Sharp MX-M950 / MX-MM1100 (serv.man18) Service Manual ▷ View online

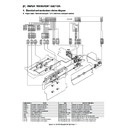

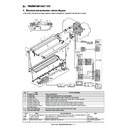

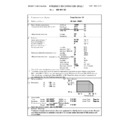

MX-M1100 PAPER TRANSPORT SECTION F – 1

MX-M1100

Service Manual

[F] PAPER TRANSPORT SECTION

1. Electrical and mechanism relation diagram

A. Paper pass / Vertical transport / LCC interface transport section

Signal name

Name

Type

Function / Operation

C1PFD

Cassette 1 paper entry detection

Reflection type

Detects the cassette 1 paper pass.

C1PPD1

Cassette 1 transport detection 1

Reflection type

Detects the cassette 1 paper transport.

C1PPD2

Cassette 1 transport detection 2

Reflection type

Detects the cassette 1 paper transport.

C1PTC

Horizontal transport clutch

Electromagnetic clutch

Controls ON/OFF of the transport roller.

C2PFD

Cassette 2 paper entry detection

Reflection type

Detects the cassette 2 paper pass.

LCCPTC

LCC transport clutch

Electromagnetic clutch

Controls ON/OFF of the transport roller.

MM1

Paper feed motor 1

DC brushless motor

Drives the paper feed section 1.

PPD1

Transport detection 1

Reflection type

Detects paper transport in the transport path.

VPPD

Vertical transport detection

Reflection type

Detects paper transport in the vertical transport path.

VPTC2

Vertical transport clutch (Intermediate)

Electromagnetic clutch

Controls ON/OFF of the vertical transport roller.

VPTC3

Vertical transport clutch (Upper)

Electromagnetic clutch

Controls ON/OFF of the vertical transport roller.

14

GND2

16

+5V_C

18

XMM

20

MMCLK

22

MM-T

38V0

1

GND1

2

GND2

1

+5V_C

2

XMM

3

MMCLK

4

MM-T

5

3

GND1

3

4

+38V0

4

2

GND1

7

+38V0

HL PWB

PCU PWB

CN-21

B40B-PNDZS-1

1

+24V_A

3

10

+24V_A

2

(NC)

2

3

C1PTC

1

12

C1PTC

BU03P-TR-P-H

+24V_A

28

XLCCPTC

30

3

+24V_A

1

2

(NC)

2

1

XLCCPTC

3

LCCPTC

BU03P-TR-P-H

CN-13

1

+24V_A

3

B36B-PNDZS-1

2

(NC)

2

3

VPTC2

1

2

+24V_A

4

VPTC2

1

+24V_A

3

6

+24V_A

2

(NC)

2

3

VPTC3

1

8

VPTC3

9

+5V_C

11

C2PFD

13

GND2

14

+5V_C

15

+5V_C

16

GND2

17

PPD1

+5V_C

1

4

+5V_C

4

18

C1PFD

C2PFD

2

5

C2PFD

5

19

GND2

GND2

3

6

GND2

6

20

C1PPD1

7

+

5V_C

7

21

+5V_C

+5V_C

1

8

PPD1

8

22

C1PPD2

PPD1

2

9

GND2

9

23

VPPD

GND2

3

10

+5V_C

10

11

VPPD

11

25

GND2

+5V_C

1

12

GND2

12

VPPD

2

GND2

3

+5V_C

1

+5V_C

2

+5V_C

1

+5V_C

3

C1PFD

2

+5V_C

4

GND2

3

1

+5V_C

1

1

+

5V_C

1

2

C1PFD

2

2

C

1PFD

2

3

GND2

3

3G

N

D

2

3

+5V_C

1

4

+5V_C

4

4

+5V_C

4

C1PPD1

2

5

C1PPD1

5

5C

1

P

P

D

1

5

GND2

3

6

GND2

6

6

GND2

6

7

+5V_C

7

7

+5V_C

7

8

C1PPD2

8

8

C

1PPD2

8

9

GND2

9

9

GND2

9

+5V_C

1

C1PPD2

2

GND2

3

GND2

4

GND2

3

GND2

2

GND2

1

DF11-4DS-2C

+

SP1

SMR-12V-N/SMP-12V-NC

BU03P-TR-P-H

BU03P-TR-P-H

DF11-4DS-2C

+

SP1

SMR-09V-B/SMP-09V-BC

SMP-09V-NC/SMR-09V-N

179228-3

179228-3

179228-3

CN6

B14B-PASK-1(LF)(SN)

