Panasonic CS-BE25TKE / CS-BE35TKE / CS-BE50TKE / CU-BE25TKE / CU-BE35TKE / CU-BE50TKE (serv.man2) Service Manual ▷ View online

37

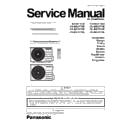

11.2.3 Indoor Unit Installation

11.2.3.1 For the Right Rear Piping

11.2.3.2 For the Right and Right

Bottom Piping

11.2.3.3 For the Embedded Piping

(This can be used for left rear piping and bottom

piping also.)

•

Do not turn over the unit without it’s shock absorber during pull out the piping.

It may cause intake grille damage.

It may cause intake grille damage.

•

Use shock absorber during pull out the piping to protect the intake grille from damage.

Intake grille

Piping

pull ou

t the

pip

in

g

Piping

Shock absorber

pull o

ut t

he

p

ip

in

g

Install the Indoor Unit

Pull out the Indoor piping

Step-2

Secure the Indoor Unit

Insert the power supply cord and connection cable

Step-1

Step-3

Step-4

• Insert the cables from bottom of the unit through the control board hole until

terminal board area.

Install the Indoor Unit

Pull out the Indoor piping

Step-2

Insert the power supply cord and connection cable

Secure the Indoor Unit

Step-1

Step-3

Step-4

• Insert the cables from bottom of the unit through the control board hole until

terminal board area.

terminal board area.

• Use a spring bender or equivalent to bend the piping so that the piping is not

crushed.

crushed.

• When determining the dimensions of the piping, slide the unit all the way to the

left on the installation plate.

left on the installation plate.

• Refer to the section “Cutting and flaring the piping”.

Bend the embedded piping

Cut and flare the embedded piping

Replace the drain hose

Pull the connection cable into Indoor Unit

• The power supply cord and indoor unit and outdoor unit connection cable can

be connected without removing the front grille.

be connected without removing the front grille.

• Please refer to “Connecting the piping” column in outdoor unit section.

(Below steps are done after connecting the outdoor piping and gas-leakage

confirmation.)

(Below steps are done after connecting the outdoor piping and gas-leakage

confirmation.)

Connect the piping

• Please refer to “Insulation of piping connection” column as mentioned in

indoor/outdoor unit installation.

indoor/outdoor unit installation.

Install the Indoor Unit

Secure the Indoor Unit

Insulate and finish the piping

Step-1

Step-2

Step-3

Step-4

Step-5

Step-6

Step-7

Step-8

In case of the cover is cut, keep the cover at the rear

of chassis as shown in the illustration for future

reinstallation.

of chassis as shown in the illustration for future

reinstallation.

(Left, right and 2 bottom covers for piping.)

How to keep the cover

Hook the indoor unit onto the upper

portion of installation plate. (Engage the

indoor unit with the upper edge of the

installation plate). Ensure the hooks are

properly seated on the installation plate

by moving it in left and right.

portion of installation plate. (Engage the

indoor unit with the upper edge of the

installation plate). Ensure the hooks are

properly seated on the installation plate

by moving it in left and right.

Press the lower left and right side of the unit against

the installation plate until hooks engages with their

slot (sound click).

the installation plate until hooks engages with their

slot (sound click).

Right Rear piping

Right and Right Bottom piping

Install the indoor unit

Secure the Indoor Unit

Insert the connection cable

Cover for the

bottom piping

bottom piping

Cover for the

bottom piping

bottom piping

Tape it with piping in a

position as mentioned

in Fig. below.

Cover for

the right

piping

the right

piping

Piping

Drain

hose

hose

Cover for

the left

piping

the left

piping

Cover for

the bottom

piping

the bottom

piping

Tape it with piping in a

position as mentioned

in Fig. below.

