Sharp VC-M331HM (serv.man4) Service Manual ▷ View online

28

VC-M321HM

VC-M331HM

VC-M331HM

5. ELECTRICAL ADJUSTMENT

Notes:

• Before the adjustment:

• Before the adjustment:

Electrical adjustments discussed here are often required after replacement of electronic components and mechani-

cal parts such as video heads.

Check that the mechanism and all electric components are in good working condition prior to the adjustments,

otherwise adjustments can not be completed.

cal parts such as video heads.

Check that the mechanism and all electric components are in good working condition prior to the adjustments,

otherwise adjustments can not be completed.

• Instruments required:

Colour TV monitor

Dual-trace oscilloscope

Dual-trace oscilloscope

Alignment tape (VROCPSV)

Blank video cassette tape

DC voltmeter

Screwdriver for adjustment

DC voltmeter

Screwdriver for adjustment

Servicing precations

When the IC705 (E

When the IC705 (E

2

PROM) has been replaced, make the following reprogramming. Depending on models, the IC705

(E

2

PROM) has been factry-adjusted for it’s memory function.

It’s therefore necessary to reprogram the memory function for the model in question.

Note that the servo circuit requires readjustments for the head switching point, slow and still modes.

Note that the servo circuit requires readjustments for the head switching point, slow and still modes.

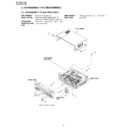

• Location of controls and test points

P201

P1501

P802 P801

R1626

RF AGC

RF AGC

IC1602

TU1551

SC1501

T1601

VCO

VCO

SW813 SW806 SW811

SW810 SW807

SW812 SW808 SW809

Figure 5-1.

29

VC-M321HM

VC-M331HM

VC-M331HM

SERVO CIRCUIT ADJUSTMENT

ADJUSTMENT OF HEAD SWITCHING POINT

Measuring

instrument

instrument

Mode

Cassette

Dual-trace oscilloscope

Colour TV monitor

Colour TV monitor

Playback

Alignment tape (VROCPSV)

Test point

Pin(2) of P201 (H.SW.P.) to CH-1,

VIDEO OUT jack to CH-2

(CH-1 trigger slope switch at (+),

Internal trigger at CH-1 side.)

VIDEO OUT jack to CH-2

(CH-1 trigger slope switch at (+),

Internal trigger at CH-1 side.)

Specification

6.5

±

0.5H (lines)

1. Remove the front panel and play the alignment tape.

(VROCPSV)

(Playback picture on the monitor screen.)

(Playback picture on the monitor screen.)

2. Press the PLAY button.

3. Make for a moment short-circuit P802, located at the

3. Make for a moment short-circuit P802, located at the

front side on the main PWB.

Be sure that all the fluorescent display tubes light up

into the TEST mode.(See Note below)

Be sure the "PLAY" appears in the fluorescent display

tubes flashing (about 1Hz) into the auto PG adjust-

ment operating.

Be sure that all the fluorescent display tubes light up

into the TEST mode.(See Note below)

Be sure the "PLAY" appears in the fluorescent display

tubes flashing (about 1Hz) into the auto PG adjust-

ment operating.

Note:

When the manual PG adjustment, obseve the wave-

form with an oscilloscope and make adjustment FF or

REW button so that the specification.

form with an oscilloscope and make adjustment FF or

REW button so that the specification.

4. Stop the "PLAY" appears in the flashing of fluorescent

display tubes at adjusted.

5. Press the STOP button in the return to normal mode.

6. Make this checking of waveform on the oscilloscope

6. Make this checking of waveform on the oscilloscope

screen be as shown in Figure 5-2. just after the head

switching point have been adjusted.

switching point have been adjusted.

Note:

1

Set-up of TEST mode.

When the adjustment of HEAD SWITCHING POINT,

AUTO TRACKING function is invalid.

When the adjustment of HEAD SWITCHING POINT,

AUTO TRACKING function is invalid.

2

When the cassette housing control ass’y is removed,

set-up of mechanism operating mode.

set-up of mechanism operating mode.

