Sharp XR-10XL (serv.man4) Service Manual ▷ View online

XR-10X-L/XR-10S-L/XG-MB50X-L/XR-11XC-L/XR-HB007X-L

4 – 5

1. Adjustment of ballast unit output power (lamp power)

1. List of parts requiring adjustment

When replacing the following parts, adjust the ballast unit output power (lamp power).

2. Adjustment jigs

The following jigs are required for adjusting the ballast unit output power (lamp power).

3. Ballast unit output power (lamp power) adjustment method

Adjust the ballast unit output power (lamp power) in the following method.

2. Adjustment method

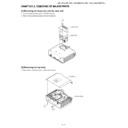

1) Unplug the ballast unit lamp cable of the projector from the lamp and connect the cable to the connecting cord

(QCNWKA016WJZZ).

2) Connect the connecting cord (QCNWKA016WJZZ) to the adjustment jig (RUNTZA018WJZZ).

3) Connect TP1 of the adjustment jig (RUNTZA018WJZZ) to the negative terminal of the tester and TP2 to the positive terminal.

4) Turn on the projector.

5) Check the Lamp setting to “Bright”.

6) Age the projector for 60 seconds or more.

7) Adjust the volume resistor (R7728) of the ballast control PWB (DUNTKD148WEF4) so that the voltage of the tester reaches 74

± 0.5 V.

Adjustment value: 74

±0.5 V

CAUTION: (1) Caution for electric shock: Do not touch the test points TP1 and TP2 of the adjustment jig when supplying power since a high voltage

and large current is applied to them.

(2) Caution for heat: Be careful that the resistance load of the adjustment jig produces a high temperature when supplying power.

(3) Connection of the lamp cable: Check that the lamp cable and connecting cord (QCNWKA016WJZZ) are connected securely.

Poor connection may cause smoking or ignition due to arc discharge.

Part name

Ref No.

Part code

1

Cement resistor

R905

RR-FZA002WJZZ

2

Ballast Control PWB

——

DUNTKD148WEF4

3

Ballast microprocessor

IC7707

RH-iXB932WJZZQ

4

5V regulator

IC7704

VHITA78L05F-1Y

5

Ballast Unit

IC7701

VHIM51995AF-1Y

Part name

Part code

Manufacturer

1

Adjustment jig (resistance load 25

Ω)

RUNTZA018WJZZ

Asahi Communication

2

Connecting cord (conversion cable)

QCNWKA016WJZZ

SMK

Ballast Unit

Lamp Cable

Adjustment Jig

(RUNTZA018WJZZ)

Connecting Cord

(QCNWKA016WJZZ)

XG-MB50X-L

XR-11XC-L

XR-10S-L/X-L

XR-HB007X-L

Projector

TP1

TP2

[Setting method]

Tester

(Voltage)

XR-10X-L/XR-10S-L/XG-MB50X-L/XR-11XC-L/XR-HB007X-L

4 – 5

1. Adjustment of ballast unit output power (lamp power)

1. List of parts requiring adjustment

When replacing the following parts, adjust the ballast unit output power (lamp power).

2. Adjustment jigs

The following jigs are required for adjusting the ballast unit output power (lamp power).

3. Ballast unit output power (lamp power) adjustment method

Adjust the ballast unit output power (lamp power) in the following method.

2. Adjustment method

1) Unplug the ballast unit lamp cable of the projector from the lamp and connect the cable to the connecting cord

(QCNWKA016WJZZ).

2) Connect the connecting cord (QCNWKA016WJZZ) to the adjustment jig (RUNTZA018WJZZ).

3) Connect TP1 of the adjustment jig (RUNTZA018WJZZ) to the negative terminal of the tester and TP2 to the positive terminal.

4) Turn on the projector.

5) Check the Lamp setting to “Bright”.

6) Age the projector for 60 seconds or more.

7) Adjust the volume resistor (R7728) of the ballast control PWB (DUNTKD148WEF4) so that the voltage of the tester reaches 74

± 0.5 V.

Adjustment value: 74

±0.5 V

CAUTION: (1) Caution for electric shock: Do not touch the test points TP1 and TP2 of the adjustment jig when supplying power since a high voltage

and large current is applied to them.

(2) Caution for heat: Be careful that the resistance load of the adjustment jig produces a high temperature when supplying power.

(3) Connection of the lamp cable: Check that the lamp cable and connecting cord (QCNWKA016WJZZ) are connected securely.

Poor connection may cause smoking or ignition due to arc discharge.

Part name

Ref No.

Part code

1

Cement resistor

R905

RR-FZA002WJZZ

2

Ballast Control PWB

——

DUNTKD148WEF4

3

Ballast microprocessor

IC7707

RH-iXB932WJZZQ

4

5V regulator

IC7704

VHITA78L05F-1Y

5

Ballast Unit

IC7701

VHIM51995AF-1Y

Part name

Part code

Manufacturer

1

Adjustment jig (resistance load 25

Ω)

RUNTZA018WJZZ

Asahi Communication

2

Connecting cord (conversion cable)

QCNWKA016WJZZ

SMK

Ballast Unit

Lamp Cable

Adjustment Jig

(RUNTZA018WJZZ)

Connecting Cord

(QCNWKA016WJZZ)

XG-MB50X-L

XR-11XC-L

XR-10S-L/X-L

XR-HB007X-L

Projector

TP1

TP2

[Setting method]

Tester

(Voltage)

XR-10X-L/XR-10S-L/XG-MB50X-L/XR-11XC-L/XR-HB007X-L

4 – 5

1. Adjustment of ballast unit output power (lamp power)

1. List of parts requiring adjustment

When replacing the following parts, adjust the ballast unit output power (lamp power).

