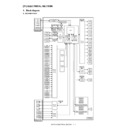

Sharp MX-5500N / MX-6200N / MX-7000N (serv.man46) Service Manual ▷ View online

MX-7000N SIMULATION 7 – 4

22

1

Used to check the print count value in each section and operation mode.

(Used to check the maintenance timing.)

(Used to check the maintenance timing.)

Adjustment/Setting/Operation data

output/Check

output/Check

2

Used to check the total numbers of misfeed and troubles. (When the number

of total jam is considerably great, it is judged as necessary for repair.)

of total jam is considerably great, it is judged as necessary for repair.)

Adjustment/Setting/Operation data

check

check

3

Used to check the misfeed positions and the number of misfeed at each

position.

* The trouble position can be troubleshooted according to this data.

position.

* The trouble position can be troubleshooted according to this data.

Adjustment/Setting/Operation data

check

check

4

Used to check the trouble (self diag) history.

Adjustment/Setting/Operation data

check

check

5

Used to check the ROM version of each unit (section).

Other

6

Used to output the list of the setting and adjustment data (simulations, FAX

soft switch, counters).

soft switch, counters).

Adjustment/Setting/Operation data

check

check

8

Used to check the counter value of the finisher, the DSPF, and the scan

(reading).

(reading).

Adjustment/Setting/Operation data

check

check

9

Used to check the number of use (print quantity) of each paper feed section.

Adjustment/Setting/Operation data

check

check

Paper feed, ADU, LCC

10

Used to check the system configuration (option, internal hardware).

Adjustment/Setting/Operation data

check

check

11

Used to check the use frequency of FAX (send/receive). (Only when FAX is

installed.)

installed.)

Adjustment/Setting/Operation data

check

check

FAX

12

Used to check the misfeed position in the DSPF and the number of misfeed

of each position. (If the number of misfeed is considerably great, it may lead

to the decision for repair.)

of each position. (If the number of misfeed is considerably great, it may lead

to the decision for repair.)

Adjustment/Setting/Operation data

check

check

DSPF

13

Used to check the running time of the process section. (OPC drum, DV unit,

toner bottle).

toner bottle).

Adjustment/Setting/Operation data

check

check

19

Used to check each counter value related the network scanner.

Adjustment/Setting/Operation data

check

check

90

Used to output the list of various set data.

Adjustment/Setting/Operation data

check

check

23

2

Used to check the trouble history of paper jam and misfeed. (If the number of

misfeed and troubles is considerably great, it may be judged as necessary to

repair.)

misfeed and troubles is considerably great, it may be judged as necessary to

repair.)

Adjustment/Setting/Operation data

check

check

80

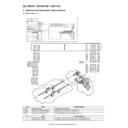

Used to check the operations of the sensors and detectors in the paper feed

and transport section.

and transport section.

Operation test/Check

Paper feed, transport

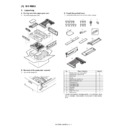

24

1

Used to clear the jam counter, and the trouble counter. (The counters are

cleared after completion of maintenance.)

cleared after completion of maintenance.)

Data clear

2

Used to clear the number of use (the number of prints) of each paper feed

section.

section.

Data clear

3

Used to clear the counter value of the finisher, the DSPF, and scan

(reading).

(reading).

Data clear

4

The maintenance counter and the print counters of the transfer unit and the

fusing unit are cleared. (After completion of maintenance, the counters are

cleared.)

fusing unit are cleared. (After completion of maintenance, the counters are

cleared.)

Data clear

5

Used to clear the developer counter. (After replacement of developer, this

counter is cleared.)

counter is cleared.)

Data clear

6

Used to clear the copy counter value.

Data clear

7

Used to clear the OPC drum counter value. (After replacement of the OPC

drum, this counter is cleared.)

drum, this counter is cleared.)

Data clear

9

Used to clear the printer mode print counter and the self print mode print

counter.

counter.

Data clear

10

Used to clear the FAX counter value. (Only when FAX is installed.)

Data clear

15

Used to clear various counters in the scan mode related to image send.

Data clear

30

Used to initialize the administrator password.

Data clear

31

Used to initialize the service mode password.

Data clear

25

1

Used to check the operations of the developing section.

