Sharp MX-M850 (serv.man16) Service Manual ▷ View online

MX-M1100 TRAY PAPER FEED SECTION E – 5

2. Operational descriptions

A. Preliminary operation before paper feed

1)

Set paper in the tray, and insert the tray into the machine. The

tray sensor turns on.

tray sensor turns on.

2)

The lift-up motor operations to lift the tray.

3)

The paper upper limit sensor turns on to stop the tray at the

specified position.

specified position.

B. Paper feed operation

1)

When copy/print operation is started, the motors (MM1, MM2)

and the clutch (C1PFC) are turned on to turn on the colenoid

(C1PUS) at the timing of paper pickup. This rotates and falls

the take-up roller to pick up paper.

and the clutch (C1PFC) are turned on to turn on the colenoid

(C1PUS) at the timing of paper pickup. This rotates and falls

the take-up roller to pick up paper.

2)

At the same time, the paper feed roller rotates to feed paper to

the transport section.

At that time, the separation roller rotates to prevent against

double feed of paper.

the transport section.

At that time, the separation roller rotates to prevent against

double feed of paper.

C. Each paper feed tray paper size detection method

Paper feed tray (Paper feed tray 3), multi purpose paper feed tray

(Paper feed tray 4).

1)

(Paper feed tray 4).

1)

Paper width detection

The paper width is calculated with the VR voltage value (A/D

conversion value) linked with the side guide plate.

Paper width and paper size (set in the range of standard value

± 6 mm).

The paper width is calculated with the VR voltage value (A/D

conversion value) linked with the side guide plate.

Paper width and paper size (set in the range of standard value

± 6 mm).

2)

Paper size detection

The paper size detection is made by the combination of the

cassette paper size detector 1 to 4.

The paper size detection is made by the combination of the

cassette paper size detector 1 to 4.

Relationship between paper size and detection by the paper size detector.

3)

Combination of size detection.

Width size

detection

pattern

Paper size

Standard

value

[mm]

Range [mm]

A

A3/A4

297.0

303.0 to 291.0

B

WLT/LT

279.4

285.4 to 273.4

C

B4/B5

257.0

263.0 to 251.0

D

LG/LTR/Foolscap

215.9

221.9 to 209.9

E

A4R

210.0

216.0 to 204.0

F

Exective-R

184.1

190.1 to 178.1

G

B5R

182.0

188.0 to 176.0

CSS2

CSS1

CSS3

CSS4

Vertical size

detection

Pattern

Detection SW state

AB size

Inch size

Width of detection

range

CSS1

CSS2

CSS3

CSS4

1

ON

ON

OFF

ON

B5

Extra

147.0 to 198.0

2

OFF

ON

OFF

ON

A4

LT

198.0 to 237.0

3

OFF

ON

ON

ON

B5R

EX-R

237.0 to 274.0

4

OFF

OFF

ON

ON

A4R

LTR

274.0 to 314.0

5

ON

OFF

ON

ON

Foolscap

Extra

314.0 to 347.0

6

ON

OFF

ON

OFF

B4

LGL

347.0 to 389.0

7

ON

ON

ON

OFF

A3

WLT

389.0 to 432.8

0

OFF

OFF

OFF

OFF

Paper feed tray not attached

Paper size

Width detection

pattern

Vertical detection

pattern

B5

C

1

A4

A

2

B5R

G

3

A4R

E

4

Foolscap

D

5

B4

B

6

A3

A

7

LT

B

2

EX-R

F

3

LTR

D

4

LGL

D

6

WLT

B

7

MX-M1100 TRAY PAPER FEED SECTION E – 6

D. Remaining paper detection

(1) Remaining paper detection

Remaining paper detection is performed according to four stages,

i.e. three stages with paper and one stage with no paper, and the

result is displayed.

i.e. three stages with paper and one stage with no paper, and the

result is displayed.

(2) Detection method

The number of remaining sheets is determined according to the

number of times the remaining paper sensor changes from the time

the paper feed tray starts lifting up to the time when the upper

detection sensor comes ON.

number of times the remaining paper sensor changes from the time

the paper feed tray starts lifting up to the time when the upper

detection sensor comes ON.

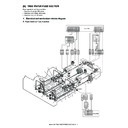

E. Outline

The paper transport section serves the function of transferring

paper from each paper feed port to the registration roller section.

Paper from paper feed tray units 1 and 2, paper feed tray 3 and

paper feed tray 4 is transported vertically to the registration roller

section.

The detection of double-feed is done before transferring paper to

the registration roller, and the check of the off-center is carried out

by the image position sensor.

