Sharp AR-FN1 (serv.man5) Service Manual ▷ View online

2. Explanation of each section

The 3-tray finisher consists of (1)an upper paper transfer section, (2)a

reversion section, (3)a staple tray, (4)an offset tray, and (5)an eleva-

tor section.

reversion section, (3)a staple tray, (4)an offset tray, and (5)an eleva-

tor section.

It has the following functions: Paper discharge to a selected tray,

paper reversion, stapling for paper delivered to the offset tray (3

positions), offset, and elevation. Each function is performed according

to the mode instructed by the copier.

paper reversion, stapling for paper delivered to the offset tray (3

positions), offset, and elevation. Each function is performed according

to the mode instructed by the copier.

A. Upper paper transfer section

1) Paper transfer

By rotating the main driving motor (FM), the transfer rollers in the

finisher are driven.

finisher are driven.

The transfer speed is switched over between the copier speed mode

and the high-speed mode according to the paper discharge mode

and paper size.

and the high-speed mode according to the paper discharge mode

and paper size.

2) Paper entry gate (4)

The paper entry gate (4) is operated by the paper entry sole-

noid(INGSL) to select the upper transfer (outside route) and rever-

sion/short path according to the mode.

noid(INGSL) to select the upper transfer (outside route) and rever-

sion/short path according to the mode.

3) Paper discharge gate 1 (1)

The paper discharge gate 1 (1) is operated by the paper discharge

gate 1 solenoid (OG1SL), to select between the routes for paper

discharge to the tray 1 (10) and transport to the tray 2 (7)/staple tray.

gate 1 solenoid (OG1SL), to select between the routes for paper

discharge to the tray 1 (10) and transport to the tray 2 (7)/staple tray.

4) Paper discharge gate 2 (8)

The paper discharge gate 2 (8) is operated by the paper discharge

gate 2 solenoid (OG2SL) to select between the routes for paper

discharge to the tray 2 (7) and transport to the staple tray.

gate 2 solenoid (OG2SL) to select between the routes for paper

discharge to the tray 2 (7) and transport to the staple tray.

5) Trays 1 (10) and 2 (7) paper discharge operation

When paper is delivered to the trays 1 (10) and 2 (7) at a high-speed

in the 3 tray finisher, the trays 1 and 2 deceleration clutch (13) is

operated at paper delivery timing to decelerate the paper discharge

rollers 1 and 2 in order to align the paper to the trays 1 (10) and 2 (7)

with high accuracy.

in the 3 tray finisher, the trays 1 and 2 deceleration clutch (13) is

operated at paper delivery timing to decelerate the paper discharge

rollers 1 and 2 in order to align the paper to the trays 1 (10) and 2 (7)

with high accuracy.

6) Trays 1 (10) and 2 (7) paper full detection

Whether the trays 1 (10) and 2 (7) are filled with paper is detected by

the tray 1 and 2 paper full sensor.

the tray 1 and 2 paper full sensor.

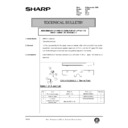

No.

Signal name

Name

(1)

—

Paper discharge gate

(2)

PFD2

Transfer detecting sensor 2

(3)

PFD1

Transfer detecting sensor 1

(4)

—

Paper entry gate

(5)

INPD

Paper entry sensor

(6)

PFD4

Transfer detecting sensor 4

(7)

—

Tray 2

(8)

—

Paper discharge gate 2

(9)

T2PF

Tray 2 paper full detecting sensor

(10)

—

Tray 1

(11)

PFD3

Transfer detecting sensor 3

(12)

T1PF

Tray paper full sensor

(13)

TI2CL

Trays 1 and 2 deceleration clutch

1)

4)

5)

3)

2)

(13)

(12)

(1)

(2)

(3)

(4)

(5)

(11)

(10)

(8)

(7)

(6)

(9)

Document reversion and

short-cut path

short-cut path

To stapler tray

4 – 3

B. Reversion unit

1) Reversion motor (RVM)

The reversion motor is connected to the reversion roller (4).

The paper is pulled into the reversion path by the reversion motor

rotating in forward, and fed into the upper transfer route by the motor

rotating in reverse. When the paper is discharged through the short-

path, its transfer is performed by the reversion roller (4) until the

paper enters the staple tray.

rotating in forward, and fed into the upper transfer route by the motor

rotating in reverse. When the paper is discharged through the short-

path, its transfer is performed by the reversion roller (4) until the

paper enters the staple tray.

