Sharp MX-FNX2 (serv.man7) Service Manual ▷ View online

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 3

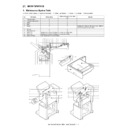

• Inputs to and Outputs from the Finisher Controller PCB (1/2)

• Inputs to and Outputs from the Finisher Controller PCB (2/2)

D. Inputs to and Outputs from the Punch

Controller PCB (option)

• Inputs to and Outputs from the Punch Controller PCB

• Outputs from the Punch Controller PCB

Finisher controller PCB

CN72A-5

Stapler unit

Staple driver home

position sensor

position sensor

Selfprime

sensor

sensor

Staple empty

sensor

sensor

CN11-2

CN11-7

CN11-1

FSTHPD

+5V

+5V

+5V

FSHPD

+5V

HOOK_S

STPL_HP

SLID_HP

STPL_CNCT

Host

machine

CN2-1

-3

-4

-5

-7

-6

-4

-5

-7

-6

CN1-5

CN1-3

CN1-2

CN1-1

+24V

+24V

+5V

+5V

SELF_P

+5V

Staple shift home

position sensor

position sensor

CN11-6

CN11-5

CN11-4

CN11-3

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72-5

CN72-4

CN72-3

CN72-2

CN72-6

CN72-1

CN72-7

SLIDMTR_A

SLIDMTR_*A

SLIDMTR_B

SLIDMTR_*B

FSM

CN7-3

CN7-4

CN7-5

CN7-6

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72-10

CN72-11

CN72-12

CN72-13

Staple shift motor

GND

GND

TXD

GND

TXD

RXD

FSPD

FSD

When the stapler is

connected, ‘0’.

connected, ‘0’.

When the cartridge has

staples, ‘0’.

staples, ‘0’.

When the staple is at top

the stapler, ‘0’.

the stapler, ‘0’.

When the stapler is at

stapling home position, ‘0’.

stapling home position, ‘0’.

When the stapler is at home

position, ‘1’.

position, ‘1’.

Communication line

Switches between ‘1’ and

‘0’ according to the direction

ofmotor rotation.

‘0’ according to the direction

ofmotor rotation.

Finisher control PWB

FJPM

Interface

transport

motor

transport

motor

Interface transport

unit inlet port

sensor

unit inlet port

sensor

FJPID

Interface transport

unit outlet port

sensor

unit outlet port

sensor

FJPOD

Interface transport

unit cover sensor

unit cover sensor

FJPDD

CN19-

-2

-3

-4

-5

-3

-4

-5

CNFJ5

CN73B-

-6

-5

-5

-6

-4

-3

-2

-2

*A

*B

A

B

+24V

+24V

CN73D-9

-6

-7

-8

-8

-5

-4

-4

CNFJ1-2

-3

-2

-6

-5

-4

-5

-4

-5

-7

-3

-1

CNFJ1-2

-7

-6

-6

-5

-4

-4

-3

CNFJ2-1

+5V

+5V

+5V

LVL_E_S

LVL_P_S

LVL_C_S

-2

-3

CNFJ3-1

-3

-2

CNFJ4-3

-2

-1

CNFJ1-

CNFJ1-

CNFJ1-

-17

-16

-14

-13

-13

-11

-10

CNFJ1-

CNFJ1-

CNFJ1-

-17

-16

-14

-13

-13

-11

-10

-10

CN73C-1

-2

-3

-3

-5

CN73C-4

CN73C-7

-6

-8

CN73D-2

CN73A-8

CN73A-5

CN73A-2

-7

-6

-4

-3

-3

-1

CN73B-8

CN21-

-2

-3

-3

CN21-4

CN21-7

-5

-6

-8

-9

-9

"0" when paper is detected.

"0" when paper is detected.

"0" when the interface

transport cover is open.

transport cover is open.

The pulse signal is

switched depending

on the motor RPM.

switched depending

on the motor RPM.