Cover for

the right

piping

the right

piping

Piping

Drain hose

Cover for

the left

piping

the left

piping

Drain hose

Sleeve for piping hole

Indoor unit

Hooks at installation

plate

plate

Piping

Cover for piping

Guide

surface

surface

Connection cable

About

70 – 80 mm

Connection cable

Gas side piping

Liquid side piping

Drain hose

Installation

plate

plate

Unit’s hook

To take out the unit, push the marking at the bottom

unit, and pull it slightly towards you to disengage the hooks

from the unit.

unit, and pull it slightly towards you to disengage the hooks

from the unit.

g

n

i

k

r

a

m

38

11.2.4 Connect the Cable to the Indoor Unit

The power supply cord, indoor and outdoor unit connection cable can be connected without removing the front grille.

1 Install the indoor unit on the installing holder that mounted on the wall.

2 Open the front panel and grille door by loosening the screw.

3 Cable connection to the power supply through Isolating Devices (Disconnecting means).

2 Open the front panel and grille door by loosening the screw.

3 Cable connection to the power supply through Isolating Devices (Disconnecting means).

o

Connect approved type polychloroprene sheathed power supply cord 3 x 1.5 mm

2

(3/4 ~ 1.5HP) or 3 x

2.5 mm

2

(2.0HP) type designation 60245 IEC 57 or heavier cord to the terminal board, and connect the

others end of the cord to Isolating Devices (Disconnecting means).

o

Do not use joint power supply cord. Replace the wire if the existing wire (from concealed wiring, or

otherwise) is too short.

otherwise) is too short.

o

In unavoidable case, joining of power supply cord between isolating devices and terminal board of air

conditioner shall be done by using approved socket and plug with earth pin rated 15/16A (3/4 ~ 1.5HP)

or 16A (2.0HP). Wiring work to both socket and plug must follow to national wiring standard.

conditioner shall be done by using approved socket and plug with earth pin rated 15/16A (3/4 ~ 1.5HP)

or 16A (2.0HP). Wiring work to both socket and plug must follow to national wiring standard.

4 Bind all the power supply cord lead wire with tape and route the power supply cord via the left escapement.

5 Connection cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed

5 Connection cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed

4 x 1.5 mm

2

(3/4 ~ 1.5HP) or 4 x 2.5 mm

2

(2.0HP) flexible cord, type designation 60245 IEC 57 or heavier

cord. Do not use joint connection cable. Replace the wire if the existing wire (from concealed wiring, or

otherwise) is too short. Allowable connection cable length of each indoor unit shall be 30 mm or less.

otherwise) is too short. Allowable connection cable length of each indoor unit shall be 30 mm or less.

6 Bind all the indoor and outdoor connection cable with tape and route the connection cable via the right

escapement.

•

How to pull the piping and drain hose out, in case of the

embedded piping.

embedded piping.

•

In case of left piping how to insert the

connection cable and drain hose.

connection cable and drain hose.

Rear view for left piping installation

Drain cap

Drain hose

Adjust the piping slightly

downwards.

downwards.

Drain hose

Connection cable

PVC tube

for drain

hose

for drain

hose

Indoor unit

100 mm

Piping

Cable

Apply putty or

caulking material

to seal the wall

opening.

caulking material

to seal the wall

opening.

Connection cable

Piping

More than

470 mm

More than

950 mm

PVC tube (VP-65) for piping

and connection cable

and connection cable

PVC tube for drain hose (VP-30)

PVC tube for drain

hose (VP-20)

hose (VP-20)

More than 700 mm

Drain hose

from main unit

from main unit

Exchange the drain hose and cap

Cable

45°

Drain

hose

hose

Piping

Sleeve for piping hole

Drain hose

Piping

Connection cable

More than 950 mm

(For the right piping, follow the same procedure)

39

7 Remove the tapes and connect the power supply cord and connection cable between indoor unit and outdoor

unit according to the diagram below.

8 Secure the power supply cord and connection cable onto the control board with the holder.

9 Close grille door by tighten with screw and close the front panel.

9 Close grille door by tighten with screw and close the front panel.

Note:

Isolating Devices (Disconnecting means) should have minimum 3.0 mm contact gap.

