Sharp MX-5500N / MX-6200N / MX-7000N (serv.man45) Service Manual ▷ View online

MX-7000N ADJUSTMENTS 6 – 4

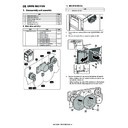

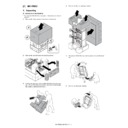

3)

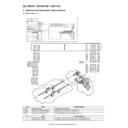

Insert a thickness gauge of 0.45mm between 40mm – 70mm

from the edge of the developing doctor.

from the edge of the developing doctor.

4)

Push the developing doctor in the arrow direction, and tighten

the fixing screw of the developing doctor. (Perform the similar

procedure for the front frame and the rear frame.)

the fixing screw of the developing doctor. (Perform the similar

procedure for the front frame and the rear frame.)

5)

Check that the doctor gaps at two positions in 40mm – 70mm

from the both sides of the developing doctor are in the range of

0.45

from the both sides of the developing doctor are in the range of

0.45

± 0.05mm.

* When inserting a thickness gauge, be careful not to scratch the

developing doctor and the developing roller.

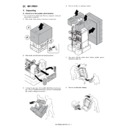

ADJ 4

Developing roller main pole

position adjustment (For black)

position adjustment (For black)

This adjustment must be executed in the following cases:

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When the developing unit is disassembled.

* When the print image density is low.

* When there is a blur on the print image.

* When there is unevenness in the print image density.

* There is abnormally much toner dispersion.

1)

* There is abnormally much toner dispersion.

1)

Remove the developing doctor cover, and place the develop-

ing unit on a flat surface.

ing unit on a flat surface.

2)

Attach a thread to a needle or a pin.

3)

Hold the thread and bring the needle near the developing

roller. (Do not use a paper clip because it will not provide a cor-

rect position.)

roller. (Do not use a paper clip because it will not provide a cor-

rect position.)

4)

Mark the developing roller surface on the extension line of the

needle with the needle at 2 – 3mm from the developing roller

surface. (Never touch the needle tip with the developing roller.)

needle with the needle at 2 – 3mm from the developing roller

surface. (Never touch the needle tip with the developing roller.)

5)

Measure the distance between the marking position and posi-

tion A of the developing unit frame, and check that it is 62.1

tion A of the developing unit frame, and check that it is 62.1

±

0.5mm.

If the distance is not within the above range, adjust the devel-

oping roller main pole position in the following procedures.

If the distance is not within the above range, adjust the devel-

oping roller main pole position in the following procedures.

6)

Remove the developing unit front cover, loosen the fixing

screw of the developing roller main pole adjustment plate, and

move the adjustment plate in the arrow direction to adjust.

screw of the developing roller main pole adjustment plate, and

move the adjustment plate in the arrow direction to adjust.

Repeat procedures 3) – 6) until the developing roller main pole

position comes to the specified range.

position comes to the specified range.

7)

After completion of the adjustment of the developing roller

main pole position, fix the developing roller main pole adjust-

ment plate with the fixing screw.

main pole position, fix the developing roller main pole adjust-

ment plate with the fixing screw.

40mm

70mm

70mm

40mm

40mm

70mm

70mm

40mm

2

㨪3mm

62.1 0.5mm

+

62.1 0.5mm

+

A

MX-7000N ADJUSTMENTS 6 – 5

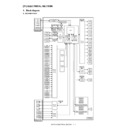

ADJ 5

Toner density control reference

value setting

value setting

This adjustment must be executed in the following cases:

* When developer is replaced.

* When developer is replaced.

NOTE: Be sure to execute this adjustment only when developer is

replaced. Never execute it in the other cases.

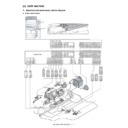

1)

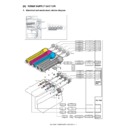

With the front cover (lower) open, enter SIM25-2.

2)

Close the front cover (lower).

3)

Select a developing unit to be adjusted.

4)

When [EXECUTE] key it pressed, it is highlighted. The devel-

oping roller rotates, and the toner sensor detects toner density,

and the output value is displayed.

The above operation is executed for 3 minutes, and the aver-

age value of the toner density sensor detection level is set

(saved) as the reference toner density control value.

When the reference toner density control adjustment operation

is completed, [EXECUTE] key display return, to normal from

highlight. This makes you know whether the adjustment opera-

tion is completed or not.