MM1

MM1

C1PTC

C1PTC

VPTC3

VPTC3

LCCPTC

LCCPTC

VPTC2

VPTC2

VPPD

VPPD

C2PFD

C2PFD

C1PFD

C1PFD

PPD1

PPD1

C1PPD2

C1PPD2

C1PPD1

C1PPD1

SMR-10V-N/SMP-10V-NC

MX-M1100 PAPER TRANSPORT SECTION F – 2

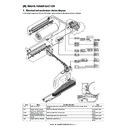

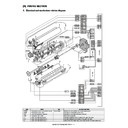

B. Upper transport / PS roller section

Signal name

Name

Type

Function/Operation

APFD1

ADU paper entry detection 1

Reflection type

Detects the ADU paper pass.

APFD2

ADU paper entry detection 2

Reflection type

Detects the ADU paper pass.

CFM-PS

PS cooling fan

Axial-flow fan (40)

Cools the PS section.

DPFS-R

Double feed sensor (receiving)

Supersonic sensor

Detects paper double feed.

DPFS-T

Double feed sensor (transmitting)

Supersonic sensor

Detects paper double feed.

PPD2

Transport detection 2

Reflection type

Detects paper transport in the transport path.

PPD3

Transport detection 3

Reflection type

Detects paper transport in the transport path.

PPD4

Transport detection 4

Reflection type

Detects paper transport in the transport path.

PSM

PS motor

Stepping motor

Drive the PS roller.

TRM

Transport motor

Stepping motor

Drives the transport roller.

VPM

Vertical transport motor

Stepping motor

Drives the vertical transport roller.

PPD4

PPD4

PSM

PSM

TRM

TRM

VPM

VPM

PPD3

PPD3

CFM-PS

CFM-PS

CIS

CIS

PPD2

PPD2

APFD1

APFD1

APFD2

APFD2

DPFS-T

DPFS-T

DPFS-R

DPFS-R

PS/Transfer drawer

CN4

CN1

Double

feed

detection

PWB

CN4

PCU

PPD2,3,4

CN1

CN3

PED

cis

PWB

PSF

PCU PWB

3

2

1

GND2

3

PPD4

2

+5V

1

+24V-PS

14

RXD_CIS

12

+24V-PSM1

1

RSE_CIS

11

GND2

13

PSM_A//

18

+24V-PSM2

2

PSM_A/

19

+24V(ON/OFF)

15

5V_PS

10

GND2

9

PPD4

8

PPD3

7

PPD2

6

n_GCS

5

n_GINC

4

DPFCK

3

GND2

2

DPFAout

1

GND2

20

GND2

19

GUn_D

17

GND2

16

GND2

14

5V_C

13

APFD1

11

APFD2

10

FRM_CIS

9

CLK_CIS

8

PAGE_CIS

7

DPF

18

1

2

2

1

2

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

ADD_CIS

6

TXD_CIS

5

PSM_B/

2

PSM_B//

1

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

19

20

2

3

4

5

6

7

8

10

11

12

13

14

15

16

19

20

+12V_PS

15

+5V_APFD1

1

APFD1

2

GND2

3

+5V_APFD2

1

APFD2

2

GND2

3

SI

4

CIS_CLK

5

+3.3V

3

+24V

7

GLED

6

1 SIG

GND2

2

6

5

4

3

2

1

+24V-PSM2

6

+24V-PSM1

5

PSM_B/

4

PSM_B//

3

PSM_A//

2

PSM_A/

1

4

2

1

3

+24V(ON/OFF)

