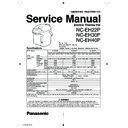

Panasonic NC-EH22P / NC-EH30P / NC-EH40P / NC-EH30PWTW / NC-EH40PWTW Service Manual ▷ View online

࠴ࠚ࠶ࠢࡐࠗࡦ࠻

- 5 -

NC-EH22P, EH30P, EH40P

Check points

Keep warm heater

(between the orange, white

and the yellow.

Thermal fuse comp.

(between the blue

and white)

Boiling heater

(between the orange, white

and red)

Motorized pump

Confi rm motor rotation

sound while power is on,

switch on Unlock pad and

turn on hot water Pour out

pad.

sound while power is on,

switch on Unlock pad and

turn on hot water Pour out

pad.

Lead wire “E” comp.

(0Ω)

Thermistor (complete)

between white

and white :

approx. 20°C,

approx. 45kΩ

Check point-1

2.2. Dismantle procedure for

failure diagnotics

failure diagnotics

Orange

White

Red

Blue

White

Yellow

White

White

Red

Tapping screw

(M4 x 12)

Truss head screw

Bottom plate

Sleeve

Screw B

Waterproof

cover B

cover B

Body

CAUTION

When touching or near the control unit,

discharge static electricity by grounding

the human body, clothes, work table, etc.

through a resister of a few mega ohms.

discharge static electricity by grounding

the human body, clothes, work table, etc.

through a resister of a few mega ohms.

Microcomputer may be damaged by static

electricity.

electricity.

Note

When copper foil pattern on control unit is broken,

do not repair and reuse it.

do not repair and reuse it.

1. Remove 2 Tapping screws and 1 Truss head

screw from Bottom plate.

2. Remove 1 screw and Sleeve from Body.

3. Remove white, orange Lead wire and Earth wire

from Peg frame.

4. Remove Body off.

5. Remove Waterproof cover B.

3. Remove white, orange Lead wire and Earth wire

from Peg frame.

4. Remove Body off.

5. Remove Waterproof cover B.

White

NC-EH22_30_40P.indd 5

NC-EH22_30_40P.indd 5

1/14/08 9:36:19 AM

1/14/08 9:36:19 AM

- 6 -

NC-EH22P, EH30P, EH40P

2.3. Failure Diagnostics Chart

2.3.1. No power. (There is no power indication.)

describe electric power supply.

The items in the “Check” column correspond to those shown in Check Points on P.5.

Check

Diagnostics Method

Action

Thermal fuse comp.

Is there connection between the white lead wire on the peg

frame and the CN3 connector of the control unit A? (0Ω)

frame and the CN3 connector of the control unit A? (0Ω)

Replace the thermal fuse comp.

Keep warm heater

Is there connection across the boiling heater contacts?

(approx. 133Ω)

(approx. 133Ω)

The container comp.

Power cord

Is there connection in the power cord? (0Ω)

Replace the power cord.

Lead wire assy. E comp.

Is there connection in the lead wire assy. E? (0Ω)

Replace the lead wire assy. E.

When the above parts are normal

Replace the control unit A (bottom)

When the above parts are normal

Replace the control unit B (operation)

2.3.2. Water is not boiling. (Water comes out.)

The items in the “Check” column correspond to those shown in Check Points on P.5.

Check

Diagnostics Method

Action

Water Heater

Is there connection between the white lead wire and

the red lead wire? (approx.14Ω)

the red lead wire? (approx.14Ω)

Replace the container comp.

When the above parts are normal

Replace the control unit A (bottom)

When the above parts are normal

Replace the control unit B (operation)

2.3.3. Water does not come out, or water fl ow is restricted. (Water is boiling.)

Check point

Diagnostics Method

Action

Is the fi lter (located at the bottom of container) clogged?

Clean or replace the fi lter.

The items in the “Check” column correspond to those shown in Check Points on P.5.

Check

Diagnostics Method

Action

Electric pump

Turn on the 100V power, and press the Lock/Unlock pad fi rst

and then the Pour out pad. Is the motor heard running?

and then the Pour out pad. Is the motor heard running?

Replace the electric pump.

Lead wire assy. E comp.

Is there a miss-connection in the lead wire assy. E (0Ω)

Replace the lead wire assy. E.

When the above parts are normal

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.4. Reboil and Vacuum Keep Warm lamps illuminate alternately.

(Overheating protection mode/Bottom thermistor disconnection comp. mode)

Check point

Diagnostics Method

Action

Is there water inside?

Supply water and press Reboil pad.

The items in the “Check” column correspond to those shown in Check Points on P.5.

Check

Diagnostics Method

Action

Thermistor comp.

