Panasonic CS-TZ20TKEW / CS-TZ25TKEW / CS-TZ35TKEW / CS-TZ42TKEW / CS-MTZ16TKE / CU-TZ20TKE / CU-TZ25TKE / CU-TZ35TKE / CU-TZ42TKE Service Manual ▷ View online

65

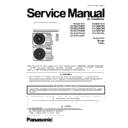

13.6.6 Re-insertion of refrigerant in service

When re-insertion is needed, follow the procedures to ensure the insertion of new refrigerant at correct amount.

1. Attach charging hose (blue) to the service port of the outdoor unit.

2. Attach charging hose (red) to the vacuum pump. Fully open the 2-way and 3-way valves.

3. Place the refrigerant cylinder on the digital scale for refrigerant charging and connect the charge hose (yellow) to

1. Attach charging hose (blue) to the service port of the outdoor unit.

2. Attach charging hose (red) to the vacuum pump. Fully open the 2-way and 3-way valves.

3. Place the refrigerant cylinder on the digital scale for refrigerant charging and connect the charge hose (yellow) to

the connection port of the vacuum pump and the digital scale. Leave the cylinder valve fully open.

4. Fully open the handles Lo and Hi of the manifold gauge, and switch on the vacuum pump, and then perform

evacuation for at or more than one hour.

5. Confirm the compound gauge of -0.1 MPa (-76cmHg) and fully open the handles of Lo and Hi, and switch off the

vacuum pump. Leave it for about 1 ~ 2 minutes and confirm the needle of the compound gauge does not turn

back.

Refer to the picture below to follow the procedures below.

back.

Refer to the picture below to follow the procedures below.

6. Remove the charging hose (red) of the manifold gauge from the vacuum pump adopter.

7. After adjusting the digital scale to zero, open the cylinder valve and the valve Lo of the manifold gauge, and

7. After adjusting the digital scale to zero, open the cylinder valve and the valve Lo of the manifold gauge, and

insert the refrigerant.

8. If it is not possible to insert the refrigerant at regulated amount at once, operate the cooling mode and gradually

insert the refrigerant (recommended amount approx. 150 g / 1 time)

*Do not insert much refrigerant at once.

*Do not insert much refrigerant at once.

9. Close the open/close valve and insert the refrigerant in the charging hose to the outdoor unit.

*Perform this procedure during operating cooling operation. Close the stem of the two-way valve, and when the

pressure of the manifold gauge becomes zero (0), quickly remove the charging hose (blue). Immediately open

the 2-way valve, and stop the cooling operation.

pressure of the manifold gauge becomes zero (0), quickly remove the charging hose (blue). Immediately open

the 2-way valve, and stop the cooling operation.

10. Final checking • • • Confirm the 2-way and 3-way valves are fully open.

Attach the caps of the service port and control valve, and then check the gas leakage around the caps.

(Liquid side)

(Indoor unit)

(Outdoor unit)

(Gas side)

Two-way

valve

Open

Open

Three-way

valve

Hi

Lo

Vacuum

pump

adaptor

Vacuum

pump

Vacuum pump

charging hose

Electronic scale

66

13.7 Repairing of refrigerant cycle / Brazing point

13.7.1 Preparation for repairing of refrigerant cycle / brazing

Brazing which is a technique needed for repairing refrigerant cycle requires advanced technique and experience, and

this brazing procedure can only be performed by the workers who completed “Gas Welding Skill Training” regulated

by the Occupational Safety and Health Act, and went through the training programs of refrigerant operations.

Dismantling and re-connecting (assembling) refrigerant system requires working space, and the space has to ensure

good air flow and fire prevention (water bucket and fire extinguisher). Moreover, the worker has to ensure the

wearing of goggles, grabs, safety shoes, and long sleeve shirts, and be aware of work safety and attempt to prevent

secondary defect (quality assurance of products). For brazing the indoor / outdoor unit structural components (heat

exchangers, compressors, expansion valves, four-way valve blocks), after the recovery of all refrigerant, confirm that

no refrigerant remains in the system, and fully open the 2-way and 3-way valves. When the brazing is conducted

outside, check and make sure no refrigerant is contained in the air (be careful with vaporized refrigerant).

