Sharp AR-M351U / AR-M451U (serv.man16) Service Manual ▷ View online

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 2

9) Move the adjustment plate in the arrow direction and adjust.

<Adjustment specification>

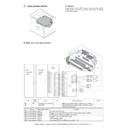

C. High voltage output adjustment

(1) Developing bias output check and setup

1) Remove the rear cabinet to allow checking of the high voltage

monitor output pin.

2) Execute the simulation of the target high voltage.

(See the table below.)

3) Select the mode to be set with 10-key, and press START key.

4) Enter the set value with 10-key and press START key. The set

value is outputted for 30 sec.

5) Apply a high voltage tester between the measurement pin and

the frame.

Note: Take care not to short the measuring pin and the frame.

6) The unit stops after 30 sec of output.

6) The unit stops after 30 sec of output.

Specification

Marking position

Measure from

the P surface above.

the P surface above.

54.2mm

P

Default

Set range

Measurement

pin

High voltage

probe

impedance

Monitor output voltage

Set value

MC grid MAIN GRID

(SIM 8-2)

(SIM 8-2)

AUTO

AE mode

45PPM: -650V±5V

35PPM: -620V±5V

35PPM: -620V±5V

45PPM: 645

35PPM: 615

35PPM: 615

200~900

CN2-7

100M

Ω

CHARACTER Text mode

-650V±5V

645

200~900

MIX

Text/Photo mode

-650V±5V

645

200~900

PHOTO

Photo mode

-650V±5V

645

200~900

PRINTER

Printer mode

-650V±5V

645

200~900

FAX

Fax mode

-650V±5V

645

200~900

Transfer current

(THV+ (SIM 8-6)

(THV+ (SIM 8-6)

FRONT

Front

45PPM: 267

35PPM: 220

35PPM: 220

0~620

BACK

Back

45PPM: 310

35PPM: 267

35PPM: 267

0~620

Developing bias DV

BIAS (SIM 8-1)

BIAS (SIM 8-1)

AUTO

AE mode

45PPM: -500V±5V

35PPM: -470V±5V

35PPM: -470V±5V

485

0~745

CN2-1

100M

Ω

CHARACTER Text mode

-500V±5V

485

0~745

MIX

Text/Photo mode

-500V±5V

485

0~745

PHOTO

Photo mode

-500V±5V

485

0~745

PRINTER

Printer mode

-500V±5V

485

0~745

FAX

Fax mode

-500V±5V

485

0~745

PLUS

Positive bias

+150V±5V

150

0~255

Separation voltage SHV

(SIM 8-17)

(SIM 8-17)

FRONT

Front

45PPM: +0.22±0.1V

35PPM: +1.37V±0.1V

45PPM: 160

35PPM: 120

35PPM: 120

0~240

CN2-3

10M

Ω

BACK

Rear

45PPM : +0.22±0.1V

35PPM: +1.37V±0.1V

45PPM: 160

35PPM: 120

35PPM: 120

0~240

Transfer voltage THV

(SIM 8-17)

(SIM 8-17)

-800V±10V

780

0~1250

CN2-5

10G

Ω

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 3

2. Image check, adjustment

(1) Copy image check

1) Place a test chart (UKOG-0089CSZZ) on the reference posi-

tion of the OC, and make a copy.

2) Place a test chart (made as shown below) face-down on the

(D)SPF, set the document guide, and make a copy. (Single

→

Single)

3) Place a test chart (made as shown below) face-up on the

DSPF, set the document guide, and make a copy. (Duplex

→

Single)

4) Check each output copy.

(Image distortion/ each void/ lead edge position/ Off-center/

Magnification ratio/ Density/ Dirt, etc.)

Magnification ratio/ Density/ Dirt, etc.)

5) If there is no problem in copy images, the image check is com-

pleted.

(2) Division of adjustment positions

1) If there is any problem in checked images, perform self-print

and the adjustment positions (scanner side/ engine side) are

divided.

divided.