1) Replug the AC power cord it a few minutes later.

2) Make a short-circuit P801 located at the front side on

2) Make a short-circuit P801 located at the front side on

the main PWB, and press both tracking control button

at the same time to set the tracking in center.

at the same time to set the tracking in center.

3) AC power cord is plugged in.

4) You can mechanism operatig mode, Replug the AC

4) You can mechanism operatig mode, Replug the AC

power cord a few minutes later.

Measuring

instrument

instrument

Mode

Cassette

Colour TV monitor

Playback

Self-recorded tape

(SP/LP mode)(See Note below)

(SP/LP mode)(See Note below)

Control

Tracking control buttons (+) or (–)

Specification

Minimized noise on

monitor screen

monitor screen

6.5

±

0.5H (lines)

CH-1: 1V/div 50

µ

s/div

CH-2: 2V/div 50

µ

s/div

V-sync.

CH-1

HEAD

SWITCHING

PULSE

HEAD

SWITCHING

PULSE

CH-2

VIDEO OUT

VIDEO OUT

Figure 5-2.

ADJUSTMENT OF PAL SYSTEM SP/LP

SLOW TRACKING PRESET

SLOW TRACKING PRESET

1. Have the unit to receive a good TV broadcast or feed

a video signal to the VIDEO IN jack. (See note

2

below)

2. Set the tape speed in SP mode by using the remote

control and record the signal on tape.

3. Rewind and play the tape where signal was recorded

in above step.

4. Press the SLOW button on the remote control, and

playback the recorded portion in the slow mode.

5. Make for a moment short-ciucuit P802, located at the

front side on the main PWB.

Be sure that all the fluorescent display tubes light up

into the TEST mode.

Be sure that all the fluorescent display tubes light up

into the TEST mode.

6. Look at the monitor screen and adjust the (+) or (–)

TRACKING buttons so that the there is noise disap-

pears from the screen.

pears from the screen.

7. Press the STOP button to return to normal mode.

8. Play the tape a few seconds then press the SLOW

8. Play the tape a few seconds then press the SLOW

button again and make sure there is on noise in the

screen.(For the LP mode put adjustment at the same

adjustmet way as SP mode.)

screen.(For the LP mode put adjustment at the same

adjustmet way as SP mode.)

Notes:

1

Self-recorded tape means a cassette whose pro-

gram was recorded by the unit being adjusted.

gram was recorded by the unit being adjusted.

2

The TV program will not be recorded if RCA or 21pin

plugs are pluged in to the AUDIO/VIDEO input

terminals.

plugs are pluged in to the AUDIO/VIDEO input

terminals.

30

VC-M321HM

VC-M331HM

VC-M331HM

Measuring

instrument

instrument

Mode

Test point

Colour TV monitor

DV voltmeter

DV voltmeter

RF signal at 40CH(by VHF

signal generator)

signal generator)

Pin(2)(Sig.) of P1501.

Pin(4)(GND.) of P1501.

Pin(4)(GND.) of P1501.

Control

R1626 RF AGC control

Specification

4.3

±

0.2V(G/S Hi-Fi models)

1.Receive the 40 channel signal(colour bar signal at

87.5% modulated.) at input field strength: 57dB

87.5% modulated.) at input field strength: 57dB

µ

of

antenna terminal.

2.Connect a DC voltmeter to test point shown in table.

3.Look the voltmerter and adjust R1626 so that the

voltage be specified.

2.Connect a DC voltmeter to test point shown in table.

3.Look the voltmerter and adjust R1626 so that the

voltage be specified.

Measuring

instrument

instrument

Mode

Test point

Colour TV monitor

DV voltmeter

DV voltmeter

Control

T1601 VCO control

Specification

2.5

±

0.2V

RF signal at 40CH(by VHF

signal generator)

signal generator)

Pin(1)(Sig.) of P1501.

Pin(4)(GND.) of P1501.

Pin(4)(GND.) of P1501.

ADJUSTMENT OF RF AGC ADJUSTMENT

Note:

When power is turned on, tune in to station in the test

mode.

mode.

