Sharp CD-MD3000 (serv.man8) Service Manual ▷ View online

CD-MD3000H/CD-MD3000W

– 40 –

C) Tracking setting

Step No.

Setting Method

Display

Step 19

Press the EQUALIZER button.

[S L C T m _ _ _

]

Step 20

Press the EQUALIZER button.

[T C R S C 1 P _

]

Step 21

Press the EQUALIZER button.

[T C R S C 0 h _

]

Step 22

Press the EQUALIZER button.

[T C R S C 0 L _

]

Step 23

Press the EQUALIZER button.

[T C R S C H h _

]

Step 24

Press the EQUALIZER button.

[T C R S C H L _

]

Step 25

Press the EQUALIZER button.

[C O T L V p _ _

]

Step 26

Press the EQUALIZER button.

[C O T L V r _ _

]

Step 27

Press the EQUALIZER button.

[J P i n t _ _ _

]

Step 28

Press the EQUALIZER button.

[K I K 1 0 _ _ _

]

•

: Setting value

D) Sled setting

Step No.

Setting Method

Display

Step 1

Test mode STOP state

[ t s m

e

]

Step 2

Press the EQUALIZER button eight times. [ E E P R O M_ S E T ]

Step 3

Press the TAPE REC button.

[ _ _ F o c u s _ _ _ ]

Step 4

Press the EQUALIZER button three times. [ _ _ _ S l e d _ _ _ ]

Step 5

Press the TAPE REC button.

[S L G _ _ _ _ _

]

Step 6

Press the EQUALIZER button.

[S L 2 _ _ _ _ _

]

Step 7

Press the EQUALIZER button.

[S L D L I M _ _

]

Step 8

Press the EQUALIZER button.

[S L D L E V _ _

]

Step 9

Press the EQUALIZER button.

[S L K L V k _ _

]

Step 10

Press the EQUALIZER button.

[S L K L V t _ _

]

Step 11

Press the EQUALIZER button.

[S L K L V m _ _

]

Step 12

Press the EQUALIZER button.

[S L B K M _ _ _

]

Step 13

Press the EQUALIZER button.

[S L K r i o _ _

]

Step 14

Press the EQUALIZER button.

[S L K r o i _ _

]

Step 15

Press the EQUALIZER button.

[S L K l i o _ _

]

Step 16

Press the EQUALIZER button.

[S L K l o i _ _

]

•

: Setting value

E) TEMP setting

Step No.

Setting Method

Display

Step 1

EJECT state

[ _ _ E J E C T _ _ _ ]

Step 2

Press the X-BASS button.

[ T E M P_

_

]

•

: Setting value,

: Measurement value

F) CONTROL setting

Step No.

Setting Method

Display

Step 1

Test mode STOP state

[ t s m

e

]

Step 2

Press the EQUALIZER button eight times. [ E E P R O M_ S E T ]

Step 3

Press the TAPE REC button.

[ _ _ F o c u s _ _ _ ]

Step 4

Press the EQUALIZER button five times.

[ _ C o n t r o l _ _ ]

Step 5

Press the TAPE REC button.

[C O N T R L 1 _

]

Step 6

Press the EQUALIZER button.

[C O N T R L 2 _

]

Step 7

Press the EQUALIZER button.

[A D J T T M _ _

]

Step 8

Press the EQUALIZER button.

[H D E Q A D _ _

]

Step 9

Press the EQUALIZER button.

[L D E Q A D _ _

]

Step 10

Press the EQUALIZER button.

[G D E Q A D _ _

]

Step 11

Press the EQUALIZER button.

[H D E Q B C _ _

]

Step 12

Press the EQUALIZER button.

[L D E Q B C _ _

]

Step 13

Press the EQUALIZER button.

[G D E Q B C _ _

]

Step 14

Press the EQUALIZER button.

[H A L S G _ _ _

]

Step 15

Press the EQUALIZER button.

[L A L S G _ _ _

]

– 41 –

CD-MD3000H/CD-MD3000W

6. TEST-PLAY mode

Step 1

Test mode STOP state

The AUTO preliminary adjustment should have been completed.

[ t s m e

]

Step 2

Press the X-BASS button.

TEST-PLAY menu

[ T E S T _ P L A Y _ ]

Step 3

Press once the DISP/CHARACTER button. ADDRESS setting (Target address initial value is indicated)

[ A D R E S _ 0 0 3 2 ]

Press once the TAPE REC button.

Step 4

Continuous playback (pit section) (Address + C1 error indication)

[s

c

]

Continuous playback (groove section) (Address + C1 error indication)

[a

c

]

Step 5

Press once the DISP/CHARACTER button. (Address + ADIP error indication)

[a

a

]

Continuous playback (groove section) (HIGH reflection STEP 6)

Step 6

Continuous playback (pit section) Address + Jitter

[s

j

]

Continuous playback (groove section)

[a

j

]

Step 7

Press once the MD STOP button.

TEST-PLAY menu

[ T E S T _ P L A Y _ ]

Step No.

