Sharp AR-M550 (serv.man18) Service Manual ▷ View online

AR-M550/M620 MAINTENANCE LIST 11 - 14

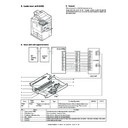

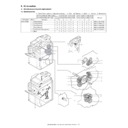

3. Maintenance and disassembly

A. Necessary execution items in maintenance and servicing

(1) Execution items before maintenance and servicing

(2) Necessary execution items in maintenance and servicing

The necessary execution items in maintenance are shown below. (The items necessary to be executed are marked with "

∗

" in the table below.)

The following items must be executed regardless of maintenance or not. (

∗

).

(

∗

• The JOB No. indicates the title number of the adjustment item described in the chapter of the adjustments.

• Refer to the details based on this number according to necessity.

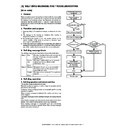

(3) Execution items after maintenance and servicing

Item

Simulation

Check the developer counter value.

22

13

Check the OPC drum counter value.

22

13

Check the print count mode in each section and each operation mode.

22

1

Check the number of paper jam troubles.

22

2

Check the positions and contents of paper jams.

22

3

Check the positions and contents of paper jams (SPF section).

22

12

Check the contents of troubles.

22

4

Print the setting values and the adjustment values.

22

6

Check the number of use of the SPF, the scanner, the finisher, and inserter, the stapler, and the punch.

22

8

Check the number of use of each paper feed section.

22

9

Check the ROM version.

22

5

No.

JOB

No.

Work item

Simulation

When repairing (replacing consumable parts)/maintenance

When repairing

of consumable

parts)/inspecting

When

installing

When

replacing the

OPC drum

When

replacing

developer

After cleaning

the scanner

(read) section

Periodic

maintenance

1

—

Toner concentration reference control level setting

25-2

∗

∗

2

—

The photoconductor counter is cleared.

24-7

∗

3

—

The photoconductor rotation counter is cleared.

24-11

∗

4

ADJ9

Copy image quality adjustment (check)

46-2,9,10,

11,18,31

∗

∗

∗

∗

∗

5

ADJ10 FAX mode print image quality adjustment (check)

46-12,13,

14,15,16,45

∗

∗

∗

∗

∗

6

ADJ11 Scanner mode image quality adjustment (check)

46-21,22,

23,24,25,27

∗

∗

∗

∗

∗

Item

Simulation

The paper jam/trouble data are cleared.

24

1

The use quantity counter of each paper feed section is cleared.

24

2

The numbers of use of the SPF, the scanner, the finisher, the inserter, the stapler, and the punch are cleared.

24

3

The maintenance counter is cleared.

24

4

The list of setting values and adjustment values is printed.

22

6

AR-M550/M620 MAINTENANCE LIST 11 - 14

3. Maintenance and disassembly

A. Necessary execution items in maintenance and servicing

(1) Execution items before maintenance and servicing

(2) Necessary execution items in maintenance and servicing

The necessary execution items in maintenance are shown below. (The items necessary to be executed are marked with "

∗

" in the table below.)

The following items must be executed regardless of maintenance or not. (

∗

).

(

∗

• The JOB No. indicates the title number of the adjustment item described in the chapter of the adjustments.

• Refer to the details based on this number according to necessity.

(3) Execution items after maintenance and servicing

Item

Simulation

Check the developer counter value.

22

13

Check the OPC drum counter value.

22

13

Check the print count mode in each section and each operation mode.

22

1

Check the number of paper jam troubles.

22

2

Check the positions and contents of paper jams.

22

3

Check the positions and contents of paper jams (SPF section).

22

12

Check the contents of troubles.

22

4

Print the setting values and the adjustment values.

22

6

Check the number of use of the SPF, the scanner, the finisher, and inserter, the stapler, and the punch.

22

8

Check the number of use of each paper feed section.

22

9

Check the ROM version.

22

5

No.

JOB

No.

Work item

Simulation

When repairing (replacing consumable parts)/maintenance

When repairing

of consumable

parts)/inspecting

When

installing

When

replacing the

OPC drum

When

replacing

developer

After cleaning

the scanner

(read) section

Periodic

maintenance

1

—

Toner concentration reference control level setting

25-2

∗

∗

2

—

The photoconductor counter is cleared.

24-7

∗

3

—

The photoconductor rotation counter is cleared.

24-11

∗

4

ADJ9

Copy image quality adjustment (check)

46-2,9,10,

11,18,31

∗

∗

∗

∗

∗

5

ADJ10 FAX mode print image quality adjustment (check)

46-12,13,

14,15,16,45

∗

∗

∗

∗

∗

6

ADJ11 Scanner mode image quality adjustment (check)

46-21,22,

23,24,25,27

∗

∗

∗

∗

∗

Item

Simulation

The paper jam/trouble data are cleared.

24

1

The use quantity counter of each paper feed section is cleared.

24

2

The numbers of use of the SPF, the scanner, the finisher, the inserter, the stapler, and the punch are cleared.

