Sharp 28JW-73H (serv.man12) Service Manual ▷ View online

-:+

5

ELECTRICAL CHARACTERISTICS

(refer to Figure 1 on page 3)

Tamb = 25

°

C unless otherwise specified, Vcc =

±

12V, f

vert

=50Hz

Note: 1

Input voltage = 0, measured after the filter (e.g. accross the 470 nF filter capacitor)

Note: 2

Supply rejection of the positive or negative power supply. Vcc ripple =1Vpp, f=100Hz, measured on the sense

resistor.

resistor.

Note: 3

Power dissipated in the circuit in the case of the application from Figure 1 and the current in the deflection

yoke adjusted to 2.5App. The corresponding power dissipated in the vertical deflection yoke is 2.8W.

yoke adjusted to 2.5App. The corresponding power dissipated in the vertical deflection yoke is 2.8W.

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Units

+Vcc

Positive supply range

+10

+18

V

-Vcc

Negative supply range

-18

-10

V

∆

Vcc

Maximum recommended difference

between +Vcc and

between +Vcc and

±

4

V

Vcc

start

Low Vcc detection

±

6.5

V

Iq

Quiescent supply current

Input voltage = 0

14

mA

Iy

Maximum recommended vertical

yoke current

yoke current

±

1.25

A

I

13

, I

12

Amplifier Input bias current

-0.1

µ

A

V

OS

Output Offset voltage

Note 1

-50

+50

mV

SVR

Supply voltage rejection

Note 2

82

dB

Fly

thr

Flyback detection threshold

(positive slope)

(positive slope)

V(14)

1.5

V

Fly

thf

Flyback detection threshold

(negative slope)

(negative slope)

V(14)

0.5

V

Pd

Integrated circuit

Dissipated power

Dissipated power

Note 3

1.1

W

Fsw

Switching frequency

R

freq

= 10k

Ω

120

140

160

kHz

Fsw - op

Switching frequency operative range

100

200

kHz

R

freq

Frequency controller resistor range

Pin 10

7

10

14

k

Ω

Vcc

–

679,&

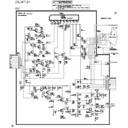

Figure

1.

Test

Test

and

Application

Cir

cuit

Flyback

Flyback

Output

Modulator

+

_

drive

generator

detection

+VCC

+VCC power

CFLYBACK

CFLY+

100nF

VREG

IN+

IN -

1k

Ω

10k

Ω

EA out

-VCC power

-VCC

-VCC

BOOT

Cboot

470nF

10k

Ω

4.7nF

FREQ

FEEDCAP

SGND

Pins 1,2,3,18,19,20

OUT

0.5

Ω

Deflect.

Yoke*

CFLY-

+VCC

1mH

Input signal

1k

Ω

220nF

-VCC

100nF

100nF

1000

µ

F

1000

µ

F

STV9380

100

µ

F

14

11

9

17

560pF

150

Ω

200

Ω

15

16

8

TDA9380

5

6

7

4

13

12

150

Ω

10

Vref

-VCC

470pF

* Deflection yoke characteristics: R = 5.5

Ω

, L = 7mH

100nF

Sense

resistor

f

vert

= 50Hz

-:+

7($,&

%ORFN'LDJUDP

PINNING

SYMBOL PIN

DESCRIPTION

V

CC

1

supply voltage

GND

2

ground

CTRL

3

control input

DEM

4

input from auxiliary winding for

demagnetization timing, OVP and OPP

demagnetization timing, OVP and OPP

I

sense

5

programmable current sense input

DRIVER

6

gate driver output

HVS

7

high voltage safety spacer, not

connected

connected

DRAIN

8

drain of external MOS switch, input for

start-up current and valley sensing

start-up current and valley sensing

handbook, halfpage

MGU231

TEA1507

1

2

3

4

VCC

GND

CTRL

DEM

DRAIN

HVS

DRIVER

Isense

8

7

6

5

Fig.3 Pin configuration.

h

SUPPLY

MANAGEMENT

internal

supply

UVLO

start

M-level

VCC

1

2

3

GND

S1

CTRL

FREQUENCY

CONTROL

VOLTAGE

CONTROLLED

OSCILLATOR

LOGIC

LOGIC

OVER-

VOLTAGE

PROTECTION

OVERPOWER

PROTECTION

PROTECTION

short

winding

soft

start

S2

OVER-

TEMPERATURE

PROTECTION

S

Q

R

UVLO

Q

MAXIMUM

ON-TIME

PROTECTION

POWER-ON

RESET

−

1

VALLEY

TEA1507

100 mV

clamp

DRIVER

START-UP

CURRENT SOURCE

0.75 V

0.5 V

5

Isense

6

DRIVER

MGU230

4

DEM

8

DRAIN

7

HVS

n.c.

n.c.

OCP

LEB

blank

Iss

2.5 V

burst

detect

detect

-:+

CHARACTERISTICS

T

T

amb

= 25

°

C; V

CC

= 15 V; all voltages are measured with respect to ground (pin 2); currents are positive when flowing

into the IC; unless otherwise specified.

