Sharp MX-RBX1 (serv.man7) Service Manual ▷ View online

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 1

âºíuÇ´

Service Manual

[5] OPERATIONAL DESCRIPTION

1. Basic operations

A. Specifications

The finisher serves to deliver sheets coming from its host machine.

The mode of delivery may be non-sort stack, job offset *, or staple

delivery.

The saddle unit built into the finisher is used to fold a stack of

sheets coming from the finisher unit in half for delivery.

The punch unit (option) is designed for installation to the pickup

assembly of the finisher, and is used to punch holes in sheets com-

ing from the host machine.

The above operations are controlled with various commands from

the finisher controller PCB as well as the commands from the

punch controller PCB.

The mode of delivery may be non-sort stack, job offset *, or staple

delivery.

The saddle unit built into the finisher is used to fold a stack of

sheets coming from the finisher unit in half for delivery.

The punch unit (option) is designed for installation to the pickup

assembly of the finisher, and is used to punch holes in sheets com-

ing from the host machine.

The above operations are controlled with various commands from

the finisher controller PCB as well as the commands from the

punch controller PCB.

*: The position of delivery is shifted to the front/rear for each stack

to assist sorting.

to assist sorting.

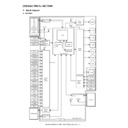

B. Outline of the Electrical Circuitry

The sequence of finisher operations is controlled by the finisher

controller PCB. The finisher controller PCB is a 16-bit microproces-

sor (CPU), and is also used for combination with the host machine

(serial).

The finisher controller PCB drive motors and other loads in

response to the various commands from the host machine. It also

communicates such data as on the states of various sensors and

switches to the host machine by way of the serial communication

line.

The ICs mounted to the finisher controller PCB have the following

functions:

• IC13 (CPU): Controls sequence of operations.

• IC12 (EEP-ROM): Backs up adjustment settings.

• IC6: Stores sequence programs.

• IC11 (expansion port): I/O port

The flow of signals between finisher and options controller is shown

as below.

controller PCB. The finisher controller PCB is a 16-bit microproces-

sor (CPU), and is also used for combination with the host machine

(serial).

The finisher controller PCB drive motors and other loads in

response to the various commands from the host machine. It also

communicates such data as on the states of various sensors and

switches to the host machine by way of the serial communication

line.

The ICs mounted to the finisher controller PCB have the following

functions:

• IC13 (CPU): Controls sequence of operations.

• IC12 (EEP-ROM): Backs up adjustment settings.

• IC6: Stores sequence programs.

• IC11 (expansion port): I/O port

The flow of signals between finisher and options controller is shown

as below.

Punch unit drive

system (punch unit;

option)

system (punch unit;

option)

Alignment drive system

Stapler drive system

Delivery drive system

Feed drive system

Tray drive system

Saddle section

drive system

Interface pass

drive system

Control

system

Host machine DC

controller PCB

CPU

controller PCB

CPU

Punch controller

PCB

Finisher

controller

PCB

controller

PCB

IC13

CPU

CPU

IC12

EEP-ROM

IC11

Communication

IC

IC6

ROM

Motor

Clutch

Switch

Sensor

Motor

Sensor

Finisher unit

Punch unit (option)

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 2

C. Inputs to and Outputs from the Finisher

Controller PCB

• Inputs to the Finisher Controller PCB (1/2)

• Inputs to the Finisher Controller PCB (2/2)

• Outputs from the Finisher Controller PCB (1/2)

• Outputs from the Finisher Controller PCB (2/2)

Entry paper

sensor

sensor

Paddle home

position sensor

position sensor

Bundle roller

home position

sensor

home position

sensor

Aligning plate

home position

sensor (front)

home position

sensor (front)

Aligning plate

home position

sensor (rear)

home position

sensor (rear)

Delivery belt

home position

sensor

home position

sensor

Alignment

tray sensor

tray sensor

Tray paper sensor

Paper surface

sensor

sensor

Bookbinding

position sensor

position sensor

When the sensor

detects paper, ‘1’ .

detects paper, ‘1’ .

