Sharp AR-M351U / AR-M451U (serv.man16) Service Manual ▷ View online

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 4

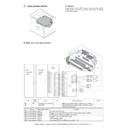

<Specification>

<2> Print off-center adjustment

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

Items which must be executed after completion of this adjust-

ment.

ment.

• Each tray resist amount setting

• Print lead edge adjustment

• Front/rear and left/right void amount setting

1) Execute SIM50-10.

2) Set the paper feed tray and the magnification ratio for the

adjustment.

3) After entering the adjustment values, press START key, and

printing is started.

4) Check the off-center (distance from the paper edge) of the

printed copy. Repeat procedure 2) until the specification is

satisfied.

satisfied.

• For the duplex mode (Single

→

Duplex), add 10 to the above set value.

• When the print line is shifted toward a from the paper center, decrease the value.

• When the print line is shifted toward b from the paper center, increase the value.

<3> Each tray resist amount setting

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• Print lead edge adjustment

• Front/rear and left/right void amount setting

1) Execute SIM 51-2.

2) Enter the resist adjustment value with 10-key.

3) Press [START] key.

When [START] key is pressed, the adjustment value is set and

paper feed and copying are performed.

paper feed and copying are performed.

4) Adjust the resist quantity so that paper is transferred stably.

Measuring

point

Specification

Set value

Print

distortion

adjustment

distortion

adjustment

Self print

pattern 71

pattern 71

θ

= 90° ± 0.13°

θ

changes about 0.25

degrees for 1 scale of

adjustment. (A shifts

about 1mm.)

adjustment. (A shifts

about 1mm.)

a b

Print lead edge

2

SIMULATION 50-10

PRINT OFF-CENTER ADJUSTMENT. SELECT 0-8, AND PRESS

START.

0.TRAY SELECT

1

1.COPY START

2.MAGNIFICATION

100

(ADJUSTMENT DATA)

3.TRAY1

50

4.TRAY2

50

5.TRAY3

50

6.TRAY4

50

7.BPT

50

8.ADU

50

Adjustment position

Measurement

reference

Specification

Set value

Default

Range

Tray 1

Tray 1

Output pattern

center line

center line

0±1.5mm

50

0 - 99

Set value 1: 0.1mm shift

Tray 2

Tray 2

Tray 3

Tray 3/LCC left

Tray 4

Tray 4/LCC right

MFT

Manual feed

ADU

Duplex

a

b

Print lead edge

∗

This adjustment is executed when there is any lead edge vari-

ation or skew for each tray.

ation or skew for each tray.

1

SIMULATION 51-2

RESIST TIMING ADJUSTMENT. SELECT 0-8, AND PRESS START.

0.TRAY SELECT

1

1.PRINT START

2.TRAY1

60

3.TRAY2

50

4.DESK

50

5.BPT

55

6.ADU

50

7.SPF(HIGH)

60

8.SPF(LOW)

75

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 5

When the set value is increased, the warp amount of paper is

increased. When the adjustment value is decreased, the warp

amount of paper is decreased.

increased. When the adjustment value is decreased, the warp

amount of paper is decreased.

<4> Self print lead edge adjustment

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

• Resist amount adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• Front/rear and left/right void amount setting

• OC scan lead edge adjustment

• SPF scan lead edge adjustment

1) Execute SIM 50-5.

2) Set the lead edge void adjustment value (DENA) as specified

2) Set the lead edge void adjustment value (DENA) as specified

below.

(Standard set value) Paper lead edge void: 3.5mm (DENA:

35)

35)

∗

Set the adjustment value of DENA to 35. (Enter 35 as the

adjustment value of DENA, and press [P] key.)

adjustment value of DENA, and press [P] key.)

3) Check the lead edge void area on the self print pattern

(SIM67-1).

(Enter 1 and press [START] key.)

4) If the adjustment result is not satisfactory, perform the follow-

ing procedures.

∗

If the lead edge void area is not 3.5mm:

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.)

(Shift for the adjustment value change: 0.1mm/step)

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.)

