Sony KLV-32V200A / KLV-40V200A / KLV-46V200A (serv.man3) Service Manual ▷ View online

– 20 –

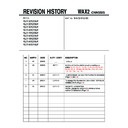

KLV-32V200A/40V200A/46V200A

RM-GA005

AD-Adjust RF Spec

Spec.

Reference register name

S-REG: APL_LUMA

TARGET_Y_RF±2

i+

5

+

(DIGIT 5)

(ON SCREEN

(TV)

VOLUME +)

DISPLAY)

Screen Size

32"

40"

46"

TARGET_Y_RF(PAL)

165

165

165

ADJ_COLOR_Y_ATT(PAL)

128

128

128

ADJ_COLOR_PAL(PAL)

4

4

4

0

1

2

3

4

5

6

7

SECTION 2

SERVICE ADJUSTMENTS

2-1. How to enter Service Mode

Service adjustments to this model can be performed using the supplied

remote Commander RM-GA005.

remote Commander RM-GA005.

1. Turn on the power to the TV set and enter into the stand-by

mode.

2. Press the following sequence of buttons on the Remote

Commander.

3. The following menu will then appear on the screen.

4. Move to the relevant command using the up or down arrow

buttons on the remote commander.

5. Press the right arrow button to enter into the required menu

item.

6. Press the ‘Menu’ button on the remote commander to quit the

Service Mode when all adjustments have been completed.

Note :

• After carrying out the service adjustments, to prevent the

• After carrying out the service adjustments, to prevent the

customer accessing the ‘Service Menu’ switch the TV set

OFF and then ON.

OFF and then ON.

Caution : Aging mode.

1) Aging setting

1) Aging setting

a) Set no signal and monitor as aging mode.

2) Aging condition

a) Aging condition before white balance as follows

Supply volt : Rating

Times : 20 minutes or over (aging Timer registor setting)

Ambient time : 22

Supply volt : Rating

Times : 20 minutes or over (aging Timer registor setting)

Ambient time : 22

°C ~ 28°C

Brightness : Set by aging mode.

[Led lighting pattern during aging]

Aging Timer > 0

Green (0.5sec)

[Led lighting pattern during aging]

Aging Timer > 0

Green (0.5sec)

➔ off (0.5sec) ➔ Green (0.5 sec) ➔ off (0.5sec)

Aging Timer = 0

Green (3.0sec)

Green (3.0sec)

➔ off (3.0 sec)➔ Green (3.0 sec) ➔ off (3.0sec)

Note:

If power off instantansously between aging and W/B adjustment, do

aging 30 seconds or more then adjust W/B.

If power off instantansously between aging and W/B adjustment, do

aging 30 seconds or more then adjust W/B.

2-2. Signal Level Adjustment

2-2-1. Set up of AD calibration 1 adjustment for

terrestrial analog.

The following adjustments are done via ECS.

1. Send ECS_ADJUST_LEVEL_SETING_INIT command.

2. Ensure noise reduction NR=3 (HIGH), GAMMA_EN=0,

2. Ensure noise reduction NR=3 (HIGH), GAMMA_EN=0,

P4_CVD2_85=0.

3. Set the following registration items.

2-2-2. Y signal calibration 1 adjustment for

terrestrial analog.

1. Input PAL colour bar 75%Y, 75%C via terrestrial input.

2. Send ECS_ADJUST_TCD3_CONT_RF command.

3. Read the value of S_REG:APL:LUMA via ECS. Confirming that

3. Read the value of S_REG:APL:LUMA via ECS. Confirming that

the value is within spec of the table below.

2-2-3. Set up of C signal calibration 1 adjustment

for terrestrial analog.

1. Input PAL colour bar 75%Y, 75%C via terrestrial input.

2. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

3. Ensure noise reduction NR=3 (High). GAMMA_EN=0,

2. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

3. Ensure noise reduction NR=3 (High). GAMMA_EN=0,

P4_CVD2_85_0

– 21 –

KLV-32V200A/40V200A/46V200A

RM-GA005

2-2-4. C signal calibration1 adjustment for

terrestrial analog.

