LG 42PG2500-ZA (CHASSIS:PD82A) Service Manual ▷ View online

8. EDID

(The Extended Display Identification Data )

/DDC

(Display Data Channel)

download

8-1. Required Test Equipment

(1) Adjusting PC with S/W for writing EDID Data.

(S/W : EDID TESTER Ver.2.5)

(2) A Jig for EDID Download.

(3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

(3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

15Pin cable, DVI to HDMI cable.

8-2. Required Test Equipment

8-3. Preparation for Adjustment

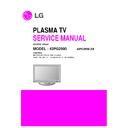

1) As above Fig.5, Connect the Set, EDID Download Jig, PC

& Cable.

2) Turn on the PC & EDID Download Jig. And Execute the

S/W : EDID TESTER Ver,2.5.

3) Set up S/W option.

Repeat Number : 5

Device Address : A0

PageByte : 8

Device Address : A0

PageByte : 8

4) Power on the Set.

8-4. Sequence of Adjustment

(1) EDID Download

1) Init the data.

2) Load the EDID data.(Open File).

[ Analog file ] (for RGB)]

[ Digital file ] (for HDMI)

[ Digital file ] (for HDMI)

3) Set the S/W as below.

4) Push the “Write Data & Verify”button. And confirm “Yes”.

5) If the writing is finished, you will see the “OK” message.

4) Push the “Write Data & Verify”button. And confirm “Yes”.

5) If the writing is finished, you will see the “OK” message.

6) If TV has two HDMI, you must download two times for

each HDMI.

8-5. EDID DATA

1) Analog-RGB.

=> Detail EDID Options are below([1],[2],[3],[4],[5])

1.[1]-Product ID

2. [2]-Serial No : Controlled on production line.

3. [3]-Month, Year : Controlled on production line.

3. [3]-Month, Year : Controlled on production line.

ex) Monthly: '03' => '03'

Year : '2006' => '10'

4. [4]-Model Name : model name.

5. [5]-Checksum (7EH) -> Changeable by total EDID data.

- 9 -

(Fig.5) Connection Diagram of DDC download

[1]

[2]

[3]

[4]

[5]

Open File

Open File

50PG6500

Product ID

Product ID

Model Name

EDID table

B19C

Hex

9CB1

40013

50PG6500

00 00 00 FC 00 35 30 50 47 36 35 30 30 0A 20 20 20 20

Model Name

Model Name(Hex)

2) HDMI 1.

=> Detail EDID Options are below([1],[2],[3],[4],[5])

1.[1]-Product ID

2. [2]-Serial No : Controlled on production line.

3. [3]-Month, Year : Controlled on production line.

3. [3]-Month, Year : Controlled on production line.

ex) Monthly: '03' => '03'

Year : '2006' => '10'

4. [4]-Model Name : model name.

5. [5]-Checksum (7EH) -> Changeable by total EDID data.

3) HDMI 2.

=> Detail EDID Options are below([1],[2],[3],[4],[5])

* Please refer HDMI 1

- EDID Download is needed HDMI 1~ HDMI 4.

- EDID Download is needed HDMI 1~ HDMI 4.

- 10 -

[1]

[2]

[3]

[4]

[5]

[5]

50PG6500

00 00 00 FC 00 35 30 50 47 36 35 30 30 0A 20 20 20 20

Model Name

Model Name(Hex)

50PG6500

Product ID

Product ID

Model Name

EDID table

B29C

Hex

9CB2

40114

[1]

[2]

[3]

[4]

[5]

[5]

9. Adjustment of White Balance

9-1. Required Equipment

(1) Remote control for adjustment.

(2) Color Analyzer : CA-100+, CA210 or same product.

(2) Color Analyzer : CA-100+, CA210 or same product.

- CH : 10

(3) Auto W/B adjustment instrument.(only for Auto adjustment)

(4) AV Pattern Generator.

(4) AV Pattern Generator.

W

Color temperature standards according to CSM and Module.

W

CS-1000/CA-100+/CA-210(CH 10) White balance adjustment

coordinate and color temperature.

* PC(for communication through RS-232C)

-> UART Baud rate : 115200 bps

9-2. Connection Picture of the Measuring

Instrument(On Automatic control)

(1) Inside PATTERN is used when W/B is controlled. Connect

to auto controller or push control R/C IN-START -> Enter

the mode of White-Balance, the pattern will come out.

the mode of White-Balance, the pattern will come out.

9-3. Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked.(illumination is less than 10ux)

(2) Measure and adjust after sticking the Color Analyzer(CA-

100+, CA210) to the side of the module.

(3) Aging time

- After ajing start, keep the power on(no suspension of

power supply) and heat-run over 15minutes.

- keep white pattern using inside pattern.

V

Auto adjustment Map(RS-232C)

10. Adjustment of White Balance

(Manual white Balance)

V

One of R Gain/ G Gain/ B Gain should be kept on 80, and

others are controlled lowering from 80

(1) Press ‘power on’ of the control R/C, set heat run to white

by pressing and heat run over 15 minutes.(Set: RS-232

Host: PC, Baud Rate: 115200bps, Download: Cortez)

Host: PC, Baud Rate: 115200bps, Download: Cortez)

(2) Zero Calibrate CA-100+, and stick the sensor to the center

of PDP module surface when you adjust.

