Panasonic CS-TZ50TKEW / CU-TZ50TKE Service Manual ▷ View online

37

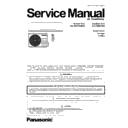

AIR PURGING METHOD IS PROHIBITED FOR R32 SYSTEM

12.3.3 Evacuation of the Equipment

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND

PIPES in the following procedure.

PIPES in the following procedure.

Do not purge the air with refrigerants but use a vacuum pump to vacuum the installation.

There is no extra refrigerant in the outdoor unit for air purging.

OPEN

CLOSE

Gas side

Liquid side

Outdoor unit

Two-way valve

Three-way valve

Indoor unit

Vacuum

pump

pump

Close

Close

1 Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way

valve.

o

Be sure to connect the end of the charging hose with the push pin to the service port.

2 Connect the center hose of the charging set to a vacuum pump.

3 Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from

3 Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from

0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa). Then evacuate the air approximately ten minutes.

4 Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in the

gauge does not move after approximately five minutes.

Note: BE SURE TO TAKE THIS PROCEDURE IN ORDER TO AVOID REFRIGERENT GAS LEAKAGE.

Note: BE SURE TO TAKE THIS PROCEDURE IN ORDER TO AVOID REFRIGERENT GAS LEAKAGE.

5 Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve.

6 Tighten the service port caps of the 3-way valve at a torque of 18 N•m with a torque wrench.

7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “OPEN”

6 Tighten the service port caps of the 3-way valve at a torque of 18 N•m with a torque wrench.

7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “OPEN”

using a hexagonal wrench (4 mm).

8 Mount valve caps onto the 2-way valve and the 3-way valve.

o

Be sure to check for gas leakage.

If gauge needle does not move from 0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa), in step 3 above take the following measure:

-

If the leak stops when the piping connections are tightened further, continue working from step 3.

-

If the leak does not stop when the connections are retightened, repair location of leak.

-

Do not release refrigerant during piping work for installation and reinstallation.

-

Take care of the liquid refrigerant, it may cause frostbite.

38

12.3.4 Connect the Cable to the Outdoor Unit

1 Remove the control board cover from the unit by loosening the screw.

2 Cable connection to the power supply through Isolating Devices (Disconnecting means).

2 Cable connection to the power supply through Isolating Devices (Disconnecting means).

o

Connect approved type polychloroprene sheathed power supply cord 3 x 1.5 mm

2

(3/4 ~ 1.75HP),

3 x 2.5 mm

2

(2.0 ~ 2.5HP) type designation 60245 IEC 57 or heavier cord to the terminal board, and

connect the others end of the cord to Isolating Devices (Disconnecting means).

o

Do not use joint power supply cord. Replace the wire if the existing wire (from concealed wiring, or

otherwise) is too short.

otherwise) is too short.

o

In unavoidable case, joining of power supply cord between isolating devices and terminal board of air

conditioner shall be done by using approved socket and plug with earth pin rated 15/16A (3/4 ~ 1.75HP)

or 16A (2.0HP) or 20A (2.5HP). Wiring work to both socket and plug must follow to national wiring

standard.

conditioner shall be done by using approved socket and plug with earth pin rated 15/16A (3/4 ~ 1.75HP)

or 16A (2.0HP) or 20A (2.5HP). Wiring work to both socket and plug must follow to national wiring

standard.

3 Connection cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed

4 x 1.5 mm

2

flexible cord, type designation 60245 IEC 57 or heavier cord. Do not use joint connection cable.

Replace the wire if the existing wire (from concealed wiring, or otherwise) is too short. Allowable connection

cable length of each indoor unit shall be 30 m or less.

cable length of each indoor unit shall be 30 m or less.

4 Connect the power supply cord and connection cable between indoor unit and outdoor unit according to the

diagram below.

3

2

1

t

i

n

u

r

o

o

d

n

i

e

h

t

n

o

s

l

a

n

i

m

r

e

T

Colour of wires (connection cable)

Terminals on the outdoor unit

L

N

1

2

3

(Power supply cord)

Terminals on the isolating

devices (Disconnecting means)

devices (Disconnecting means)

(L) (N)

5 Secure the power supply cord and connection cable onto the control board with the holder.

6 Attach the control board cover back to the original position with screw.

7 For wire stripping and connection requirement, refer to instruction 12.2.4 of indoor unit.

6 Attach the control board cover back to the original position with screw.

7 For wire stripping and connection requirement, refer to instruction 12.2.4 of indoor unit.

Terminal

Board

Holder

Isolating Devices

Indoor unit

Power

supply

cord

Indoor &

outdoor

connection

cable

Earth wire

longer

than

others

AC wires

for safety

reason

longer

than

others

AC wires

for safety

reason

WARNING

This equipment must be properly earthed.

