Sharp R-959SLM (serv.man6) Service Manual ▷ View online

R959(SL)M

8 – 5

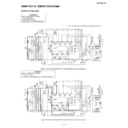

[14] Procedure N: KEY UNIT TEST

If the display fails to clear when the STOP/CLEAR

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

CARRY OUT 4R CHECKS.

[15] Procedure O: RELAY TEST

CARRY OUT 3D CHECKS.

Remove the outer case and check voltage between Pin Nos. 1 and 3 of the 4 pin connector (E) on the control unit with an A.C. voltmeter. The meter

should indicate 230 - 240 volts, if not check oven circuit.

should indicate 230 - 240 volts, if not check oven circuit.

Relay Test

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation, grill operation, convection operation or dual operation.

DC. voltage indicated ................................... Defective relay.

DC. voltage not indicated ............................. Check diode which is connected to the relay coil. If diode is good, control unit is defective.

CARRY OUT 4R CHECKS.

[16] Procedure P: PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE

PRINTED WIRING BOARD (PWB) IS OPEN

PRINTED WIRING BOARD (PWB) IS OPEN

Problem: POWER ON, indicator does not light up.

CARRY OUT 3D CHECKS.

NOTE: *At the time of these repairs, make a visual inspection of the varistor for burning damage and

examine the transformer with tester for the presence of layer short circuit (check primary coil

resistance).

resistance).

If any abnormal condition is detected, replace the power unit.

CARRY OUT 4R CHECKS.

RELAY SYMBOL

OPERATIONAL VOLTAGE

CONNECTED COMPONENTS

RY1

APPROX. 18.0V D.C.

Oven lamp / Turntable motor

RY2

APPROX. 18.0V D.C.

High voltage transformer

RY3

APPROX. 24.0V D.C.

Grill (Top) heating element

RY4

APPROX. 24.0V D.C.

Convection heating element

RY5

APPROX. 24.0V D.C.

Fan motor

RY6

APPROX. 24.0V D.C.

Touch control transformer

RY7

APPROX. 24.0V D.C.

Convection motor

RY8

APPROX. 24.0V D.C.

Damper motor

STEPS

OCCURRENCE

CAUSE OR CORRECTION

1

The rated AC voltage is not present between Pin No. 1 and 3 of

the 4-pin connector (E).

the 4-pin connector (E).

Check supply voltage and oven power cord.

2

The rated AC voltage is present at primary side of low voltage

transformer.

transformer.

Low voltage transformer or secondary circuit defective.

Check and replace power unit.

Check and replace power unit.

3

Only pattern at “a” is broken.

*Insert jumper wire J1 and solder.

4

Pattern at “a” and “b” are broken.

Replace power unit. (CARRY OUT 3D CHECKS BEFORE REPAIR)

G8

G7

G6

G5

G1

G2

G3

G4

G9

G10

G12

G

11

MINCED

MEAT

10min.

1min.

10sec.

CHICKEN

PORTIONS

COMBI.

ROAST

PORK

AUTO

COOK

(TIME)

AUTO

START

CLOCK

START

AUTO

MINUTE

(WEIGHT)

GRILL

KITCHEN

TIMER

STOP

CLEAR

䂦

ROAST

POULTRY

(TIME)

䂦

MICRO.

POWER

CONV.

(ºC)

(WEIGHT)

ROAST

BEEF/

LAMB

BEEF/

LAMB

STEAK/

CHOPS

CHOPS

(J1)

(J2)

9

1

7

C

N-E

CN

-

A

VRS1

a

c

d

b

R959(SL)M

8 – 5

[14] Procedure N: KEY UNIT TEST

If the display fails to clear when the STOP/CLEAR

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

CARRY OUT 4R CHECKS.

[15] Procedure O: RELAY TEST

CARRY OUT 3D CHECKS.

Remove the outer case and check voltage between Pin Nos. 1 and 3 of the 4 pin connector (E) on the control unit with an A.C. voltmeter. The meter

should indicate 230 - 240 volts, if not check oven circuit.

should indicate 230 - 240 volts, if not check oven circuit.

Relay Test

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation, grill operation, convection operation or dual operation.

DC. voltage indicated ................................... Defective relay.

DC. voltage not indicated ............................. Check diode which is connected to the relay coil. If diode is good, control unit is defective.

CARRY OUT 4R CHECKS.

[16] Procedure P: PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE

PRINTED WIRING BOARD (PWB) IS OPEN

PRINTED WIRING BOARD (PWB) IS OPEN

Problem: POWER ON, indicator does not light up.

CARRY OUT 3D CHECKS.

NOTE: *At the time of these repairs, make a visual inspection of the varistor for burning damage and

examine the transformer with tester for the presence of layer short circuit (check primary coil

resistance).

resistance).