3

+24V(ON/OFF)

+24V(ON/OFF)

+24V(ON/OFF)

3

1

2

2

+5V_C

+5V_APFD1

+5V_APFD2

+5V_APFD2

4

2

+5V_PS

19

+24V(ON/OFF)

18

PPD3

13

+12V_PS

12

PPD2

11

GND2

10

n_GCS

9

GUn_D

8

n_GINC

7

FRM_CIS

20

DPF

6

DPFCK

5

GND2

3

GND2

2

DPFAout

1

18

17

15

13

12

11

10

9

8

7

6

5

3

2

1

17

15

13

12

11

10

9

8

7

6

5

3

2

1

PPD4

15

PAGE_CIS

24

RXD_CIS

23

RSE_CIS

21

CLK_CIS

22

19

20

21

22

23

GND2

25

24

ADD_CIS

26

26

25

25

GND2

17

28

27

27

TXD_CIS

28

+24V-PS

27

GND2

1

+24V-PS

2

FRM_CIS

3

CLK_CIS

4

PAGE_CIS

5

ADD_CIS

6

TXD_CIS

7

RSE_CIS

8

RXD_CIS

9

CN19

XCFM-PS

9

+24V-PS

11

CLK_CIS

12

PAGE_CIS

10

CN_LEDout19

2

TXD_CIS

6

ADD_CIS

8

GND2

13

FRM_CIS

14

RXD_CIS

15

APFD2

16

RSE_CIS

17

APFD1

18

+5V_PS

19

GND2

21

PPD4

23

+5V_C

24

PPD3

25

PPD2

27

+12V_PS

28

n_GCS

29

GND2

30

n_GINC

31

GUn_D

32

DPFCK

33

DPF

34

GND2

35

GND2

36

GND2

26

GND2

38

DPFAout

37

CN_LEDin19

40

3

1

2

2

GND2

GND2

GND2

GND2

4

GND2

1

2

GND2

2

DPFS-T

1

DPFS-R

1

GND2

2

GND2

1

+5V_PS

2

+5V

3

GND2

4

LOCK1

9

GND2

10

3

1

2

2

+5V

+5V

+5V

+5V

4

+5V

CN3

VPMB//

4

+24V-PS

5

PSM_A//

8

PSM_B/

9

VPMB/

3

+24V-PSM1 11

PSM_A/

7

+24V-PS

6

1

VPMA/

VPMA//

VPMA//

2

+24V-PSM2 12

PSM_B//

10

1

(95/110only)

(95/110only)

(95/110only)

(95/110only)

2

3

+24V(ON/OFF) 1

LOCK1

2

GND2

3

PSM_A//

1

+24V-PSM1

2

PSM_A/

3

PSM_B//

4

+24V-PSM2

5

PSM_B/

6

6

5

4

3

2

1

GND2

6

APFD2

5

+5V_APFD2

4

GND2

3

APFD1

2

+5V_APFD1

1

+5V

1

PPD2

2

GND2

3

+5V

1

PPD3

2

GND2

3

B08B-PNDZS-1

GND2

1

SIG

2

+3.3V

3

SI

4

CIS_CLK 5

GLED

GLED

6

+24V

7

DPFS-T

1

GND2

2

2

1

GND2

2

DPFS-T

1

CN3

n_GINC

4

GUn_D

5

DPF

3

1

DPFCK

GND2

GND2

2

n_GCS

6

6

5

4

3

2

1

PPD4

6

PPD3

5

PPD2

4

GND2

3

(NC)