The above operation is executed each of the lower speed

mode, the middle speed mode and the high speed mode, and

the reference toner density control value is set for each of

them.

NOTE: If the operation is interrupted within 3 minutes, the

oping roller rotates, and the toner sensor detects toner density,

and the output value is displayed.

The above operation is executed for 3 minutes, and the aver-

age value of the toner density sensor detection level is set

(saved) as the reference toner density control value.

When the reference toner density control adjustment operation

is completed, [EXECUTE] key display return, to normal from

highlight. This makes you know whether the adjustment opera-

tion is completed or not.

The above operation is executed each of the lower speed

mode, the middle speed mode and the high speed mode, and

the reference toner density control value is set for each of

them.

NOTE: If the operation is interrupted within 3 minutes, the

adjustment result is not reflected (enabled).

When [EXECUTE] key is pressed during rotation, the opera-

tion is stopped and [EXECUTE] key returns to the normal dis-

play.

If [EE-EU], [EE-EL], or [EE-EG] is displayed, setting of the ref-

erence toner density control value is not completed normally.

tion is stopped and [EXECUTE] key returns to the normal dis-

play.

If [EE-EU], [EE-EL], or [EE-EG] is displayed, setting of the ref-

erence toner density control value is not completed normally.

5)

Use SIM24-5 to clear the developer counter.

6)

Use SIM44-27 to clear the half-tone correction data.

NOTE:

1)

1)

When replacing developer, always replace all the three colors

of Yellow, Magenta, and Cyan.

If only one color is replaced, color balance may be adversely

affected. Black developer can be replaced individually.

of Yellow, Magenta, and Cyan.

If only one color is replaced, color balance may be adversely

affected. Black developer can be replaced individually.

2)

After replacement of developer or the photoconductor, be sure

to execute SIM44-27 to clear the half-tone correction data.

If the above procedure is neglected, the half-tone correction

may not be performed correctly.

to execute SIM44-27 to clear the half-tone correction data.

If the above procedure is neglected, the half-tone correction

may not be performed correctly.

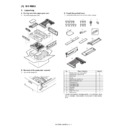

ADJ 6

High voltage adjustments

6-A

Main charger grid voltage adjustment

This adjustment must be executed in the following cases:

* When the MC/DV high voltage power PWB is replaced.

* When U2 trouble occurs.

* When the PCU PWB is replaced.

* When EEPROM on the PCU PWB is replaced.

* When the MC/DV high voltage power PWB is replaced.

* When U2 trouble occurs.

* When the PCU PWB is replaced.

* When EEPROM on the PCU PWB is replaced.

EXECUTE

M

K

Adjustment completed

EXECUTE

Abnormal end

Y

C

AUTOMATIC DEVELOPER ADJUSTMENT

EXECUTE

TCD_K

45

:

1/1

SIMULATION NO.25-02

TEST

CLOSE

TCV_K

45

:

TCD_C

50

:

TCD_M

50

:

TCD_Y

45

:

TCV_C

50

:

TCV_M

50

:

TCV_Y

50

:

M

K

M

Y

C

K

AUTOMATIC DEVELOPER ADJUSTMENT

EXECUTE

AT DEVE ADJ_L_K

128

:

AT DEVEVO_L_Y

128

:

1/1

SIMULATION NO.25-02

TEST

CLOSE

AT DEVE ADJ_M_K

128

:

AT DEVE VO_M_Y

128

:

AT DEVE ADJ_L_C

128

:

AT DEVE VO_M_K

128

:

AT DEVE ADJ_L_M

128

:

AT DEVE VO_M_C

128

:

AT DEVE ADJ_L_Y

128

:

AT DEVE VO_M_M

128

:

AT DEVE ADJ_M_C

128

:

AT DEVE VO_H_K

128

:

AT DEVE ADJ_M_M

128

:

AT DEVE ADJ_M_Y

128

:

AT DEVE ADJ_H_K

128

:

AT DEVEVO_L_K

128

:

AT DEVEVO_L_M

128

:

AT DEVEVO_L_C

128

:

or process interrupt

Y

C

AUTOMATIC DEVELOPER ADJUSTMENT

EXECUTE

TCD_K

EE-EL

:

1/1

SIMULATION NO.25-02

TEST

CLOSE

TCV_K

:

