Sharp AL-1555 (serv.man11) Service Manual ▷ View online

AL-1555 ADJUSTMENTS 9 - 5

(2) Perform the adjustment in each mode.

1) Execute SIM 46-1.

2) Select the mode to be adjusted with the exposure mode select key.

Set the exposure level to 3 for all adjustment. (Except for the auto

mode.)

mode.)

3) Make a copy.

Check the adjustment level (shown in the above table) of the

exposure test chart (Sharp Gray Scale).

exposure test chart (Sharp Gray Scale).

(When too bright): Decrease the value displayed on the copy quantity

display.

(When too dark):

Increase the value displayed on the copy quantity

display.

display.

* The value can be set in the range of 1 - 99.

3. High voltage adjustment

A. Main charger (Grid bias)

Note:

• Use a digital multi meter with internal resistance of 10M

Ω

or more

measurement.

• After adjusting the grid LOW output, adjust the HIGH output. Do not

reverse the sequence.

Procedures

1) Set the digital multi meter range to DC700V.

2) Set the positive side of the test rod to the connector CN11-3

(GRID) of high voltage section of the power PWB and set the

negative side to the frame ground (power frame).

negative side to the frame ground (power frame).

3) Execute SIM 8-3. (The main charger output is supplied for 30 sec

in the grid voltage LOW output mode.)

4) Adjust the control volume (VRG2) so that the output voltage is

– 390 ±20V.

5) Execute SIM 8-2. (The main charger output is supplied for 30 sec

in the grid voltage HIGH output mode.)

6) Adjust the control volume (VRG1) so that the output voltage is 580

±12V.

B. DV bias check

Procedures

1) Set the digital multi meter range to DC500V.

2) Set the positive side of the test rod to the connector CN-10-1 (DV

BIAS) and set the negative side to the frame ground (power

frame).

frame).

3) Execute SIM 25-1 to output the developing bias for 30sec, and

check that the output is – 400 ±8V.

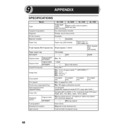

Adjustment mode

Exposure mode

display lamp

Sharp gray chart

adjustment level

Auto mode

Auto lamp ON

"3" is slightly copied.

Manual mode

Manual lamp ON

"3" is slightly copied.

Photo mode

Photo lamp ON

"3" is slightly copied.

Manual T/S mode Manual lamp/Photo lamp

ON

"3" is slightly copied.

Auto T/S mode

Auto lamp/Photo lamp ON "3" is slightly copied.

Sharp Gray Scale adjustment level

Non toner

save mode

save mode

Toner save

mode

mode

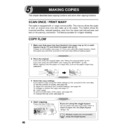

(1) Mode select key/display

lamp

(2) Exposure level select

key/display lamp

(1)

(2)

1

10

W

2

3

4

5

6

7

8

9

Slightly copied.

Not copied.

1

10

W

2

3

4

5

6

7

8

9

Slightly copied.

Not copied.

Note: • A digital multi meter with internal resistance of 1G

Ω

must be

use for correct check.

• The adjustment volume is locked, and no adjustment can be

made.

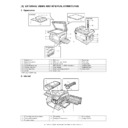

VRG1

VRG2

VRDV

AL-1555 ADJUSTMENTS 9 - 6

4. Duplex adjustment

A. Adjusting the paper reverse position in memory

for duplex copying

This step adjusts the front surface printing (odd-number pages of a

document set) in the S-D mode copying and the leading edge position

of an image on even-number pages in the D-S mode.

document set) in the S-D mode copying and the leading edge position

of an image on even-number pages in the D-S mode.

That is, it covers the adjustment of the second surface printing mode

(image loss at the front edge of an image) in which image data is once

stored in memory.

(image loss at the front edge of an image) in which image data is once

stored in memory.

The image data is read, starting from its front end in the document

delivery direction (Reference direction of document setting in the OC

mode)and stored in memory.

delivery direction (Reference direction of document setting in the OC

mode)and stored in memory.

This stored image data is printed starting at the printing start position,

in the order of last-stored data to the first-stored data.

in the order of last-stored data to the first-stored data.

In other words, the front edge image loss of the image can be adjusted

by changing the document read end position.

by changing the document read end position.

(Adjustment procedure)

1) Preparing test chart (Draw a scale at the rear end of one side of a

sheet of A4 white paper or letter paper)

2) Set the test chart so that the scale is positioned as shown below, in

the S-D mode and the D-S mode.

3) Execute simulation 50-18 to make a copy and check the front edge

image loss at the area where the scale is printed.

Adjust the setting so that the front edge image loss is less than 4.0

mm in the R-SPF mode.