2

+5V

1

+5V

1

PPD4

2

GND2

3

1

2

GND2

2

DPFS-R

1

3

1

GND2

GND2

GND2

GND2

GND2

4

2

CN2

DPFAout

2

GND2

3

+12V_PS

4

1

GND2

CN3

7 +24V4A

8 GND1

8 GND1

CN1

GND2

1

1 GND2

1

CN6

+5V_D

2

2 +5V_D

2

+24V4_A

3

3 +24V4_A

3

GND1

4

4 GND1

4

3 5V_D

4 GND2

4 GND2

DCPS2 PWB

(MAIN)

(MAIN)

CN-7

CN-2

XVPMA

3

3

XVPMA

XVPMB

4

4

XVPMB

XVPMXA

5

5

XVPMXA

XVPMXB

6

6

XVPMXB

1 TRMA//

1

CN-4

2 +24V-TR

2

3 TRMB//

3

TRMA/

1

4 TRMA/

4

TRMA//

2

5 +24V-TR

5

TRMB//

3

6 TRMB/

6

TRMB/

4

XTRMA

13

13

XTRMA

+24V-TR

5

XTRMB

14

14

XTRMB

+24V-TR

6

XTRMXA

15

15

XTRMXA

XTRMXB

16

16

XTRMXB

PCU

PWB

PWB

Driver

PWB

(Paper

feed)

1 VPMA/

1

2 VPMA//

2

3 VPMB//

3

4 VPMB/

4

5 +24V-VP 5

6 +24V-VP 6

6 +24V-VP 6

1 VPMA//

2 +24V-VP

3 VPMA/

4 VPMB//

5 +24V-VP

6 VPMB/

2 +24V-VP

3 VPMA/

4 VPMB//

5 +24V-VP

6 VPMB/

MX-M1100 PAPER TRANSPORT SECTION F – 3

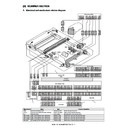

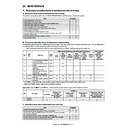

2. Operational descriptions

A. Outline

The paper transport section serves the function of transferring

paper from each paper feed port to the registration roller section.

Paper from paper feed tray units 1 and 2, paper feed tray 3 and

paper feed tray 4 is transported vertically to the registration roller

section.

The detection of double-feed is done before transferring paper to

the registration roller, and the check of the off-center is carried out

by the image position sensor.

After the leading edge of the paper is synchronized with the leading

edge of the drum image in the registration roller section, the paper

that is transfer printed with the image in the transfer section passes

through the fusing section and is discharged either face-down or

face-up.

paper from each paper feed port to the registration roller section.

Paper from paper feed tray units 1 and 2, paper feed tray 3 and

paper feed tray 4 is transported vertically to the registration roller

section.

The detection of double-feed is done before transferring paper to

the registration roller, and the check of the off-center is carried out

by the image position sensor.

After the leading edge of the paper is synchronized with the leading

edge of the drum image in the registration roller section, the paper

that is transfer printed with the image in the transfer section passes

through the fusing section and is discharged either face-down or

face-up.

[Operation of Image position sensor]

It detects the position of the paper transferred by the contact image

sensor (CIS) and automatically adjusts the off center.

• CIS: Contact Image Sensor

It detects the position of the paper transferred by the contact image

sensor (CIS) and automatically adjusts the off center.

• CIS: Contact Image Sensor

It is a contact image sensor integrated with the light source, the

lens (Selfoc ) and the sensor.

lens (Selfoc ) and the sensor.

B. Paper transport operation

Straight-Through Path (No Inversion, No Duplexing)

The paper transported from the each tray section is sent to the

paper exit roller (which is driven by the paper exit motor (POM))

with the transport roller).

paper exit roller (which is driven by the paper exit motor (POM))

with the transport roller).

Paper transportation speed

C. Paper face-down output operation

Invertion Path (Face-down Output, No Duplexing)

When face-down print is selected, the paper is passed under the

Face-up/face-down select gate.

After paper passing, the paper exit gate guide falls down by its own

weight.

When the specified time has passed from detection of the paper

lead edge by Face down reverse detection, Paper exit reverse

motor (SBRM) rotates reverse direction in the specified time. (The

rotation time differs depending on the paper size.)