When the aligning

plate (rear) is at

home position, ‘1’.

plate (rear) is at

home position, ‘1’.

When the delivery belt

is at home position, ‘1’.

is at home position, ‘1’.

When the paddle is at

home position, ‘1’.

home position, ‘1’.

When the swing guide

is at home position, ‘1’.

is at home position, ‘1’.

When paper is present

on the tray, ‘1’.

on the tray, ‘1’.

When the paper

surface is detected,

‘1’.

surface is detected,

‘1’.

When the aligning

plate (front) is at

home position, ‘1’.

plate (front) is at

home position, ‘1’.

When the sensor

detects paper, ‘1’.

detects paper, ‘1’.

When paper is

detected, ‘0’.

When LED is lit, ‘1’.

detected, ‘0’.

When LED is lit, ‘1’.

FOBHPD

FAD

FRJHPD

FFJHPD

FARHPD

FPDHPD

FED

CN44-3

-2

-1

CN16-10

Finisher controller PCB

+5V

ENT_S

ENT_S

+5V

PDL_HP

PDL_HP

+5V

FJOG_HP

FJOG_HP

+5V

RJOG_HP

RJOG_HP

+5V

ADJ_TRAY_S

ADJ_TRAY_S

+5V

EJCT_BLT_HP

EJCT_BLT_HP

+5V

BDL_ROL_HP

BDL_ROL_HP

-11

-12

-2

CN43-1

-3

-2

CN42-3

-1

CN9-1

-2

-3

CN51-1

-2

-3

CN55-3

-2

-1

CN9-7

-8

-9

-2

CN54-1

-3

-2

CN53-3

-1

FFPD

FSLD

FBED

+5V

TRY_EMPS

TRY_EMPS

+5V

LVL_S

LVL_S

+5V

BIND_P

BIND_P

CN4

-2

-3

CN23-3

-2

-1

CN5-13

-14

-15

CN36-3

-2

-1

CN30-3

-2

-1

CN5-1

-2

-3

-2

CN29-1

-3

-8

CN28-9

-7

CN31-3

-2

-1

-4

-5

-6

CN32-3

-2

-1

-7

-8

-9

-4

-5

-6

-7

-8

-9

-6

-5

-4

-3

-2

-1

CN35-3

-2

-1

CN5-10

-11

-12

-2

CN34-1

-3

-2

CN33-3

-1

CN39-3

-1

-2

CN16-1

-3

-2

-3

CN38-1

-2

-7

CN37-9

-8

BIND_L

Bookbinding

home position

sensor

home position

sensor

Bookbinding

roller home

position sensor

roller home

position sensor

Bookbinding

paper sensor

paper sensor

Bookbinding

lock sensor

lock sensor

Lift upper sensor

Lift lock sensor

Lift lower sensor

Finisher controller PCB

When at folding home

position, ‘0’.

position, ‘0’.

When the tray is at the

upper limit, ‘1’.

upper limit, ‘1’.

While the lift motor

is rotating, alternates

between ‘1’ and ‘0’.

is rotating, alternates

between ‘1’ and ‘0’.

When the stack feed roller

(upper) is at home position, ‘1’.

(upper) is at home position, ‘1’.

When the sensor

detects paper, ‘1’.

detects paper, ‘1’.

Front door sensor

Upper cover sensor

When the front door

is open, ‘1’.

is open, ‘1’.

When the upper cover

is open, ‘1’.

is open, ‘1’.

When the paper is

full, ‘1’.

full, ‘1’.

When the staple/fold motor is

rotating, alternates between

‘1’ and ‘0’.

rotating, alternates between

‘1’ and ‘0’.

When the tray is at the

lower limit, ‘1’.

lower limit, ‘1’.

Tray middle sensor

Joint switch

When the front

door is closed, ‘1’.

door is closed, ‘1’.

Front door switch

Stapler safety

switch

switch

When the swing

guide is closed, ‘1’.

guide is closed, ‘1’.

When connected to

the host machine, ‘1’.

the host machine, ‘1’.