(3) Double click In-start key on Controlling R/C and get in

‘white balance’.

(4) Set test-pattern on and display inside pattern. Control is

carried out on three color temperature, COOL, MEDIUM,

WARM. (Control is carried out three times.)

WARM. (Control is carried out three times.)

(5) When the R/G/B GAIN is 80 on OSD, it is the FULL

DYNAMIC Range of the Module. In order to control white

balance without the saturation of FULL DYNAMIC Range

and DATA, one of R Gain / G Gain / B Gain should be kept

on 80, and other two is controlled lowering from 80.

balance without the saturation of FULL DYNAMIC Range

and DATA, one of R Gain / G Gain / B Gain should be kept

on 80, and other two is controlled lowering from 80.

* Color Temperature: Cool, Medium, Warm

(1) When R GAIN is set to 80

- Control G GAIN and B GAIN by lowering from 80.

(2) When B GAIN is set to 80

- Control R GAIN and G GAIN by lowering from 80.

(3) When G GAIN is set to 80

- Control R GAIN and B GAIN by lowering from 80.

- Control R GAIN and B GAIN by lowering from 80.

One of R Gain / G Gain / B Gain should be kept on 80, and

adjust other two lower than 80.

(When R/G/B GAIN are all 80, it is the FULL DYNAMIC

Range of Module)

adjust other two lower than 80.

(When R/G/B GAIN are all 80, it is the FULL DYNAMIC

Range of Module)

11. Input the Shipping Option Data

1) Push the IN-START key in a Adjust Remocon.

2) Input the Option Number that was specified in the BOM, into

2) Input the Option Number that was specified in the BOM, into

the Shipping area.

3) The work is finished, Push

V

Key.

- 11 -

* Befor adjusting White-balance, the AV ADC should be done.

If ADC status were “NG”, Need to ADC adjustment.

If ADC status were “NG”, Need to ADC adjustment.

PLASMA

Remark

11000K

9300K

6500K

Cool

Normal

Warm

CSM

Color Coordinate

x

y

0.283±0.002

0.293±0.002

0.329±0.002

11,000K

9,300K

6,500K

0.000

0.000

0.003

0.276±0.002

0.285±0.002

0.313±0.002

COOL

MEDIUM

WARM

CSM

Temp

uv

(Fig.6) Auto AV(CVBS) Color Balance Test Pattern

Full White Pattern

RS-232C Communication

CA-210

Color

ANALYZER

TYPE : CA-210

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

j

a

j

b

j

c

j

d

j

e

j

f

Stop bit

1

Parity

NONE

PD82A

Protocol

Setting

Data

Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

128(80)

128(80)

128(80)

128(80)

128(80)

128(80)

12. Default Value in Adjustment mode

12-1. Auto Color Balance

12-2. Write Balance

13. EEPROM Data Write(Serial No D/L)

13-1. Signal TABLE

CMD

: A0h

LENGTH : 85~94h (1~16 bytes)

ADH

ADH

: E

2

PROM Sub Address high (00~1F)

ADL

: E

2

PROM Sub Address low (00~FF)

Data

: Write data

CS

: CMD + LENGTH + ADH + ADL + Data_1 + ... + Data_n

Delay

: 20ms

13-2. Command Set

* Description

FOS Default write : <7mode data> write

Vtotal, V_Frequency, Sync_Polarity, Htotal, Hstart, Vstart, 0, Phase

Data write : Model Name and Serial Number write in EEPROM,.

Vtotal, V_Frequency, Sync_Polarity, Htotal, Hstart, Vstart, 0, Phase

Data write : Model Name and Serial Number write in EEPROM,.

13-3. Method & Notice

(1) Serial number D/L is using of scan equipment.

(2) Setting of scan equipment operated by Manufacturing

(2) Setting of scan equipment operated by Manufacturing

Technology Group.

(3) Serial number D/L must be conformed when it is produced

in production line, because serial number D/L is mandatory

by D-book 4.0.

by D-book 4.0.

14. Set Information

(Serial No& Model name, Option Table)

14-1. Setting up ‘Tool Option1,2’

(After setting white balance, this is set)

(Setting: Press ADJ Key in the Adjust remocon)

(1) Press ADJ Key in the R/C for adjustment.

(2) Insert Option value by a number key.

(3) Press the Enter Button.

(2) Insert Option value by a number key.

(3) Press the Enter Button.

- 12 -

(Fig. 7) Default on OSD

<Component>

<RGB>

<AV>

(Fig. 8) Default on OSD

CMD LENGTH ADH ADL DATA_1

DATA_n

...

CS

DELAY

Model

Name

42PG6500

Tool

Option1

10240

1697

0

14

2

1

192

Tool

Option2

Area

Option

Option1 Option2 Option3 Option4

No

1

EEPROM WRITE A0h

84h+n

n-byted Write

(n=1~16)

Adjust mode

CMD(hex) LENGTH(hex)

Description

Click on the first or last page to see other 42PG2500-ZA (CHASSIS:PD82A) service manuals if exist.