Operation test/Check

Process (Developing

section)

section)

2

Used to make the initial setting of the toner density when replacing

developer. (Automatic adjustment)

developer. (Automatic adjustment)

Setting

Process (Photoconductor/

Developing/Transfer/

Cleaning)

Developing/Transfer/

Cleaning)

26

2

Used to set the paper size of the large capacity tray (LCC). (When the paper

size is changed, this simulation must be executed to change the paper size

in software.)

size is changed, this simulation must be executed to change the paper size

in software.)

Setting

Paper feed

3

Used to set the auditor setting mode. (Setting must be made according to

the auditor use conditions.)

the auditor use conditions.)

Setting

Auditor

5

Used to set the count mode of the total counter and the maintenance

counter.

counter.

Setting

6

Used to set the specifications according to the destination. (Paper, fixed

magnification ratios, etc.)

magnification ratios, etc.)

Setting

10

Used to set the trial mode of the network scanner.

Setting

18

Used to set Disable/Enable of the toner save mode operation. (For the

Japan and the UK versions.)

Japan and the UK versions.)

Setting

30

Used to set the operation mode corresponding to the CE mark (Europe

safety standards). (For slow start to drive the fusing heater lamp)

safety standards). (For slow start to drive the fusing heater lamp)

Setting

Main

Sub

Function (Purpose)

Purpose

Section

MX-7000N SIMULATION 7 – 5

26

35

Used to set the display mode of SIM 22-4 trouble history when a same

trouble occurred repeatedly. There are two display modes: display as one

trouble and display as several series of troubles.

trouble occurred repeatedly. There are two display modes: display as one

trouble and display as several series of troubles.

Setting

38

Used to set whether printing is continued or stopped when the developer life

is expired or when the fusing wed ends.

is expired or when the fusing wed ends.

Setting

41

Used to set Enable/Disable of the magnification ratio automatic select

function (AMS) in the center binding mode.

function (AMS) in the center binding mode.

Setting

49

Used to set the copy speed mode of postcards.

Setting

50

Used to set Enable/Disable of the black and white highlight function and the

2-color/Single display function.

2-color/Single display function.

Setting

52

Used to set whether non-print paper (insertion paper, cover, etc.) is counted

or not.

or not.

Setting

53

Used to set YES/NO of the auto color calibration.

Setting

54

Used to set the printer calibration YES/NO.

Setting

65

Used to set the finisher alarm mode.

Setting

67

Used to set the summer time timing and the time zone.

Setting

69

Used to set the display of spare toner preparation and near end when the

toner quantity reaches 25%.

toner quantity reaches 25%.

Setting

27

1

Used to set non-detection of communication error (U7-00) with RIC

Setting

2

Used to set the FSS function (sender registration number, host server

telephone number).

telephone number).

Setting

4

Used to set the FSS function (initial, call, toner order automatic send).

Setting

5

Used to set the machine tag No. (This function allows the host computer to

check the machine tag No.)

check the machine tag No.)

Setting

Communication (RIC/

MODEM)

MODEM)

6

Used to set the FSS function (manual service call).

Setting

7

Used to set the FSS function (enable, alert call).

Setting

9

Paper transport time between sensors / Gain adjustment retry number

setting

setting

Setting

10

Used to clear the history information of trouble prediction

Data clear

11

Used to check the serial communication retry number history and the

scanner gain adjustment retry number history.

scanner gain adjustment retry number history.

Other

12

Used to check the error history of high density, half tone process control,

and automatic registration adjustment.

and automatic registration adjustment.

Other

13

Used to check the history of paper transport time between sensors.

Other

14

Used to set the FSS function connection mode. (Only "Disable

→ Enable" is

allowed.)

Setting

30

1

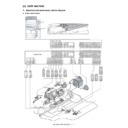

Used to check the operations of the sensors and the detectors in other than

the paper feed section and the control circuits.

the paper feed section and the control circuits.

Operation test/Check

2

Used to check the operations of the sensors and the detectors in the paper

feed section and the control circuits.

feed section and the control circuits.

Operation test/Check

33

1

Used to check the operations of the card reader sensor and the control

circuit.

circuit.

Operation test/Check

40

2

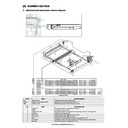

Manual paper feed tray paper width detector detection level adjustment

Adjustment/Setting

Paper feed

7

Used to adjust the manual paper feed tray width detection level.

Adjustment/Setting

Paper feed

12

Used to perform the tray 3 paper width detection level adjustment.