FLE

FLLD

FULD

FFE

FFED

FFRHPD

FFHPD CN40-3

-2

-1

CN16-4

+5V

BIND_HP

BIND_HP

+5V

BIND_ROL_HP

BIND_ROL_HP

+5V

BIND_CLK

BIND_CLK

+5V

SIFT_UPLMT

SIFT_UPLMT

+5V

SIFT_DNLMT

SIFT_DNLMT

+5V

SIFT_CLK

SIFT_CLK

+5V

BIND_EMPS

BIND_EMPS

-5

-6

-5

CN38-4

-6

-5

CN37-6

-4

-7

-8

-9

CN41-3

-2

-1

CN47-3

-2

-1

CN15-1

-2

-3

FCD

FFDD

+5V

FDOOR_S

FDOOR_S

+5V

TOPCOV_S

TOPCOV_S

CN9-6

-4

-5

CN52-1

-3

-2

CN15-10

-11

-12

CN50-3

-2

-1

CN49-3

-2

-1

CN15-7

-8

-9

CN48-3

-2

-1

-5

-6

CN25-3

-2

-1

-8

-9

CN24-3

-2

-1

CN4-4

-5

-6

+5V

PAPER_F

PAPER_F

CN73-3

-2

-1

CN19-1

-2

-3

-7

-8

-9

-3

-2

-1

CN15-4

CN4-7

FFDDW

N. O.

+24VP

FJSW

FMLD

FSSSW

N. O.

N. O.

JOINT SW

FRONT SW

STPLSAFE SW

CN69-2

-1

CN8-6

-5

CN8-4

-3

CN8-2

-1

CN68-2

-1

CN66-2

-1

When the drive is transmitted,

‘1’.

‘1’.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

‘0’ according to the

direction of motor rotation.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

‘0’ according to the

direction of motor rotation.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

‘0’ according to the

direction of motor rotation.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

‘0’ according to the

direction of motor rotation.

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

‘0’ according to the

direction of motor rotation.

Finisher controller PCB

Feed motor

FEEDMTR_A

+24V

CN10-1

-1

CN62-5

Paddle motor

+24V

FPM

FFC

B_CLU

+24V

CN72

-1

-2

-2

-1

CN18-1

-2

Binding clutch

Bundle exit motor

+24V

FAM

Alignment motor

(front)

+24V

FFJM

Alignment motor

(rear)

+24V

FRJM

-2

-3

-4

-5

-6

FFM

-2

-3

-4

-5

-6

CN56

-6

-5

-4

-3

-2

-1

FEEDMTR_*A

FEEDMTR_B

FEEDMTR_*B

PDLMTR_A

PDLMTR_*A

PDLMTR_B

PDLMTR_*B

CN10-7

-8

-9

-10

-11

-12

-1

-2

-3

-4

-5

-6

CN57

-6

-5

-4

-3

-2

-1

EJCTMTR_A

EJCTMTR_*A

EJCTMTR_B

EJCTMTR_*B

CN13-1

-1

-2

-3

-4

-5

-6

-2

-3

-4

-5

-6

CN59

-6

-5

-4

-3

-2

-1

CN3-1

-2

-3

-4

-5

FJOGMTR_A

FJOGMTR_*A

FJOGMTR_B

FJOGMTR_*B

CN63-1

-2

-3

-4

-5

-4

-3

-2

-1

CN64-5

CN3-6

-7

-8

-9

-10

CN65-1

-2

-3

-4

-5

-4

-3

-2

-1

RJOGMTR_A

RJOGMTR_*A

RJOGMTR_B

RJOGMTR_*B

Finisher controller PCB

Lift motor

SIFTMTR_1

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

‘–’ according to the

direction of motor rotation.

CN6-1

-2

FLM

-2

-1

CN70

-2

-1

SIFTMTR_0

-2

-1

-2

-1

-2

-1

CN70

-2

-1

Staple motor

BINDMTR_1

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

‘–’ according to the

direction of motor rotation.