Note

Isolating Devices (Disconnecting means) should have minimum 3.0 mm contact gap.

Earth wire shall be Yellow/Green (Y/G) in colour and longer than other AC wires for safety reason.

Always ensure all above connections compliant with national wire rules.

39

12.3.5 Piping

Insulation

1 Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2 If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E FOAM with thickness 6 mm or above.

12.3.5.1 Cutting

and

Flaring the Piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end

2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end

down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

When properly fl ared, the internal surface of the

fl are will evenly shine and be of even thickness.

Since the fl are part comes into contact with the

connections, carefully check the fl are fi nish.

fl are will evenly shine and be of even thickness.

Since the fl are part comes into contact with the

connections, carefully check the fl are fi nish.

Improper fl aring

Inclined Surface

damaged

Cracked Uneven

thickness

1. To cut

2. To remove burrs

3. To fl are

Bar

Red arrow mark

Handle

Core

Yoke

Clamp handle

Bar

0 – 0.5 mm

Copper pipe

Reamer

Point down

Pipe

12.3.6 How

to

Take

Out Front Grille

Please follow the steps below to take out front grille if

necessary such as when servicing.

necessary such as when servicing.

1 Set the vertical airflow direction louvers to the

horizontal position.

2 Remove the 2 caps (1/2 ~ 1.75HP) or 3 caps

(2.0 ~ 2.5HP) on the front grille as shown in

the illustration at right, and then remove the

3 (1/2 ~ 1.75HP) or 4 (2.0 ~ 2.5HP) mounting

screws.

the illustration at right, and then remove the

3 (1/2 ~ 1.75HP) or 4 (2.0 ~ 2.5HP) mounting

screws.

3 Pull the lower section of the front grille

towards you to remove the front grille.

When reinstalling the front grille, first set the

vertical airflow direction louver to the horizontal

position and then carry out above steps 2 - 3 in

the reverse order.

vertical airflow direction louver to the horizontal

position and then carry out above steps 2 - 3 in

the reverse order.

Screw

Screw

Vane

Cap

Test pen

Move

the vane

downward

the vane

downward

• Use Test pen to

remove Cap

(only for 2.0HP ~ 2.5HP

model)

Front grille

Front grille

12.3.7 Disposal of Outdoor Unit Drain Water

If a drain elbow is used, the unit should be placed

on a stand which is taller than 3 cm.

If the unit is used in an area where temperature

falls below 0°C for 2 or 3 days in succession, it is

recommended not to use a drain elbow, for the

drain water freezes and the fan will not rotate.

recommended not to use a drain elbow, for the

drain water freezes and the fan will not rotate.

Hose

Install the hose at an angle so that the

water smoothly fl ows out.

water smoothly fl ows out.

Drain elbow

7

12.3.8 Check the Drainage

Open front panel and remove air filters. (Drainage

checking can be carried out without removing the

front grille.)

front grille.)

Pour a glass of water into the drain tray-styrofoam.

Ensure that water flows out from drain hose of the

indoor unit.

Drain tray-styrofoam

40

12.3.9 Evaluation of the Performance

Operate the unit at cooling/heating operation

mode for fifteen minutes or more.

Measure the temperature of the intake and

discharge air.

Ensure the difference between the intake

temperature and the discharge is more than 8°C

during Cooling operation or more than 14°C

during Heating operation.

during Cooling operation or more than 14°C

during Heating operation.

Discharge air

12.3.10 Installation of Air Purifying Filter

1 Open the front panel.

2 Remove the air filters.

3 Put the Air purifying filter into place as shown

2 Remove the air filters.

3 Put the Air purifying filter into place as shown

in illustration at right.

1

3

2

Air fi lter

Air purifying filter

8

Click on the first or last page to see other CS-TZ50TKEW / CU-TZ50TKE service manuals if exist.