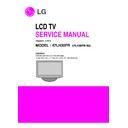

LG 47LH30FR (CHASSIS:LP91A) Service Manual ▷ View online

C

2009

- 13 -

ADJUSTMENT INSTRUCTION

1. Application Range

This specification sheet is applied to all of the 47”/55” LCD

TV, LP91A/B/C/D chassis.

TV, LP91A/B/C/D chassis.

2. Specification

1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

transformer will help protect test instrument.

2) Adjustment must be done in the correct order.

3) The adjustment must be performed in the circumstance of

3) The adjustment must be performed in the circumstance of

25 ±5 °C of temperature and 65±10% of relative humidity if

there is no specific designation.

there is no specific designation.

4) The input voltage of the receiver must keep 100~220V,

50/60Hz.

5) Before adjustment, execute Heat-Run for 5 minutes at RF

no signal.

3. Adjustment items

3.1. PCB assembly adjustment items

1) Download the MSTAR main software

(IC800, Mstar ISP Utility)

(1) Using D/L Jig (2) Using USB Memory Stick.

2) ADC Calibration – RGB / Component

3) Input Tool-Option/Area option.

4) Check SW Version.

3) Input Tool-Option/Area option.

4) Check SW Version.

3.2. SET assembly adjustment items

1) Adjustment of White Balance : Auto & Manual

2) Intelligent Sensor Inspection Guide

3) Preset CH information

4) Factoring Option Data input.

2) Intelligent Sensor Inspection Guide

3) Preset CH information

4) Factoring Option Data input.

4. PCB assembly adjustment method

4.1. Mstar Main S/W program download

4.1.1. Using D/L Jig

4.1.1.1. Preliminary steps

(1) Connect the download jig to D-sub(RGB) jack

(1) Connect the download jig to D-sub(RGB) jack

4.1.1.2. Download steps

(1) Execute ‘ISP Tool’ program, the main window(Mstar ISP

utility Vx.x.x) will be opened

(2) Click the “Connect” button and confirm “Dialog Box”

(3) Click the “Config.” button and Change speed I2C Speed

setting : 350Khz~400Khz

(4) Read and write bin file.

Click “(1)Read” tab, and then load download file(XXXX.bin)

by clicking “Read”.

by clicking “Read”.

L1

Filexxx.bin

L1

Filexxx.bin

Filexxx.bin

(5) Click “(2)Auto” tab and set as below

(6) Click “(3)Run”.

(7) After downloading, you can see the “(4)Pass” message.

(6) Click “(3)Run”.

(7) After downloading, you can see the “(4)Pass” message.

4.1.2. Using the Memory Stick

* Caution

Using ‘power on’ button of the control R/C, power on TV.

USB file (EPK) version must be bigger than downloaded

version of main B/D.

1) Insert the USB memory stick to the SET.

2) Power on the TV by using ‘power on’ button of the control R/C.

3) S/W download process is executed automatically

USB file (EPK) version must be bigger than downloaded

version of main B/D.

1) Insert the USB memory stick to the SET.

2) Power on the TV by using ‘power on’ button of the control R/C.

3) S/W download process is executed automatically

4.2. EDID D/L method

4.2.1. Manual Method

1) Press the ADJ key

2) Move to the EDID D/L and Press the right direction key(¢∫)

3) Press the right direction key(¢∫) at Start.

4) After about a few seconds, appear “OK”, then compele.

2) Move to the EDID D/L and Press the right direction key(¢∫)

3) Press the right direction key(¢∫) at Start.

4) After about a few seconds, appear “OK”, then compele.

4.2.2. RS-232C command Method

1) Command : AE 00 10

* Caution : Don’t connect HDMI and RGB(D-SUB) cable when

downloading the EDID. If the cables are connected,

Downloading of edid could be failed.

Downloading of edid could be failed.

4.2.3. EDID data

1. 10BIT FHD MODEL(47/55 inch FHD)

<Analog(RGB): 128bytes>

1. 10BIT FHD MODEL(47/55 inch FHD)

<Analog(RGB): 128bytes>

<HDMI 1 : 256Bytes>

<HDMI 2 : 256Bytes>

<HDMI 3 : 256Bytes>

- 14 -

C

2009

\1

Filexxx.bin

4.3 ADC Calibration

4.3.1. RGB (Using External pattern)

* Caution: Do not connect external input cable

* Caution: Adjustment result is applied after SET Off/On.

* Caution: Adjustment result is applied after SET Off/On.

4.3.1.1. Process

1) Change the Input to RGB mode.

2) Input the PC 1024x768@60Hz Horizontal Color Bar

2) Input the PC 1024x768@60Hz Horizontal Color Bar

signal into RGB.

(MSPG-925F Model: 60 / Pattern: 65 )

3) Press ADJ key on R/C for adjustment.

4) Enter Password number. Password is “0 0 0 0”.

5) Select “0. ADC calibration : RGB” by using

4) Enter Password number. Password is “0 0 0 0”.

