Sharp DV-RW360H Service Manual ▷ View online

2-3-4

H9941MA

No Good

Good

FM envelope output signal is low.

2ms

FM envelope signal

CTL signal

Center Position

FM envelope output signal

is adjusted at maximum.

is adjusted at maximum.

Fig. M7

6. Set the Tracking Control Circuit to the preset position

by pressing [PROGRAMME

o]

] button and then [VCR

PLAY

]

] button on the unit.

1-C. Checking/Adjustment of Enve-

lope Waveform

Purpose:

To achieve a satisfactory picture, adjust the Guide Rollers

so that the PB FM envelope becomes as flat as possible.

so that the PB FM envelope becomes as flat as possible.

Symptom of Misalignment:

If the envelope output is poor, noise will appear in the

picture. The tracking will then lose precision and the

playback picture will be distorted by any slight variation

of the Tracking Control Circuit.

picture. The tracking will then lose precision and the

playback picture will be distorted by any slight variation

of the Tracking Control Circuit.

1. Connect the oscilloscope to TP301 (C-PB) on the

Main CBA. Use TP504 (RF-SW) as a trigger.

2. Playback the Gray Scale on the Test Tape

(9HSFL6NS8). Set the Tracking Control Circuit to the

preset position by pressing [PROGRAMME

preset position by pressing [PROGRAMME

o

] button

and then [PLAY] button on the unit. Adjust the height

of Guide Rollers [2] and [3] (Fig. M3, Page 2-3-3)

watching the oscilloscope display so that the envelope

becomes as flat as possible. To do this adjustment,

turn the top of the Guide Roller with the Guide Roller

Adj. Screwdriver.

of Guide Rollers [2] and [3] (Fig. M3, Page 2-3-3)

watching the oscilloscope display so that the envelope

becomes as flat as possible. To do this adjustment,

turn the top of the Guide Roller with the Guide Roller

Adj. Screwdriver.

3. If the envelope is as shown in Fig. M8, adjust the height

of Guide Roller [2] (Refer to Fig. M3) so that the

waveform looks like the one shown in Fig. M10.

waveform looks like the one shown in Fig. M10.

4. If the envelope is as shown in Fig. M9, adjust the height

of Guide Roller [3] (Refer to Fig. M3) so that the

waveform looks like the one shown in Fig. M10.

waveform looks like the one shown in Fig. M10.

5. When Guide Rollers [2] and [3] (Refer to Fig. M3) are

aligned properly, there is no envelope drop either at

the beginning or end of track as shown in Fig. M10.

the beginning or end of track as shown in Fig. M10.

Dropping envelope level at the beginning of track.

Fig. M8

Dropping envelope level at the end of track.

Fig. M9

Envelope is adjusted properly. (No envelope drop)

Fig. M10

Note: Upon completion of the adjustment of Guide

Rollers [2] and [3] (Refer to Fig. M3), check the X Value

by pushing the [PROGRAMME

Rollers [2] and [3] (Refer to Fig. M3), check the X Value

by pushing the [PROGRAMME

o

] or [PROGRAMME

p

]

buttons alternately, to check the symmetry of the envelope.

Check the number of pushes to ensure preset position.

The number of pushes of the [PROGRAMME

Check the number of pushes to ensure preset position.

The number of pushes of the [PROGRAMME

o

] button to

achieve 1/2 level of envelope should match the number of

pushes of the [PROGRAMME

pushes of the [PROGRAMME

p

] button from center. If

required, redo the "X Value Alignment."

2-3-5

H9941MA

1-D. Azimuth Alignment of Audio/

Control/ Erase Head

Purpose:

To correct the Azimuth alignment so that the Audio/

Control/Erase Head meets tape tracks properly.

Control/Erase Head meets tape tracks properly.

Symptom of Misalignment:

If the position of the Audio/Control/Erase Head is not

properly aligned, the Audio S/N Ratio or Frequency

Response will be poor.

properly aligned, the Audio S/N Ratio or Frequency

Response will be poor.

1. Connect the oscilloscope to the audio output jack on

the rear side of the deck.

2. Playback the Test Tape (9HSFL6NS8) and confirm

that the audio signal output level is 8kHz.

3. Adjust Azimuth Adj. Screw so that the output level on

the AC Voltmeter or the waveform on the oscilloscope

is at maximum. (Fig. M6)

is at maximum. (Fig. M6)

Note: Upon completion of the adjustment of Azimuth Adj.

