Sony CCD-TRV63 / CCD-TRV66 / CCD-TRV66PK Service Manual ▷ View online

5-49

4-3.

SERVICE MODE

Note:

After the completion of the all adjustments, cancel the service mode

by either of the following ways.

by either of the following ways.

1)

Unplug the main power supply and remove the lithium battery.

(In this case, date and time and menu setting have been set by

users are canceled. Perform resetting.)

(In this case, date and time and menu setting have been set by

users are canceled. Perform resetting.)

2)

After data on page: D and F is restored, return data of the

address: 01 on page: 0 to 00. And when data on page: 2 is

changed, return the data to the original condition.

address: 01 on page: 0 to 00. And when data on page: 2 is

changed, return the data to the original condition.

1. Test Mode Setting

Set/release each test mode. Set page: 0, address: 01, data: 01 before

setting the data of page D and F.

setting the data of page D and F.

Page F

Address 2C

Data

Function

00

Normal

01

Test mode

Various emergency prohibitions and releases Drum

emergency, capstan emergency, loading motor

emergency, reel emergency, tape top and end, DEW

detection

Various emergency prohibitions and releases Drum

emergency, capstan emergency, loading motor

emergency, reel emergency, tape top and end, DEW

detection

Page D

Address 10

Data

Function

00

Normal

01

Camera power ON

02

VTR power ON

03

Camera + VTR power ON

*

For page D and F, the data set will be recorded in the nonvolatile

memory by pressing the PAUSE button on the adjustment

remote commander. Take note that, in this case, the test mode

will not be released even if the main power has been turned

off.

memory by pressing the PAUSE button on the adjustment

remote commander. Take note that, in this case, the test mode

will not be released even if the main power has been turned

off.

*

Be sure to return this address data to 00 after completing

adjustments/repairs and press the PAUSE button of the

adjustment remote commander. And set page: 0, address: 01,

data: 00.

adjustments/repairs and press the PAUSE button of the

adjustment remote commander. And set page: 0, address: 01,

data: 00.

5-50

2. Emergency Memory Address

Page F

Address 10 to 1B

Address

Contents

10

1st EMG code

12

Upper: MSW code when the mechanism starts

shifting the 1st time

Lower: MSW code when the 1st emergency occurs

13

Lower: Target MSW code of the 1st emergency

occurs

14

2nd EMG code

16

Upper: MSW code when the mechanism starts

shifting the 2nd time

Lower: MSW code when the 2nd emergency occurs

17

Lower: Target MSW code of the 2nd emergency

occurs

18

Last EMG code

1A

Upper: MSW code when the mechanism starts

shifting the last time

Lower: MSW code when the last emergency occurs

1B

Lower: Target MSW code of the last emergency

occurs

occurs

When there are no emergency, data 00 will be written in the above

addresses (10 to 1B). When the first emergency occurs, the data

corresponding to the emergency will be written in the address (10

to 13) for this first emergency. In the same way, when the second

emergency occurs, the data corresponding to the emergency will be

written in the address (14 to 17) for this second emergency.

The data corresponding to the emergency occurring the last will be

written in the address (18 to 1B) for this last emergency.

Therefore the data of addresses 18 to 1B are renewed each time an

emergency occurs.

addresses (10 to 1B). When the first emergency occurs, the data

corresponding to the emergency will be written in the address (10

to 13) for this first emergency. In the same way, when the second

emergency occurs, the data corresponding to the emergency will be

written in the address (14 to 17) for this second emergency.

The data corresponding to the emergency occurring the last will be

written in the address (18 to 1B) for this last emergency.

Therefore the data of addresses 18 to 1B are renewed each time an

emergency occurs.

Note 1:

Be sure to rewrite the data of addresses 10 to 1B to 00 after repairs/

adjustments.

adjustments.

Note 2:

When rewriting the data, be sure to press the PAUSE button of the

remote commander after setting the data.

remote commander after setting the data.

2-1. EMG code (Emergency code)

The codes shown in the following table which correspond to errors

that occur are recorded in addresses 10, 14, and 18.

that occur are recorded in addresses 10, 14, and 18.