Adjustment/Setting

Paper feed

41

1

Used to check the operations of the document size sensor and the control

circuit.

circuit.

Operation test/Check

2

Used to adjust the document size sensor detection level.

Adjustment

3

Used to check the operations of the document size sensor and the control

circuit.

circuit.

Operation test/Check

43

1

Used to set the fusing temperature in each mode.

Setting

4

Used to perform the fusing temperature setup 2 in each operation mode.

(Continued from SIM 43-1.)

(Continued from SIM 43-1.)

Setting

20

Used to set the environmental correction under low temperature and low

humidity (L/L) for the fusing temperature setting in each mode (SIM 43-1).

humidity (L/L) for the fusing temperature setting in each mode (SIM 43-1).

Adjustment/Setting

21

Used to set the environment correction under high temperature and high

humidity (H/H) for the fusing temperature setting (SIM 43-1) in each paper

mode.

humidity (H/H) for the fusing temperature setting (SIM 43-1) in each paper

mode.

Adjustment/Setting

22

Used to set the environment correction under low temperature and low

humidity (L/L) for the fusing temperature setting (SIM 43-4) in each paper

mode.

humidity (L/L) for the fusing temperature setting (SIM 43-4) in each paper

mode.

Adjustment/Setting

23

Used to set the environment correction under high temperature and high

humidity (H/H) for the fusing temperature setting (SIM 43-4) in each paper

mode.

humidity (H/H) for the fusing temperature setting (SIM 43-4) in each paper

mode.

Adjustment/Setting

24

Used to set the correction of the temperature adjustment value of SIM 43-1

and 43-4.

and 43-4.

Adjustment/Setting

31

Used to check the operation of the fusing web cleaning motor and the

control circuit.

control circuit.

Operation test/Check

32

Used to set the compulsory operation of fusing web cleaning at job end.

Adjustment/Setting

Main

Sub

Function (Purpose)

Purpose

Section

MX-7000N SIMULATION 7 – 6

44

1

Used to set each correction operation function in the image forming

(process) section.

(process) section.

Setting

Process (Photoconductor/

Developing/Transfer/

Cleaning)

Developing/Transfer/

Cleaning)

2

Image density sensor gain adjustment

Adjustment/Setting

Process

4

Used to set the target density level in the image density correction.

(Do not use this function unless

specially required.)

specially required.)

6

Used to execute the high density process correction compulsorily.

Adjustment

9

Used to check data of correction results in the image forming section.

(Do not use in the market.)

Process (Photoconductor/

Developing/Transfer/

Cleaning)

Developing/Transfer/

Cleaning)

12

Used to check the sampling toner image patch density data in the image

density correction.

density correction.

(Do not use in the market.)

Image process

(Photoconductor/

Developing)

(Photoconductor/

Developing)

13

Used to adjust the color image sensor.

Adjustment/Setting

14

Used to check the output level of the temperature/humidity sensor.

Adjustment, setting, operation data

check

check

Image process

(Photoconductor/

Developing)

(Photoconductor/

Developing)

16

Used to check the toner density control data.

(Do not use in the market.)

21

Used to set the half tone process control.

Adjustment/Setting

Process

22

Used to check the toner patch image density level of each color in half tone

image forming section correction (process correction).

image forming section correction (process correction).

(Do not use in the market.)

24

Used to display the process control result.

(Do not use in the market.)

25

Used to set the initial conditions of the process control half tone correction.

(Do not use in the market.)

26

Used to execute the half tone process control compulsorily.

Adjustment/Setting

Process

27

Used to clear the half tone process correction value.

Data clear

28

Used to set the process control execution timing.

Adjustment/Setting

29

Used to select the half tone correction during a job.

(Do not use in the market.)

31

Used to adjust the phase of the photoconductor.

Adjustment/Setting

Process

37

Used to perform the image density correction setting.

Adjustment/Setting

43

Used to check installation of the developing unit and the current state.

(Do not use in the market.)

52

Used to check the image density level of each color toner patch in 1-pixel

half tone correction.

half tone correction.

(This simulation should not be

executed unless specially required.)

executed unless specially required.)

54

The 1-pixel half tone correction result is displayed.

(This simulation should not be

executed unless specially required.)

executed unless specially required.)

56

The 1-pixel half tone correction is executed compulsorily.