An increase of 1 in setting represents an increase of 0.1 mm in

image loss.

Adjust the setting so that the front edge image loss is less than 4.0

mm in the R-SPF mode.

An increase of 1 in setting represents an increase of 0.1 mm in

image loss.

B. Adjusting trailing edge void in duplex copy mode

This is the adjustment of the first surface printing mode (rear end void)

in duplex copying.

in duplex copying.

In a duplex copying operation, the paper is delivered starting from the

rear end of the first printing surface. It is therefore necessary to make a

void area at the rear end on the first printing surface to prevent paper

jam at the fusing part.

rear end of the first printing surface. It is therefore necessary to make a

void area at the rear end on the first printing surface to prevent paper

jam at the fusing part.

There are two adjustment modes:

1) Image cut rear end void quantity (R-SPF) 50-19(AE)

The size (length) of a document read from the R-SPF is detected,

the image at the trailing edge of the first printing surface is cut to

make a void area. (The adjustment of void quantity at the time

when the cassette paper size is not recognized.)

the image at the trailing edge of the first printing surface is cut to

make a void area. (The adjustment of void quantity at the time

when the cassette paper size is not recognized.)

2) Paper trailing edge void quantity 50-19 (TEXT)

This adjustment is made when the cassette paper size is

recognized. The trailing edge void quantity can be adjusted by

changing the trailing edge image laser OFF timing.

recognized. The trailing edge void quantity can be adjusted by

changing the trailing edge image laser OFF timing.

The paper void quantity should be first adjusted before the image cut

trailing edge void quantity (R-SPF) is adjusted.

trailing edge void quantity (R-SPF) is adjusted.

(Adjustment procedure)

(1) Paper trailing edge void quantity

1) Preparing test chart (Draw a scale at the rear end of one side of a

sheet of A/4 white paper or letter paper)

2) Set the test chart on the document glass as shown below.

3) Using the user simulation [18], set the paper size of the first

cassette.

• Letter paper: 4

• A4 paper: 3

5 10

Scale (S-D mode)

Scale (D-S mode)

5 10

The front edge of the

scale on test chart

scale on test chart

Front edge of paper

Void area

less than 4 mm

2nd printing surface where scale is printed (lower side)

Document guide

The trailing edge has a scale

Table glass

AL-1555 ADJUSTMENTS 9 - 7

4) Execute simulation 50-19 to turn on the TEXT lamp and make the

printing mode in OC-D mode.

Make a copy of the test chart to check the void area of the scale on

the image.

Make a copy of the test chart to check the void area of the scale on

the image.

Adjust the setting so that the void area is 4 - 5 mm. An increase in 1 of

setting represents 0.1 mm in void area.

setting represents 0.1 mm in void area.

(2) Image cut trailing edge void quantity (R-SPF)

1) Set the test chart so that the scale is positioned as shown below.

2) Execute simulation 50-19 to turn on the AE lamp(on the operation

panel) and make the printing mode in the D-D mode.

3) Remove and reinsert the cassette.

Note: Make sure to carry out this step before making a copy during

this adjustment.

4) Make a copy and check the void area of the scale on the image.

Adjust the setting so that the void area is 2 - 4 mm. An increase of

1 in setting represents an increase of 0.1 mm in void area.

l Void position to be checked

1 in setting represents an increase of 0.1 mm in void area.

l Void position to be checked

The trailing edge void on the first printing surface

is shown above.

is shown above.

Paper

Void position to be check

Scale (D-D mode)

AL-1555 ADJUSTMENTS 9 - 7

4) Execute simulation 50-19 to turn on the TEXT lamp and make the

printing mode in OC-D mode.

Make a copy of the test chart to check the void area of the scale on

the image.

Make a copy of the test chart to check the void area of the scale on

the image.

Adjust the setting so that the void area is 4 - 5 mm. An increase in 1 of

setting represents 0.1 mm in void area.

setting represents 0.1 mm in void area.

(2) Image cut trailing edge void quantity (R-SPF)

1) Set the test chart so that the scale is positioned as shown below.

2) Execute simulation 50-19 to turn on the AE lamp(on the operation

panel) and make the printing mode in the D-D mode.

3) Remove and reinsert the cassette.

Note: Make sure to carry out this step before making a copy during

this adjustment.

4) Make a copy and check the void area of the scale on the image.

Adjust the setting so that the void area is 2 - 4 mm. An increase of

1 in setting represents an increase of 0.1 mm in void area.

l Void position to be checked

1 in setting represents an increase of 0.1 mm in void area.

l Void position to be checked

The trailing edge void on the first printing surface

is shown above.

is shown above.

Paper

Void position to be check

Scale (D-D mode)

Display