*:

If there is any problem in the copy image and no problem in

the self print, an adjustment on the scanner side is required.

the self print, an adjustment on the scanner side is required.

If there is any problem on the copy image and any problem in

the self print, an adjustment on the engine side is required.

the self print, an adjustment on the engine side is required.

(3) Adjustment procedures

Perform the adjustment procedures as described below.

A. Adjustments on the engine side

<1> LSU right angle adjustment

Items which must have been completed before this adjust-

ment.

ment.

• Nothing special

Items which must be executed after completion of this adjust-

ment.

ment.

• Print off-center adjustment

• Print lead edge adjustment

• Front/rear and left/right void amount setting

1) Execute SIM64-1.

2) The print pattern "71" is printed.

3) Check the output print.

4) Loosen two fixing screws of the LSU unit

(M4 screws which are fixing the LSU and the top plate).

5) Adjust the LSU fixing position with the adjustment memory as

the reference.

6) Tighten two fixing screws of the LSU unit.

7) Print again in the grid pattern and check the print.

8) Repeat procedures 4) to 7) until the specification is satisfied.

<Right angle check method>

<1> Make self-print of pattern 71.

<2> Draw a line perpendicular to the sub scan direction (paper

transport direction) with a square.

The point of intersection of the perpendicular line and the

horizontal line is regarded as the starting point.

The point of intersection of the perpendicular line and the

horizontal line is regarded as the starting point.

<3> Measure distance A (between the self-printed line and the

perpendicular line drawn with a square) at a position of

220mm from the starting point.

220mm from the starting point.

<4> Check that distance A satisfies the following specification.

Making of SFP test chart

a.

Use standard paper of A3.

b.

Mark to the full width of the paper so that each void/image

loss can be checked.

loss can be checked.

c.

At that time, mark so that the front /rear and the top/bottom

can be identified.

can be identified.

d.

Draw a center line in the paper transport direction to identify

the off center.

the off center.

1

LSU right angle adjustment

SIM64-1: Pattern “71”

2

Print off-center adjustment

SIM50-10

3

Each tray resist amount setting

SIM51-2

4

Print lead edge adjustment

SIM50-5

5

Front/rear and left/right void

amount setting

amount setting

SIM50-1

6

OC scan distortion adjustment

7

SPF height adjustment

8

SPF scan distortion

adjustment

adjustment

SIM51-2

9

Scan magnification ratio

SIM48-1

10

SPF/DSPF scan magnification

ratio

ratio

SIM48-1

11

OC scan lead edge adjustment

SIM50-1

12

SPF scan lead edge

adjustment

adjustment

SIM50-6

13

Original off-center adjustment

SIM50-12

Center line

Standard paper of A3

SIMULATION 64-1

SELF PRINT MODE. SELECT 0-7, AND PRESS START.

0. TRAY SELECT :

1

1. PRINT START

2. PRINT PATTERN:

87

3. DENSITY :

1

4. MULTI :

1

5. MODE :

1

6. LEVEL :

1

7. DUPLEX :

1

1

A

A

220mm

Print

lead edge

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 4

<Specification>

<2> Print off-center adjustment

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

Items which must be executed after completion of this adjust-

ment.

ment.

• Each tray resist amount setting

• Print lead edge adjustment

• Front/rear and left/right void amount setting

1) Execute SIM50-10.

2) Set the paper feed tray and the magnification ratio for the

adjustment.

3) After entering the adjustment values, press START key, and

printing is started.

4) Check the off-center (distance from the paper edge) of the

printed copy. Repeat procedure 2) until the specification is

satisfied.

satisfied.

• For the duplex mode (Single

→

Duplex), add 10 to the above set value.

• When the print line is shifted toward a from the paper center, decrease the value.

• When the print line is shifted toward b from the paper center, increase the value.

<3> Each tray resist amount setting

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• Print lead edge adjustment

• Front/rear and left/right void amount setting

1) Execute SIM 51-2.

2) Enter the resist adjustment value with 10-key.

3) Press [START] key.

When [START] key is pressed, the adjustment value is set and

paper feed and copying are performed.

paper feed and copying are performed.