Code

Type of Emergency

00

No error

10

Loading motor time-out during load

11

Loading motor time-out during unload

20

T reel emergency (reel slack) during unloading

21

S reel emergency (reel slack) during unloading

22

T reel emergency

23

S reel emergency

30

FG emergency at the start up of the capstan

31

FG emergency during the normal rotation of the

capstan

capstan

40

FG emergency at the start up of the drum

41

PG emergency at the start up of the drum

42

FG emergency during the normal rotation of the

drum

drum

43

PG emergency during the normal rotation of the

drum

drum

44

Phase emergency during the normal rotation of the

drum

drum

5-51

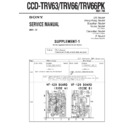

2-2. MSW codes

•

The lower parts of the data of addresses 12, 16 and 1A represent

the MSW codes (mode switch, mechanism position) when

errors occurs.

the MSW codes (mode switch, mechanism position) when

errors occurs.

•

The upper parts of the data of addresses 12, 16 and 1A represent,

when the mechanism position is to be moved, the MSW codes

at the start of movement (when moving the loading motor).

when the mechanism position is to be moved, the MSW codes

at the start of movement (when moving the loading motor).

•

The lower parts of the data of addresses 13, 17 and 1B represent

the MSW codes of the desired movement when the mechanism

position is to be moved.

the MSW codes of the desired movement when the mechanism

position is to be moved.

0001=1

0111=7

0011=3

0010=2

0111=7

0101=5

0111=7

0111=7

0000=0

0111=7

0100=4

0111=7

0110=6

Mechanism position

MODE SW C

MODE SW B

MODE SW A

MSB

←

Unloading

Releasing lock of

cassette campartment

cassette campartment

LS chassis movement range

Pinch roller is pressed

Pinch roller is detached

EJECT

BL

USE

LOAD

BL

REW

BL

BL

REC/PB

BL

TURN

BL

STOP

Loading

→

Contents

Position at which the cassette compartment lock is released. The mechanism will not move any

further in the unloading direction.

further in the unloading direction.

BLANC code. Between two codes. The mechanism will not be stopped by this code while it is

operating.

operating.

EJECT completion position. When the cassette is ejected, the mechanism will stop at this

position.

position.

Code during loading/unloading. Code that is used while the LS chassis is moving.

Normal stop position. The pinch roller separates, the tension regulator returns, and the brakes of

both reels turn on.

both reels turn on.

Position at which is used when the pendulum gear swings from S to T or from T to S.

PB, REC, CUE, REV, PAUSE, FF positions.

The pinch roller is pressed and tension regulator is on.

The pinch roller is pressed and tension regulator is on.

REW position. REW are carried at this position.

The mechanism will not move any further in the loading direction.

The mechanism will not move any further in the loading direction.

Mechanism Position

EJECT

BL

USE

LOAD

STOP

TURN

RECP/PB

REW

MSW Code

1

7

3

2

6

4

0

5

5-52

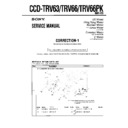

3. Bit Value Discrimination

Bit values must be discriminated using the display data of the

adjustment remote commander for the following items. Us the table

below to discriminate if the bit value is “1” or “0”.

adjustment remote commander for the following items. Us the table

below to discriminate if the bit value is “1” or “0”.

(Example)

If the remote commander display is “8E”, bit value from bit

7 to bit 4 can be discriminated from the column A, and

those from bit 3 to bit 0 from column B.

7 to bit 4 can be discriminated from the column A, and

those from bit 3 to bit 0 from column B.

Page

Address

bit3 to bit0 discrimination

bit7 to bit4 discrimination

Display on the adjustment remote commander

Display on the

adjustment

remote

commander

0

1

2

3

4

5

6

7

8

9

A (

A

)

B (

b

)

C (

C

)

D (

d

)

E (

E

)

F (

F

)

Bit values

bit3

or

bit7

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

bit2

or

bit6

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

bit1

or

bit5

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

bit0

or

bit4

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

A

B

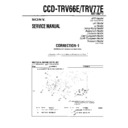

Bit

0

1

2

3

4

5

6

7

Function

MIC jack

AUDIO terminal

VIDEO terminal

S VIDEO terminal

When bit value = 1

MIC jack is used

Monaural

VIDEO terminal is used

When bit value = 0

Stereo

S VIDEO terminal is used

4. Input/output selection check

Page 2

Address 49

Using method:

1)

1)

Select page: 2, address: 49.

2)

By discriminating the bit value of display data, the state of the

input/output selection can be discriminated.

input/output selection can be discriminated.

5. LED, LCD (display window) check

Using method:

1)

1)

Select page: 2, address: 05, and set the bit value of Bit5 to “1”.

2)

Check that all LED are lit and all segments of LCD (display

window) are lit.

window) are lit.

3)

Select page: 2, address: 05, and set the bit value of Bit5 to “0”.

Page 2

Address 05

Bit5