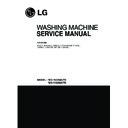

LG WD-16223FD / WD-16226FD Service Manual ▷ View online

* Water Supply : W·S * Intermittent Spin : I·S * Disentangle : D·T

* Basic Cycle

* Optional Cycle

* Pre-Setting Time : Water Supply - 120 sec. * Basic time is minute in washing chart

* Optional Cycle

* Pre-Setting Time : Water Supply - 120 sec. * Basic time is minute in washing chart

Drain - 60 sec.

* The actual program time can be varied with the load amount,

* ~ Time for varies as the temperature or the amount of laundry water temperature or ambient tempe rature

Washing

Rinse

Spin

W

·

S

Pre

Main

Washing

Drain

I

·

·

S

W

·

S

Rinsing

Washing

Staycooling

Heating

Washing

Drain

W

·

S

1

2

3

7

6

5

4

9

8

10

Normal

Drain

I

·

S

11

12

1

W

·

S

Rinsing

13

14

Drain

I

·

S

15

16

2

W

·

S

Rinsing

17

18

Drain

I

·

S

19

20

W

·

S

Rinsing

21

22

Drain

I

·

S

23

24

W

·

S

Rinsing

25

26

Rinse +

Drain

Spin

D·

T

T

A

U

T

O

O

O

F

F

F

3

4

27

28

29

20

E

N

D

D

20

Cotton

(BIG)

Normal

Working

Time

(Hour:Minute)

About 2:45

120 MIN 60

MIN

120

240

60

120

60

60 240 120 360 60 240 120 360 60 240 120 360 60 240 120 360 60 480 120 20

20

C

Y

C

L

E

S

T

E

P

C

O

U

R

O

U

R

S

E

E

Time

(SEC)

8

42

~

87

Synthetic

Delicate

Wool/Silk

About 1:03

About 1:01

About 1:39

4

18

Drain

About 1

Rinsing

+ Spin

About 27(24)

4

18

26

~

51

Handwash

About 55

4

24

Quick

About 30

Cotton

(Small)

About 2:41

8

42

~

47

12

6. WIRING DIAGRAM

/

PROGRAM CHART

MAIN PWB(DD)

MAIN PWB(DD)

DISPLAY

DISPLAY

PWB

PWB

PWB

: TERMINAL+ HOUSING (#250)

: TERMINAL+ HOUSING (#250)

: TERMINAL (#250)

: TERMINAL (#250)

PRESSURE

PRESSURE

SENSOR

SENSOR

THERMISTOR

THERMISTOR

(S)

(S)

(S)

(S)

(G)

(G)

DOOR LOCK S/W

DOOR LOCK S/W

HEATER

HEATER

WIRE COLOR : BASE/LINE

WIRE COLOR : BASE/LINE

: EARTH TERMINAL

: EARTH TERMINAL

: "n" PIN CONNECTOR

: "n" PIN CONNECTOR

n

n

+

+

HbHb

HaHa

GNDGND

Motor

Motor

WH

WH

2

2

2

2

1

1

1

1

NA

NA

WH

WH

BL

BL

1

1 2

2

1

1 2

2

3

3

3

3

WH

WH

VL

VL WH

WH

WH

WH

BL

BL

OR

OR

WH

WH

2

2

2

2

3

3

3

3

W

W

1

1

1

1

V

V U

U

5

5

5

5

4

4

4

4

3

3

3

3

2

2

2

2

1

1

1

1

YL

YL

RD

RD BL

BL

GY

GY

BL

BL

RD

RD

WH

WH

2

2

NA

NA

2

2

1

1

1

1

1

4

4

3

3

4

4

3

3

1

1

3

3

2

2

RD

RD

1

1

3

3

2

2

5

5

5

5

5

NA

NA

3

3

2

2

1

1

2

2

3

3

1

1

4

4

4

4

4

CIRCULATION

CIRCULATION

3

3

2

2

1

1

INLET VALVE

INLET VALVE

1

1

P

P

E

E

R

R

2

2

1

1

2

2

M

M

II

A

A

N

N

PTC

PTC

PUMP

PUMP

DRAIN

DRAIN

PUMP

PUMP

3

3

BK

BK

1

1

2

2

2

2

BK

BK

1

1

2

2

1

1

WH

WH

GY

GY

BK

BK

WH

WHSBL

SBL

BK

BK

WH

WH

BK

BK

YL

YL

BN

BN

RD

RD

YL

YL

BK

BK

1

1

RD

RD

1

1

NA

NA

RD

RD

POWER

POWER

CORD

CORD

CORD

GN/YL

GN/YL

WH

WH

WASHING

WASHING

GN

GN

FUSEFUSE

FUSEFUSE

YL

YL

RD

RD

YL

YL

YL

YL

GN

GN

BL

BL

BL

BL

BN

BN

BN

BN

RD

RD

NA

NA

1

1

2

2

6

6

1

1

2

2

6

6

3

3

4

4

3

3

4

4

1

1

3

3

BL

BL

2

2

1

1

3

3

2

2

RD

RD

2

2

1

1

2

2

1

1

3

3

3

3

WH

WH

3

3

2

2

1

1

3

3

2

2

1

1

3

3

2

2

1

1

3

3

2

2

1

1

3

3

2

2

1

1

3

3

2

2

1

1

※ ( ) : WD-14223FD/WD-14226FD

13

7. TROUBLESHOOTING

7-1.BEFORE PERFORMING SERVICE

■ Be careful of electric shock or disconnecting the parts while troubleshooting.