1. Send ECS_ADJUST_TCD3_HUE_RF command.

2. Read S-REG: READ_BACK_B00 via ECS. (READ_AREA=0).

3. Read S-REG: READ_BACK_B01 via ECS. (READ_AREA=6).

4. Confirm that 8 bits of MSB of item number 2) and 3) are within

spec of the table below.

Reference Item

Spec.

READ_BACK_B0*difference value

±2

2-2-5. Set up of AD calibration1 adjustment for

P A L _ v i d e o .

1. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

2. Ensure noise reduction NR=1 (Low), GAMMA_EN=0,

P4_CVD2_85=0.

3. Set the following registration items.

2-2-6. Y signal calibration1 adjustment for video.

1. Input PAL colour bar 75%Y, 75%C via AV1 input.

2. Send ECS_ADJUST_TCD3_CONT_V command.

3. Read the value of S-REG:APL_LUMA via ECS. Confirming that

the value is within spec of the table below.

AD-Adjust Video Spec

Spec.

Reference register name

S-REG: APL_LUMA

TARGET_Y_V±2

5. Switch the TV set OFF and then ON again to retain adjustment

values.

2-2-7. Set up of C signal calibration1 adjustment

for video.

1. Input PAL colour bar 75%Y, 75%C via AV1 input.

2. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

3. Ensure noise reduction NR=1 (Low), GAMMA_EN=0,

P4_CVD2_85=0.

4. Set the following registration items.

2-2-8. C signal calibration1 adjustment for video.

1. Send ECS_ADJUST_TCD3_HUE_V command.

2. Read S-REG: READ_BACK_B00 via ECS. (READ_AREA=0).

3. Read S-REG: READ_BACK_B01 via ECS. (READ_AREA=6).

4. Confirm that 8 bits of MSB of item number 2) and 3) are within

spec of the table below.

Reference Item

Spec.

READ_BACK_B0*difference value

±2

5. Read S-REG: TCD3_SATURATION via ECS.

6. Switch the TV set OFF and then ON again to retain adjustment

values.

2-2-9. Set up of AD calibration2 adjustment for

N T S C _ v i d e o .

1. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

2. Ensure noise reduction NR=1 (Low), GAMMA_EN=0,

P4_CVD2_85=0.

3. Set the following registration items.

2-2-10.

Y signal calibration2 adjustment for video.

1. Input NTSC colour bar 75%Y , 75%C via AV1 input.

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

Screen Size

32"

40"

46"

TARGET_Y_V(PAL)

165

165

165

ADJ_COLOR_Y_ATT(PAL)

128

128

128

ADJ_COLOR_PAL(PAL)

4

4

4

Screen Size

32"

40"

46"

ADJ_COLOR_Y_ATT(PAL)

128

128

128

ADJ_COLOR_PAL(PAL)

4

4

4

Screen Size

32"

40"

46"

TARGET_Y_V(NTSC)

165

165

165

ADJ_COLOR_Y_ATT(NTSC)

128

128

128

ADJ_COLOR_PAL(NTSC)

1

1

1

– 22 –

KLV-32V200A/40V200A/46V200A

RM-GA005

1. Ensure TEST_PATTEN_ON=1.

2. Ensure TEST_G_LEVEL=204.

3. Ensure TEST_R_LEVEL=0.

4. Ensure TEST_B_LEVEL=0.

5. Measure brightness A.

6. Ensure TEST_G_LEVEL=102.

7. Ensure TEST_R_LEVEL=0.

8. Ensure TEST_B_LEVEL=0.

9. Measure brightness B.

10. Set up G_GAMMA_OFST_01=brightness B/brightness

A*10000. The result is written to G_GAMMA_OFST_01.

11. Send Gamma_Tbl_Search_1 command.

12. Ensure TEST_G_LEVEL=153.

2-3-2. Set up Trident internal SG and brightness

measurement

measurement

13. Ensure TEST_R_LEVEL=0.

14. Ensure TEST_B_LEVEL=0.

15. Measure brightness C.

16. Set up G_GAMMA_OFST_02=brightness C/brightness

A*10000. The result is written to G_GAMMA_OFST_02.

17. Send Gamma_Tbl_Search_2 command.

18. Save set up value in NVM in register G_GAM_IDX_OFST.

* Incase of 26V need reduce 2 from original data.