Is there connection between blue lead wire and blue

lead wire? (approx.45Ω at approx. 20°C)

lead wire? (approx.45Ω at approx. 20°C)

Replace the thermistor comp.

Lead wire E comp.

Is there connection in the lead wire assy. E? (0Ω)

Replace lead wire E comp.

When the above parts are normal

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.5. The Select pad does not work

Check

Diagnostics Method

Action

–

–

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.6. The Lock/Unlock pad does not work.

The items in the “Check” column correspond to those shown in Check Points on P.5.

Check

Diagnostics Method

Action

Lead wire E comp.

Is there miss-connection in the lead wire assy E? (0Ω)

Replace lead wire E comp.

When the above parts are normal

Replace the control unit B (bottom)

When the above parts are normal

Replace the control unit A (operation)

2.3.7. Hot water does not dispense smoothly.

(Immediately after being boiled in particular) Boiling is too noisy.

Scale accumulation becomes severe inside the container.

Check

Diagnostics Method

Action

–

–

Clean with citric acid

NC-EH22_30_40P.indd 6

NC-EH22_30_40P.indd 6

1/14/08 9:36:20 AM

1/14/08 9:36:20 AM

ᓮၮ᧼ #㧔ᐩㇱ㧕

ᬺࡐࠗࡦ࠻

⚵┙ᤨߩࡐࠗࡦ࠻

- 7 -

NC-EH22P, EH30P, EH40P

3. Disassembly and reassembly

instructions

Note :

Reassemble in the reverse order of disassembly

referring to “Points on Reassembly”.

3.1. Bottom plate and Body

1. Remove 2 Tapping screws and 1 Truss screw from

Bottom plate.

2.

Remove 1 screw and Sleeve from Body.

3.

Remove white, orange Lead Wire and Earth wire

from Peg frame.

from Peg frame.

4.

Remove Body off.

5. Remove Waterproof cover B.

CAUTION

Be careful of injury from sharp

metal edges when disassembling,

replacement and reassembling.

metal edges when disassembling,

replacement and reassembling.

Wear gloves while working.

3.2. Control unit-A at bottom

CAUTION

When touching or near the control unit,

discharge static electricity by grounding

the human body, clothes, work table, etc.

through a resister of a few mega ohms.

discharge static electricity by grounding

the human body, clothes, work table, etc.

through a resister of a few mega ohms.

Microcomputer may be damaged by static

electricity.

electricity.

Note

When copper foil pattern on control unit is broken,

do not repair and reuse it.

do not repair and reuse it.

1. Remove 3 claws holding waterproof cover B, and

remove it.

2. Remove all the connectors, fastener terminals and

lead wire E comp. at the bottom of Control unit A.

3. Remove the nonfl ammable tube.

Service point

• Remove the fastener terminal stoppers by pulling

them while pressing the part indicated by arrows.

Points for reassembly

• When inserting the lead wire E comp. into control unit

A at bottom, insert it toward the direction shown on

fi gure for Disassembly-2.

fi gure for Disassembly-2.

Tapping screw

(M4 x 12)

Truss head screw

Bottom plate

Sleeve

Screw

Waterproof

cover B

cover B

Body

Waterproof cover

Control unit A

at bottom

at bottom

Nonfl ammable

w Lead wire

comp. (It can be

removed just by

pulling it.)

removed just by

pulling it.)

Non- printed

side

side

DISASSEMBLY-2

DISASSEMBLY-1

NC-EH22_30_40P.indd 7

NC-EH22_30_40P.indd 7

1/14/08 9:36:21 AM

1/14/08 9:36:21 AM

- 8 -

NC-EH22P, EH30P, EH40P

4x8 Deltite screw

Motorized pump

Communicating bushing

Water pipe packing A

Water pipe

comp.

comp.

Container

comp.

comp.

DISASSEMBLY-3

DISASSEMBLY-4

Water pipe comp.

3.5x12 lock head

self-tapping

screws

self-tapping

screws

Case of A comp.

Lead wire E comp.

3.3. Motorized Pump

1. Remove one holding screw for motorized pump.

2. Remove the communicating bushing from the water

2. Remove the communicating bushing from the water

pipe packing A and container comp.

3.4. Water Pipe Comp.

1. Remove water pipe comp.

2. Remove case A comp. after removing 2 screws fi xing

2. Remove case A comp. after removing 2 screws fi xing

case of A comp.

NC-EH22_30_40P.indd 8

NC-EH22_30_40P.indd 8

1/14/08 9:36:23 AM

1/14/08 9:36:23 AM

Click on the first or last page to see other NC-EH22P / NC-EH30P / NC-EH40P / NC-EH30PWTW / NC-EH40PWTW service manuals if exist.