Furthermore, protect the compressor terminal with metal plates, and heat but use wet clothes to cool down (releasing

the heat) the expansion valves, and four way valves (prevent destruction of parts). In brazing, it is important to pour

the brazing material without melting the base metal based on capillary action principle. In case of holes and oxidizing

caused by overheating, do not perform re-brazing or alteration but replace the parts.

this brazing procedure can only be performed by the workers who completed “Gas Welding Skill Training” regulated

by the Occupational Safety and Health Act, and went through the training programs of refrigerant operations.

Dismantling and re-connecting (assembling) refrigerant system requires working space, and the space has to ensure

good air flow and fire prevention (water bucket and fire extinguisher). Moreover, the worker has to ensure the

wearing of goggles, grabs, safety shoes, and long sleeve shirts, and be aware of work safety and attempt to prevent

secondary defect (quality assurance of products). For brazing the indoor / outdoor unit structural components (heat

exchangers, compressors, expansion valves, four-way valve blocks), after the recovery of all refrigerant, confirm that

no refrigerant remains in the system, and fully open the 2-way and 3-way valves. When the brazing is conducted

outside, check and make sure no refrigerant is contained in the air (be careful with vaporized refrigerant).

Furthermore, protect the compressor terminal with metal plates, and heat but use wet clothes to cool down (releasing

the heat) the expansion valves, and four way valves (prevent destruction of parts). In brazing, it is important to pour

the brazing material without melting the base metal based on capillary action principle. In case of holes and oxidizing

caused by overheating, do not perform re-brazing or alteration but replace the parts.

13.7.2 Adjustment

of vacuum pump pressure

1. Cylinder with adjustment handle

1. Check and confirm the adjustment handle of the 1

st

pressure adjuster is loosen (anticlockwise). If cylinder

valve is opened when the 1

st

gauge pressure adjust handle is closed, the 2

nd

gauge might get broken.

The primary gauge

(High pressure)

The secondary gauge

(Low pressure)

The secondary gauge

(Low pressure)

Adjustment

handle

Adjustment

handle

Oxygen regulator

Propane regulator

Main valve

Main valve

2. Open the cylinder valve, and check the remaining amount with the first t side pressure gauge.

3. Check the pressure of 2

3. Check the pressure of 2

nd

gauge and turn the adjustment handle to clock-wise direction to adjust the

pressure.

◎

◎

Oxygen 2

nd

side gauge pressure・・・・・・・・・・0.5 MPa (5.0 kgf / cm

2

)

◎

Propane 2

nd

side gauge pressure・・・・・・・0.05 MPa (0.5 kgf / cm

2

)

67

2. Cylinder without adjustment valve

2

nd

side gauge pressure is adjusted by the adjuster.

Check the both side valves of the torch and open the cylinder valve to check the remaining refrigerant in the

cylinder.

Caution: Do not attach oil component on the connection port of the adjuster.

Especially, use an oxygen cylinder adjuster which is no oil substance type. Do not dismantle or repair the

adjuster and pressure gauge.

cylinder.

Caution: Do not attach oil component on the connection port of the adjuster.

Especially, use an oxygen cylinder adjuster which is no oil substance type. Do not dismantle or repair the

adjuster and pressure gauge.

Propane tank

(Gray)

Oxygen tank

(Black)

Black hose

Orange hose

Regulator

Regulator

Main valve

Main valve

Fuel gauge

0~25 MPa

(0~250 k

gf / cm²)

Fuel gauge

0~3 MPa

(0~30 k

gf / cm²)

13.7.3 Checking of gas provision

Checking there is no fire around the torch, and then confirm the provision of gas.