20IRE

TEST_R_LEVEL

51

TEST_G_LEVEL

51

TEST_B_LEVEL

51

2-4-1. Set up mode for White Balance Adjustment

Send ECS_ADJUST_LEVEL_SETTING_INIT command.

Ensure COL_MATRIX_INDEX=15.

Ensure hreg p1_d_p_26=0 and hreg p1_d_p_28=0.

Ensure DYNAMIC_EN=0.

2-4-2. White Balance of colour temperature "High"

Set up COLOR_TEMP=0.

Set up GAMMA_OFF=15.

R_GAMMA_OFST_01=128

R_GAMMA_OFST_02=128

R_GAMMA_OFST_03=128

R_GAMMA_OFST_04=128

B_GAMMA_OFST_01=128

B_GAMMA_OFST_02=128

B_GAMMA_OFST_03=128

Set up B_GAMMA_OFST_04=128.

4. Set up "Wait".

5. Set up the correct values for 20IRE for TEST_R_LEVEL,

TEST_G_LEVEL and TEST_B_LEVEL.

2. Send ECS_ADJUST_TCD3_CONT_V command.

3. Read the value of S-REG:APL_LUMA via ECS. Confirming that

the value is within spec of the table below.

AD-Adjust Video Spec

Spec.

Reference register name

S-REG: APL_LUMA

TARGET_Y_V±2

2-2-11. Set up of C signal calibration2 adjustment

for video.

1. Input NTSC colour bar 75%Y, 75%C via AV1 input.

2. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

3. Ensure noise reduction NR=1 (Low), GAMMA_EN=0,

P4_CVD2_85=0.

4. Set the following registration items.

2-2-12. C signal calibration2 adjustment for video.

1. Send ECS_ADJUST_TCD3_HUE_V command.

2. Read S-REG: READ_BACK_B00 via ECS. (READ_AREA=0).

3. Read S-REG: READ_BACK_B01 via ECS. (READ_AREA=6).

4. Confirm that 8 bits of MSB of item number 2) and 3) are within

spec of the table below.

Reference Item

Spec.

±2

5. Read S-REG: TCD3_SATURATION via ECS.

6. Switch the TV set OFF and then ON again to retain adjustment

values.

1. Send ECS_ADJUST_LEVEL_SETTING_INIT command.

The following adjustments are done via ECS.

Note: Before Gamma adjustment can begin the set needs 1 hour aging.

2. Ensure COL_MATRIX_INDEX=15.

3. Ensure hreg p1_d_p_26=0 and hreg p1_d_p_28=0.

4. Ensure G_GAMMA_IDX_OFST=15.

5. Ensure DYNAMIC_EN=0.

2-3-1. Set up mode for Gamma Adjustment

2-3. Gamma Adjustment

2-4. White Balance Adjustment

Screen Size

32"

40"

46"

ADJ_COLOR_Y_ATT(NTSC)

128

128

128

ADJ_COLOR_PAL(NTSC)

1

1

1

READ_BACK_B0*difference value

1.

2.

3.

4.

1.

2.

3.

– 23 –

KLV-32V200A/40V200A/46V200A

RM-GA005

(*1) If adjustment results exceed the tolerance please extend

the tolerance to 0.6JND.

40IRE

TEST_R_LEVEL

102

TEST_G_LEVEL

102

TEST_B_LEVEL

102

6. Adjust R_GAMMA_OFST_01 and B_GAMMA_OFST_01

chroma values so that they are within tolerance in the table below.

chroma values so that they are within tolerance in the table below.

chroma values so that they are within tolerance in the table below.

10. Adjust R_GAMMA_OFST_03 and B_GAMMA_OFST_03

7. Set up the correct values for 40IRE for TEST_R_LEVEL,

TEST_G_LEVEL and TEST_B_LEVEL.

8. Adjust R_GAMMA_OFST_02 and B_GAMMA_OFST_02

chroma values so that they are within tolerance in the table below

.

9. Set up the correct values for 60IRE for TEST_R_LEVEL,

TEST_G_LEVEL and TEST_B_LEVEL.