2) Reversion pressure release roller

The reversion pressure release roller (3) is pressure released or pres-

surized through ON/OFF control of the reversion roller pressure re-

lease solenoid, to achieve the reversion of the paper at a high speed

without reducing JOB efficiency.

surized through ON/OFF control of the reversion roller pressure re-

lease solenoid, to achieve the reversion of the paper at a high speed

without reducing JOB efficiency.

No.

Signal name

Part name

(1)

RVPD

Reversion paper delivery sensor

(2)

—

Reversion gate

(3)

—

Reversion pressure release roller

(4)

—

Reversion roller

C. Staple tray

1) Jogger motor (JGM)

The jogger motor is driven when the paper is fed into the staple tray,

to operate the jog plates F and R so as to align the sidewise edge of

the paper.

to operate the jog plates F and R so as to align the sidewise edge of

the paper.

2) Puddler (11)

The puddler clutch (PDCL) is turned ON when the paper is fed into

the staple tray, to give the puddler a full turn so as to drop the paper

downward (pusher), thus achieving alignment in the vertical direction.

the staple tray, to give the puddler a full turn so as to drop the paper

downward (pusher), thus achieving alignment in the vertical direction.

3) Pusher motor (PSM)

With the pusher motor rotating, the paper stored inside the staple tray

is lowered from the home position (discharge position) to the stapling

position; after stapling, the paper inside the staple tray is elevated

from the stapling position to the home position.

is lowered from the home position (discharge position) to the stapling

position; after stapling, the paper inside the staple tray is elevated

from the stapling position to the home position.

4) Staple unit movement motor (STUM)

The staple unit is moved to the stapling positions (front, far end, 2

centers) by the staple unit motor.

centers) by the staple unit motor.

5) Short path switching gate (1)

The short path switching gate (1) is operated by the short path

switching solenoid (SPSL), to select the short path to feed paper to

the reversion path and stable tray.

switching solenoid (SPSL), to select the short path to feed paper to

the reversion path and stable tray.

6) Staple tray paper discharge

When the paper delivery roller pressure release clutch (STORCL) is

turned ON, the paper delivery pressure release roller (4) is pressur-

ized through the cam to discharge the paper from the stable tray.

turned ON, the paper delivery pressure release roller (4) is pressur-

ized through the cam to discharge the paper from the stable tray.

7) Paper discharge gate 3 (5)

The paper discharge gate 3 (5) is operated by the paper discharge

gate 3 solenoid (OG3SL) to switch over the routes of paper inside the

staple tray between the paper discharge side and the staple side of

the off-set tray.

gate 3 solenoid (OG3SL) to switch over the routes of paper inside the

staple tray between the paper discharge side and the staple side of

the off-set tray.

8) Tray 3 speed change clutch (8) (2)

The paper discharge rollers 3 and 4 are speed changed to improve

the stackability of stapled paper being discharged to the off-set tray.

the stackability of stapled paper being discharged to the off-set tray.

No.

Signal name

Part name

(1)

—

Short path switching gate

(2)

T3SLCL

Tray 3 speed change clutch

(3)

—

Pusher

(4)

—

Paper delivery pressure release roller

(5)

—

Paper discharge gate 3

(6)

STPD

Staple tray paper detection sensor

(7)

—

Staple unit

(8)

T3ORSL

Tray 3 speed change clutch

(9)

T3OD

Tray 3 paper delivery sensor

(10)

STID

Staple tray paper entry sensor

(11)

—

Puddler

(4)

(2)

(1)

(3)

(1st sheet is reversed

and discharged.)

and discharged.)

(2nd sheet is reversed

and entered.)

and entered.)

Entry

Discharged

Pressure

release

release

(11)

(10)

(9)

(8)

(6)

(5)

(4)

(3)

(2)

(7)

(1)

4 – 4

(Operation of stapling)

Jogging in lateral direction

1) The jog plates are moved to the stand-by position before the

paper is fed to the staple tray.

2) Immediately after the paper is fed into the staple tray, the jog plate

is moved to the paper size position to ensure the alignment of the

paper.

paper.

Staple unit movement at the time of stapling (1-point

stapling)

stapling)

1) The stapler unit is moved to the stapling position.

– The number of sheets to be stapled is fed to the staple tray –

2) The pusher (the sheets to be stapled) is lowered the stapling

position.

3) The paper is stapled ... (in the case of 2-point stapling, the action

that is described on the following page is added.)

4) The pusher (the sheets stapled) is elevated to the paper dis-

charge position.

5) After the job, the stapler unit is returned to the home position.