1. Slightly open the “propane valve” of the torch, and make sure the gas comes out from the torch crater and then

1. Slightly open the “propane valve” of the torch, and make sure the gas comes out from the torch crater and then

close the “propane valve”.

2. Slightly open the “oxygen valve” of the torch and make sure the gas comes out from the torch crater and then

close the “oxygen valve”.

Check there is no gas leakage around the hose connection.

Check there is no gas leakage around the hose connection.

13.7.4 Adjustment

of

flame

1. Slightly open the “propane valve” of the torch and lit with spark lighter.

This moment, the flame is only by propane and the color is red.

2. Gradually open the “oxygen valve” of the torch to mix oxygen, and adjust the amount of propane and oxygen with

the valve to make the flame suitable for brazing work.

If the white core flame splits into two, the torch crater might be clogged. In this case, remove the crater from the

torch and check.

If the white core flame splits into two, the torch crater might be clogged. In this case, remove the crater from the

torch and check.

Oxygen (Black hose)

Propane (Orange hose)

Propane valve

Oxygen valve

Nozzle

68

13.7.5 Types of flame

Types of flame change based on the proportion of propane and oxygen.

[Neutral Flame]

Perform brazing with this flame

(This is a flame when oxygen and propane are mixed at proper proportion, and has lesser effect on the brazed

metals)

[Neutral Flame]

Perform brazing with this flame

(This is a flame when oxygen and propane are mixed at proper proportion, and has lesser effect on the brazed

metals)

White core flame

10 ~ 15 mm

Outer flame (Light orange color)

[Carbide Flame]

When propane is excessive, the flame has white color flame in between the white core flame and outer flame.

(This is due to the lack of oxygen and the proportion of unburned propane is excessive.

The black carbon created during the brazing work may contaminate the surface of the brazed metal).

When propane is excessive, the flame has white color flame in between the white core flame and outer flame.

(This is due to the lack of oxygen and the proportion of unburned propane is excessive.

The black carbon created during the brazing work may contaminate the surface of the brazed metal).

White core flame

Pale white

Outer flame (Blue color)

[Oxidizing Flame]

Oxygen is more compared to the neutral flame. Although the flame size is small, this has the highest flame heat.

However, due to the excessive oxygen contained in the flame, the brazing point gets oxidized. (This flame may cause

holes, due to the high heat. The pipe may get melt)

Oxygen is more compared to the neutral flame. Although the flame size is small, this has the highest flame heat.

However, due to the excessive oxygen contained in the flame, the brazing point gets oxidized. (This flame may cause

holes, due to the high heat. The pipe may get melt)

White core flame

Outer flame (Blue orange color)

13.7.6 Closing the flame

[In case of short break]

1. Close the “propane valve” of the torch.

2. Close the “oxygen valve” of the torch.

[In case of finishing work]

1. As above, close the flame following the procedure of “In case of short break”.

2. Completely close the valves of oxygen and propane cylinders.

3. Release the remaining gas inside the hose by opening the “oxygen valve” and “propane valve” of the torch.

Confirm the 1

1. Close the “propane valve” of the torch.

2. Close the “oxygen valve” of the torch.

[In case of finishing work]

1. As above, close the flame following the procedure of “In case of short break”.

2. Completely close the valves of oxygen and propane cylinders.

3. Release the remaining gas inside the hose by opening the “oxygen valve” and “propane valve” of the torch.

Confirm the 1

st

and 2

nd

side gauge pressures of “oxygen” and “propane” cylinder pressure adopter are “zero”.

Click on the first or last page to see other CS-TZ20TKEW / CS-TZ25TKEW / CS-TZ35TKEW / CS-TZ42TKEW / CS-MTZ16TKE / CU-TZ20TKE / CU-TZ25TKE / CU-TZ35TKE / CU-TZ42TKE service manuals if exist.