Setting Method

7. TEST-REC mode

Step 1

Test mode STOP state

The AUTO preliminary adjustment should have been completed.

[ t s m e

]

Step 2

Press twice the X-BASS button.

TEST-REC menu

[ T E S T _ R E C _ _ ]

Step 3

Press once the DISP/CHARACTER button. ADDERS setting (indication of address initial value)

[ a 0 0 3 2 _ p w

]

Step 4

Press once the TAPE REC button. Continuous recording

[ a

_ p w

]

Step 5

Press once the MD STOP button. TEST-REC menu

[ T E S T _ R E C _ _ ]

Step No.

Setting Method

Remarks

Display

Remarks

Display

(For confirmation of the playback ability at the named address.)

With recording mini disk (For confirmation of the playback ability at the named address.)

8. INNER mode

Step 1

Test mode STOP state

[ t s m e

]

Step 2

Press the MD PLAY button.

INNER menu

[ _ _ I N N E R _ _ ]

Step 3

Press once the TAPE REC button. INNER switch position measurement

[s

c

]

(SUBQ address and C1 error are also indicated.)

Step 4

Press once the MD STOP button.

INNER menu

[ _ _ I N N E R _ _ ]

Step No.

Setting Method

Remarks

Display

•

: Address

Step No.

Setting Method

Display

Step 16

Press the EQUALIZER button.

[G A L S G _ _ _

]

Step 17

Press the EQUALIZER button.

[H A L S O F S _

]

Step 18

Press the EQUALIZER button.

[L A L S O F S _

]

Step 19

Press the EQUALIZER button.

[G A L S O F S _

]

G) ADJUST setting

Step No.

Setting Method

Display

Step 1

Test mode STOP state

[ t s m

e

]

Step 2

Press the EQUALIZER button eight times. [ E E P R O M_ S E T ]

Step 3

Press the TAPE REC button.

[ _ _ F o c u s _ _ _ ]

Step 4

Press the EQUALIZER button six times.

[A D J S E T _ _ _ _ ]

Step 5

Press the TAPE REC button.

[C O K _ _ _ _ _

]

Step 6

Press the EQUALIZER button.

[F A T _ _ _ _ _

]

Step 7

Press the EQUALIZER button.

[T A T _ _ _ _ _

]

Step 8

Press the EQUALIZER button.

[C A T _ _ _ _ _

]

Step 9

Press the EQUALIZER button.

[F A B _ _ _ _ _

]

Step 10

Press the EQUALIZER button.

[S T R _ _ _ _ _

]

Step 11

Press the EQUALIZER button.

[S F S _ _ _ _ _

]

Step 12

Press the EQUALIZER button.

[S T C _ _ _ _ _

]

•

: Setting value

•

: Setting value

• Whenever the X-BASS button is pressed in the address setting mode, the address changes as follows.

0 0 3 2

0 0 3 2

→

0 3 C 0

→

0 7 0 0

→

0 8 A 0

→

0 9 5 0

→

0 0 3 2

→

…………

• Whenever the X-BASS button is pressed in the address setting mode, the address changes as follows.

0 0 3 2

0 0 3 2

→

0 3 C 0

→

0 7 0 0

→

0 8 A 0

→

0 9 5 0

→

0 0 3 2

→

…………

CD-MD3000H/CD-MD3000W

– 42 –

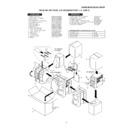

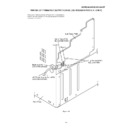

Figure 42-3 Optical Pickup Grating Deviation

Measuring Method

Mechanism Adjustment

1. Optical pickup grating inspecting method

After auto adjustment (COMPLETE appears) in the test mode (auto)

using the high reflection MD disc TGYS1, adjust the Lissajou's

waveform (x-y) of EOUT to FOUT.

1. Slightly loosen the 3 screws of the spindle motor, adjust while

using the high reflection MD disc TGYS1, adjust the Lissajou's

waveform (x-y) of EOUT to FOUT.

1. Slightly loosen the 3 screws of the spindle motor, adjust while

observing the Lissajou's waveform.

2. After adjustment, tighten screws 1, 2, and 3 in numerical order.

(See Fig. 42-4.)

Lead-in switch position measurement mode

Insert the high reflection test disk TGYS1.

Note: Adjust the lead-in switch position within the range of FF85 -

FFD2.

1. Measure the lead-in switch position. Loosen the screw (A1) x 1 pc.

Note: Adjust the lead-in switch position within the range of FF85 -

FFD2.

1. Measure the lead-in switch position. Loosen the screw (A1) x 1 pc.

which fixes the mechanism switch PWB.

2. When the lead-in switch is located FF85 or less, tighten the screw

while pressing the PWB in the direction of the arrow A. When FFD2

or more, to direction B. Measure the lead-in switch position again.

After position adjustment is completed, fix the PWB with the screw

(A1) x 1 pc.(shown in Figure 42-1)

or more, to direction B. Measure the lead-in switch position again.