Screw, check the X Value by pushing the [PROGRAMME

Screw, check the X Value by pushing the [PROGRAMME

o

] or [PROGRAMME

p

] buttons alternately, to check the

symmetry of the envelope. Check the number of pushes

to ensure preset position. The number of pushes of the

[PROGRAMME

to ensure preset position. The number of pushes of the

[PROGRAMME

o

] button to achieve 1/2 level of envelope

should match the number of pushes of the [PROGRAMME

p

] button from center. If required, redo the "X Value

Alignment."

1-E. Checking and Alignment of

Tape Path during reversing

Purpose:

To make sure that the tape path is well stabilized during

reversing.

reversing.

Symptom of Misalignment:

If the tape path is unstable during reversing, the tape will

be damaged.

be damaged.

Note: Do not use an Test Tape for this procedure. If the

unit is not correctly aligned, the tape may be damaged.

unit is not correctly aligned, the tape may be damaged.

1. Insert a blank cassette tape into the tray and set the

unit to REV. Then confirm if the tape has been curled

up or bent at the Take-up Guide Post [4] or REV Post

[5] (Refer to Fig. M11 and M12.)

up or bent at the Take-up Guide Post [4] or REV Post

[5] (Refer to Fig. M11 and M12.)

2. When the tape has been curled up or bent, turn the

alignment screw to adjust the height of REV Post.

(Refer to Fig. M11 and M13.)

(Refer to Fig. M11 and M13.)

Take-up Guide Post [4]

REV Post [5]

Fig. M11

Take-up Guide

Post

Post

Tape

REV Post

Tape

Correct

Incorrect

Fig. M12

Fig. M13

Tape Guide

Assembly

Assembly

Alignment

Screw

Screw

2-4-1

H9941DA

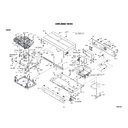

DISASSEMBLY/ASSEMBLY PROCEDURES OF DECK

MECHANISM

Before following the procedures described below, be sure to remove the deck assembly from the cabinet. (Refer to

CABINET DISASSEMBLY INSTRUCTIONS.)

CABINET DISASSEMBLY INSTRUCTIONS.)

All the following procedures, including those for adjustment and replacement of parts, should be done in Eject mode;

see the positions of [44] and [45] in Fig. DM1H on page 2-4-3. When reassembling, follow the steps in reverse order.

see the positions of [44] and [45] in Fig. DM1H on page 2-4-3. When reassembling, follow the steps in reverse order.

No.

/LOC.

STEP

No.

ING

START-

PART

REMOVAL

INSTALLATION

Fig. No.

UNPLUG/DESOLDER

UNLOCK/RELEASE/

REMOVE/*UNHOOK/

CONDITION

ADJUSTMENT

[1]

[1]

Guide Holder A

T

DM3H

2(S-1)

[2]

[1]

Assembly

Cassette Holder

T

DM4H

[3]

[2]

Slider (SP)

T

DM5H

(S-1A), *(L-1)

[4]

[2]

Slider (TU)

T

DM5H

*(L-2)

[5]

[4]

Lock Lever

T

DM5H

*(L-3), *(P-1)

[6]

[2]

Cassette Plate

T

DM5H

[7]

[7]

Cylinder Assembly

T

DM1H, DM6H

Desolder, 3(S-2)

[8]

[8]

Assembly

Loading Motor

T

DM1H, DM7H

2(S-3)

Desolder, LDG Belt,

[9]

[9]

ACE Head Assembly

T

DM1H, DM7H

(S-4)

[10]

[2]

Assembly

Tape Guide Arm

T

DM1H, DM8H-1

*(P-2)

[11]

[10]

C Door Opener

T

DM1H, DM8H-1

(S-4A), *(L-4)

[12]

[11]

Pinch Arm (B)

T

DM8H-2

DM1H, DM8H-1,

*(P-3)

[13]

[12]

Assembly

Pinch Arm (A)

T

DM8H-2

DM1H, DM8H-1,

[14]

[14]

FE Head

T

DM1H, DM9H

(S-5)

[15]

[15]

Prism

T

DM1H, DM9H

(S-6)

[16]

[2]

Slider Shaft

T

DM10H

*(L-5)

[17]

[16]

C Drive Lever (SP)

T

DM10H

[18]

[16]

C Drive Lever (TU)

T

DM10H

(S-7), *(P-4)

[19]

[19]

Capstan Motor

B

DM2H, DM11H

3(S-8), Cap Belt

[20]