Punch controller PCB

-1

J2008-3

+5V

PUNCH

PUNCH

-2

-6

J1006-4

-5

SREG1*

SREG2*

SREG3*

SREG2*

SREG3*

-9

-10

-11

J1007-12

-13

SREG4*

-8

PAEND*

-7

Horizontal

registration

home position

sensor

registration

home position

sensor

FPMCK

-1

J2009-3

+5V

CLOCK

CLOCK

-2

-9

J1006-7

-8

Punch home

position sensor

position sensor

+5V

+5V

PT1

PT2

PT3

PT4

PT5

FPSHPD

FPHPD

-1

J2007-3

+5V

SLIDE

SLIDE

-2

-3

J1006-1

-2

Punch motor

lock sensor

lock sensor

Side resist photo sensor PCB (FPTD)

DUSTLED

Waste full LED PCB

J1005-1

PT131

LED121

DUSTPTR

+5V

4

Waste full photosensor PCB (FPDD)

-2

J1005-3

When the hole puncher is

at home position, ‘0’.

at home position, ‘0’.

While the punch motor

is rotating, alternates

between ‘0’ and ‘1’.

is rotating, alternates

between ‘0’ and ‘1’.

When the punch slide

unit is at home position,

‘1’.

unit is at home position,

‘1’.

When paper is

detected, ‘0’.

detected, ‘0’.

When the light is

blocked, ‘0’.

blocked, ‘0’.

Punch controller PCB

FPSM

Punch side resist motor

B*

A*

B

A

J1001-1

-2

-3

-4

FPNM

Punch motor

J1002-1

-2

LEDON5

LEDON4

LEDON3

LEDON2

LEDON1

LEDON4

LEDON3

LEDON2

LEDON1

-4

-5

-1

J1007-6

+5V

-3

-2

-2

LED5

LED4

LED3

LED2

LED1

Side resist LED PCB (FPSD)

Switches between ‘+’

and ‘–’ according to

the direction ofmotor

rotation.

and ‘–’ according to

the direction ofmotor

rotation.

When ‘1’, LED goes ON.

Switches the pulse

signals according to

the rotation ofthe motor.

signals according to

the rotation ofthe motor.

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 4

2. Feed/Drive System

A. Outline

The machine performs the following in response to the commands

coming from its host machine on the sheets arriving from the host

machine for delivery: simple stacking, job offset, and stapling or

folding (in two).

If a punch unit (option) is installed, the sheets are pouched and

delivered to the delivery tray.

Sheets may be delivered in either of five ways (including one for

the punch unit):

coming from its host machine on the sheets arriving from the host

machine for delivery: simple stacking, job offset, and stapling or

folding (in two).

If a punch unit (option) is installed, the sheets are pouched and

delivered to the delivery tray.

Sheets may be delivered in either of five ways (including one for

the punch unit):

(1) Normal Delivery

a. Simple Stacking

The machine pulls in the sheet once to the processing tray and

then delivers it to the delivery tray.

The machine pulls in the sheet once to the processing tray and

then delivers it to the delivery tray.

b. Job Offset

The machine pulls the sheet once to the processing tray. It then

moves the sheet to the front or the rear using the aligning plate.

When it has deposited a specific number of sheets, it delivers them

in the form of a aligning plane. When the number of sheets stacked

on the processing tray reaches a specified value, the sheets are

delivered in a form of a stack.

The machine pulls the sheet once to the processing tray. It then

moves the sheet to the front or the rear using the aligning plate.

When it has deposited a specific number of sheets, it delivers them

in the form of a aligning plane. When the number of sheets stacked

on the processing tray reaches a specified value, the sheets are

delivered in a form of a stack.

c. Stapling

The machine stacks sheets coming from its host machine on the

processing tray. When the number of sheets stacked on the pro-

cessing tray reaches a specified value, the finisher staples them

delivers the stapled stack to the delivery tray.

The machine stacks sheets coming from its host machine on the

processing tray. When the number of sheets stacked on the pro-

cessing tray reaches a specified value, the finisher staples them

delivers the stapled stack to the delivery tray.

Punching

Normal delivery

Delivery method

Middle 2-point stapling

Job offset

Simple stacking

Stapling

Front 1-point stapling

Rear 1-point stapling

Middle 2-point stapling

Stitching

Saddle delivery

Tray

Paper

4th set

(direction of delivery)

Results of offset delivery (4 jobs)

2nd set

3rd set

1st set

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 5

d. Saddle Delivery

The machine deposits a stack of sheets on the processing tray, sta-

ples it (middle 2-point), and then moves it to the saddle unit. The

saddle unit folds the stack in two, and delivers it to the bind tray.

