Panasonic CS-MC90KH / CU-MC140KH / CS-MC90KH / CU-MC180KH / CS-MC90KH / CU-3MC200KH Service Manual ▷ View online

– 28 –

ORDER NO. MAC9807010C3

CS-MC90KH

Installation parts you must

purchase (

purchase (

*

)

Installation plate

1

Sleeve (

*

)

Bushing-Sleeve (

*

)

Putty, (Gum Type Sealer) (

*

)

Bend the pipe as closely on the

wall as possible, but be careful

that it doesn’t break.

wall as possible, but be careful

that it doesn’t break.

Vinyl tape (Wide) (

*

)

•

Apply after carrying out a

drainage test.

drainage test.

•

To carry out the drainage

test, remove into the air filters

and pour water into the heat

exchanger.

test, remove into the air filters

and pour water into the heat

exchanger.

Saddle (

*

)

Connecting cable

(3-CORE WIRE/1.5 mm

(3-CORE WIRE/1.5 mm

2

)

Locally approved cable.

•

This illustration is for explanation purposes only.

The indoor unit will actually face a different way.

The indoor unit will actually face a different way.

•

Carry out insallation

after checking for gas

leaks.

after checking for gas

leaks.

•

After securing with

three of the vinyl

tape

three of the vinyl

tape

7

, wrap with

vinyl tape

8

.

Vinyl tape

8

Air purifying filter

5

Vinyl tape

7

(Left and right are identical)

Additional drain hose (

*

)

Vinyl tape (

*

)

(Narrow)

1/4" Liquid side piping (

*

)

3/8" Gas side piping (

*

)

1/4" Liquid side piping (

*

)

3/8" Gas side piping (

*

)

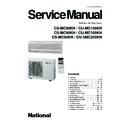

Installation Information

Indoor / Outdoor unit installation diagram

Piping direction

Attention not to bend up drain hose

Right

rear

rear

Right bottom

Left

rear

rear

Left bottom

Left

(Front side)

Right

,

,,

5 cm or

more

5 cm or

more

150 cm

or more

10 cm

or more

30 cm

or more

Insulation of piping connection

Attaching the remote control holder to the wall

Remote

Control

Control

3

Remote Control holder

fixing screws

fixing screws

!

Remote

Control

holder

Control

holder

9

Untitled-18

6/26/00, 3:39 PM

28

– 29 –

ORDER NO. MAC9807010C3

CS-MC90KH

3-way Valve

Shaft Position

Closed

(With valve cap)

Closed

(Clockwise)

Open

(With valve cap)

Open

(Counter-clockwise)

Open

(Counter-clockwise)

Open

(Counter-clockwise)

Open

(Counter-clockwise)

Open

(Counter-clockwise)

Service Port

Closed

(With cap)

Open

(Connected manifold

gauge w/charging

cylinder)

Closed

(With cap)

Closed

(With cap)

Open

(Connected manifold

gauge)

Open

(Connected manifold

gauge)

Closed

(With cap)

Open

(Connected manifold

gauge)

3-way Valve (Liquid Side)

3-way Valve (Gas Side)

Service Port

Closed

(With cap)

Open

(Push-pin)

Closed

(With cap)

Open

(Connected manifold

gauge)

Open

(Connected manifold

gauge)

Open

(Connected manifold

gauge)

Open

(Connected manifold

gauge)

Open

(Connected manifold

gauge)

Works

Shipping

Air purging

Installation and

Re-installation

Operation

Pumping down

(Transferring)

Evacuation

(Servicing)

Gas charging

(Servicing)

Pressure check

(Servicing)

Gas releasing

(Servicing)

Valve cap

To

piping

connection

piping

connection

Shaft Position

Closed

(With valve cap)

Closed

(Clockwise)

Open

(With valve cap)

Closed

(Clockwise)

Open

(Counter-clockwise)

Open

(Counter-clockwise)

Open

(Counter-clockwise)

Open

(Counter-clockwise)

Flare nut

Hexagonal wrench(4 mm)

Open position

Closed position

Closed position

Pin

Service

port cap

port cap

To outdoor unit

Service port

To

piping

connection

piping

connection

Flare nut

Open position

Closed position

Closed position

Pin

Service port

To outdoor unit

Service

port cap

port cap

Untitled-19

6/26/00, 3:41 PM

29

– 30 –

ORDER NO. MAC9807010C3

CS-MC90KH

1 Air purging

Required tools: Hexagonal wrench, adjustable wrench,

torque wrenches, wrench to hold the

joints, gas leak detector, and charging

set.

joints, gas leak detector, and charging

set.