[20]

Clutch Assembly (HI)

B

DM2H, DM12H

(C-1)

[21]

[20]

Center Gear

B

DM12H

[22]

[22]

F Brake Assembly (HI)

B

DM2H, DM12H

*(L-6)

[23]

[22]

Worm Holder

B

DM2H, DM13H-1

(S-9), *(L-7), *(L-8)

[24]

[22]

Pulley Assembly (HI)

B

DM2H, DM13H-1

[25]

[25]

Mode Gear (LM)

B

DM2H, DM13H-1

(C-2)

[26]

[20],[25] Mode Lever (HI)

B

DM13H-2

DM2H, DM13H-1, (C-3)

[27]

[26]

[22],[23],

Cam Gear (A) (HI)

B

DM13H-2

DM2H, DM13H-1, (C-4)

Sec.Page 2-5-1

(+)Refer to Alignment

[28]

[26]

TR Gear C

B

DM2H, DM13H-1

(C-5)

2-4-2

H9941DA

No.

/LOC.

STEP

No.

ING

START-

PART

REMOVAL

INSTALLATION

Fig. No.

UNPLUG/DESOLDER

UNLOCK/RELEASE/

REMOVE/*UNHOOK/

CONDITION

ADJUSTMENT

[29]

[28]

TR Gear Spring

B

DM13H-1

[30]

[29]

TR Gear A/B

B

DM13H-1

[31]

[31]

FF Arm (HI)

B

DM1H, DM14H

[32]

[26]

Idler Assembly (HI)

B

DM1H, DM14H

*(L-9)

[33]

[26]

BT Arm

B

DM2H, DM14H

*(P-5)

[34]

[26]

Assembly

Loading Arm (SP)

B

DM2H, DM14H

Sec.Page 2-5-1

(+)Refer to Alignment

[35]

[34]

Assembly

Loading Arm (TU)

B

DM2H, DM14H

Sec.Page 2-5-1

(+)Refer to Alignment

[36]

[16],[26]

Assembly (HI)

M Brake (TU)

T

DM1H, DM15H

[37]

[2],[26]

Assembly (HI)

M Brake (SP)

T

DM1H, DM15H

*(P-6)

[38]

[37]

Assembly

Tension Lever

T

DM1H, DM15H

[39]

[38]

T Lever Holder

T

DM15H

*(L-10)

[40]

[40]

M Gear (HI)

T

DM1H, DM15H

(C-6)

[41]

[15],[40] Sensor Gear (HI)

T

DM1H, DM15H

(C-7)

[42]

[36],[40] Reel T

T

DM1H, DM15H

[43]

[38]

Reel S

T

DM1H, DM15H

[44]

[34],[38]

Preparation

Moving Guide S

T

DM1H, DM16H

(S-11), Slide Plate

[45]

[35]

Preparation

Moving Guide T

T

DM1H, DM16H

[46]

[19]

TG Post Assembly

T

DM1H, DM16H

*(L-11)

[47]

[27]

Rack Assembly

R DM17H

Sec.Page 2-5-1

(+)Refer to Alignment

[48]

[47]

F Door Opener

R DM17H

[49]

[49]

Cleaner Assembly

T

DM1H, DM6H

[50]

[49]

CL Post

T

DM6H

*(L-12)

(6)

(5)

(4)

(3)

(2)

(1)

(7)

(1): Follow steps in sequence. When reassembling, follow the steps in reverse order.

These numbers are also used as identification (location) No. of parts in the figures.

(2): Indicates the part to start disassembling with in order to disassemble the part in column (1).

(3): Name of the part

(4): Location of the part: T=Top B=Bottom R=Right L=Left

(5): Figure Number

(6): Identification of parts to be removed, unhooked, unlocked, released, unplugged, unclamped, or desoldered.

(3): Name of the part

(4): Location of the part: T=Top B=Bottom R=Right L=Left

(5): Figure Number

(6): Identification of parts to be removed, unhooked, unlocked, released, unplugged, unclamped, or desoldered.

P=Spring, W=Washer, C=Cut Washer, S=Screw, *=Unhook, Unlock, Release, Unplug, or Desolder

e.g., 2(L-2) = two Locking Tabs (L-2).

e.g., 2(L-2) = two Locking Tabs (L-2).

(7): Adjustment Information for Installation

(+):Refer to Deck Exploded Views for lubrication.

Click on the first or last page to see other DV-RW360H service manuals if exist.