5) Select “0. ADC calibration : RGB” by using

/

(CH +/-

) and press ENTER(

).

6) ADC adjustment is executed automatically .

7) When ADC adjustment is finished, this OSD appear”OK”

7) When ADC adjustment is finished, this OSD appear”OK”

4.3.2. Component (Using External pattern)

* Required Equipments

• Remote controller for adjustment

• MSPG-925F/MSPG-1025/MSPG-3233 Pattern Generator

• Remote controller for adjustment

• MSPG-925F/MSPG-1025/MSPG-3233 Pattern Generator

4.3.2.1. Process

1) Change the Input to Component1 or 2 mode..

2) Input the Component 480i@60Hz 100% Color Bar YPbPr

2) Input the Component 480i@60Hz 100% Color Bar YPbPr

signal into Component1 or 2.

(MSPG-925F Model: 209 / Pattern: 65 )

3) Press ADJ key on R/C for adjustment.

4) Enter Password number. Password is “0 0 0 0”.

5) Select “0. ADC calibration : Component” by using

4) Enter Password number. Password is “0 0 0 0”.

5) Select “0. ADC calibration : Component” by using

/

(CH +/-) and press ENTER(

).

6) ADC adjustment is executed automatically .

7) When ADC adjustment is finished, this OSD appear”OK”

7) When ADC adjustment is finished, this OSD appear”OK”

4.4. Input Tool-Option, Area Option.

** TOOL Option, Area Option change and AC OFF

Before PCBA check, you have to change the Tool option,

Area option and have to AC off/on (Plug out and in)

(If missing this process, set can operate abnormally)

Before PCBA check, you have to change the Tool option,

Area option and have to AC off/on (Plug out and in)

(If missing this process, set can operate abnormally)

4.4.1. Profile : Must be changed the option value because being

different with some setting value depend on module maker,

inch and market

inch and market

4.4.2. Equipment : adjustment remote control.

4.4.3. Adjustment method

4.4.3. Adjustment method

The input methods are same as other chassis.(Use IN-START

Key on the Adjust Remocon.)

(If not changed the option, the input menu can differ the

model spec.)

*Refer to Job Expression of each main chassis

Key on the Adjust Remocon.)

(If not changed the option, the input menu can differ the

model spec.)

*Refer to Job Expression of each main chassis

ass’y(EBTxxxxxxxx) for Option value

**Never push the IN-STOP KEY after completing the function

inspection.

4.5. Check SW Version

4.5.1. Method

(1) Push In-star key on Adjust remote-controller.

(2) SW Version Check.

(2) SW Version Check.

SW VER : V3.xx

– LH50

SW VER : V3.xx

Bluetooth 3.xx

Bluetooth 3.xx

– LH70

- 15 -

C

2009

SHOP Mode : auto home

ADC CAL.

RGB : OK

Component SD : OK

Component SD : OK

ADC CAL.

RGB : OK

Component SD : OK

Component SD : OK

Tool Option1 ``

39848

Tool Option2 ````

51

Area Option ````

1

OPTION1 `````

43

OPTION2 `````

46

OPTION3 `````

0

OPTION4 `````

0

System Control

Audio Prescale

Threshold

Power Off History

Panel Control

Davinci / Auto Test

Audio Prescale

Threshold

Power Off History

Panel Control

Davinci / Auto Test

LP91A ```

LPL ` L42FHD

S/W ` Ver 3.XX

UTT ``

UTT ``

97 ``

00 HDCP 0

SHOP Mode : auto home

ADC CAL.

RGB : `

ADC CAL.

RGB : `

OK

Component SD : OK

Component SD : OK

Component SD : OK

Tool Option1 ``

39848

Tool Option2 ````

51

Area Option ````

1

OPTION1 `````

43

OPTION2 `````

46

OPTION3 `````

0

OPTION4 `````

0

System Control

Audio Prescale

Threshold

Power Off History

Panel Control

Davinci / Auto Test

Audio Prescale

Threshold

Power Off History

Panel Control

Davinci / Auto Test

LP91A ```

LPL ` L42FHD

S/W ` Ver 3.XX ``

Bluetoth 3.xx

UTT ``

97 ``

00 HDCP 0

C

2009

- 16 -

TROUBLESHOOTING

Check P307 Connector.

Fail

Check short of Main B/ D

or Change Power B/ D

Pass

CHECK

24V,12V,5V,2V of

Power B/D

Check Output of

IC1001, IC1003,

IC1001, IC1003,

IC1007

Pass

1. NO POWER (LED INDICATOR OFF) : [A] Process

Fail

Fail

Change LED Assy.

Check LED Assy.

Pass

Re-soldering of Change

defect part of IC1001,

IC1003, IC1007

Check short of IC1001,

IC1003, IC1007

Pass

Change IC1002, IC1003

Fail

Click on the first or last page to see other 47LH30FR (CHASSIS:LP91A) service manuals if exist.