TCD_C

50

:

TCD_M

EE-EL

:

TCD_Y

45

:

TCV_C

:

TCV_M

:

TCV_Y

:

M

K

M

Y

C

K

AUTOMATIC DEVELOPER ADJUSTMENT

EXECUTE

AT DEVE ADJ_L_K

185

:

AT DEVEVO_L_Y

128

:

1/1

SIMULATION NO.25-02

TEST

CLOSE

AT DEVE ADJ_M_K

185

:

AT DEVE VO_M_Y

128

:

AT DEVE ADJ_L_C

128

:

AT DEVE VO_M_K

185

:

AT DEVE ADJ_L_M

185

:

AT DEVE VO_M_C

128

:

:

AT DEVE ADJ_L_Y

128

:

AT DEVE VO_M_M

185

AT DEVE ADJ_M_C

128

:

AT DEVE VO_H_K

128

:

AT DEVE ADJ_M_M

185

:

AT DEVE ADJ_M_Y

128

:

AT DEVE ADJ_H_K

185

:

AT DEVEVO_L_K

185

:

AT DEVEVO_L_M

185

:

AT DEVEVO_L_C

128

:

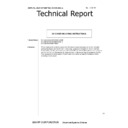

Error

display

Error name

Detail of error

Remark

EE-EL

EL

abnormality

abnormality

(1) The sensor output level is less

than 0.5V in 1min after execution

of SIM25-02.

than 0.5V in 1min after execution

of SIM25-02.

When either

of (1) or (2)

is satisfied.

of (1) or (2)

is satisfied.

(2) The sensor output level is less

than 1.5V after the adjustment for

each speed or the control voltage

exceeds 8.0V.

than 1.5V after the adjustment for

each speed or the control voltage

exceeds 8.0V.

EE-EU

EU

abnormality

abnormality

(1) The sensor output level

exceeds 4.5V in 1min after

execution of SIM25-02.

exceeds 4.5V in 1min after

execution of SIM25-02.

When either

of (1) or (2)

is satisfied.

of (1) or (2)

is satisfied.

The sensor output level exceeds

3.45V after the adjustment for

each speed or the control voltage

is less than 2.0V.

3.45V after the adjustment for

each speed or the control voltage

is less than 2.0V.

EE-EC

EC

abnormality

abnormality

The sensor output level after the

adjustment for each speed is not

2.5V

adjustment for each speed is not

2.5V

± 0.2V.

MX-7000N ADJUSTMENTS 6 – 6

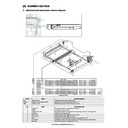

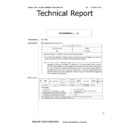

1)

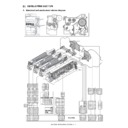

Enter SIM8-2 mode.

2)

Select an output mode to be adjusted with the mode key and the scroll key.

3)

Enter the adjustment value (specified value) of the middle speed mode and press [OK] key.

Remark: By setting the default value, the specified voltage is

normally outputted.

The adjustment value of each color mode is specified on the label

attached to the MC/DV high voltage power PWB. Enter that value.

attached to the MC/DV high voltage power PWB. Enter that value.

GBK:XXX GBC:XXX GBM:XXX GBY:XXX

When the adjustment value (specified value) of the middle speed

mode is set, the adjustment values of the other modes are auto-

matically set according to the middle speed mode setting in a cer-

tain relationship.

To adjust all the modes individually, first adjust the middle speed

mode, and then adjust the other mode.

If the middle speed mode is adjusted after adjustment of all the

modes individually, the adjustment values of the other modes are

automatically changed. Use care for that.

Therefore, unless there may be an abnormality in the output volt-

age, there is no need to check the output value.

If it must be checked that the normal voltage is outputted or if an

adjustment is required by referring to the output voltage, follow the

procedures below.

mode is set, the adjustment values of the other modes are auto-

matically set according to the middle speed mode setting in a cer-

tain relationship.

To adjust all the modes individually, first adjust the middle speed

mode, and then adjust the other mode.

If the middle speed mode is adjusted after adjustment of all the

modes individually, the adjustment values of the other modes are

automatically changed. Use care for that.

Therefore, unless there may be an abnormality in the output volt-

age, there is no need to check the output value.