CN6-3

-4

FFSM

BINDMTR_0

CN71

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 3

• Inputs to and Outputs from the Finisher Controller PCB (1/2)

• Inputs to and Outputs from the Finisher Controller PCB (2/2)

D. Inputs to and Outputs from the Punch

Controller PCB (option)

• Inputs to and Outputs from the Punch Controller PCB

• Outputs from the Punch Controller PCB

Finisher controller PCB

CN72A-5

Stapler unit

Staple driver home

position sensor

position sensor

Selfprime

sensor

sensor

Staple empty

sensor

sensor

CN11-2

CN11-7

CN11-1

FSTHPD

+5V

+5V

+5V

FSHPD

+5V

HOOK_S

STPL_HP

SLID_HP

STPL_CNCT

Host

machine

CN2-1

-3

-4

-5

-7

-6

-4

-5

-7

-6

CN1-5

CN1-3

CN1-2

CN1-1

+24V

+24V

+5V

+5V

SELF_P

+5V

Staple shift home

position sensor

position sensor

CN11-6

CN11-5

CN11-4

CN11-3

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72-5

CN72-4

CN72-3

CN72-2

CN72-6

CN72-1

CN72-7

SLIDMTR_A

SLIDMTR_*A

SLIDMTR_B

SLIDMTR_*B

FSM

CN7-3

CN7-4

CN7-5

CN7-6

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72-10

CN72-11

CN72-12

CN72-13

Staple shift motor

GND

GND

TXD

GND

TXD

RXD

FSPD

FSD

When the stapler is

connected, ‘0’.

connected, ‘0’.

When the cartridge has

staples, ‘0’.

staples, ‘0’.

When the staple is at top

the stapler, ‘0’.

the stapler, ‘0’.

When the stapler is at

stapling home position, ‘0’.

stapling home position, ‘0’.

When the stapler is at home

position, ‘1’.

position, ‘1’.

Communication line

Switches between ‘1’ and

‘0’ according to the direction

ofmotor rotation.

‘0’ according to the direction

ofmotor rotation.

Finisher control PWB

FJPM

Interface

transport

motor

transport

motor

Interface transport

unit inlet port

sensor

unit inlet port

sensor

FJPID

Interface transport

unit outlet port

sensor

unit outlet port

sensor

FJPOD

Interface transport

unit cover sensor

unit cover sensor

FJPDD

CN19-

-2

-3

-4

-5

-3

-4

-5

CNFJ5

CN73B-

-6

-5

-5

-6

-4

-3

-2

-2

*A

*B

A

B

+24V

+24V

CN73D-9

-6

-7

-8

-8

-5

-4

-4

CNFJ1-2

-3

-2

-6

-5

-4

-5

-4

-5

-7

-3

-1

CNFJ1-2

-7

-6

-6

-5

-4

-4

-3

CNFJ2-1

+5V

+5V

+5V

LVL_E_S

LVL_P_S

LVL_C_S

-2

-3

CNFJ3-1

-3

-2

CNFJ4-3

-2

-1

CNFJ1-

CNFJ1-

CNFJ1-

-17

-16

-14

-13

-13

-11

-10

CNFJ1-

CNFJ1-

CNFJ1-

-17

-16

-14

-13

-13

-11

-10

-10

CN73C-1

-2

-3

-3

-5

CN73C-4

CN73C-7

-6

-8

CN73D-2

CN73A-8

CN73A-5

CN73A-2

-7

-6

-4

-3

-3

-1

CN73B-8

CN21-

-2

-3

-3

CN21-4

CN21-7

-5

-6

-8

-9

-9

"0" when paper is detected.

"0" when paper is detected.

"0" when the interface

transport cover is open.

transport cover is open.

The pulse signal is

switched depending

on the motor RPM.

switched depending

on the motor RPM.