After position adjustment is completed, fix the PWB with the screw

(A1) x 1 pc.(shown in Figure 42-1)

Figure 42-1

Rotating the loading motor forcibly

The loading motor can be rotated forcibly by rotating the JOG UP/

DOWN knob while STOP or EJECT in the test mode appears on the

display.

DOWN knob while STOP or EJECT in the test mode appears on the

display.

Figure 42-2

Figure 42-4

Magnetic head mounting position check

•

Check the mounting position whenever the magnetic head and the

optical pickup are replaced.

•

Move the optical pickup to the center to adjust the position easily.

1. Set the adjusting transparent disc 3.

2. Press down the magnetic head up shift arm by hand to raise the

2. Press down the magnetic head up shift arm by hand to raise the

magnetic head.

3. View the set from above to check whether the magnetic head aligns

with the optical pickup objective lens.

4. Check that the magnetic head moves up and down smoothly.

(shown in Figure 42-2)

(shown in Figure 42-2)

A

B

(A1) X1

Magnetic head

Objective lens

Radiai

Head up- shift arm

Tangential direction

2

3

1

2

3

1

adjusting

hole

hole

Check the Lissajou's waveform,

shifting the mounting position with

a screwdriver (to be fitted into the

disc motor adjusting hole).

shifting the mounting position with

a screwdriver (to be fitted into the

disc motor adjusting hole).

OSILLOSCOPE

GND CH1

CH2

X

Y

4 Pin of IC1201

GND (TP1202)

11Pin of IC1201

EOUT (TP1253)

12 Pin of IC1201

FIN (TP1253)

100K

470p

470p

a

b

LISSAJOUS'S WAVEFORM

Less than a:b = 4:1

100K

CD-MD3000H/CD-MD3000W

– 42 –

Figure 42-3 Optical Pickup Grating Deviation

Measuring Method

Mechanism Adjustment

1. Optical pickup grating inspecting method

After auto adjustment (COMPLETE appears) in the test mode (auto)

using the high reflection MD disc TGYS1, adjust the Lissajou's

waveform (x-y) of EOUT to FOUT.

1. Slightly loosen the 3 screws of the spindle motor, adjust while

using the high reflection MD disc TGYS1, adjust the Lissajou's

waveform (x-y) of EOUT to FOUT.

1. Slightly loosen the 3 screws of the spindle motor, adjust while

observing the Lissajou's waveform.

2. After adjustment, tighten screws 1, 2, and 3 in numerical order.

(See Fig. 42-4.)

Lead-in switch position measurement mode

Insert the high reflection test disk TGYS1.

Note: Adjust the lead-in switch position within the range of FF85 -

FFD2.

1. Measure the lead-in switch position. Loosen the screw (A1) x 1 pc.

Note: Adjust the lead-in switch position within the range of FF85 -

FFD2.

1. Measure the lead-in switch position. Loosen the screw (A1) x 1 pc.

which fixes the mechanism switch PWB.

2. When the lead-in switch is located FF85 or less, tighten the screw

while pressing the PWB in the direction of the arrow A. When FFD2

or more, to direction B. Measure the lead-in switch position again.

After position adjustment is completed, fix the PWB with the screw

(A1) x 1 pc.(shown in Figure 42-1)

or more, to direction B. Measure the lead-in switch position again.

After position adjustment is completed, fix the PWB with the screw

(A1) x 1 pc.(shown in Figure 42-1)

Figure 42-1

Rotating the loading motor forcibly

The loading motor can be rotated forcibly by rotating the JOG UP/

DOWN knob while STOP or EJECT in the test mode appears on the

display.

DOWN knob while STOP or EJECT in the test mode appears on the

display.

Figure 42-2

Figure 42-4

Magnetic head mounting position check

•

Check the mounting position whenever the magnetic head and the

optical pickup are replaced.

•

Move the optical pickup to the center to adjust the position easily.

1. Set the adjusting transparent disc 3.

2. Press down the magnetic head up shift arm by hand to raise the

2. Press down the magnetic head up shift arm by hand to raise the

magnetic head.

3. View the set from above to check whether the magnetic head aligns

with the optical pickup objective lens.

4. Check that the magnetic head moves up and down smoothly.

(shown in Figure 42-2)

(shown in Figure 42-2)

A

B

(A1) X1

Magnetic head

Objective lens

Radiai

Head up- shift arm

Tangential direction

2

3

1

2

3

1

adjusting

hole

hole

Check the Lissajou's waveform,

shifting the mounting position with

a screwdriver (to be fitted into the

disc motor adjusting hole).

shifting the mounting position with

a screwdriver (to be fitted into the

disc motor adjusting hole).

OSILLOSCOPE

GND CH1

CH2

X

Y

4 Pin of IC1201

GND (TP1202)

11Pin of IC1201

EOUT (TP1253)

12 Pin of IC1201

FIN (TP1253)

100K

470p

470p

a

b

LISSAJOUS'S WAVEFORM

Less than a:b = 4:1

100K