(This simulation should not be

executed unless specially required.)

executed unless specially required.)

57

The 1-pixel half tone correction value is cleared.

(This simulation should not be

executed unless specially required.)

executed unless specially required.)

46

1

Used to adjust the copy density in the copy mode.

Adjustment (Color copy mode)

2

Used to adjust the copy density in the copy mode.

Adjustment (Monochrome copy

mode)

mode)

4

Used to adjust the density in the scanner mode.

Adjustment (Color scanner mode)

5

Used to adjust the density in the scanner mode.

Adjustment (Monochrome scanner

mode)

mode)

8

Used to adjust the scanner color balance RGB.

Adjustment (Color scanner mode)

9

Used to adjust the copy density in the copy mode.

Adjustment (DSPF mode)

10

Used to adjust the engine color balance manually.

Adjustment

16

Used to perform the engine color balance manual adjustment (monochrome,

all modes).

all modes).

Adjustment

19

Used to set the monochrome auto exposure mode.

Setting

21

Used to perform the engine color balance manual adjustment (color, all

modes).

modes).

Adjustment

23

Used to perform the half tone highest density correction.

Adjustment/Setting

24

Used to perform the engine half tone auto density adjustment.

Adjustment

25

Used to perform the color balance adjustment in the single color mode.

Adjustment

26

Used to perform the default setting of color balance in the single color mode.

Adjustment

27

Used to perform the engine/gamma calculation formula coefficient setting.

Adjustment/Setting

28

Used to check Auto exposure/Document auto recognition/Line number

recognition (color mode).

recognition (color mode).

(This simulation should not be used

unless specially required.)

unless specially required.)

33

Used to perform the color auto mode adjustment.

Adjustment/Setting

36

2-color (red/black) copy adjustment

Adjustment/Setting

37

Used to perform the black/white image generation adjustment.

Adjustment/Setting

39

Used to perform the image send sharpness adjustment.

Adjustment/Setting

40

Used to perform the collective adjustment of all the FAX exposure modes.

Adjustment/Setting

41

Used to perform the FAX exposure adjustment (normal character).

Adjustment/Setting

42

Used to perform the FAX exposure adjustment (small character).

Adjustment/Setting

43

Used to perform the FAX exposure adjustment (fine).

Adjustment/Setting

44

Used to perform the FAX exposure adjustment. (Super fine)

Adjustment/Setting

45

Used to perform the FAX exposure adjustment (600dpi).

Adjustment/Setting

47

Used to perform the JPEG compression rate setting in copying and

scanning.

scanning.

Adjustment/Setting

Main

Sub

Function (Purpose)

Purpose

Section

MX-7000N SIMULATION 7 – 7

48

1

Used to perform the copy magnification ratio (main scanning, sub scanning

direction) adjustment.

direction) adjustment.

Adjustment

5

Used to perform the copy magnification ratio adjustment (sub scanning

direction). When the sub scanning direction image magnification ratio is

adjusted with SIM 48-1 and a satisfactory copy image is not obtained when

copying by specifying a different copy magnification ratio, perform this

adjustment.

direction). When the sub scanning direction image magnification ratio is

adjusted with SIM 48-1 and a satisfactory copy image is not obtained when

copying by specifying a different copy magnification ratio, perform this

adjustment.

Adjustment

Scanner section

6

Used to perform the rotation speed adjustment of each motor.

Adjustment

49

1

Used to perform the firmware update.

3

Used to update the operation manual in the HDD.

Adjustment

50

1

Used to adjust the copy image position on print paper and the void area

(image loss) in the copy mode. (The similar adjustment can be performed

also with SIM 50-5 and SIM 50-2 (simple method). (Document table mode))

(image loss) in the copy mode. (The similar adjustment can be performed

also with SIM 50-5 and SIM 50-2 (simple method). (Document table mode))

2

Used to adjust the copy image position on print paper and the void area

(image loss) in the copy mode. (The similar adjustment can be performed

also with SIM 50-1. This simulation. However, is simpler.)

(image loss) in the copy mode. (The similar adjustment can be performed

also with SIM 50-1. This simulation. However, is simpler.)

Adjustment

5

Printer print lead edge adjustment

Adjustment

6

Used to adjust the DSPF document lead edge, and to adjust the copy image

position and the void area (image loss) on the print paper in the copy mode.