24

3

The maintenance counter is cleared.

24

4

The list of setting values and adjustment values is printed.

22

6

AR-M550/M620 MAINTENANCE LIST 11 - 14

3. Maintenance and disassembly

A. Necessary execution items in maintenance and servicing

(1) Execution items before maintenance and servicing

(2) Necessary execution items in maintenance and servicing

The necessary execution items in maintenance are shown below. (The items necessary to be executed are marked with "

∗

" in the table below.)

The following items must be executed regardless of maintenance or not. (

∗

).

(

∗

• The JOB No. indicates the title number of the adjustment item described in the chapter of the adjustments.

• Refer to the details based on this number according to necessity.

(3) Execution items after maintenance and servicing

Item

Simulation

Check the developer counter value.

22

13

Check the OPC drum counter value.

22

13

Check the print count mode in each section and each operation mode.

22

1

Check the number of paper jam troubles.

22

2

Check the positions and contents of paper jams.

22

3

Check the positions and contents of paper jams (SPF section).

22

12

Check the contents of troubles.

22

4

Print the setting values and the adjustment values.

22

6

Check the number of use of the SPF, the scanner, the finisher, and inserter, the stapler, and the punch.

22

8

Check the number of use of each paper feed section.

22

9

Check the ROM version.

22

5

No.

JOB

No.

Work item

Simulation

When repairing (replacing consumable parts)/maintenance

When repairing

of consumable

parts)/inspecting

When

installing

When

replacing the

OPC drum

When

replacing

developer

After cleaning

the scanner

(read) section

Periodic

maintenance

1

—

Toner concentration reference control level setting

25-2

∗

∗

2

—

The photoconductor counter is cleared.

24-7

∗

3

—

The photoconductor rotation counter is cleared.

24-11

∗

4

ADJ9

Copy image quality adjustment (check)

46-2,9,10,

11,18,31

∗

∗

∗

∗

∗

5

ADJ10 FAX mode print image quality adjustment (check)

46-12,13,

14,15,16,45

∗

∗

∗

∗

∗

6

ADJ11 Scanner mode image quality adjustment (check)

46-21,22,

23,24,25,27

∗

∗

∗

∗

∗

Item

Simulation

The paper jam/trouble data are cleared.

24

1

The use quantity counter of each paper feed section is cleared.

24

2

The numbers of use of the SPF, the scanner, the finisher, the inserter, the stapler, and the punch are cleared.

24

3

The maintenance counter is cleared.

24

4

The list of setting values and adjustment values is printed.

22

6

AR-M550/M620 MAINTENANCE LIST 11 - 14

3. Maintenance and disassembly

A. Necessary execution items in maintenance and servicing

(1) Execution items before maintenance and servicing

(2) Necessary execution items in maintenance and servicing

The necessary execution items in maintenance are shown below. (The items necessary to be executed are marked with "

∗

" in the table below.)

The following items must be executed regardless of maintenance or not. (

∗

).

(

∗

• The JOB No. indicates the title number of the adjustment item described in the chapter of the adjustments.

• Refer to the details based on this number according to necessity.

(3) Execution items after maintenance and servicing

Item

Simulation

Check the developer counter value.

22

13

Check the OPC drum counter value.

22

13

Check the print count mode in each section and each operation mode.

22

1

Check the number of paper jam troubles.

22

2

Check the positions and contents of paper jams.

22

3

Check the positions and contents of paper jams (SPF section).

22

12

Check the contents of troubles.

22

4

Print the setting values and the adjustment values.

22

6

Check the number of use of the SPF, the scanner, the finisher, and inserter, the stapler, and the punch.

22

8

Check the number of use of each paper feed section.

22

9

Check the ROM version.

22

5

No.

JOB

No.

Work item

Simulation

When repairing (replacing consumable parts)/maintenance

When repairing

of consumable

parts)/inspecting

When

installing

When

replacing the

OPC drum

When

replacing

developer

After cleaning

the scanner

(read) section

Periodic

maintenance

1

—

Toner concentration reference control level setting

25-2

∗

∗

2

—

The photoconductor counter is cleared.

24-7

∗

3

—

The photoconductor rotation counter is cleared.

24-11

∗

4

ADJ9

Copy image quality adjustment (check)

46-2,9,10,

11,18,31

∗

∗

∗

∗

∗

5

ADJ10 FAX mode print image quality adjustment (check)

46-12,13,

14,15,16,45

∗

∗

∗

∗

∗

6

ADJ11 Scanner mode image quality adjustment (check)

46-21,22,

23,24,25,27

∗

∗

∗

∗

∗

Item

Simulation

The paper jam/trouble data are cleared.

24

1

The use quantity counter of each paper feed section is cleared.

24

2

The numbers of use of the SPF, the scanner, the finisher, the inserter, the stapler, and the punch are cleared.

24

3

The maintenance counter is cleared.

24

4

The list of setting values and adjustment values is printed.

22

6