Sharp XG-NV51XE (serv.man9) Service Manual ▷ View online

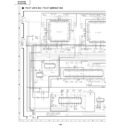

27

XG-NV51XE/XM/XA

100% White Red

100% White Red

No.

Adjusting point

Adjusting conditions

Adjusting procedure

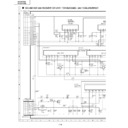

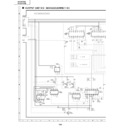

19

PAL colour

saturation level

saturation level

1. Feed the PAL colour bar

signal.

Group : VIDEO 1

Subject : P-COLOR

Group : VIDEO 1

Subject : P-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

»

Using the control switches or the remote controller

buttons, adjust the difference between the 100%

white portion and the red portion to 0.20 ±0.02 Vp-p.

buttons, adjust the difference between the 100%

white portion and the red portion to 0.20 ±0.02 Vp-p.

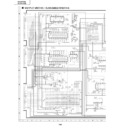

20

SECAM colour

saturation level

saturation level

1. Feed the SECAM colour

bar signal.

Group : VIDEO 1

Subject : S-COLOR

Group : VIDEO 1

Subject : S-COLOR

2. Connect the oscilloscope to

pin (1) of P801.

»

Using the control switches or the remote controller

buttons, adjust the data to have a level difference of

0.25 ±0.02 Vp-p between the 100% white portion

and the red portion.

buttons, adjust the data to have a level difference of

0.25 ±0.02 Vp-p between the 100% white portion

and the red portion.

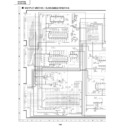

21

Video white

balance

balance

1. Feed the NTSC mono-

scope pattern signal

Group : VIDEO 2

Subject : R1-GAIN

Group : VIDEO 2

Subject : R1-GAIN

B1-GAIN

»

Using the control switches or the remote controller

buttons, adjust so that the entire screen looks

evenly colourless.

buttons, adjust so that the entire screen looks

evenly colourless.

22

Colour

irregularity

correction

position

irregularity

correction

position

1. Feed the gray-only RGB

colour signal.

2. Find the colour irregularity

position on the screen.

3. Group

: NOKO

Subject : NOKO-RL

4. Group : NOKO

Subject : NOKO-LH

»

If the colour is irregular, adjust the NOKO-RL data.

Set it to R for the right-hand colour irregularity and

to L for the left-hand one.

Set it to R for the right-hand colour irregularity and

to L for the left-hand one.

»

When there is no colour irregularity, turn off the saw-

tooth waveform correction on the NOKO-LH data.

tooth waveform correction on the NOKO-LH data.

23

Colour

irregularity

correction gain

(in case of

colourirregularity)

irregularity

correction gain

(in case of

colourirregularity)

1. Feed the gray-only RGB

colour signal.

»

Adjust R4215 to minimize the right-hand and left-

hand colour irregularity.

hand colour irregularity.

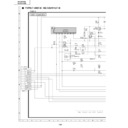

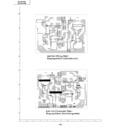

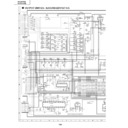

28

XG-NV51XE/XM/XA

No.

Adjusting point

Adjusting conditions

Adjusting procedure

24

1. Receive the colour bar sig-

nal.

»

In the process mode and select L1. Check the col-

our and tint.

our and tint.

26

»

In the process mode nad select L3. Check the bass,

treble and balance.

treble and balance.

25

1. Receive the monoscope

pattern signal.

»

In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

ture, brightness and sharpness.

27

RGB

performance

check

performance

check

1. Receive the RGB signal.

»

In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

28

Off-timer

performance

check

performance

check

»

In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

29

Thermistor

performance

check

performance

check

1. Heat the thermistor using a

dryer.

»

Make sure the “TEMP” is displayed.

31

IrDA

performance

check

performance

check

»

Make sure the IrDA signal can be received.

30

Automatic

synchronization

synchronization

1. Receive the PHASE check

pattern signal.

»

Call the VGA/S-VGA/XGA/SXGA mode and make

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

32

Keystone

correction

performance

check

correction

performance

check

»

Make sure the keystone correction functions well.

33

Factory settings

»

Make the following settings.

S4

“Factory setting 4”

Remote controller

setting

setting

Process

adjustment

adjustment

28

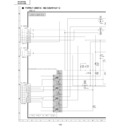

XG-NV51XE/XM/XA

No.

Adjusting point

Adjusting conditions

Adjusting procedure

24

1. Receive the colour bar sig-

nal.

»

In the process mode and select L1. Check the col-

our and tint.

our and tint.

26

»

In the process mode nad select L3. Check the bass,

treble and balance.

treble and balance.

25

1. Receive the monoscope

pattern signal.

»

In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

ture, brightness and sharpness.

27

RGB

performance

check

performance

check

1. Receive the RGB signal.

»

In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

28

Off-timer

performance

check

performance

check

»

In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

29

Thermistor

performance

check

performance

check

1. Heat the thermistor using a

dryer.

»

Make sure the “TEMP” is displayed.

31

IrDA

performance

check

performance

check

»

Make sure the IrDA signal can be received.

30

Automatic

synchronization

synchronization

1. Receive the PHASE check

pattern signal.

»

Call the VGA/S-VGA/XGA/SXGA mode and make

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

32

Keystone

correction

performance

check

correction

performance

check

»

Make sure the keystone correction functions well.

33

Factory settings

»

Make the following settings.

S4

“Factory setting 4”

Remote controller

setting

setting

Process

adjustment

adjustment

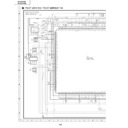

28

XG-NV51XE/XM/XA

No.

Adjusting point

Adjusting conditions

Adjusting procedure

24

1. Receive the colour bar sig-

nal.

»

In the process mode and select L1. Check the col-

our and tint.

our and tint.

26

»

In the process mode nad select L3. Check the bass,

treble and balance.

treble and balance.

25

1. Receive the monoscope

pattern signal.

»

In the process mode and select L2. Check the pic-

ture, brightness and sharpness.

ture, brightness and sharpness.

27

RGB

performance

check

performance

check

1. Receive the RGB signal.

»

In the process mode and select L4. Check the pic-

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

ture, brightness, red, blue, clock, phase, horizontal

position, and vertical position.

28

Off-timer

performance

check

performance

check

»

In the process mode and select OFF. Make sure that

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

the off-timer starts with “5” (minutes), counts down

each minute in 1 second, and turns off the set at “0”.

29

Thermistor

performance

check

performance

check

1. Heat the thermistor using a

dryer.

»

Make sure the “TEMP” is displayed.

31

IrDA

performance

check

performance

check

»

Make sure the IrDA signal can be received.

30

Automatic

synchronization

synchronization

1. Receive the PHASE check

pattern signal.

»

Call the VGA/S-VGA/XGA/SXGA mode and make

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

sure that the clock, phase, horizontal and vertical

positions can be automatically adjusted.

32

Keystone

correction

performance

check

correction

performance

check

»

Make sure the keystone correction functions well.

33

Factory settings

»

Make the following settings.

S4

“Factory setting 4”

Remote controller

setting

setting

Process

adjustment

adjustment

Display