Face-up/face-down select gate.

After paper passing, the paper exit gate guide falls down by its own

weight.

When the specified time has passed from detection of the paper

lead edge by Face down reverse detection, Paper exit reverse

motor (SBRM) rotates reverse direction in the specified time. (The

rotation time differs depending on the paper size.)

D. Double-feed sensor operation

(1) Outline of the operation

The double-feed sensor is incorporated in the paper transport sec-

tion of 110/95 ppm machine, and it detects double feed.

Paper transport stops when double feed is detected.

tion of 110/95 ppm machine, and it detects double feed.

Paper transport stops when double feed is detected.

Ultrasonic generator generates ultrasound during paper transport.

The level of reception of the ultrasonic sensor largely changes

(decreases) when double feed occurs. Double sheet feed is

detected in this method.

The level of reception of the ultrasonic sensor largely changes

(decreases) when double feed occurs. Double sheet feed is

detected in this method.

Image position sensor

Double feed

detection

1

1

2

Face-up/face-down select gate

Unit (mm/s)

110 / 95CPM

85 CPM

: Normal speed

540

400

(Process speed)

: High speed

600

500

(Paper feed and exit speed)

: High speed

1000

1000

(Switchback speed)

1

2

3

1

3

3

2

2

Face down reverse detection

Face-up/face-down select gate

solenoid OFF-Up, ON-Down

solenoid OFF-Up, ON-Down

ADU gate solenoid

OFF-Left, ON-Right

OFF-Left, ON-Right

Paper

(1 sheet)

(Double feed)

Ultrasound

Ultrasonic

generator

generator

Secondary

radiation

Reflect

Ultrasonic

sensor

sensor

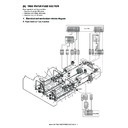

MX-M1100 PAPER TRANSPORT SECTION F – 4

Block diagram

(2) Mechanism and operation of double-feed detection

The sensor is composed of ultrasonic generator part and ultrasonic

detector part. Double feed is detected using 220kHz ultrasound.

Operation when sheets of paper are normally fed one by one

Some of the ultrasound is reflected by the paper, but the ultrasound

reaches the sensor more than the specified level.

The sensor analog output level at that time is 300mV or more, and

digital output level is "L."

Operation when double feed occurs

Most of ultrasound is reflected when double feed occurs, because

the stiffness of paper is high. As a result, the ultrasound which

reaches the sensor is weak, and less than the specified level.

At that time, the sensor analog output level is 300mV or less, the

digital output level is "H."

detector part. Double feed is detected using 220kHz ultrasound.

Operation when sheets of paper are normally fed one by one

Some of the ultrasound is reflected by the paper, but the ultrasound

reaches the sensor more than the specified level.

The sensor analog output level at that time is 300mV or more, and

digital output level is "L."

Operation when double feed occurs

Most of ultrasound is reflected when double feed occurs, because

the stiffness of paper is high. As a result, the ultrasound which

reaches the sensor is weak, and less than the specified level.

At that time, the sensor analog output level is 300mV or less, the

digital output level is "H."

3. Disassembly and assembly

A. Paper pass unit

(1) Paper pass unit

1)

Pull out the tray 1, 2 (a).

2)

Remove the screw (a), and remove the tray 1, 2 (b).

3)

Open the front cover (a), and pull out the intermediate frame

(b).

(b).

4)

Disconnect the connector (a), and remove the screw (b).

Remove the paper pass unit (c).

Remove the paper pass unit (c).

Unit

Parts

Page

Paper pass unit

A

Cassette 1 paper entry detection

F - 5/a

B

Cassette 1 transport detection 1

C

Cassette 1 transport detection 2

Ultrasonic sensor

(DFS PWB)

Ultrasound

generate

generate

Digital signal

output

output

PCU

PWB

Ultrasonic

generator

Amplifier

Detection

circuit

circuit

C

B

A

a

a

a

b

a

a

b

b

b

c

a