4) Adjust the resist quantity so that paper is transferred stably.

Measuring

point

Specification

Set value

Print

distortion

adjustment

distortion

adjustment

Self print

pattern 71

pattern 71

θ

= 90° ± 0.13°

θ

changes about 0.25

degrees for 1 scale of

adjustment. (A shifts

about 1mm.)

adjustment. (A shifts

about 1mm.)

a b

Print lead edge

2

SIMULATION 50-10

PRINT OFF-CENTER ADJUSTMENT. SELECT 0-8, AND PRESS

START.

0.TRAY SELECT

1

1.COPY START

2.MAGNIFICATION

100

(ADJUSTMENT DATA)

3.TRAY1

50

4.TRAY2

50

5.TRAY3

50

6.TRAY4

50

7.BPT

50

8.ADU

50

Adjustment position

Measurement

reference

Specification

Set value

Default

Range

Tray 1

Tray 1

Output pattern

center line

center line

0±1.5mm

50

0 - 99

Set value 1: 0.1mm shift

Tray 2

Tray 2

Tray 3

Tray 3/LCC left

Tray 4

Tray 4/LCC right

MFT

Manual feed

ADU

Duplex

a

b

Print lead edge

∗

This adjustment is executed when there is any lead edge vari-

ation or skew for each tray.

ation or skew for each tray.

1

SIMULATION 51-2

RESIST TIMING ADJUSTMENT. SELECT 0-8, AND PRESS START.

0.TRAY SELECT

1

1.PRINT START

2.TRAY1

60

3.TRAY2

50

4.DESK

50

5.BPT

55

6.ADU

50

7.SPF(HIGH)

60

8.SPF(LOW)

75

AR-M351U/M451U, AR-M355U/M455U ADJUSTMENTS 8 - 5

When the set value is increased, the warp amount of paper is

increased. When the adjustment value is decreased, the warp

amount of paper is decreased.

increased. When the adjustment value is decreased, the warp

amount of paper is decreased.

<4> Self print lead edge adjustment

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

• Resist amount adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• Front/rear and left/right void amount setting

• OC scan lead edge adjustment

• SPF scan lead edge adjustment

1) Execute SIM 50-5.

2) Set the lead edge void adjustment value (DENA) as specified

2) Set the lead edge void adjustment value (DENA) as specified

below.

(Standard set value) Paper lead edge void: 3.5mm (DENA:

35)

35)

∗

Set the adjustment value of DENA to 35. (Enter 35 as the

adjustment value of DENA, and press [P] key.)

adjustment value of DENA, and press [P] key.)

3) Check the lead edge void area on the self print pattern

(SIM67-1).

(Enter 1 and press [START] key.)

4) If the adjustment result is not satisfactory, perform the follow-

ing procedures.

∗

If the lead edge void area is not 3.5mm:

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.)

(Shift for the adjustment value change: 0.1mm/step)

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.)

(Shift for the adjustment value change: 0.1mm/step)

<Specification>

<5> Front/rear and left/right void amount setting

Items which must have been completed before this adjust-

ment.

ment.

• LSU right angle adjustment (If there is no distortion in self print,

the adjustment is not required.)

• Print off-center adjustment

• Resist amount adjustment

• Print lead edge adjustment

Items which must be executed after completion of this adjust-

ment.

ment.

• OC scan lead edge adjustment

• SPF scan lead edge adjustment

1) Execute SIM 50-1.

(Lead edge image loss/void area adjustment)

(Lead edge image loss/void area adjustment)

1) Set the lead edge image loss adjustment value (LEAD EDGE)

and the paper lead edge void adjustment value (DENA) as fol-

lows.

lows.

