Sharp MX-M950 / MX-MM1100 (serv.man24) Service Manual ▷ View online

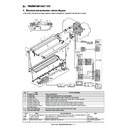

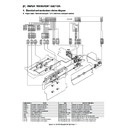

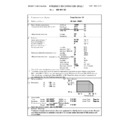

MX-M1100 TRANSFER SECTION L – 1

MX-M1100

Service Manual

[L] TRANSFER SECTION

1. Electrical and mechanism relation diagram

In this section, a positive high voltage is applied to paper to transfer toner images from the OPC drum to paper.

No.

Name

Function / Operation

1

Transfer drive roller

Drives the transfer belt.

2

Transfer belt

Transfers toner images from the OPC drum to paper.

3

Transfer roller

Applies a voltage for transfer of toner from the OPC drum to paper.

4

Transfer idle roller

Applies a pressure required for cleaning the transfer belt to the cleaning blade.

5

Transfer tension roller

Applies a proper tension to the transfer belt.

6

Transfer cleaning brush

Scrapes away residual toner from the transfer belt after transfer for cleaning.

7

Transfer cleaning blade

Scrapes away residual toner from the transfer belt after transfer for cleaning.

8

Waste toner transport screw

(Transfer section)

(Transfer section)

Transports waste toner from the transfer unit to the waste toner collection section.

9

Main high voltage PWB

Outputs the transfer voltage and the transfer cleaning voltage.

10

Sub high voltage PWB

Outputs the transfer cleaning voltage.

Code

Name

Function / Operation

Type

PTDL

Pre-transfer discharge lamp Reduces the OPC drum potential before transfer to improve the transfer efficiency.

LED

TURS

Transfer solenoid

Separates/attaches the transfer belt from/to the OPC drum.

Solenoid

DM

OPC drum motor

Drives the transfer section.

DC brushless motor

TLS2

Waste toner jam sensor

Detects a waste toner transport jam.

Transmission type photo

sensor

sensor

DM

DM

1

1

TURS

TURS

1

1 2

2

5

5

6

6

7

7

8

8

3

3

4

4

2

2

5

5

6

6

7

7

8

8

3

3

4

4

13

GND2

15

+5V_C

17

XDM

19

DMCLK

21

DM-T

3

GND1

8

+38V0

HL PWB

38V0

1

GND1

2

GND2

1

+5V_C

2

XDM

3

DMCLK 4

DM-T

DM-T

5

5 GND1

5

6 +38V0

6

DSW-F-HV

B16B-PASK

CN1

1

13

DF1B-28DES-2.5RC

DF1B-28DEP-2.5RC

DSW-F-HV

13

GND2

2

14 GND2

14

GND2

3

15 GND2

15

XTHV+PWM

7

19 XTHV+PWM 19

XTHV+REM

8

20 XTHV+REM 20

HVREMout

15

27 HVREMout

27

+24V_A

16

28 +24V_A

28

2

B40B-PNDZS-1

CN-3

DSW-F-HV2

4 GND2

6 GND2

9 DSW-F-HV

11 GND2

13 GND2

13 GND2

DSW-F-HV2

B11B-PASK

CN1

1

GND2

2

16 XTHVCLPWM

GND2

3

18 XTHVCLREM

21 XTHV+PWM

XTHVCLPWM

8

22 XBHVREM

XTHVCLREM

9

23 XTHV+REM

XBHVREM

11

1

B2P-VH

THVCL

2 THVCL

37 HVREMout

39 +24V_A

39 +24V_A

THV

PCU PWB

High voltage

PWB unit

PWB unit

(Main)

High voltage

PWB unit

PWB unit

(Sub)

3

2

1

TURS2

3

TURS1

2

+24V_TURS

1

3

2

1

TURS2

3

TURS1

2

+24V_TURS

1

+24V_TURS1

17

+24V_TURS2

16

3

4

4

TURS1

4

TURS2

3

SMR-03V-N/SMP-03V-NC

SMP-06V-NC/SMR-06V-N

DF11-4DP-2C+DF11-4DP-SP1

17

18

18

TURS2

3

TURS1

1

B40B-PNDZS-1

CN19

+24V_TURS1

5

+24V_TURS2

7

4

2

1

3

+24V_TURS2

2 +24V_TURS1

+24V_TURS

B40B-PNDZS-1

CN-21

B10B-PASK-1(LF)(SN)