Stapler unit movement at the time of stapling

(2-point stapling action is added.)

(2-point stapling action is added.)

1) The pusher is elevated to the position which makes it possible for

the staple unit to move.

2) The staple unit is moved to the staple position where the 2nd

staple is driven.

3) The pusher (sheets to be stapled) is lowered to the stapling posi-

tion.

4) Sheets are stapled.

5) The staple unit is returned to the 1st staple position.

(After the job is finished, the staple unit is returned to the home

position.)

position.)

D. Off-set tray

1) Off-set motor (3)

When the off-set motor (3) is driven, the tray is shifted sidewise

against the direction in which the sheets are delivered, so that the

sheets discharged into the off-set tray (1) are sorted by the specified

number of sheets. The rotation is unidirectional and controlled by the

crank. The motor is braked to a stop by the off-set home position

sensor (2) turning ON.

against the direction in which the sheets are delivered, so that the

sheets discharged into the off-set tray (1) are sorted by the specified

number of sheets. The rotation is unidirectional and controlled by the

crank. The motor is braked to a stop by the off-set home position

sensor (2) turning ON.

No.

Signal name

Part name

(1)

—

Tray 3 (Off-set tray)

(2)

OFHP

OFHP Off-set home position sensor

(3)

OFM

Off-set motor

1)

2)

2)

1)

Jog plate

R

R

Jog plate

F

F

Pusher

Paper size

5)

1)

3)

2)

4)

Pusher

Staple unit

Home

position

position

Paper discharge

position

position

Staple position

ST rail

Staple unit moving

motor

motor

3)

4)

2)

5)

1)

Pusher

Staple unit

moving range

moving range

Staple position

ST rail

Staple unit moving

motor

motor

(3)

(2)

(1)

Moving range

(30 mm)

4 – 5

E. Elevator

1) Elevator motor (3)

When the elevator motor (3) is driven, the winding pulley (5) is rotated

in both forward and reverse to wind up the wire (6) stretching verti-

cally so that the tray 3 (off-set tray) is moved up and down. This

allows the discharge of paper at a fixed position according to the

number of sheets to be loaded on the off-set tray.

in both forward and reverse to wind up the wire (6) stretching verti-

cally so that the tray 3 (off-set tray) is moved up and down. This

allows the discharge of paper at a fixed position according to the

number of sheets to be loaded on the off-set tray.

2) Off-set tray full and load detection

When the power is turned ON, the off-set tray lowers to the lower limit

sensor (4) position. Then it elevates until the upper limit sensor (7)

turns ON, while counting the encoder pulses of the elevator motor (3).

sensor (4) position. Then it elevates until the upper limit sensor (7)

turns ON, while counting the encoder pulses of the elevator motor (3).

The volume of paper loaded on the off-set tray is calculated (0 -

100%) by counting the number of pulses from the elevator encoder

(1).

100%) by counting the number of pulses from the elevator encoder

(1).

The off-set tray is judged to be full when both the lower and upper

limit sensors (4, 7) are turned ON.

limit sensors (4, 7) are turned ON.

3) Upper limit sensor solenoid (T3UPSL)

When the paper is discharged from the off-set tray, the upper limit

sensor solenoid is turned on to pull in the actuator so that the sheet

discharged does not ride on the actuator of the upper limit sensor (7).

sensor solenoid is turned on to pull in the actuator so that the sheet

discharged does not ride on the actuator of the upper limit sensor (7).

No.

Signal name

Part name

(1)

—

Elevator motor encoder

(2)

—

Elevator drive unit

(3)

EVM

Elevator motor

(4)

T3DN

Tray 3 lower limit sensor

(5)

—

Winding pulley

(6)

—

Wire

(7)

T3UP

Tray 3 upper limit sensor

3. Basic operation

A. Basic operation flowchart

Fig. 1 Basic operation flowchart

1) Initialization

The finisher is initialized (home positioning of each motor) at the

following timing.

following timing.

•

When the power is turned on.

•

The finisher leaves the copier and when either of the top or bottom

door is opened.

door is opened.

•

When the copier start key is pressed (JOB_START):

•

Recovery action is performed.

(7)

(6)

(5)

(1)

(2)

(4)

(3)

Power ON

Initialization when

powered on

Independent movement

of staple unit

(Staple position)

Independent shifting

Transfer

Off-set trail paper

discharge

JOB_END

Operation when

JAM error occurs

Operation when

door is closed

Stapling

JOB_START

(Offset tray)

4 – 6

Display