The machine deposits a stack of sheets on the processing tray, sta-

ples it (middle 2-point), and then moves it to the saddle unit. The

saddle unit folds the stack in two, and delivers it to the bind tray.

B. Feed/Delivery

(1) Outline

The machine forwards the sheets coming from its host machine to

the delivery tray, processing tray, or saddle unit according to the

type of delivery used. The sheets forwarded to the processing tray

or the saddle unit are offset, stapled, or folded.

The following table shows the motors that are associated with mov-

ing and aligning sheets. These motors are controlled (rotated clock-

wise or counterclockwise) by the microprocessor (CPU) on the

finisher controller PCB.

The paper path is equipped with the sensors shown in the following

figure used to monitor the arrival or passage of sheets.

If a sheet fails to arrive at or move past a specific sensor within a

specific period of time, the finisher controller will assume a jam, and

stops the ongoing operation and, at the same time, communicates

the presence of a jam to the host machine.

the delivery tray, processing tray, or saddle unit according to the

type of delivery used. The sheets forwarded to the processing tray

or the saddle unit are offset, stapled, or folded.

The following table shows the motors that are associated with mov-

ing and aligning sheets. These motors are controlled (rotated clock-

wise or counterclockwise) by the microprocessor (CPU) on the

finisher controller PCB.

The paper path is equipped with the sensors shown in the following

figure used to monitor the arrival or passage of sheets.

If a sheet fails to arrive at or move past a specific sensor within a

specific period of time, the finisher controller will assume a jam, and

stops the ongoing operation and, at the same time, communicates

the presence of a jam to the host machine.

Notation

Name

Description

Connector on

finisher

controller PCB

FFM

Feed motor

Stepping motor

CN10

FPM

Paddle motor

Stepping motor

CN10

FAM

Bundle exit motor

Stepping motor

CN13

FFJM

Alignment plate motor

(front)

(front)

Stepping motor

CN3

FRJM

Alignment plate motor

(rear)

(rear)

Stepping motor

CN3

FFSM

Staple motor

Brush DC motor

CN6

FJPM

Interface transport motor

Stepping motor

CN21

Notation

Name

Description

Connector on

finisher

controller PCB

FED

Entry paper sensor

Photointerrupter

CN16

FFPD

Bookbinding position

sensor

sensor

Photointerrupter

CN16

Staple

motor

drive

signal

BINDMTR

Bookbinding

lock

sensor

detect

signal

BIND_CLK

Finisher controller PCB (1/2)

Lift

m

otor

drive

signal

SIFTMTR

Bundle

exit

motor

drive

signal

EJCTMTR

Staple

slide

motor

drive

signal

SLIDMTR

Paddle

motor

drive

signal

PDLMTR

Alignment

motor

(rear)

drive

signal

RJOGMTR

Bind

clutch

dr

iv

e

signal

B_CLU

Interface

transport

m

otor

drive

signal

RIM

Alignment

motor

(front)

drive

signal

FJOGMTR

FFE

FRJM

FPM

FFSM

FFC

FAM

FSM

FLM

FFJM

FJPM

FFM

Finisher controller PCB (2/2)

Feed

motor

drive

signal

F

EEDMTR

Finisher controller PCB

FFPD

Bookbinding

position

detect

signal

BIND_P

FED

Entry

paper

detect

signal

ENT_S

MX-FNX2/AR-PN1/MX-RBX1 OPERATIONAL DESCRIPTION 5 – 6

C. Job Offset

(1) Outline

"Job offset" refers to the operation by which the machine delivers a

set of sheets with them pulled forward or backward for sorting.

Switching between the forward and backward directions is made

using an aligning plate (front) and an aligning plate (rear).

The sheet coming between the delivery rollers is fed onto the pro-

cessing tray and then fed toward the stopper by the paddle.

A swing guide is at the up position while a sheet is being pulled

onto the processing tray or during alignment. It is at the down posi-

tion during stack feeding, stack delivery, or stapling.