(The similar adjustment can be performed with SIM 50-7 (simple method).)

(DSPF mode)

position and the void area (image loss) on the print paper in the copy mode.

(The similar adjustment can be performed with SIM 50-7 (simple method).)

(DSPF mode)

Adjustment

DSPF

7

Used to adjust the DSPF document lead edge, and to adjust the copy image

position and the void area (image loss) on the print paper in the copy mode.

(The similar adjustment can be performed with SIM 50-7 (simple method).)

(DSPF mode)

position and the void area (image loss) on the print paper in the copy mode.

(The similar adjustment can be performed with SIM 50-7 (simple method).)

(DSPF mode)

Adjustment

DSPF

10

Used to adjust the print image off-center position. (Adjustment is made

separately for each paper feed section.)

separately for each paper feed section.)

Adjustment

12

Used to perform the scan image off-center position adjustment. (The

adjustment is made separately for each scan mode.)

adjustment is made separately for each scan mode.)

Adjustment

20

Used to perform the main scanning direction manual registration adjustment.

Adjustment

21

Used to perform the sub scanning direction manual registration adjustment.

Adjustment

22

Used to perform the main/sub scanning auto registration adjustment.

Adjustment

24

Used to display the auto registration adjustment result (SIM 50-22).

(Do not use in the market.)

27

Used to perform the image loss adjustment of the scanned image in the

FAX or scanner mode

FAX or scanner mode

Adjustment

28

Used to perform the OC adjustment, the BK main scanning direction

magnification ration correction, the DSPF adjustment, and the print position

adjustment.

magnification ration correction, the DSPF adjustment, and the print position

adjustment.

Adjustment

51

1

Used to perform the transfer voltage and the separation bias voltage ON/OF

timing adjustment.

timing adjustment.

Adjustment/Setting

2

Used to perform the paper contact pressure adjustment for each section

resist roller (main unit, each paper feed, duplex paper fed, DSPF paper

feed). (When there is a considerable fluctuation in the print image position

on print paper or a paper jam occurs, this adjustment is required.)

resist roller (main unit, each paper feed, duplex paper fed, DSPF paper

feed). (When there is a considerable fluctuation in the print image position

on print paper or a paper jam occurs, this adjustment is required.)

Adjustment/Setting

53

6

Used to perform the DSPF size width detection level adjustment.

Adjustment

7

Used to perform the DSPF size width adjustment value setting.

Adjustment/Setting

8

Used to perform the DSPF document scanning start position adjustment.

Adjustment

55

1

Used to perform the engine control operation specification setting.

(Do not use this function unless

specially required.)

specially required.)

2

Used to perform the scanner control operation specification setting.

(Do not use this function unless

specially required.)

specially required.)

3

Used to perform the controller operation specification setting.

(Do not use this function unless

specially required.)

specially required.)

56

1

Data transfer (Used in repairing the PWB.)

Backup

2

Used to backup the data (user authentication data, address book, etc.) in the

EEPROM, the SRAM, and the HDD of the main unit into the USB memory

and to transfer the data.

EEPROM, the SRAM, and the HDD of the main unit into the USB memory

and to transfer the data.

Backup

60

1

Used to check the operations (read/write) of the MFP control (SDRAM).

Operation test/Check

2

Used to set the onboard SDRAM.

(Do not use in the market.)

61

1

Used to check the polygon motor rotation and the BD signal detection.

Operation test/Check

LSU

2

Used to set the laser power. (for printer FIERY)

Adjustment/Setting

3

Used to set the laser power.

Adjustment/Setting

4

Used to perform self printing of the LSU position adjustment pattern.

Adjustment

62

1

Used to format the hard disk. (Excluding the operation manual area.)

2

Used to check read/write of the hard disk (partial).

Operation test/Check

3

Used to check read/write of the hard disk (all areas).

Operation test/Check

6

Used to perform the self diagnostics of the hard disk.

Operation test/Check

7

Used to print the hard disk self diagnostics error log.

Operation test/Check

8

Used to format the hard disk. (Excluding the system area and the operation

manual area)

manual area)

10

Used to delete the job log data.

Data clear

11

Used to delete the document filing data.

Data clear

12

Used to set Enable/Disable of auto format in a hard disk trouble.

Setting

13

Used to format the hard disk. (only the operation manual area)

Main

Sub

Function (Purpose)

Purpose

Section