(Shift for the adjustment value change: 0.1mm/step)

<Specification>

<5> Front/rear and left/right void amount setting

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

• Resist amount adjustment

• Print lead edge adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• OC scan lead edge adjustment

• SPF scan lead edge adjustment

1) Execute SIM 50-1.

(Lead edge image loss/void area adjustment)

(Lead edge image loss/void area adjustment)

1) Set the lead edge image loss adjustment value (LEAD EDGE)

and the paper lead edge void adjustment value (DENA) as fol-

lows.

lows.

(Standard set value)

Lead edge image loss: 1.5mm (LEDA: 15)

Lead edge image loss: 1.5mm (LEDA: 15)

Paper lead edge void: 3.5mm (DENA: 35)

∗

Set LEAD to 15. (Enter 15 as the adjustment value of LEAD,

and press [P] key.) (0.1mm/step)

and press [P] key.) (0.1mm/step)

∗

Set DENA to 35. (Enter 35 as the adjustment value of

DENA, and press [P] key.) (0.1mm/step)

DENA, and press [P] key.) (0.1mm/step)

2) Make a copy at the normal ratio (100%) and check the lead

edge void area and the image loss. (Enter 100 as the set value

of the copy magnification ratio (MAGNIFICATION), and press

[START] key.)

of the copy magnification ratio (MAGNIFICATION), and press

[START] key.)

3) If the adjustment result is not satisfactory, perform the follow-

ing procedures.

∗

If the lead edge void are is not 3.5mm:

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.) (1msec/step)

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.) (1msec/step)

∗

If the lead edge image loss is not 1.5mm:

Change the adjustment value of RRCA and perform the

adjustment. (Change the adjustment value of RRCA and

press [START] key.)

(Shift for the adjustment value change: 0.2mm/step)

Change the adjustment value of RRCA and perform the

adjustment. (Change the adjustment value of RRCA and

press [START] key.)

(Shift for the adjustment value change: 0.2mm/step)

(Rear edge void area adjustment)

Adjust so that the rear edge void area is 3.5mm. (Change the

adjustment value of TRAIL EDGE, and press [START] key.)

adjustment value of TRAIL EDGE, and press [START] key.)

(Front/rear frame direction image loss adjustment)

Set the adjustment value of SIDE to 20. (Enter 20 as the adjust-

ment value of SIDE, and press [P] key.)

ment value of SIDE, and press [P] key.)

When the adjustment value is changed, the image position is

shifted in the front/rear frame direction.

shifted in the front/rear frame direction.

(Front/rear frame direction void area adjustment)

Adjust so that the total of the front/rear direction void areas is

7.0mm. (Change the adjustment values of FRONT/REAR, and

press [START] key.)

7.0mm. (Change the adjustment values of FRONT/REAR, and

press [START] key.)

Front frame void area = 3.5mm

Rear frame void area = 3.5mm

If, as shown above, the front and the rear void areas are not even,

use SIM 50-5 to adjust the image off-center position.

use SIM 50-5 to adjust the image off-center position.

Item

Set

range

Default

AR-M351U/

M355U

AR-M451U/

M455U

2 TRAY1

Tray 1 resist

adjustment value

adjustment value

0 - 99

65

60

3 TRAY2

Tray 2 resist

adjustment value

adjustment value

55

50

4 DESK

Desk resist

adjustment value

adjustment value

55

50

5 BPT

Manual tray resist

adjustment value

adjustment value

60

55

6 ADU

ADU resist

adjustment value

adjustment value

55

50

Set position

Specification

Set value

Self print lead

edge

adjustment

SIM 50-5

edge

adjustment

SIM 50-5

Print start

position A of

the output

pattern 1

position A of

the output

pattern 1

A = 4.0mm or less

(Lead and tail

total: 8.0mm or

less)

(Lead and tail

total: 8.0mm or

less)

Shift of

0.175mm

(35ppm) /

0.225mm

(45ppm) for

set value 1.