After the leading edge of the paper is synchronized with the leading

edge of the drum image in the registration roller section, the paper

that is transfer printed with the image in the transfer section passes

through the fusing section and is discharged either face-down or

face-up.

paper from each paper feed port to the registration roller section.

Paper from paper feed tray units 1 and 2, paper feed tray 3 and

paper feed tray 4 is transported vertically to the registration roller

section.

The detection of double-feed is done before transferring paper to

the registration roller, and the check of the off-center is carried out

by the image position sensor.

After the leading edge of the paper is synchronized with the leading

edge of the drum image in the registration roller section, the paper

that is transfer printed with the image in the transfer section passes

through the fusing section and is discharged either face-down or

face-up.

The no-paper detection sensor

detects the state of no remaining paper.

detects the state of no remaining paper.

1/3 Field

Sensor logic: Low

Sensor logic: Low

2/3 Field

Sensor logic: Hi

Sensor logic: Hi

3/3 Field

Sensor logic: Low

Sensor logic: Low

During no-paper detection

Remaining paper 1/3 position

Remaining paper 2/3 position

Remaining paper 1/3 position

Turn plate

MCPED

(paper sensor)

(paper sensor)

Remaining Paper

Detection Actuator

Detection Actuator

MCSPD

(remaining paper detection sensor)

(remaining paper detection sensor)

(Figure showing state transition of the remaining paper detection sensor during tray elevation and

changes in status according to the number of remaining sheets)

Double feed

detection

detection

Image position sensor

MX-M1100 TRAY PAPER FEED SECTION E – 7

F. Paper transport operation

Straight-Through Path (No Inversion, No Duplexing)

The paper transported from the each tray section is sent to the

paper exit roller (which is driven by the paper exit motor (POM))

with the transport roller.

paper exit roller (which is driven by the paper exit motor (POM))

with the transport roller.

Paper transport speed

G. Paper face-down output operation

Inversion Path (Face-down Output, No Duplexing)

When face-down print is selected, the paper is passed under the

Face-up/face-down select gate.

After paper passing, the paper exit gate guide falls down by its own

weight.

When the specified time has passed from detection of the paper

lead edge by Face down reverse detection, Paper exit reverse

motor (SBRM) rotates reverse direction in the specified time. (The

rotation time differs depending on the paper size.)

Face-up/face-down select gate.

After paper passing, the paper exit gate guide falls down by its own

weight.

When the specified time has passed from detection of the paper

lead edge by Face down reverse detection, Paper exit reverse

motor (SBRM) rotates reverse direction in the specified time. (The

rotation time differs depending on the paper size.)

3. Disassembly and assembly

A. Tray 3, 4 paper feed unit

(1) Tray 3, 4 paper feed unit

1)

Open the front cover (a).

2)

Remove the waste toner bottle (a).

Unit (mm/s)

110/95CPM

85CPM

: Normal speed

540

400

(Process speed)

: High speed

600

500

(Paper feed and exit speed)

: High speed

1000

1000

(Switchback speed)

1

1

2

Face-up/face-down select gate

1

2

3

Face down reverse detection

2

3

3

1

2

Fase-up/fase-down

select gate solenold

OFF-up, ON-Down

select gate solenold

OFF-up, ON-Down

Unit

Parts

Page

Tray 3, 4 paper feed

Unit

Unit

A

Cassette 3, 4 upper limit

detection

detection

E - 9/a

B

Cassette 3, 4 paper empty

detection

detection

C

Cassette 3, 4 paper entry

detection

detection

D

Cassette 3, 4 pickup solenoid

C

B

A

D

a

a

MX-M1100 TRAY PAPER FEED SECTION E – 8

3)

Remove the right cabinet center.

* The following procedure can be performed without removing

* The following procedure can be performed without removing

the right cabinet center. However, the procedure is easier

when the right lower cabinet is removed.

when the right lower cabinet is removed.

4)

Open the vertical transport door unit (a). Push the lever (b) to

release the lock of the vertical transport door unit (a).

release the lock of the vertical transport door unit (a).

5)

Lift the vertical transport door unit (a) and disengage the ful-

crum (b) on the lower side, and remove the vertical transport

door unit (a).

crum (b) on the lower side, and remove the vertical transport

door unit (a).

6)

Pull out all paper feed tray (a).

7)

Remove the screw (a), and remove the cover (b).

8)

Remove the screw (a), and remove the fulcrum block (b) and

the paper guide (c).

the paper guide (c).

9)

Disconnect the connector (a). Remove the screw (b), and

remove the tray 3, 4 paper feed unit (c).

remove the tray 3, 4 paper feed unit (c).

a

b

b

a

a

a

a

a

b

a

b

c

a

b

b

c

c

a

Click on the first or last page to see other MX-M850 (serv.man16) service manuals if exist.