2. Adjustment jigs

The following jigs are required for adjusting the ballast unit output power (lamp power).

3. Ballast unit output power (lamp power) adjustment method

Adjust the ballast unit output power (lamp power) in the following method.

2. Adjustment method

1) Unplug the ballast unit lamp cable of the projector from the lamp and connect the cable to the connecting cord

(QCNWKA016WJZZ).

2) Connect the connecting cord (QCNWKA016WJZZ) to the adjustment jig (RUNTZA018WJZZ).

3) Connect TP1 of the adjustment jig (RUNTZA018WJZZ) to the negative terminal of the tester and TP2 to the positive terminal.

4) Turn on the projector.

5) Check the Lamp setting to “Bright”.

6) Age the projector for 60 seconds or more.

7) Adjust the volume resistor (R7728) of the ballast control PWB (DUNTKD148WEF4) so that the voltage of the tester reaches 74

± 0.5 V.

Adjustment value: 74

±0.5 V

CAUTION: (1) Caution for electric shock: Do not touch the test points TP1 and TP2 of the adjustment jig when supplying power since a high voltage

and large current is applied to them.

(2) Caution for heat: Be careful that the resistance load of the adjustment jig produces a high temperature when supplying power.

(3) Connection of the lamp cable: Check that the lamp cable and connecting cord (QCNWKA016WJZZ) are connected securely.

Poor connection may cause smoking or ignition due to arc discharge.

Part name

Ref No.

Part code

1

Cement resistor

R905

RR-FZA002WJZZ

2

Ballast Control PWB

——

DUNTKD148WEF4

3

Ballast microprocessor

IC7707

RH-iXB932WJZZQ

4

5V regulator

IC7704

VHITA78L05F-1Y

5

Ballast Unit

IC7701

VHIM51995AF-1Y

Part name

Part code

Manufacturer

1

Adjustment jig (resistance load 25

Ω)

RUNTZA018WJZZ

Asahi Communication

2

Connecting cord (conversion cable)

QCNWKA016WJZZ

SMK

Ballast Unit

Lamp Cable

Adjustment Jig

(RUNTZA018WJZZ)

Connecting Cord

(QCNWKA016WJZZ)

XG-MB50X-L

XR-11XC-L

XR-10S-L/X-L

XR-HB007X-L

Projector

TP1

TP2

[Setting method]

Tester

(Voltage)

XR-10X-L/XR-10S-L/XG-MB50X-L/XR-11XC-L/XR-HB007X-L

4 – 5

1. Adjustment of ballast unit output power (lamp power)

1. List of parts requiring adjustment

When replacing the following parts, adjust the ballast unit output power (lamp power).

2. Adjustment jigs

The following jigs are required for adjusting the ballast unit output power (lamp power).

3. Ballast unit output power (lamp power) adjustment method

Adjust the ballast unit output power (lamp power) in the following method.

2. Adjustment method

1) Unplug the ballast unit lamp cable of the projector from the lamp and connect the cable to the connecting cord

(QCNWKA016WJZZ).

2) Connect the connecting cord (QCNWKA016WJZZ) to the adjustment jig (RUNTZA018WJZZ).

3) Connect TP1 of the adjustment jig (RUNTZA018WJZZ) to the negative terminal of the tester and TP2 to the positive terminal.

4) Turn on the projector.

5) Check the Lamp setting to “Bright”.

6) Age the projector for 60 seconds or more.

7) Adjust the volume resistor (R7728) of the ballast control PWB (DUNTKD148WEF4) so that the voltage of the tester reaches 74

± 0.5 V.

Adjustment value: 74

±0.5 V

CAUTION: (1) Caution for electric shock: Do not touch the test points TP1 and TP2 of the adjustment jig when supplying power since a high voltage

and large current is applied to them.

(2) Caution for heat: Be careful that the resistance load of the adjustment jig produces a high temperature when supplying power.

(3) Connection of the lamp cable: Check that the lamp cable and connecting cord (QCNWKA016WJZZ) are connected securely.

Poor connection may cause smoking or ignition due to arc discharge.

Part name

Ref No.

Part code

1

Cement resistor

R905

RR-FZA002WJZZ

2

Ballast Control PWB

——

DUNTKD148WEF4

3

Ballast microprocessor

IC7707

RH-iXB932WJZZQ

4

5V regulator

IC7704

VHITA78L05F-1Y

5

Ballast Unit

IC7701

VHIM51995AF-1Y

Part name

Part code

Manufacturer

1

Adjustment jig (resistance load 25

Ω)

RUNTZA018WJZZ

Asahi Communication

2

Connecting cord (conversion cable)

QCNWKA016WJZZ

SMK

Ballast Unit

Lamp Cable

Adjustment Jig

(RUNTZA018WJZZ)

Connecting Cord

(QCNWKA016WJZZ)

XG-MB50X-L

XR-11XC-L

XR-10S-L/X-L

XR-HB007X-L

Projector

TP1

TP2

[Setting method]

Tester

(Voltage)

Display