0.175mm

(35ppm) /

0.225mm

(45ppm) for

set value 1.

2

SIMULATION 50-5

LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START.

0.TRAY SELECT

LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START.

0.TRAY SELECT

1

1.PRINT START

(ADJUSTMENT DATA)

LEAD EDGE: 2.RRCB

LEAD EDGE: 2.RRCB

50

3.SIDE2 ADJ.

50

RESIST: 4.T1

50

5.T2

50

6.DESK

50

7.BPT

50

8.ADU

50

OFF CENTER: 9.T1

50

10.T2

50

11.T3

50

12.T4

50

13.BPT

50

14.ADU

50

(VOID SETTING) 15.LEAD_EDGE(DENA)

50

16.TRAIL_EDGE(DENB)

30

17.FRONT/REAR

30

A

[Output pattern]

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 6

<Specification>

B. Adjustment on the scanner side

<1> OC scan distortion adjustment

Items which must have been completed before this adjust-

ment.

ment.

• Adjustment on the engine side (If there is no problem in self

print, no need to adjust.)

Items which must be executed after completion of this adjust-

ment.

ment.

• OC scan off-center

• OC scan lead edge adjustment

1) Make a test chart as shown below. (Make a self-print pattern

71.)

2) Make a copy from the table glass, and check it.

At that time, set the test chart correctly. If it is set in a distorted

position, the adjustment cannot be made correctly.

position, the adjustment cannot be made correctly.

3) If the output value is not in the specified range, perform the fol-

lowing adjustment.

4) Adjust the distortion.

Use a level gauge to check that the scanner is installed hori-

zontally.

zontally.

Make a copy and check it. If there is any distortion as shown in

Fig. 1 or Fig. 2, loosen the scanner fixing screw (M4 x 8) and

the cam A fixing screw (M3 x 12) and adjust.

Fig. 1 or Fig. 2, loosen the scanner fixing screw (M4 x 8) and

the cam A fixing screw (M3 x 12) and adjust.

• In the case of Fig. 1

Shift cam A in the direction A by the difference in the copy image.

For one scale (one groove), shift by 0.5mm.

After shifting, tighten the fixing screw (M3 x 12) of cam A and

make a copy again, and check the copy again to insure that there

is no distortion.

make a copy again, and check the copy again to insure that there

is no distortion.

• In the case of Fig. 2

Shift cam A in the direction B by the difference in the copy image.

For one scale (one groove), shift by 0.5mm.

After shifting, tighten the fixing screw (M3 x 12) of cam A and

make a copy again, and check the copy again to insure that there

is no distortion.

make a copy again, and check the copy again to insure that there

is no distortion.

After adjustment, tighten the fixing screw (M3 x 12) and the scan-

ner fixing screw (M4 x 8).

ner fixing screw (M4 x 8).

∗

If the above adjustment does not fix the problem, perform the

MB rail adjustment.

MB rail adjustment.

∗

After the OC distortion adjustment, perform SIM53-8 SPF scan-

ning position automatic adjustment.

ning position automatic adjustment.

<2> SPF height adjustment

Items which must have been completed before this adjust-

ment.

ment.

• Nothing special

Items which must be executed after completion of this adjust-

ment.

ment.

• Nothing special

1) Close the (D)SPF.

2) Check to confirm that the dove and the reference plate in the

figure below are in contact with the table glass (point a) and

the side guide (point b). (Place copy paper under the dove and

pull it out.) If they are not in contact, adjust with the set screw.

the side guide (point b). (Place copy paper under the dove and

pull it out.) If they are not in contact, adjust with the set screw.

Set position

Specification

Set

value

Lead edge void

adjustment

“LEAD EDGE

VOID (DENA)”

adjustment

“LEAD EDGE

VOID (DENA)”

Output pattern

“71” print void

quantity A

“71” print void

quantity A

A = 4.0mm or

less

(A and B total:

8.0mm or less)

less

(A and B total:

8.0mm or less)

Shift of

0.1mm

for set

value 1.