If any abnormal condition is detected, replace the power unit.

CARRY OUT 4R CHECKS.

RELAY SYMBOL

OPERATIONAL VOLTAGE

CONNECTED COMPONENTS

RY1

APPROX. 18.0V D.C.

Oven lamp / Turntable motor

RY2

APPROX. 18.0V D.C.

High voltage transformer

RY3

APPROX. 24.0V D.C.

Grill (Top) heating element

RY4

APPROX. 24.0V D.C.

Convection heating element

RY5

APPROX. 24.0V D.C.

Fan motor

RY6

APPROX. 24.0V D.C.

Touch control transformer

RY7

APPROX. 24.0V D.C.

Convection motor

RY8

APPROX. 24.0V D.C.

Damper motor

STEPS

OCCURRENCE

CAUSE OR CORRECTION

1

The rated AC voltage is not present between Pin No. 1 and 3 of

the 4-pin connector (E).

the 4-pin connector (E).

Check supply voltage and oven power cord.

2

The rated AC voltage is present at primary side of low voltage

transformer.

transformer.

Low voltage transformer or secondary circuit defective.

Check and replace power unit.

Check and replace power unit.

3

Only pattern at “a” is broken.

*Insert jumper wire J1 and solder.

4

Pattern at “a” and “b” are broken.

Replace power unit. (CARRY OUT 3D CHECKS BEFORE REPAIR)

G8

G7

G6

G5

G1

G2

G3

G4

G9

G10

G12

G

11

MINCED

MEAT

10min.

1min.

10sec.

CHICKEN

PORTIONS

COMBI.

ROAST

PORK

AUTO

COOK

(TIME)

AUTO

START

CLOCK

START

AUTO

MINUTE

(WEIGHT)

GRILL

KITCHEN

TIMER

STOP

CLEAR

䂦

ROAST

POULTRY

(TIME)

䂦

MICRO.

POWER

CONV.

(ºC)

(WEIGHT)

ROAST

BEEF/

LAMB

BEEF/

LAMB

STEAK/

CHOPS

CHOPS

(J1)

(J2)

9

1

7

C

N-E

CN

-

A

VRS1

a

c

d

b

R959(SL)M

8 – 5

[14] Procedure N: KEY UNIT TEST

If the display fails to clear when the STOP/CLEAR

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

CARRY OUT 4R CHECKS.

[15] Procedure O: RELAY TEST

CARRY OUT 3D CHECKS.

Remove the outer case and check voltage between Pin Nos. 1 and 3 of the 4 pin connector (E) on the control unit with an A.C. voltmeter. The meter

should indicate 230 - 240 volts, if not check oven circuit.

should indicate 230 - 240 volts, if not check oven circuit.

Relay Test

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation, grill operation, convection operation or dual operation.

DC. voltage indicated ................................... Defective relay.

DC. voltage not indicated ............................. Check diode which is connected to the relay coil. If diode is good, control unit is defective.

CARRY OUT 4R CHECKS.

[16] Procedure P: PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE

PRINTED WIRING BOARD (PWB) IS OPEN

PRINTED WIRING BOARD (PWB) IS OPEN

Problem: POWER ON, indicator does not light up.

CARRY OUT 3D CHECKS.

NOTE: *At the time of these repairs, make a visual inspection of the varistor for burning damage and

examine the transformer with tester for the presence of layer short circuit (check primary coil

resistance).

resistance).

If any abnormal condition is detected, replace the power unit.

CARRY OUT 4R CHECKS.

RELAY SYMBOL

OPERATIONAL VOLTAGE

CONNECTED COMPONENTS

RY1

APPROX. 18.0V D.C.

Oven lamp / Turntable motor

RY2

APPROX. 18.0V D.C.

High voltage transformer

RY3

APPROX. 24.0V D.C.

Grill (Top) heating element

RY4

APPROX. 24.0V D.C.

Convection heating element

RY5

APPROX. 24.0V D.C.

Fan motor

RY6

APPROX. 24.0V D.C.

Touch control transformer

RY7

APPROX. 24.0V D.C.

Convection motor

RY8

APPROX. 24.0V D.C.

Damper motor

STEPS

OCCURRENCE

CAUSE OR CORRECTION

1

The rated AC voltage is not present between Pin No. 1 and 3 of

the 4-pin connector (E).

the 4-pin connector (E).

Check supply voltage and oven power cord.

2

The rated AC voltage is present at primary side of low voltage

transformer.

transformer.

Low voltage transformer or secondary circuit defective.

Check and replace power unit.

Check and replace power unit.

3

Only pattern at “a” is broken.

*Insert jumper wire J1 and solder.

4

Pattern at “a” and “b” are broken.