The air in the indoor unit and in the piping must be

purged. If air remains in the refrigeration pipes, it will

affect the compressor, reduce the cooling capacity, and

could lead to a malfunction.

purged. If air remains in the refrigeration pipes, it will

affect the compressor, reduce the cooling capacity, and

could lead to a malfunction.

Service port cap

Be sure, using a torque wrench to tighten the service port nut (after using the service port), so that it prevents the gas

leakage from the refrigeration cycle.

Be sure, using a torque wrench to tighten the service port nut (after using the service port), so that it prevents the gas

leakage from the refrigeration cycle.

Procedure:

(1) Recheck the piping connections.

(2) Open the valve of the low pressure side of

Manifold gauge counterclockwise for 10 seconds,

and then close it.

and then close it.

(3) Check for gas leakage.

●

Check the flare connections for gas leakage.

(4) Purge the air from the system.

●

Open the Low pressure side valve of the manifold gauge.

●

Press the valve core pin with the hexagonal wrench to

purge the air for three seconds and then wait for one

minute.

Repeat this three times or more.

purge the air for three seconds and then wait for one

minute.

Repeat this three times or more.

(5) Balance the refrigerant in the pipings and the

indoor unit.

●

Close the Low pressure side valve of the manifold gauge.

●

Press the valve core pin with the hexagonal wrench to

release the refrigerant until the gauge indicates.

release the refrigerant until the gauge indicates.

(6) Use torque wrench CWH AD-9211 to tighten the

service port nut to a torque of 1.8kg-cm.

(7) Set the both 3-way valve to the open position.

(8) Mount the valve stem nuts to the 3-way

valves.

(9) Check for gas leakage.

●

At this time, especially check for gas leakage from the

both 3-way valve’s stem nuts, and from the service port

caps.

both 3-way valve’s stem nuts, and from the service port

caps.

Caution

If gas leakage is discovered in step (3) above, take the

following procedures:

following procedures:

1. Re-tighten the connecting portion with torque

wrenches.

If the leakage ceases, continue the works from

step (4).

If the leakage ceases, continue the works from

step (4).

2. Locate and repair the leak. (Gas leak detector)

Repeat the works from step (1).

Open

D

Closed

Lo

Hi

Closed

(Outdoor unit)

3-way

valve

Closed

Closed

3-way

valve

(Liquid side)

(Gas side)

(Indoor unit)

Untitled-19

6/26/00, 3:41 PM

30

– 31 –

ORDER NO. MAC9807010C3

CS-MC90KH

2 Pumping down

Procedure:

(1) Confirm that both the 3-way valve are set to the

open position.

●

Remove the valve stem caps and confirm that the valve

stems are in the raised position.

stems are in the raised position.

●

Be sure to use a hexagonal wrench to operate the valve

stems.

stems.

(2) Operate the unit for 10 to 15 minutes.

(3) Stop operation and wait for 3 minutes, then

connect the charge set to the service port of the

3-way valves.

3-way valves.

●

Connect the charge hose with the push pin to the gas

side service port.

side service port.

(4) Air purging of the charge hose.

●

Open the low-pressure valve on the charge set slightly to

purge air from the charge hose.

purge air from the charge hose.

(5) Set the Liquid side 3-way valve to the closed

position.

(6) Operate the air conditioner at the cooling cycle

and stop it when the gauge indicates 0 kg/cm

2

G.

●

If the unit cannot be operated at the cooling

(weather is rather cool), press the Pump Down switch on

the Indoor unit.

(weather is rather cool), press the Pump Down switch on

the Indoor unit.

●

So that the unit can be operated.

(7) Immediately set the 3-way valve to the closed

position.

●

Do this quickly so that the gauge ends up indicating

1 to 3 kg/cm

1 to 3 kg/cm

2

G.

(8) Disconnect the charge set, and mount both the

3-way valve’s stem nuts and the service port cap.

●

Use torque wrench CWHAD-9211 to tighten the service

port nut to a torque of 1.8 N•m.

port nut to a torque of 1.8 N•m.

●

Be sure to check for gas leakage.

Purge the air

(Indoor unit)

(Liquid side)

(Gas side)

CLOSED

CLOSED

Lo

Hi

3-way valve

Closed

Open

3-way valve

(Outdoor unit)

Untitled-19

6/26/00, 3:41 PM

31

Click on the first or last page to see other CS-MC90KH / CU-MC140KH / CS-MC90KH / CU-MC180KH / CS-MC90KH / CU-3MC200KH service manuals if exist.