0.1mm

for set

value 1.

Rear edge void

adjustment

“TAIL EDGE VOID

(DENB)”

adjustment

“TAIL EDGE VOID

(DENB)”

Output pattern

“71” print void

quantity B

“71” print void

quantity B

B = 4.0mm or

less

(A and B total:

8.0mm or less)

less

(A and B total:

8.0mm or less)

Side edge void

adjustment

“FRONT/REAR”

adjustment

“FRONT/REAR”

Output pattern

“71” print void

quantity C + D

“71” print void

quantity C + D

C and D total:

8.0mm or less

8.0mm or less

2

SIMULATION 50-1

LEAD EDGE ADJUSTMENT. SELECT 0-9, AND PRESS START.

0.TRAY SELECT

1

1.COPY START

2.MAGNIFICATION

100

(ADJUSTMENT DATA) 3.RRCA

50

4.RRCB

50

10.SIDE2 ADJ.

50

(IMAGE LOSS SETTING) 5.LEAD

15

6.SIDE

20

(VOID SETTING) 7.LEAD_EDGE(DENA)

50

8.TRAIL_EDGE(DENB)

30

9.FRONT/REAR

30

Print

lead edge

lead edge

Fixing screw

(M4 x 8)

(M4 x 8)

A

B

[Fig. 1]

[Fig. 2]

First copy image

First copy image

Image

Image

Paper

Paper

Difference

Difference

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 7

<Specification>

<3> SPF scan distortion adjustment

Items which must have been completed before this adjust-

ment.

ment.

• Adjustment on the engine side (If there is no problem in self

print, no need to adjust.)

• OC scan distortion adjustment

• SPF height adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• SPF off-center

• SPF lead edge adjustment

• Front/rear and left/right void amount setting

1) Make a test chart as shown below. (Print a self-print pattern

71.)

2) Make a copy with DSPF.

3) Check that it is in the specified range.

4) Execute SIM51-2 to check the SPF set value.

Change the set value of the SPF resist amount to the following

value.

value.

5) Though the SPF resist amount is the above value, if there is

any distortion in SPF scan, adjust the SPF installing position in

the following procedures.

the following procedures.

6) Loosen the nut which is fixing the adjustment set screw of the

hinge R, and adjust the adjustment set screw.

7) Make a copy again, and check again that the value is in the

specified range.

8) Tighten the nut to fix the adjustment screw.

<Specification>

∗

After the SPF distortion adjustment, perform SIM53-8 SPF

scanning position automatic adjustment.

scanning position automatic adjustment.

<4> OC scan magnification ratio adjustment

Items which must have been completed before this adjust-

ment.

ment.

• Adjustment on the engine side (If there is no problem in self

print, no need to adjust.)

• OC scan distortion adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• OC scan lead edge adjustment

• Original off-center adjustment

1) Place a print of self-print pattern (A3 or WLT) 70 or a scale on

the table glass.

2) Close the original cover, and make a copy.

3) Check that the value is within the specification.

4) If the value is not within the specified range, execute SIM48-1

(item 3, 4).

5) Make a copy again and check again that the value is within the

specification.

Specification

Adjustment

position

Distance between

dove (Reference

plate) and table

glass

dove (Reference

plate) and table

glass

3-point contact

(Left front/Left rear/Right

front when viewed from

the front)

(Left front/Left rear/Right

front when viewed from

the front)

Hinge

adjustment set

screw

adjustment set

screw

a

b

a

b

a

b

7

SPF (HIGH)

60

8

SPF (LOW)

75

Specification

Adjustment position

Skew feed

Within ±3mm

Hinge R adjustment screw

1

SIMULATION 51-2

RESIST TIMING ADJUSTMENT. SELECT 0-8, AND PRESS START.

0.TRAY SELECT

1

1.PRINT START

2.TRAY1

60

3.TRAY2

50

4.DESK

50

5.BPT

55

6.ADU

50

7.SPF(HIGH)

60

8.SPF(LOW)

75

a

b

a

b