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX. UNIT

Start-up current source (pin 8)

I

i(DRAIN)

supply current drawn from drain pin

V

CC

= 0 V; V

DRAIN

> 100 V

1.0

1.2

1.4

mA

with auxiliary supply;

V

V

DRAIN

> 100 V

−

100

300

µ

A

BV

DSS

breakdown voltage

650

−

−

V

M-level

mains-dependent operation-enabling level

60

−

100

V

V

CC

management (pin 1)

V

CC(start)

start-up voltage on V

CC

10.3

11

11.7

V

V

CC(UVLO)

under voltage lock-out on V

CC

8.1

8.7

9.3

V

V

CC(hys)

hysteresis voltage on V

CC

V

CC(start)

−

V

CC(UVLO)

2.0

2.3

2.6

V

I

i(VCC)H

pin V

CC

charging current

V

DRAIN

> 100 V; V

CC

< 3V

−

1.2

−

1

−

0.8

mA

I

i(VCC)L

pin V

CC

charging current

V

DRAIN

> 100 V;

3 V < V

CC

< V

CC(UVLO)

−

1.2

−

0.75

−

0.45 mA

I

VCC(restart)

pin V

CC

restart current

V

DRAIN

> 100 V;

V

CC(UVLO)

< V

CC

< V

CC(start)

−

650

−

550

−

450

µ

A

I

CC(operate)

supply current under normal operation

no load on pin DRIVER

1.1

1.3

1.5

mA

Demagnetization management (pin 4)

V

DEM

demagnetization comparator threshold

voltage on pin DEM

voltage on pin DEM

50

100

150

mV

I

DEM

pin DEM current

V

DEM

= 50 mV

−

50

(1)

−

0

nA

V

clamp(DEM)(neg)

negative clamp voltage on pin DEM

at I

DEM

=

−

150

µ

A

−

0.5

−

0.25

−

0.05 V

V

clamp(DEM)(pos)

positive clamp voltage on pin DEM

at I

DEM

= 250

µ

A

0.5

0.7

0.9

V

t

suppr

suppression of transformer ringing at start

of secondary stroke

of secondary stroke

1.1

1.5

1.9

µ

s

Pulse width modulator

t

on(min)

minimum on-time

−

t

leb

−

ns

t

on(max)

maximum on-time

latched

40

50

60

µ

s

Oscillator

f

oscL

oscillator low frequency (fixed frequency)

V

CTRL

> 1.5 V

5

6.5

8

kHz

f

oscH

oscillator high frequency (fixed frequency) V

CTRL

< 1 V

145

175

205

kHz

V

vco(start)

peak voltage at pin I

sense

, where

frequency reduction starts

see Fig.6

−

75

−

mV

V

vco(max)

peak voltage at pin I

sense

, where the

frequency is equal to f

oscL

−

50

−

mV

Duty cycle control (pin 3)

V

CTRL(min)

min. voltage on CTRL (max. duty cycle)

−

1.0

−

V

V

CTRL(max)

max. voltage on CTRL (min. duty cycle)

−

1.5

−

V

7($,&

-:+

7($,&

Note

1. Guaranteed by design.

Burst mode standby (pin 3)

V

th(burst)(on)

burst mode standby active threshold

voltage

voltage

at I

burst

= 6 mA

3.3

3.8

4.3

V

I

th(burst)(on)

burst mode standby active current

16

−

−

mA

I

th(burst)(off)

burst mode standby inactive current

−

−

6

mA

t

(burst-blank)

burst mode standby blanking time

25

30

35

µ

s

Valley switch (pin 8)

∆

V/

∆

t

valley

∆

V/

∆

t for valley recognition

−

85

−

+

85

V/

µ

s

t

valley-swon

delay from valley recognition to switch-on

−

150

(1)

−

ns

Current and short winding protection (pin 5)

V

sense(max)

maximum source voltage OCP

∆

V/

∆

t = 0.1 V/

µ

s

0.48

0.52

0.56

V

t

propagation

delay from detecting V

sense(max)

to

switch-off

∆

V/

∆

t = 0.5 V/

µ

s

−

140

185

ns

V

swp

short winding protection voltage

0.83

0.88

0.96

V

t

leb

blanking time for current and short

winding protection

winding protection

300

370

440

ns

I

ss

soft start current

V

sense

< 0.5 V

45

60

75

µ

A

Overvoltage protection (pin 4)

I

(OVP)(DEM)

OVP protection level at pin 4, set by the

demagnetization resistor R

demagnetization resistor R

DEM

; see

Section “OverVoltage Protection (OVP)”

54

60

66

µ

A

Overpower protection (pin 4)

I

(OPP)(DEM)

OPP current at pin 4, start of OPP

correction. Set by the demagnetization

resistor R

correction. Set by the demagnetization

resistor R

DEM

; see Section “OverPower

Protection (OPP)”

−

−

24

−

µ

A

I

(OPP50%)(DEM)

OPP current at pin 4 where maximum

source voltage is limited to 0.3 V

source voltage is limited to 0.3 V

−

−

100

−

µ

A

Driver (pin 6)

I

source

source current capability of driver

V

CC

= 9.5 V; V

DRIVER

= 2 V

−

−

170

−

88

mA

I

sink

sink current capability of driver

V

CC

= 9.5 V; V

DRIVER

= 2 V

−

300

−

mA

V

CC

= 9.5 V;

V

DRIVER

= 9.5 V

400

700

−

mA

V

o(driver)(max)

maximum output voltage of the driver

V

CC

> 12 V

−

11.5

12

V

Temperature protection

T

prot(max)

maximum temperature threshold

130

140

150

°

C

T

prot(hyst)

hysteresis temperature

−

8

(1)

−

°

C

SYMBOL

PARAMETER

CONDITIONS

MIN.

TYP.

MAX. UNIT

Display