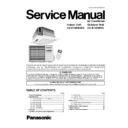

Panasonic CS-E10KB4EA / CU-E10HBEA Service Manual ▷ View online

37

11.3.5.

HEAT INSULATION

1. Use the heat insulation material for the refrigerant piping which has an excellent heat-resistance (over 120

°C).

2. Precautions in high humidity circumstance.

This air conditioner has been tested according to the “JIS Standard Conditions with Mist” and have been confirmed that there

are no faults. However, if it is operated for a long time in high humid atmosphere (dew point temperature: more than 23

are no faults. However, if it is operated for a long time in high humid atmosphere (dew point temperature: more than 23

°C),

water drops are liable to fall. In this case, add heat insulation material according to the following procedure:

• Heat insulation material to be prepared... Adiabatic glass wool with thickness 10 to 20 mm.

• Stick glass wool on all air conditioners that are located in ceiling atmosphere.

• In addition to the normal heat insulation (thickness: more than 8 mm) for refrigerant piping (gas piping: thick piping) and drain

• Stick glass wool on all air conditioners that are located in ceiling atmosphere.

• In addition to the normal heat insulation (thickness: more than 8 mm) for refrigerant piping (gas piping: thick piping) and drain

piping, add a further of 10 mm to 30 mm thickness material.

• When the outdoor unit is installed on a higher position than

the indoor unit, install the trap so as not to instill rain water

into the wall by transmitting in piping.

into the wall by transmitting in piping.

• Stuff the space among piping, the electric wire, and the drain

hose with “Putty” and seal the penetration wall hole.

Make sure that rain water do not instill into the wall.

Make sure that rain water do not instill into the wall.

Be sure to perform heat insulation on the drain, liquid and gas piping. Imperfection in heat insulation work leads

to water leakage.

to water leakage.

Wall seal

38

11.3.6.

CONNECTING THE CABLE TO THE INDOOR

• Remove the mounting screw, remove the control box cover,

and then connect the wires by following the procedure given

in the illustration.

in the illustration.

Earth lead wire shall be longer than other wires as shown in

the figure for the electrical safety in case of the slipping out of

the cord from anchorage.

the figure for the electrical safety in case of the slipping out of

the cord from anchorage.

11.3.6.1. WIRE STRIPPING AND CONNECTING REQUIREMENT

11.3.7.

INSTALLATION OF DECORATIVE PANEL

1. Remove the air inlet grille by moving the catchers to center.

2. Fitting the decorative panel

• Temporarily secure the fixing screws (3 pcs.) before

fitting the decorative panel. (For temporarily securing the

front grille.)

front grille.)

• Place decorative panel on the screws (3 pcs.) before

fitting, move decorative panel as illustrated and tighten

all the screws (4 pcs.).

all the screws (4 pcs.).

The decorative panel has its installation direction. Confirm the direction by displaying the piping side.

39

CAUTION

• Check before hand the height from the ceiling to the unit.

• The front grille fitting direction is determined by the unit

• The front grille fitting direction is determined by the unit

direction.

• Only use the screws with the length of 35mm which is

provided, to fix the decorative panel.

• Do not use other screw which is longer it may cause

damage to the drain-pan and other components.

3. Fit the decorative panel and ceiling wall together and confirm no gap in between. Readjust indoor unit height, if there is a gap

between ceiling wall and decorative panel.

4. Open the indoor control box cover. (2 pcs)

5. Insert firmly the connector of cosmetic louver to indoor

5. Insert firmly the connector of cosmetic louver to indoor

pcb CN-STM1, CN-STM2 and CN-DISP.

Be caution not to clamp the cord in between control board

and control board cover.

Be caution not to clamp the cord in between control board

and control board cover.

6. After complete, install back removed part follow opposite

procedure.

Be sure to hook the air inlet grill string, to prevent

grill from falling and causing injury from it.

grill from falling and causing injury from it.

40

11.4. Outdoor Unit

11.4.1.

SELECT THE BEST LOCATION

(Refer to “Select the best location” section)

(Refer to “Select the best location” section)

11.4.2.

INSTALL THE OUTDOOR UNIT

• After selecting the best location, start installation according

to Indoor/Outdoor Unit Installation Diagram.

1. Fix the unit on concrete or rigid frame firmly and

horizontally by bolt nut. (ø10 mm).

2. When installing at roof, please consider strong wind and

earthquake. Please fasten the installation stand firmly

with bolt or nails.

with bolt or nails.

11.4.3.

CONNECTING THE PIPING

Connect The Piping To Indoor Unit

Please make flare after inserting flare nut (locate at joint portion

of tube assembly) onto the copper pipe. (In case of using long

piping)

Connect the piping

of tube assembly) onto the copper pipe. (In case of using long

piping)

Connect the piping

• Align the center of piping and sufficiently tighten the flare nut

with fingers.

• Further tighten the flare nut with torque wrench in specified

torque as stated in the table.

Connecting The Piping To Outdoor Unit

Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge. Make flare after inserting the flare nut (locate

at valve) onto the copper pipe.

Align center of piping to valves and then tighten with torque wrench to the specified torque as stated in the table.

Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge. Make flare after inserting the flare nut (locate

at valve) onto the copper pipe.

Align center of piping to valves and then tighten with torque wrench to the specified torque as stated in the table.

CUTTING AND FLARING THE PIPING

1. Please cut using pipe cutter and then remove the burrs.

2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused.

2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder entering the pipe.

3. Please make flare after inserting the flare nut onto the copper pipes.

Model

A

B

C

D

E10HBEA

570 mm

105 mm

18.5 mm

320 mm

E15HBEA,

E18HBEA,

E18HBEA,

E21HBEA

612.5 mm

131 mm

19 mm

383 mm

Model

Piping size (Torque)

Gas

Liquid

E10HBEA

3/8” (42 N.m)

1/4” (18 N.m)

E15HBEA, E18HBEA,

E21HBEA

1/2” (55 N.m)

1/4” (18 N.m)

CAUTION

Do not over tighten, over tightening cause gas leakage.

Click on the first or last page to see other CS-E10KB4EA / CU-E10HBEA service manuals if exist.