CN7

SMR-10V-N/SMP-10V-NC

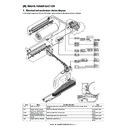

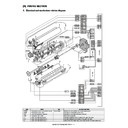

MX-M1100 TRANSFER SECTION L – 2

2. Operational descriptions

A. Pre-transfer discharge operation

Light is radiated onto the OPC drum after development to reduce

negative charges on the OPC drum. In the areas where toner is

attached to, an electric attraction force between the OPC drum and

toner is weakened to improve the efficiency in transfer operations.

In the areas where toner is not attached to, an electric attraction

force between paper and the OPC drum after transfer is weakened

to improve the separation performance.

negative charges on the OPC drum. In the areas where toner is

attached to, an electric attraction force between the OPC drum and

toner is weakened to improve the efficiency in transfer operations.

In the areas where toner is not attached to, an electric attraction

force between paper and the OPC drum after transfer is weakened

to improve the separation performance.

B. Transfer operation

A positive high voltage is applied to the transfer roller to charge

paper on the transfer belt positively, transferring negatively

charged toner images onto paper.

paper on the transfer belt positively, transferring negatively

charged toner images onto paper.

(Transfer current)

The transfer current control signal (XTHV+PWM) duty is changed

to control the output current.

The transfer current ON / OFF is controlled by the signal (XTHV +

REM).

In addition, the other transfer current control signal XTHV-PWM

and the transfer current ON/OFF control signal (XTHV-REM) are

outputted simultaneously.

to control the output current.

The transfer current ON / OFF is controlled by the signal (XTHV +

REM).

In addition, the other transfer current control signal XTHV-PWM

and the transfer current ON/OFF control signal (XTHV-REM) are

outputted simultaneously.

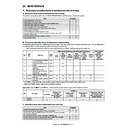

C. Transfer belt cleaning operation

In the transfer belt cleaning operation, a negative high voltage

including the AC component is applied to the transfer roller to

attach unnecessary residual toner from the transfer belt to the OPC

drum, cleaning the transfer belt.

including the AC component is applied to the transfer roller to

attach unnecessary residual toner from the transfer belt to the OPC

drum, cleaning the transfer belt.

The transfer belt cleaning control signal (XTHV-PWM) duty is

changed to control the output voltage.

The transfer belt cleaning ON/OFF is controlled by the signal

(XTHV-REM).

On the other hand, the AC component controls the output voltage

by changing the duty of XTHVACPWM. The AC component ON/

OFF is controlled by the signal (XTHVACREM).

The transfer belt cleaning is executed mainly by the transfer blade

belt cleaning belt.

Unnecessary residual toner on the transfer belt is removed and

transported to the waste toner collection section by the waste toner

transport screw.

changed to control the output voltage.

The transfer belt cleaning ON/OFF is controlled by the signal

(XTHV-REM).

On the other hand, the AC component controls the output voltage

by changing the duty of XTHVACPWM. The AC component ON/

OFF is controlled by the signal (XTHVACREM).

The transfer belt cleaning is executed mainly by the transfer blade

belt cleaning belt.

Unnecessary residual toner on the transfer belt is removed and

transported to the waste toner collection section by the waste toner

transport screw.

In addition, the cleaning brush is provided in the transfer section,

where the transfer belt is cleaned, too.

In the transfer belt cleaning, the cleaning roller (brush type)

removes unnecessary residual toner from the transfer belt, and a

positive voltage (+200V) is applied to the removed toner to attach

them to the cleaning roller.

where the transfer belt is cleaned, too.

In the transfer belt cleaning, the cleaning roller (brush type)

removes unnecessary residual toner from the transfer belt, and a

positive voltage (+200V) is applied to the removed toner to attach

them to the cleaning roller.