1.Receive the 40 channel signal(colour bar signal at

87.5% modulated.) at input field strength: 70dB

87.5% modulated.) at input field strength: 70dB

µ

of

antenna terminal.

2.Connect a DC voltmeter to test point shown in table.

3.Look the voltmerter and adjust T1601 so that the

voltage be specified.

2.Connect a DC voltmeter to test point shown in table.

3.Look the voltmerter and adjust T1601 so that the

voltage be specified.

ADJUSTMENT OF VCO CIRCUIT

Measuring

instrument

instrument

Mode

Cassette

Colour TV monitor

Playback still

Self-recorded tape (SP mode)

(See Note below

(See Note below

2

)

Control

Tracking control buttons (+) or (–)

Specification

No vertical jitter of picture

ADJUSTMENT OF PAL SYSTEM FV(False

Vertical Sync) OF STILL PICTURE

Vertical Sync) OF STILL PICTURE

1. Play a cassette which was recorded by the unit in SP

mode.

2. Press the PAUSE/STILL button to freeze the picture.

3. Look at the monitor screen and adjust (+) or (–)

3. Look at the monitor screen and adjust (+) or (–)

TRACKING buttons so that the vertical jitter of the

picture to be minimized.

picture to be minimized.

4. Play and freeze the self-recorded tape in SP mode

and make sure vertical jitter of the picture is not

noticeable.(For the LP mode put adjustment at the

same adjustment way as SP mode.)

noticeable.(For the LP mode put adjustment at the

same adjustment way as SP mode.)

Note:

1

The FV goes back to the it’s initial state when the unit

is put into the system controller reset mode due to

power failure, etc.

In this case, preset the FV once again.

is put into the system controller reset mode due to

power failure, etc.

In this case, preset the FV once again.

2

Self-recorded tape is a cassette whose program was

recorded by the unit being adjusted.

recorded by the unit being adjusted.

31

VC-M321HM

VC-M331HM

VC-M331HM

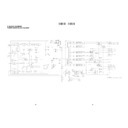

;;

;;

;;;

0

5

10

15

20

25

F mechanical timing

Mode

Rotation angle

Mode check

Cam mark

Mode detection outside

(D705 SW B)

Mode detection inside

(D708 SW A)

Cam graph E

60

120

180

240

300

360

CA/END

CS/EJ

33.82

UL

81

VSR

218

PU(LD)

188

PB

252

SLOW

269

CL

293

STOP

309

FF

325

Cam switch

0

Mode detection outside

Mode detection inside

S sensor

S sensor

Mode detection inside

Sensor A

Mode detection outside

Sensor B

CS/EJ

ULD

PU LD

VSR

PB

STILL

CL

STOP

FF

1

1

1

0

0

0

0

0

0

0

1

1

1

0

1

0

0

0

open

close

0

1

EJ

UL

FF

PU

0

1

1

0

0

0

0

1

1 or 0

1

1

1

0

10

0

0

0

0

1

1

1

1

1

1

VSR

PB

SLW

S

TP

CL

0

;

;

Loading motor turns in reverse

direction and master cam

counterclockwise.

CASSETTE INSERTION STOP

Cassette

inserting

Full-

loading

YES

YES

YES

NO

NO

NO

Unloading

Loading motor starts in normal

direction and master cam counter

clockwise.

Does mechanism position sw.

come off within 2.5 sec.?

Are start/end sensors at low level

before cassette insertion ?

Insert cassette.

Double action rack slides.

Drum motor starts.

Tape loading.

Pinch roller comes into contact.

Cam switch is at PB position.

Loading motor stop.

Is drum FG pulse outputted ?

End

End

Cassette is ejected and loading

motor stops.

Start sensor close.

(Cassette is judged

caught halfway.)

(Cassette LED or some other part

is judged defective.)

6.

MECHANISM OPERA

TION FLO

WCHAR

T AND

TR

OUBLESHOO

TING GUIDE

MECHANISM OPERATION FLOWCHART