Sharp AR-M351U / AR-M451U (serv.man14) Service Manual ▷ View online

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 48

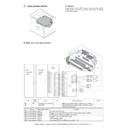

C. Operational descriptions

(1) CCD/lens unit

This machine employs the reduction optical-type line CCD (Charge Coupled Device) of scan resolution of 600dpi and 7450 pixels.

CCD scan is performed by shifting the scan positions sequentially by the carriage unit (lamp and mirror) scan or moving the document with

the SPF.

the SPF.

Lights reflected by the document are reflected by each mirror to form images on CCD elements through the reduction-type lens. The CCD

converts the optical energy into electrical energy (analog). (Photoelectric conversion)

converts the optical energy into electrical energy (analog). (Photoelectric conversion)

(2) CIS unit

The image sensor which scans back document images is attached to the SPF. The close-contact type image sensor (Contact Image Sen-

sor) with scan resolution of 600dpi and 7196 pixels is employed.

sor) with scan resolution of 600dpi and 7196 pixels is employed.

For the CIS to scan documents, the scan position is sequentially shifted by shifting the document by the SPF, and the LED light in the unit

is radiated to the back of the document, and photo energy is converted into electric energy (analog signal).

is radiated to the back of the document, and photo energy is converted into electric energy (analog signal).

No.

Name

Function

1

Copy lamp unit

Lights up to radiate documents. A xenon lamp (operating on 3.15KV) is employed.

2

Reflector

This mirror converges lights on documents.

3

No. 1 mirror

Secures the optical path between a document and No. 2 mirror.

4

No. 2 mirror

Secures the optical path between No. 1 mirror and No. 3 mirror.

5

No. 3 mirror

Secures the optical path between No. 2 mirror and the CCD.

6

CCD/Lens unit

The reduction optical type CCD (Charge Coupled Device) of 7,450 pixels is employed. The scan resolution

is 600dpi. Converts photo energy reflected by the mirrors into electric energy.

is 600dpi. Converts photo energy reflected by the mirrors into electric energy.

7

White balance sheet

Serves as the reference sheet of white for scanning with the CCD/Lens unit. If dust or dirt is attached to

this sheet, white streaks may be produced.

this sheet, white streaks may be produced.

8

Table glass

A document is set on this glass. The glass surface is coated for protection against static electricity.

A document is set to the top left corner.

A document is set to the top left corner.

9

SPF scan glass

The copy lamp unit is fixed, and a document is moved over this glass to scan line by line. The glass

surface is coated for protection against static electricity. If dust or dirt is attached to this sheet, black

streaks may be produced.

surface is coated for protection against static electricity. If dust or dirt is attached to this sheet, black

streaks may be produced.

10

Mirror home position

sensor (MHPS)

sensor (MHPS)

Detects the home position of the mirror base unit.

11

Scan motor

Drives the mirror base and the copy lamp unit.

12

DSPF white balance

sheet

sheet

Serves as the reference sheet of white for scanning with the CIS unit.

If dust or dirt is attached to this sheet, white streaks may be produced.

If dust or dirt is attached to this sheet, white streaks may be produced.

Lens center line

Focus point

LED PWB

CIS

CIS UNI

Auto-focus lens

Glass

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 49

(3) Image signal flow

The image signal converted into electric energy (analog signal) is

A-D converted on the CCD PWB. Image processes such as white

balance and shading correction are performed on the scanner

control PWB. The image signal is then sent through the mother

board to the MFP control PWB.

A-D converted on the CCD PWB. Image processes such as white

balance and shading correction are performed on the scanner

control PWB. The image signal is then sent through the mother

board to the MFP control PWB.

In the MFP control PWB, image process is performed according to

the setting content of the operation panel. The image data are

converted into laser lighting signals (VIDEO signals), and sent

through the mother PWB and the PCU to the LSU (Laser Scan

Unit).

the setting content of the operation panel. The image data are

converted into laser lighting signals (VIDEO signals), and sent

through the mother PWB and the PCU to the LSU (Laser Scan

Unit).

In the LSU, the VIDEO signals are converted into laser beams,

which are radiated onto the drum.

which are radiated onto the drum.

(4) Carriage (lamp unit) shift (scan) speed

The carriage scan speed depends on the copy magnification ratio.

Speed up to 171% = 110mm/s

Speed of 172% - 400% = 55mm/s

(5) Timing chart

Platen timing chart

SPF duplex timing chart

PSW

CCD

MHPS

MIMD

MM

Feed

Return

Home position

Home position

Scan

CCD

SPOD

CIS

SPPD4

SRRC

SPFM

1030mS

181mS

55mS

94mS

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 50

D. Maintenance and parts replacement

(1) Maintenance list

(2) Maintenance and parts replacement

Unit name

Part name

When

calling

100K 200K 300K 400K 500K 600K 700K 800K

Remark

Scanner

section

section

Mirror/Lens/Reflector/Sensors

❍

❍

❍

❍

❍

❍

❍

❍

❍

Table glass/Dust-proof glass/OC

❍

❍

❍

❍

❍

❍

❍

❍

❍

White reference glass

❍

❍

❍

❍

❍

❍

❍

❍

❍

Rails

✩

✩

✩

✩

✩

✩

✩

✩

Drive belt/Drive wire/Pulley

✕

✕

✕

✕

✕

✕

✕

✕

1

3

4

2

1

1

2

4

5

5

No.

Unit

Parts

a

Scanner unit

1

OC

❍

2

Dust-proof glass

❍

3

Table glass

❍

4

White reference glass

❍

5

Mirror

❍

6

Rails

✩

7

Drive wire

✕

8

Pulley

✕

9

Drive belt

✕

10

Scan motor

11

OC open sensor

12

Mirror home position sensor

13

Scanner control PWB

14

Scanner interface PWB

b

Lamp unit

1

Reflector

❍

2

Mirror

❍

3

Lamp

4

Inverter PWB

c

CCD lens

PWB unit

PWB unit

1

CCD lens

a-2

a-10

a-11

a-11

a-12

a-14

a-13

a-4

a-5

a-5

a-6

b-2

b-1

b

a-7

b-3

b-4

a-8

a-8

a-9

a-7

c

a-1

a-3

c-1

a-6

AR-M351U/M451U, AR-M355U/M455U MAINTENANCE AND DETAILS OF EACH SECTION 7 - 51

a. Scanner unit

a-1. OC

1) Remove the OC cover.

a-2. Dust-proof glass

a-3. Table glass

a-4. White reference glass

1) Remove the table glass holder and the white reference glass

holder, and remove the table glass and the white reference

glass.

glass.

a-5. Mirror

1) Remove the table glass.

2) Clean mirror.

a-6. Rails

1) Remove the table glass.

2) Grease up the rails.

a-7. Drive wire

a-8. Pulley

a-9. Drive belt

1) Remove the table glass.

2) Check the drive wire, pulley and drive belt.

a-10. Scan motor

1) Remove the scanner rear cabinet and the rear lower cabinet.

1)

1)

2)

3)

4)

3)

1)

2)

1)

3)

4)

4)

5)

6)

1)

1)

2)

3)

3)

4)

Click on the first or last page to see other AR-M351U / AR-M451U (serv.man14) service manuals if exist.