(Standard set value)

Lead edge image loss: 1.5mm (LEDA: 15)

Lead edge image loss: 1.5mm (LEDA: 15)

Paper lead edge void: 3.5mm (DENA: 35)

∗

Set LEAD to 15. (Enter 15 as the adjustment value of LEAD,

and press [P] key.) (0.1mm/step)

and press [P] key.) (0.1mm/step)

∗

Set DENA to 35. (Enter 35 as the adjustment value of

DENA, and press [P] key.) (0.1mm/step)

DENA, and press [P] key.) (0.1mm/step)

2) Make a copy at the normal ratio (100%) and check the lead

edge void area and the image loss. (Enter 100 as the set value

of the copy magnification ratio (MAGNIFICATION), and press

[START] key.)

of the copy magnification ratio (MAGNIFICATION), and press

[START] key.)

3) If the adjustment result is not satisfactory, perform the follow-

ing procedures.

∗

If the lead edge void are is not 3.5mm:

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.) (1msec/step)

Change the adjustment value of RRCB and perform the

adjustment. (Change the adjustment value of RRCB and

press [START] key.) (1msec/step)

∗

If the lead edge image loss is not 1.5mm:

Change the adjustment value of RRCA and perform the

adjustment. (Change the adjustment value of RRCA and

press [START] key.)

(Shift for the adjustment value change: 0.2mm/step)

Change the adjustment value of RRCA and perform the

adjustment. (Change the adjustment value of RRCA and

press [START] key.)

(Shift for the adjustment value change: 0.2mm/step)

(Rear edge void area adjustment)

Adjust so that the rear edge void area is 3.5mm. (Change the

adjustment value of TRAIL EDGE, and press [START] key.)

adjustment value of TRAIL EDGE, and press [START] key.)

(Front/rear frame direction image loss adjustment)

Set the adjustment value of SIDE to 20. (Enter 20 as the adjust-

ment value of SIDE, and press [P] key.)

ment value of SIDE, and press [P] key.)

When the adjustment value is changed, the image position is

shifted in the front/rear frame direction.

shifted in the front/rear frame direction.

(Front/rear frame direction void area adjustment)

Adjust so that the total of the front/rear direction void areas is

7.0mm. (Change the adjustment values of FRONT/REAR, and

press [START] key.)

7.0mm. (Change the adjustment values of FRONT/REAR, and

press [START] key.)

Front frame void area = 3.5mm

Rear frame void area = 3.5mm

If, as shown above, the front and the rear void areas are not even,

use SIM 50-5 to adjust the image off-center position.

use SIM 50-5 to adjust the image off-center position.

Item

Set

range

Default

AR-M351U/

M355U

AR-M451U/

M455U

2 TRAY1

Tray 1 resist

adjustment value

adjustment value

0 - 99

65

60

3 TRAY2

Tray 2 resist

adjustment value

adjustment value

55

50

4 DESK

Desk resist

adjustment value

adjustment value

55

50

5 BPT

Manual tray resist

adjustment value

adjustment value

60

55

6 ADU

ADU resist

adjustment value

adjustment value

55

50

Set position

Specification

Set value

Self print lead

edge

adjustment

SIM 50-5

edge

adjustment

SIM 50-5

Print start

position A of

the output

pattern 1

position A of

the output

pattern 1

A = 4.0mm or less

(Lead and tail

total: 8.0mm or

less)

(Lead and tail

total: 8.0mm or

less)

Shift of

0.175mm

(35ppm) /

0.225mm

(45ppm) for

set value 1.

0.175mm

(35ppm) /

0.225mm

(45ppm) for

set value 1.

2

SIMULATION 50-5

LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START.

0.TRAY SELECT

LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START.

0.TRAY SELECT

1

1.PRINT START

(ADJUSTMENT DATA)

LEAD EDGE: 2.RRCB

LEAD EDGE: 2.RRCB

50

3.SIDE2 ADJ.

50

RESIST: 4.T1

50

5.T2

50

6.DESK

50

7.BPT

50

8.ADU

50

OFF CENTER: 9.T1

50

10.T2

50

11.T3

50

12.T4

50

13.BPT

50

14.ADU

50

(VOID SETTING) 15.LEAD_EDGE(DENA)

50

16.TRAIL_EDGE(DENB)

30

17.FRONT/REAR

30

A

[Output pattern]