11. Set up the correct values for 80IRE for TEST_R_LEVEL,

TEST_G_LEVEL and TEST_B_LEVEL.

12. Adjust R_GAMMA_OFST_04 and B_GAMMA_OFST_04

13. Write R_GAMMA_OFST_01~R_GAMMA_OFST_04 and

B_GAMMA_OFST_01~B_GAMMA_OFST_04 in the NVM.

14. Write R_GAMMA_OFST_04~R_GAMMA_OFST_05 and

B_GAMMA_OFST_04~B_GAMMA_OFST_05 in the NVM.

15. Set up TEST_PATTEN_ON=0.

16. Set up COL_MATRIX_INDEX=30.

17. Set up hreg_p1_d_p_26=3.

18. Set up hreg_p1_d_p_28=3.

(*1) If adjustment results exceed the tolerance please extend

the tolerance to 0.6JND.

(*1) If adjustment results exceed the tolerance please extend

the tolerance to 0.6JND.

(*1) If adjustment results exceed the tolerance please extend

the tolerance to 0.6JND.

20IRE

0.713

0.2755

0.8JND

32"

40IRE

0.761

0.2784

0.5JND

60IRE

0.2733

0.2766

0.5JND

80IRE

0.2739

0.2776

0.5JND

20IRE

0.2741

0.2737

0.8JND

40"

46"

40IRE

0.2738

0.2751

0.5JND

60IRE

0.2736

0.2756

0.5JND

80IRE

0.2731

0.2756

0.5JND

20IRE

0.2791

0.2829

0.8JND

40IRE

0.2772

0.2821

0.5JND

60IRE

0.2765

0.2821

0.5JND

80IRE

0.2765

0.2818

0.5JND

X

Y

TOLERANCE

20IRE

0.713

0.2755

0.8JND

32"

40IRE

0.761

0.2784

0.5JND

60IRE

0.2733

0.2766

0.5JND

80IRE

0.2739

0.2776

0.5JND

20IRE

0.2741

0.2737

0.8JND

40"

46"

40IRE

0.2738

0.2751

0.5JND

60IRE

0.2736

0.2756

0.5JND

80IRE

0.2731

0.2756

0.5JND

20IRE

0.2791

0.2829

0.8JND

40IRE

0.2772

0.2821

0.5JND

60IRE

0.2765

0.2821

0.5JND

80IRE

0.2765

0.2818

0.5JND

X

Y

TOLERANCE

20IRE

0.713

0.2755

0.8JND

32"

40IRE

0.761

0.2784

0.5JND

60IRE

0.2733

0.2766

0.5JND

80IRE

0.2739

0.2776

0.5JND

20IRE

0.2741

0.2737

0.8JND

40"

46"

40IRE

0.2738

0.2751

0.5JND

60IRE

0.2736

0.2756

0.5JND

80IRE

0.2731

0.2756

0.5JND

20IRE

0.2791

0.2829

0.8JND

40IRE

0.2772

0.2821

0.5JND

60IRE

0.2765

0.2821

0.5JND

80IRE

0.2765

0.2818

0.5JND

X

Y

TOLERANCE

20IRE

0.713

0.2755

0.8JND

32"

40IRE

0.761

0.2784

0.5JND

60IRE

0.2733

0.2766

0.5JND

80IRE

0.2739

0.2776

0.5JND

20IRE

0.2741

0.2737

0.8JND

40"

46"

40IRE

0.2738

0.2751

0.5JND

60IRE

0.2736

0.2756

0.5JND

80IRE

0.2731

0.2756

0.5JND

20IRE

0.2791

0.2829

0.8JND

40IRE

0.2772

0.2821

0.5JND

60IRE

0.2765

0.2821

0.5JND

80IRE

0.2765

0.2818

0.5JND

X

Y

TOLERANCE

60IRE

TEST_R_LEVEL

3 15

TEST_G_LEVEL

3 15

TEST_B_LEVEL

3 15

80IRE

TEST_R_LEVEL

204

TEST_G_LEVEL

204

TEST_B_LEVEL

204

Click on the first or last page to see other KLV-32V200A / KLV-40V200A / KLV-46V200A (serv.man3) service manuals if exist.