Ensure the colour of wires of outdoor unit and the terminal Nos. are the same to the indoor’s respectively.

Earth wire shall be Yellow/Green (Y/G) in colour and longer than other AC wires as shown in the figure for the

electrical safety in case of the slipping out of the cord from the anchorage.

11.2.4.1 Wire Stripping and Connecting Requirement

3

2

1

t

i

n

u

r

o

o

d

t

u

o

e

h

t

n

o

s

l

a

n

i

m

r

e

T

Colour of wires (connection cable)

Terminals on the indoor unit

L

N

1

2

3

(Power supply cord)

Terminals on the isolating devices

(Disconnecting means)

(Disconnecting means)

(L) (N)

Recommended

length (mm)

length (mm)

a b

c

d e

f

g

55 35 35 50 40 35 60

WARNING

This equipment must

be properly earthed.

Recommended

length (mm)

Tape

Connection cable

Tape

Power supply cord

Terminal Board

Control

Board

Earth wire

longer than

others

AC wires

for safety

reason

longer than

others

AC wires

for safety

reason

Holder

Holder

Indoor & outdoor

connection cable

connection cable

Isolating Devices

Outdoor unit

Power supply

cord

OR

OR

OR

Do not joint wires

Use complete wire without joining.

Use approved socket and plug with earth pin.

Wire connection in this area must follow to national wiring rules.

Conductor

over inserted

Wire stripping

No loose strand

when inserted

when inserted

10 ± 1 mm

Conductor

fully inserted

PROHIBITED

Conductor not

fully inserted

PROHIBITED

ACCEPT

Indoor/outdoor

connection

terminal board

connection

terminal board

5 mm or more

(gap between wires)

WARNING

RISK OF FIRE

JOINING OF WIRES

MAY CAUSE

OVERHEATING AND

FIRE.

JOINING OF WIRES

MAY CAUSE

OVERHEATING AND

FIRE.

40

11.3 Outdoor Unit

11.3.1 Install the Outdoor Unit

After selecting the best location, start installation to Indoor/Outdoor Unit Installation Diagram.

1 Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø10 mm).

2 When installing at roof, please consider strong wind and earthquake.

2 When installing at roof, please consider strong wind and earthquake.

Please fasten the installation stand firmly with bolt, screws or nails.

Model A

B

C

D

BE20***

KE25***, BE25***, DE25***

KE35***, BE35***, DE35***

KE25***, BE25***, DE25***

KE35***, BE35***, DE35***

570 mm 105 mm 18.5 mm 320 mm

KE50***, BE50***, DE50*** 540 mm 160 mm 18.5 mm 330 mm

11.3.2 Connect the Piping

11.3.2.1 Connecting

the Piping to Indoor

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

Align the center of piping and sufficiently tighten

the flare nut with fingers.

Further tighten the flare nut with torque wrench in

specified torque as stated in the table.

Do not overtighten, overtightening may cause gas leakage.

Piping size

Torque

6.35 mm (1/4")

[18 N•m (1.8 kgf•m)]

9.52 mm (3/8")

[42 N•m (4.3 kgf•m)]

12.7 mm (1/2")

[55 N•m (5.6 kgf•m)]

15.88 mm (5/8")

[65 N•m (6.6 kgf•m)]

19.05 mm (3/4")

[100 N•m (10.2 kgf•m)]

11.3.2.2 Connecting

the

Piping to Outdoor

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe.

Align center of piping to valve and then tighten with

torque wrench to the specified torque as stated in the

table.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe.

Align center of piping to valve and then tighten with

torque wrench to the specified torque as stated in the

table.

A

B

C

D

Torque

wrench

wrench

Spanner or

Wrench

Wrench

Click on the first or last page to see other CS-BE25TKE / CS-BE35TKE / CS-BE50TKE / CU-BE25TKE / CU-BE35TKE / CU-BE50TKE (serv.man2) service manuals if exist.