Punch controller PCB

-1

J2008-3

+5V

PUNCH

PUNCH

-2

-6

J1006-4

-5

SREG1*

SREG2*

SREG3*

SREG2*

SREG3*

-9

-10

-11

J1007-12

-13

SREG4*

-8

PAEND*

-7

Horizontal

registration

home position

sensor

registration

home position

sensor

FPMCK

-1

J2009-3

+5V

CLOCK

CLOCK

-2

-9

J1006-7

-8

Punch home

position sensor

position sensor

+5V

+5V

PT1

PT2

PT3

PT4

PT5

FPSHPD

FPHPD

-1

J2007-3

+5V

SLIDE

SLIDE

-2

-3

J1006-1

-2

Punch motor

lock sensor

lock sensor

Side resist photo sensor PCB (FPTD)

DUSTLED

Waste full LED PCB

J1005-1

PT131

LED121

DUSTPTR

+5V

4

Waste full photosensor PCB (FPDD)

-2

J1005-3

When the hole puncher is

at home position, ‘0’.

at home position, ‘0’.

While the punch motor

is rotating, alternates

between ‘0’ and ‘1’.

is rotating, alternates

between ‘0’ and ‘1’.

When the punch slide

unit is at home position,

‘1’.

unit is at home position,

‘1’.

When paper is

detected, ‘0’.

detected, ‘0’.

When the light is

blocked, ‘0’.

blocked, ‘0’.

Punch controller PCB

FPSM

Punch side resist motor

B*

A*

B

A

J1001-1

-2

-3

-4

FPNM

Punch motor

J1002-1

-2

LEDON5

LEDON4

LEDON3

LEDON2

LEDON1

LEDON4

LEDON3

LEDON2

LEDON1

-4

-5

-1

J1007-6

+5V

-3

-2

-2

LED5

LED4

LED3

LED2

LED1

Side resist LED PCB (FPSD)

Switches between ‘+’

and ‘–’ according to

the direction ofmotor

rotation.

and ‘–’ according to

the direction ofmotor

rotation.

When ‘1’, LED goes ON.

Switches the pulse

signals according to

the rotation ofthe motor.

signals according to

the rotation ofthe motor.

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 4

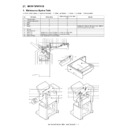

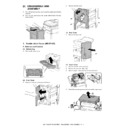

2. Feed/Drive System

A. Outline

The machine performs the following in response to the commands

coming from its host machine on the sheets arriving from the host

machine for delivery: simple stacking, job offset, and stapling or

folding (in two).

If a punch unit (option) is installed, the sheets are pouched and

delivered to the delivery tray.

Sheets may be delivered in either of five ways (including one for

the punch unit):

coming from its host machine on the sheets arriving from the host

machine for delivery: simple stacking, job offset, and stapling or

folding (in two).

If a punch unit (option) is installed, the sheets are pouched and

delivered to the delivery tray.

Sheets may be delivered in either of five ways (including one for

the punch unit):

(1) Normal Delivery

a. Simple Stacking

The machine pulls in the sheet once to the processing tray and

then delivers it to the delivery tray.

The machine pulls in the sheet once to the processing tray and

then delivers it to the delivery tray.

b. Job Offset

The machine pulls the sheet once to the processing tray. It then

moves the sheet to the front or the rear using the aligning plate.

When it has deposited a specific number of sheets, it delivers them

in the form of a aligning plane. When the number of sheets stacked

on the processing tray reaches a specified value, the sheets are

delivered in a form of a stack.

The machine pulls the sheet once to the processing tray. It then

moves the sheet to the front or the rear using the aligning plate.

When it has deposited a specific number of sheets, it delivers them

in the form of a aligning plane. When the number of sheets stacked

on the processing tray reaches a specified value, the sheets are

delivered in a form of a stack.

c. Stapling

The machine stacks sheets coming from its host machine on the

processing tray. When the number of sheets stacked on the pro-

cessing tray reaches a specified value, the finisher staples them

delivers the stapled stack to the delivery tray.

The machine stacks sheets coming from its host machine on the

processing tray. When the number of sheets stacked on the pro-

cessing tray reaches a specified value, the finisher staples them

delivers the stapled stack to the delivery tray.

Punching

Normal delivery

Delivery method

Middle 2-point stapling

Job offset

Simple stacking

Stapling

Front 1-point stapling

Rear 1-point stapling

Middle 2-point stapling

Stitching

Saddle delivery

Tray

Paper

4th set

(direction of delivery)

Results of offset delivery (4 jobs)

2nd set

3rd set

1st set