If it must be checked that the normal voltage is outputted or if an

adjustment is required by referring to the output voltage, follow the

procedures below.

or after 30 sec.

10-key

A : 583

;

MIDDLE SPEED GB_K

B : 635

;

MIDDLE SPEED GB_C

C : 635

;

MIDDLE SPEED GB_M

D : 635

;

MIDDLE SPEED GB_Y

A:

SIMULATION NO.08-02

DV SETTING AND OUTPUT

XXX

230

850

OK

TEST

EXECUTE

EXECUTE

CLOSE

LOW/HIGH

MIDDLE

A : 500

;

MIDDLE SPEED GB_K

B : 635

;

MIDDLE SPEED GB_C

C : 635

;

MIDDLE SPEED GB_M

D : 635

;

MIDDLE SPEED GB_Y

A:

SIMULATION NO.08-02

DV SETTING AND OUTPUT

XXX

230

850

OK

TEST

EXECUTE

EXECUTE

CLOSE

LOW/HIGH

MIDDLE

Item Mode

Adjustment value

Monitor (MC/DV high voltage PWB)

Actual

voltage

Adjustment

range

Default value

Monitor voltage

(Specified value)

Connector

Pin

No.

No.

MIDDLE

A

MIDDLE SPEED

GB_K

GB_K

K

Main charger grid voltage

(Middle speed mode)

(Middle speed mode)

230 – 850

583

54.1

± 1.62V

CNMON

8

–620V

B

MIDDLE SPEED

GB_C

GB_C

C Main charger grid voltage

(Middle speed mode)

230 – 850

635

55.5

± 1.67V

CNMON

6

–635V

C MIDDLE SPEED

GB_M

M Main charger grid voltage

(Middle speed mode)

230 – 850

635

55.5

± 1.67V

CNMON

4

–635V

D MIDDLE SPEED

GB_Y

Y

Main charger grid voltage

(Middle speed mode)

(Middle speed mode)

230 – 850

635

55.5

± 1.67V

CNMON

2

–635V

LOW/

HIGH

HIGH

A

LOW SPEED

GB_K

GB_K

K

Main charger grid voltage

(Low speed mode)

(Low speed mode)

230 – 850

552

50.9

± 1.53V

CNMON

8

–585V

B

LOW SPEED

GB_C

GB_C

C Main charger grid voltage

(Low speed mode)

230 – 850

600

52.3

± 1.57V

CNMON

6

–600V

C LOW SPEED

GB_M

M Main charger grid voltage

(Low speed mode)

230 – 850

600

52.3

± 1.57V

CNMON

4

–600V

D LOW SPEED

GB_Y

Y

Main charger grid voltage

(Low speed mode)

(Low speed mode)

230 – 850

600

52.3

± 1.57V

CNMON

2

–600V

E

HIGH SPEED

GB_K

GB_K

K

Main charger grid voltage

(High speed mode)

(High speed mode)

230 – 850

604 (70-sheets machine)

598 (62/55-sheets

machine)

60.5

± 1.82V

CNMON

8

–690V

MX-7000N ADJUSTMENTS 6 – 7

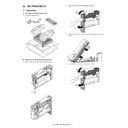

1)

Remove the screw, and remove the main unit rear cover.

2)

Open the PWB holder.

3)

Enter SIM8-2 mode.

4)

Select an output mode to be adjusted with the mode key and

the scroll key.

the scroll key.

5)

Check the relationship between the pin No. of the connector

CNMON on the MC/DV high voltage PWB and each adjust-

ment mode.

CNMON on the MC/DV high voltage PWB and each adjust-

ment mode.

6)

Apply a digital multi-meter to the connector CNMON pin on the

MC/DV high voltage PWB corresponding to the adjusted

mode.

MC/DV high voltage PWB corresponding to the adjusted

mode.

7)

Press [EXECUTE] key.

The main charger grid voltage is outputted for 30sec.

If this procedure is executed for a long time, the OPC drum

and the developing roller may be adversely affected. Use this

procedure as short as possible.

If possible, it is recommendable to use an unnecessary devel-

oping unit and an unnecessary OPC drum for this adjustment.

The main charger grid voltage is outputted for 30sec.

If this procedure is executed for a long time, the OPC drum

and the developing roller may be adversely affected. Use this

procedure as short as possible.