Replace power unit. (CARRY OUT 3D CHECKS BEFORE REPAIR)

G8

G7

G6

G5

G1

G2

G3

G4

G9

G10

G12

G

11

MINCED

MEAT

10min.

1min.

10sec.

CHICKEN

PORTIONS

COMBI.

ROAST

PORK

AUTO

COOK

(TIME)

AUTO

START

CLOCK

START

AUTO

MINUTE

(WEIGHT)

GRILL

KITCHEN

TIMER

STOP

CLEAR

䂦

ROAST

POULTRY

(TIME)

䂦

MICRO.

POWER

CONV.

(ºC)

(WEIGHT)

ROAST

BEEF/

LAMB

BEEF/

LAMB

STEAK/

CHOPS

CHOPS

(J1)

(J2)

9

1

7

C

N-E

CN

-

A

VRS1

a

c

d

b

R959(SL)M

8 – 5

[14] Procedure N: KEY UNIT TEST

If the display fails to clear when the STOP/CLEAR

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

pad is depressed, first verify the flat ribbon cable is

marking good contact, verify that the door sensing

switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and

open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat rib-

bon cable that connects the key unit to the control

unit and make sure the door sensing switch is

closed (either close the door or short the door sens-

ing switch connecter). Use the Key unit matrix indi-

cated on the control panel schematic and place a jumper wire between the pins that correspond to the STOP/CLEAR pad marking momentary

contact. If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the control unit does not respond, it is faulty

and must be replaced. If a specific pad does not respond, the above method may be used (after clearing the control unit) to determine if the control

unit or key pad is at fault.

CARRY OUT 4R CHECKS.

[15] Procedure O: RELAY TEST

CARRY OUT 3D CHECKS.

Remove the outer case and check voltage between Pin Nos. 1 and 3 of the 4 pin connector (E) on the control unit with an A.C. voltmeter. The meter

should indicate 230 - 240 volts, if not check oven circuit.

should indicate 230 - 240 volts, if not check oven circuit.

Relay Test

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking operation, grill operation, convection operation or dual operation.

DC. voltage indicated ................................... Defective relay.

DC. voltage not indicated ............................. Check diode which is connected to the relay coil. If diode is good, control unit is defective.

CARRY OUT 4R CHECKS.

[16] Procedure P: PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE

PRINTED WIRING BOARD (PWB) IS OPEN

PRINTED WIRING BOARD (PWB) IS OPEN

Problem: POWER ON, indicator does not light up.

CARRY OUT 3D CHECKS.

NOTE: *At the time of these repairs, make a visual inspection of the varistor for burning damage and

examine the transformer with tester for the presence of layer short circuit (check primary coil

resistance).

resistance).

If any abnormal condition is detected, replace the power unit.

CARRY OUT 4R CHECKS.

RELAY SYMBOL

OPERATIONAL VOLTAGE

CONNECTED COMPONENTS

RY1

APPROX. 18.0V D.C.

Oven lamp / Turntable motor

RY2

APPROX. 18.0V D.C.

High voltage transformer

RY3

APPROX. 24.0V D.C.

Grill (Top) heating element

RY4

APPROX. 24.0V D.C.

Convection heating element

RY5

APPROX. 24.0V D.C.

Fan motor

RY6

APPROX. 24.0V D.C.

Touch control transformer

RY7

APPROX. 24.0V D.C.

Convection motor

RY8

APPROX. 24.0V D.C.

Damper motor

STEPS

OCCURRENCE

CAUSE OR CORRECTION

1

The rated AC voltage is not present between Pin No. 1 and 3 of

the 4-pin connector (E).

the 4-pin connector (E).

Check supply voltage and oven power cord.

2

The rated AC voltage is present at primary side of low voltage

transformer.

transformer.

Low voltage transformer or secondary circuit defective.

Check and replace power unit.

Check and replace power unit.

3

Only pattern at “a” is broken.

*Insert jumper wire J1 and solder.

4

Pattern at “a” and “b” are broken.

Replace power unit. (CARRY OUT 3D CHECKS BEFORE REPAIR)

G8

G7

G6

G5

G1

G2

G3

G4

G9

G10

G12

G

11

MINCED

MEAT

10min.

1min.

10sec.

CHICKEN

PORTIONS

COMBI.

ROAST

PORK

AUTO

COOK

(TIME)

AUTO

START

CLOCK

START

AUTO

MINUTE

(WEIGHT)

GRILL

KITCHEN

TIMER

STOP

CLEAR

䂦

ROAST

POULTRY

(TIME)

䂦

MICRO.

POWER

CONV.

(ºC)

(WEIGHT)

ROAST

BEEF/

LAMB

BEEF/

LAMB

STEAK/

CHOPS

CHOPS

(J1)

(J2)

9

1

7

C

N-E

CN

-

A

VRS1

a

c

d

b

Display