

Adjust R61 so that the saturation level of Rch becomes

maximum and the distortion in the circle area becomes

minimum as shown in Fig. 4-1.

8

Change the connection of the Oscilloscope to E501.

8

Adjust R57 so that the saturation level of Bch becomes

maximum and the distortion in the circle area becomes

minimum as shown in Fig. 4-1.

Fig. 4-1

(4). V

SUB

Voltage Adjustment

Adjust:

R1 (VSUB-B)

Drive Board

R2 (VSUB-G)

Drive Board

R3 (VSUB-R)

Drive Board

Observe:

Video Monitor

8

Aim the Camera at the 40-watt Lamp placed in the dark

background.

8

Open the menu and set the electronic shutter speed to

1/500.

8

Open the Lens Iris so that the blooming becomes visible.

Saturation level

becomes

maximum

Distortion

becomes minimum

Good

No Good

No Good

Good

Position of White Clip VR

Position of Preamp. DC VR

Click on the first or last page to see other AW-E800E service manuals if exist.