Model

Operation mode

Output current

85 -sheet model

Front print

30uA

Back print

35uA

95 -sheet model

Front print / Back print

40uA

110 -sheet model

Front print / Back print

40uA

PTDL1

PTDL1

OPC drum

CTL

CGL

Aluminum

layer

layer

Cleaning

mode

mode

Transfer

mode

mode

OPC drum

CTL

CGL

Aluminum

layer

-400v/-600v

AC4.5kv

(p-p)

(p-p)

30-40

μA

Cleaning

mode

mode

Transfer

mode

mode

OPC drum

CTL

CGL

Aluminum

layer

-400v/-600v

AC4.5kv

(p-p)

(p-p)

30-40

μA

Cleaning

mode for

transfer belt

mode for

transfer belt

Cleaning

mode for

cleaning roller

mode for

cleaning roller

-500v

+200v

MX-M1100 TRANSFER SECTION L – 3

The toner attached to the cleaning roller is then cleaned by the

cleaning roller cleaning blade.

The transfer cleaning control signal (XTHVCLPWM) duty is

changed to control the polarity and the output voltage.

The transfer cleaning ON/OFF is controlled by the signal (XTHVCL-

REM).

cleaning roller cleaning blade.

The transfer cleaning control signal (XTHVCLPWM) duty is

changed to control the polarity and the output voltage.

The transfer cleaning ON/OFF is controlled by the signal (XTHVCL-

REM).

The cleaning roller itself is also cleaned. In this mode, a negative

voltage (-500V) is applied to attach residual toner on the cleaning

roller to the transfer belt. Then toner attached on the transfer belt is

cleaned by the transfer belt cleaning blade.

The transfer cleaning control signal (XTHVCLPWM) duty is

changed to control the polarity and the output voltage.

The transfer cleaning ON/OFF is controlled by the signal (XTHVCL-

REM).

voltage (-500V) is applied to attach residual toner on the cleaning

roller to the transfer belt. Then toner attached on the transfer belt is

cleaned by the transfer belt cleaning blade.

The transfer cleaning control signal (XTHVCLPWM) duty is

changed to control the polarity and the output voltage.

The transfer cleaning ON/OFF is controlled by the signal (XTHVCL-

REM).

D. Transfer belt separation operation

The transfer belt separation is executed by the transfer solenoid.

When the print engine receives print data and performs printing,

the transfer belt is in close contact with the OPC drum.

In the following cases, the transfer belt is separated from the OPC

drum.

* When the process control is executed.

* When a jam occurs.

* When the power is turned OFF.

When the print engine receives print data and performs printing,

the transfer belt is in close contact with the OPC drum.

In the following cases, the transfer belt is separated from the OPC

drum.

* When the process control is executed.

* When a jam occurs.

* When the power is turned OFF.

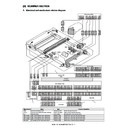

3. Disassembly and assembly

A. Transfer unit

(1) Transfer unit

1)

Open the front cover (a), and pull out the intermediate frame

(b).

(b).

2)

Remove the screw (a), and remove the cover (b).

Cleaning

mode for

transfer belt

mode for

transfer belt

Cleaning

mode for

cleaning roller

mode for

cleaning roller

-500v

+200v

Cleaning

mode for

transfer belt

mode for

transfer belt

Cleaning

mode for

cleaning roller

mode for

cleaning roller

-500v

+200v

OPC Drum

Unit

Parts

Page

Transfer unit

A

Transfer separation solenoid

L - 4 / a

A

a

b

a

b

MX-M1100 TRANSFER SECTION L – 4

3)

Remove the screw (a), and remove the holder (b).

4)

Remove the transfer belt unit (a).

5)

Disconnect the connector (a), and remove the screw (b).

Remove the trandfer belt frame unit (c).

Remove the trandfer belt frame unit (c).

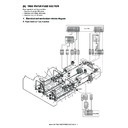

a. Transfer separation solenoid

1)

Remove the transfer unit.

2)

Remove the screw (a), and remove the transfer cleaning blade

(b).

(b).

3)

Remove the screw (a), and remove the mounting plate (b).

4)

Remove the screw (a), and remove the mounting plate (b).

Remove the stopper (c), the gear (d), the E-ring (e), and the

bearing (f).

Remove the stopper (c), the gear (d), the E-ring (e), and the

bearing (f).

5)

Remove the screw (a), and remove the plate (b). Remove the

bearing (c) and the gear unit (d).

bearing (c) and the gear unit (d).

a

b

a

a

b

b

c

a

b

a

b

a

b

c

d

e

f

a

b

d

c

a

a

Display