LG WD-90KFT Service Manual ▷ View online

12

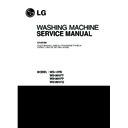

6. WIRING DIAGRAM

/

PROGRAM CHART

MAIN PWB

NA

YL

YL

BL

BL

RD

WH

RD

RD

FUSE

DOOR LOCK S/W

DRAIN

MOTOR

U V W

BK

BK

BL

BN

GN

/

YL

GN

/

YL

VL

/

WH

WH

/

RD

BL

/

RD

YL

/

RD

BN

/

YL

WH

/

BK

GY

/

WH

YL

/

BK

YL

/

RD

BN

/

YL

S

K

Y

BK

/

WH

RD

/

WH

GN

/

YL

WH

WH

BK

BK

BL

BN

RD

P

C P

C

C

P

P

WASHING

HEATER

HEATER

POWER

CORD

DRY

HEATER

HEATER

THER-

MOSTAT

MOSTAT

INLET

VALVE

VALVE

Ha

Hb

GND

MOTOR

FAN MOTOR

PRESSURE

SENSOR

n

PIN CONNECTOR NUMBER

TERMINAL+HOUSING (#250)

EARTH TERMINAL

WIRE COLOR: BASE/LINE

(S)

(S)

(G)

THERMISTOR

THERMISTOR

TH3

(Dry Duct Dry H/T)

(Tub)

D

R

Y

R

Y

M

A

I

N

P

R

E

R

E

BK

WH BK YL

OR BL

BL RD YL

BL RD

RD

BK

YL BK

/

WH

BN GY PK

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

1

2

3

4

5

6

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

1

1

1

2

3

1

2

3

1

2

3

4

1 4

1

1

2 3

2 3

2 3

4

1

4

1

2

3

2

3

4

5 6

1 2 3 4 5

1 2 3 4 5

1 2 3

1 2 3

1 2 3

1 2

1 2

1 2

1 2

1 2

1 2

1 2

3

DISPLAY

PWB

PWB

WH

NA

RD

RD

RD

SKY BL

RD

WH

WH

NA

WH

WH

WH

/RD

/RD

WH/RD

WH

WH

NA

VL

NA

NOISE

FILTER

1

2

1

2

* Water Supply : W·S * Intermittent Spin : I·S * Disentangle : D·T

* Basic Cycle

* Optional Cycle

* ~ Time for varies as the temperature or the amount of laundry.

* Pre-Setting Time : Water Supply - 120 sec.

Drain - 60 sec.

Wash

Rinse

Spin

W

·

S

Pre

Main

Washing

Drain

I

·

S

W

·

S

Rinse

Washing Staycooling

Heat

Wash

Drain

W

·

S

1

2

3

7

6

5

4

9

8

10

Normal (Hold)

Drain

I

·

S

11 12

1

W

·

S

Rinse

13 14

Drain

I

·

S

15 16

2

W

·

S

Rinse

17 18

Drain

I

·

S

19 20

W

·

S

Rinse

21 22

Drain

I

·

S

23 24

W

·

S

Rinse

25 26

Extra (Hold)

Drain

Spin

D·T

A

U

T

U

T

O

O

O

F

F

F

3

4

27 28 29

20

E

D

R

Y

R

Y

N

D

D

20

Coloreds

Heating

Delicate

Normal

Working

Time

(Hour:Minute)

About 1:25

120 MIN 60

MIN

120

300

60

120

60 60 300 120 360 60 300 120 360 60 300 120 360 60 300 120 360 60 600 120

20 20

C

Y

C

L

E

Y

C

L

E

S

T

E

P

T

E

P

C

O

U

R

S

E

Time

(SEC)

8

1

32

About 2:20

About 45

8

Wash+Dry

Wool

Blanket

Wash

Rinse

Rinse Hold

Wash

+ Rinse

20

About 45

About 59

About 4:37

About 1:05

About 28

15

Spin

Dry

About 28

About 3:45

About 10

Rinse

+ Spin

Wash

+Spin

About 1:16

About 52

About 37

10

30

15

32

1

~

~

1

32

1

32

Rapid

About 42

8

10

PROGRAM CHART

* Basic time is minute in washing chart

* The actual program time can be varied with the load amount,

water temperature or ambient temperature

* The actual program time can be varied with the load amount,

water temperature or ambient temperature

13

7. TROUBLE SHOOTING

7-1.BEFORE SVC CHECKING

■ Be careful of electric shock or disconnecting the parts while trouble shooting.