If possible, it is recommendable to use an unnecessary devel-

oping unit and an unnecessary OPC drum for this adjustment.

8)

Check the monitor voltage with the digital multi-meter.

If the monitor voltage is not in the range of the specified values

shown in the table above, change the adjustment value and

adjust again. If the specified value voltage is not obtained even

though the adjustment value is changed, the following parts

may be defective.

MC/DV high voltage PWB

PCU PWB

Developing unit

OPC drum unit

High voltage circuit electrode

If the monitor voltage is not in the range of the specified values

shown in the table above, change the adjustment value and

adjust again. If the specified value voltage is not obtained even

though the adjustment value is changed, the following parts

may be defective.

MC/DV high voltage PWB

PCU PWB

Developing unit

OPC drum unit

High voltage circuit electrode

6-B

Developing bias voltage adjustment

This adjustment must be executed in the following cases:

* When MC/DV high voltage power PWB is replaced.

* When U2 trouble occurs.

* When PCU PWB is replaced.

* When EEPROM on the PCU PWB is replaced.

1)

* When MC/DV high voltage power PWB is replaced.

* When U2 trouble occurs.

* When PCU PWB is replaced.

* When EEPROM on the PCU PWB is replaced.

1)

Enter SIM8-1 mode.

2)

Select an output mode to be adjusted with the mode key and

the scroll key.

the scroll key.

3)

Enter the adjustment value (specified value) of the middle

speed mode and press [OK] key.

speed mode and press [OK] key.

1

2

or after 30 sec.

10-key

A : 450

;

MIDDLE SPEED DVB_K

B : 450

;

MIDDLE SPEED DVB_C

C : 450

;

MIDDLE SPEED DVB_M

D : 450

;

MIDDLE SPEED DVB_Y

A:

SIMULATION NO.08-01

DV SETTING AND OUTPUT

XXX

0

700

OK

TEST

EXECUTE

EXECUTE

CLOSE

LOW/HIGH

MIDDLE

A : 500

;

MIDDLE SPEED DVB_K

B : 450

;

MIDDLE SPEED DVB_C

C : 450

;

MIDDLE SPEED DVB_M

D : 450

;

MIDDLE SPEED DVB_Y

A:

SIMULATION NO.08-01

DV SETTING AND OUTPUT

XXX

0

700

OK

TEST

EXECUTE

EXECUTE

CLOSE

LOW/HIGH

MIDDLE

Item

Mode

Adjustment value

Monitor (MC/DV high voltage PWB)

Actual

voltage

Adjustment

range

Default

value

Monitor voltage

(Specified value)

Connector

Pin

No.

No.

MIDDLE

A

MIDDLE SPEED DVB_K

K

Developing bias voltage (Middle

speed mode)

speed mode)

0 – 700

450

12.0

± 0.36V

CNMON

7

–450V

B

MIDDLE SPEED DVB_C

C

Developing bias voltage (Middle

speed mode)

speed mode)

0 – 700

450

12.0

± 0.36V

CNMON

5

–450V

C

MIDDLE SPEED DVB_M

M

Developing bias voltage (Middle

speed mode)

speed mode)

0 – 700

450

12.0

± 0.36V

CNMON

3

–450V

D

MIDDLE SPEED DVB_Y

Y

Developing bias voltage (Middle

speed mode)

speed mode)

0 – 700

450

12.0

± 0.36V

CNMON

1

–450V

LOW/

HIGH

HIGH

A

LOW SPEED DVB_K

K

Developing bias voltage (Low

speed mode)

speed mode)

0 – 700

420

11.1

± 0.33V

CNMON

7

–420V

B

LOW SPEED DVB_C

C

Developing bias voltage (Low

speed mode)

speed mode)

0 – 700

420

11.1

± 0.33V

CNMON

5

–420V

C

LOW SPEED DVB_M

M

Developing bias voltage (Low

speed mode)

speed mode)

0 – 700

420

11.1

± 0.33V

CNMON

3

–420V

D

LOW SPEED DVB_Y

Y

Developing bias voltage (Low

speed mode)

speed mode)

0 – 700

420

11.1

± 0.33V

CNMON

1

–420V

E

HIGH SPEED DVB_K

K

Developing bias voltage (High

speed mode)

speed mode)

0 – 700

450

12.0

± 0.36V

CNMON

7

–450V