At power-on, the finisher controller PCB drives the aligning motor

(front) (FFJM) and the aligning motor (rear) (FRJM) to return the

two aligning plates to their home positions.

set of sheets with them pulled forward or backward for sorting.

Switching between the forward and backward directions is made

using an aligning plate (front) and an aligning plate (rear).

The sheet coming between the delivery rollers is fed onto the pro-

cessing tray and then fed toward the stopper by the paddle.

A swing guide is at the up position while a sheet is being pulled

onto the processing tray or during alignment. It is at the down posi-

tion during stack feeding, stack delivery, or stapling.

At power-on, the finisher controller PCB drives the aligning motor

(front) (FFJM) and the aligning motor (rear) (FRJM) to return the

two aligning plates to their home positions.

(2) Processing Tray Paper Stacking Operation

A sheet coming between the delivery rollers is fed onto the pro-

cessing tray. Then, the paddle taps on the sheet surface to locate

the sheet against the processing tray stopper.

cessing tray. Then, the paddle taps on the sheet surface to locate

the sheet against the processing tray stopper.

(3) Offset Operation

Each sheet is pulled forward or backward using the aligning plate

(front) and the aligning plate (rear).

The offset operation is performed each time a sheet is pulled onto

the processing tray.

Offsetting in the forward direction

(front) and the aligning plate (rear).

The offset operation is performed each time a sheet is pulled onto

the processing tray.

Offsetting in the forward direction

Offsetting in the backward direction

(4) Stack Delivery Operation

Stack delivery takes place when 1 sheet of large-size paper or 25

sheets of small-size paper have been stacked on the processing

tray with them offset in either direction.

The paddle motor (FPM) rotates and the swing guide descends to

hold the paper stack between the upper and lower stack delivery

rollers. The stack delivery motor (FAM) rotates in the forward direc-

tion to rotate the delivery rollers, feeding the paper stack in the

delivery direction. The delivery belt home position sensor is turned

OFF. The delivery motor is driven a specified number of pulses,

causing the swing guide to ascend. Next, the paper delivery motor

is driven. Next, the delivery motor is driven to deliver the paper

stack with the nails of the delivery belt that rotates in sync with the

stack delivery rollers.

sheets of small-size paper have been stacked on the processing

tray with them offset in either direction.

The paddle motor (FPM) rotates and the swing guide descends to

hold the paper stack between the upper and lower stack delivery

rollers. The stack delivery motor (FAM) rotates in the forward direc-

tion to rotate the delivery rollers, feeding the paper stack in the

delivery direction. The delivery belt home position sensor is turned

OFF. The delivery motor is driven a specified number of pulses,

causing the swing guide to ascend. Next, the paper delivery motor

is driven. Next, the delivery motor is driven to deliver the paper

stack with the nails of the delivery belt that rotates in sync with the

stack delivery rollers.

Sensor

Symbol

Connector

Aligning home position sensor (front)

FFJHPD

CN4-3

Aligning home position sensor (rear)

FRJHPD

CN5-15

Stack roller home position sensor

FARHPD

CN9-9

Paddle home position sensor

FPDHPD

CN9-3

Function

Motor

Symbol

Drives the aligning plate (front)

Aligning motor (front)

FFJM

Drives the aligning plate (rear)

Aligning motor (rear)

FRJM

Drives the swing guide drive

Paddle motor

FPM

Drives the paddle (feeds paper)

Paddle motor

FPM

Aligning plate

(front)

(front)

Alignment motor (front)

(FFJM)

Aligning home position sensor (front)

(FFJHPD)

Alignment

motor (rear)

motor (rear)

(FRJM)

Light-shielding plate

(Front)

Paper

Light-shielding plate

Aligning home position sensor (rear)

(FRJHPD)

Aligning plate

(rear)

(rear)

Swing guide

Delivery belt

Stack delivery roller (lower)

Processing tray stopper

Paddle

Stack delivery roller (upper)

Aligning plate

Paper

Aligning plate (rear)

Sheet to be offset

Tray

Aligning plate (front)

Tray

Aligning plate (rear)

Sheet to be offset

Aligning plate (front)

Swing guide