■ Voltage of each terminal in 110V and DC while applying an electric current.

■ Voltage of each terminal in 110V and DC while applying an electric current.

7-2.QC TEST MODE.

① Pressing Rinse, and Spin button simultaneously.

② Power supply ON with pressing upper two button.Then buzzer sound twice.

③ Press the Start/Pause button as follows.

② Power supply ON with pressing upper two button.Then buzzer sound twice.

③ Press the Start/Pause button as follows.

[Press the Start/Pause button more 4 times until stop spinning]

7-3.HOW TO KNOW THE WATER LEVEL FREQUENCY

✽ Press the Rinse and Spin button simultaneously.

ex) 241 : Water level frequency = 241

× 10-1㎑

=24.1

㎑

7-4.HOW TO KNOW TO TEMPERATURE OF EACH THERMISTOR

AT OPERATING CONDITION.

■ Thermistor in tub : Press the [WATER TEMP] button.

■ Thermistor in dry duct : Press the [DRY] button.

■ Thermistor in condensing duct : Press the [SPIN] and [DRY] button simultaneously.

■ Thermistor in dry duct : Press the [DRY] button.

■ Thermistor in condensing duct : Press the [SPIN] and [DRY] button simultaneously.

The digits means water level frequency(10

-1

㎑

)

Pressing number of

[Start/Pause]button

Checking Point

Display Status

None

All lamps turn on

1 time

Clockwise spin(right)

Drum rpm(About 40~52)

2 times

Low speed Spin

Drum rpm(About 70~90)

3 times

High speed Spin

Drum rpm(About 90~110)

4 times

Inlet valve for pre-wash operation

Water level frequency(25~65)

5 times

Inlet valve for main-wash operation

Water level frequency(25~65)

6 times

Inlet valve for dry operation

Water level frequency(25~65)

7 times

Counterclockwise spin(left)

Drum rpm(About 40~52)

8 times

Heater is in operation for 3 sec.

Water temperature

9 times

Draining pump operation

Water level frequency

10 times

Dry operation for 6 minutes

Auto off operation after 6 minutes

14

7-5.ERROR DISPLAY.

• If you press the Start/Pause button in error condition, any error except ‘

’ will disappear and the

machine will change into pause status.

• In case of 『

』, 『

』, 『

』, if the error is not resolved within 20 sec., and in case of other errors,

if the error is not resolved within 4 min., power will be turned off automatically and the error only will be

blinked. But in case of

blinked. But in case of

『 』, power will not be turned off.

ERROR

SYMPTOM CAUSE

1

2

3

4

5

6

7

• Not reached to the water level(2 level)within 4

minutes after water supplied or not reached to

the preset water level within 25 minutes.

• Not fully drained within 5 minutes.

• Water is over flowing(over 8 level).

※ If is displayed, drain pump operates to

drain water automatically.

• The sensor pressure switch is out of order.

• In case of operating the reservation function or

the other function with door opened. Close the

door, then the error display is resolved.

• The door switch is out of order.

• The appliance is tilted.

• Laundry is gatherd to one side.

• The THERMISTOR is out of order.

WATER INLET

ERROR

DRAIN ERROR

OVERFLOW

ERROR

SENSOR PRESSURE

S/W ERROR

DOOR OPEN

ERROR

IMBALANCE

ERROR

HEATING

ERROR

ERROR

SYMPTOM CAUSE

8

9

10

• MAIN PWB ASSEMBLY is out of order

☞ Replace the MAIN PWB ASSEMBLY

• Winding in the STATOR ASSEMBLY is short-circuited.

☞ Replace the STATOR ASSEMBLY

• “ ” is dispplayed during a high spin

☞ Replace the LEAD WIRE ASSEMBLY (MOTOR)

• The connector in the LEAD WIRE ASSEMBLY is not connected to

the connnector of STATOR ASSEMBLY

☞ Reconnect or repair the connector

• The hall sensor is out of order/defective.

☞ Replace the STATOR ASSEMBLY

• The Dry Heater is out of order

☞ Replace the Dry Heater

• The Connector of the Dry Heater is not connected properly to the

connector in the Main PWB ASSEMBLY

☞ Reconnect or repair the connector

☞ Reconnect or repair the connector

• The Dry fan motor is out of order

☞ Replace the fan Motor.

CURRENT

ERROR

MOTOR

ERROR

DRY

HEATOR

ERROR

15

Click on the first or last page to see other WD-90KFT service manuals if exist.