■ Voltage of each terminal in 220-240V~ and DC while applying an electric current.

■ Voltage of each terminal in 220-240V~ and DC while applying an electric current.

7-2.QC TEST MODE.

①

① Pressing Option1, and Spin button simultaneously.

②

②

② Power supply on with pressing upper two button.Then buzzer sound twice.

③

③

③ Press the Start/Pause button as follows.

~Press the Start/Pause button more 4 times until stop spinning₩

7-3.HOW TO KNOW THE WATER LEVEL FREQUENCY

Press the Rinse and Spin button simultaneously.

ex) 241 : Water level frequency = 241

× 10-1㎑

=24.1

㎑

The digits means water level frequency (10

-1

㎑

)

Pressing number of

[Start/Pause]button

Checking Point

Display Status

None

All lamps turn on

1 time

Clockwise spin (right)

Drum rpm (About 40~50)

2 times

Low speed Spin

Drum rpm (About 53~65)

3 times

High speed Spin

Drum rpm (About 140~160)

4 times

Inlet valve for prewash operation

Water level frequency (25~65)

5 times

Inlet valve for mainwash operation

Water level frequency (25~65)

Hot inlet valve in case of hot water fill

6 times

Inlet valve for mainwash operation

Water level frequency (25~65)

7 times

Counterclockwise spin (left)

Drum rpm (About 40~50)

8 times

Heater is in operation for 3 sec.

Water temperature

9 times

Circulation pump operation

Water level frequency

10 times

Draining pump operation

Water level frequency

11 times

Auto off operation

14

ERROR SYMPTOM

CAUSE

1

WATER INLET

ERROR

Load is too small.

2

IMBALANCE

The appliance is tilted.

ERROR

Laundry is gathered to one side.

Non-distributable things are put into the drum.

3

DRAIN ERROR

Water has not drained enough within 10 min.

4

OVERFLOW

Water is automatically being pumped out because too much

ERROR

water is in the tub.

5

SENSOR

PRESSURE

The sensor pressure switch is out of order.

S/W ERROR

6

DOOR OPEN

The

Start/Pause

button is pressed with the door open.

ERROR

The door switch is out of order.

7

HEATING

ERROR

The THERMISTOR is out of order.

7-4.ERROR DISPLAY.

If you press the Start/Pause button when an error in displayed, any error except will disappear and

the machine will change into pause status.

In case of

,

,

, if the error is not resolved within 20 sec. In the case of other errors,

if the error is not resolved within 4 min., power will be turned off automatically and the error only will be

blinked. But in the case of

blinked. But in the case of

, power will not be turned off.

Water has not reached to the pre-set level within 4

min. since inlet valve operated, or water has not

reached to the normal level within 25 min.

If water leakage occured in the inlet hose, indicator

“

min. since inlet valve operated, or water has not

reached to the normal level within 25 min.

If water leakage occured in the inlet hose, indicator

“

” will be changed red color.

15

ERROR

SYMPTOM CAUSE

8

9

10

• MAIN PWB ASSEMBLY is out of order

Replace the MAIN PWB ASSEMBLY

• Winding in the STATOR ASSEMBLY is short-circuited.

Replace the STATOR ASSEMBLY

• The connector (3-pin, male, white) in the LEAD WIRE ASSEMBLY

is not connected to the connector (3-pin, female, white) of

STATOR ASSEMBLY.

Reconnect or repair the connector

• The electric contact between the connectors

~3-pin, male, white in

the LEAD WIRE ASSEMBLY and 4-pin, female, natural in the

MAIN PWB ASSEMBLY is bad or unstable.

Reconnect or repair the contact in the connector

• The LEAD WIRE ASSEMBLY between the STATOR ASSEMBLY

and MAIN PWB ASSEMBLY is cut (open circuited).

Repair the damaged (open-circuited) the LEAD WIRE

ASSEMBLY

• The hall sensor is out of order/defective.

Replace the STATOR ASSEMBLY

• Water leaks.

CURRENT

ERROR

LOCK

ERROR

AQUA

LOCK

Click on the first or last page to see other WD-16223FD / WD-16226FD service manuals if exist.