Sharp AR-C170 (serv.man31) Service Manual ▷ View online

AR-C170M PRINTER CONTROLLER SECTION 14 - 8

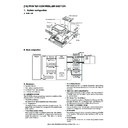

C. Interface

a. USB I/F (CN13)

This connector is USB Type-B 4-pin connector.

USB I/F (CN13) Pin Assignment

OKI ML60852A is used as USB controller. The USB Controller

device is connected with the 32-bit I/O Bus of D8501A, and IOCS0

is used. Moreover, a DMA controller uses DMAC Ch.0 in D8501A.

device is connected with the 32-bit I/O Bus of D8501A, and IOCS0

is used. Moreover, a DMA controller uses DMAC Ch.0 in D8501A.

b. IEEE1284 I/F (CN15)

Built-in 1284 controller in D8501A is used, and 1284 interfaces are

controlled.

controlled.

D8501A internal 1284 Controller Specification

• Supports IEEE1284 Compatible mode, Nibble Mode, Forward/

Reverse ECP mode (without decompression)

• Internal 16 bytes transmit buffer and 16 bytes receive buffer

supports.

• 2 channel DMA support (32 bit packed)

• Transfer data amount has to be multiple of 4-bytes.

This connector is 36 pin Amphenol connector based on IEEE1284.

Pin Assignment

c. Engine I/F

Engine Interface is supported in PRTC (Alpha-5) board. There are

a power supply line, Video-related signals, Scanner-related sig-

nals, and signals of communication relation with engine in this

Engine Interface. Moreover, Video-related signals and communi-

cation-related signals are controlled by D8501A. Scanner-related

signals are controlled by SCNIF ASIC on the SCNIF board via PCI

I/F.

a power supply line, Video-related signals, Scanner-related sig-

nals, and signals of communication relation with engine in this

Engine Interface. Moreover, Video-related signals and communi-

cation-related signals are controlled by D8501A. Scanner-related

signals are controlled by SCNIF ASIC on the SCNIF board via PCI

I/F.

Pin No

Signal

1

VCC

2

DATA -

3

DATA +

4

GND

Spec

OKI ML60852A

USB Rev.

1.1

Transfer type

Control, Bulk, Interrupt, Isochronous

End Point

5 or 6

USB transceiver

Built-in

EP1 DMA

Supported

DMA Channel

2

Bus-powered devices

Supported

DMA Data Width

8 or 16

Intelligent SIE

Supported

D+

D-

D8501A

(IC22)

SA[23:1]

244 Buffer

(IC23-25)

245 Buffer

(IC14-17)

IOWRZ0

IORDZ

SD[31:0]

IOCS0

ED[15:0]

EXTREZ0

EXTACKZ0

OKI

ML60852A

(IC45)

/CS

A[7:0]

D[15:0]

XIN

DMREQ

DMACK_N

D+

D-

EA[29:22]

/WR

/RD

INTX6

USBINTZ

/INTR

USBINTZ

GPIO3

+

-

USB I/F

(CN13)

Vbus

10K

10K

5V

6MHz

(Y2)

XOUT

10K

1M

No. Compatible

Nibble, Byte

ECP

No.

Compatible,

Byte Nibble,

Byte Nibble,

ECP

1

Nstrobe

HostClk

HostClk

19

GND

2

D1

D1

D1

20

GND

3

D2

D2

D2

21

GND

4

D3

D3

D3

22

GND

5

D4

D4

D4

23

GND

6

D5

D5

D5

24

GND

7

D6

D6

D6

25

GND

8

D7

D7

D7

26

GND

9

D8

D8

D8

27

GND

10

Nack

PrtClk

PeriphClk

28

GND

11

Busy

PrtBusy

PriphAck

29

GND

12

Rerror

AckDatReq

nAckReverse

30

GND

13

Select

Xflag

Xflag

33

N.C

14

NautoFd

HostBusy

HostAck

34

N.C

15

N.C

N.C

N.C

35

N.C

16

GND

GND

GND

17

FGND

FGND

FGND

18

LogicHigh

LogicHigh

LogicHigh

31

Nlnit

Nlnit

NrserveReqyest

32

Nfault

NdataAvil

NperiphRequest

36

Nselection IEEE1284active IEEE1284active

Engine I/F

(CN1)

244 Buffer

(IC3-4,

IC6-7)

/CNTUP

/ENGUP

/CNTWU

/ENGWU

KD[3:0]

CD[3:0]

MD[3:0]

YD[3:0]

/KVSYNC

/CVSYNC

/MVSYNC

/YVSYNC

/KHSYNC

/CHSYNC

/MHSYNC

/YHSYNC

/TXD_PRT

/RXD_PRT

DTR_PRT

DSR_PRT

RES_PRT

RES_PCU

PWM

POF

ECLK

Video Data

(4bit/color)

(4bit/color)

Video Clock

Vertical

Synchronization

Synchronization

Horizontal

Synchronization

Synchronization

Communication

Signals

(GPIO)

Signals

(GPIO)

Engine Power

Status Signals

Status Signals

D8501A

(IC22)

VD3[3:0]

VD2[3:0]

VD1[3:0]

VD0[3:0]

ECLK[3:0]

VSYNCZ / INTX4

INTX10

INTX9

INTX8

HSYNC3

HSYNC2

HSYNC1

HSYNC0

GPIO15

GPIO14

RTSZ

CTSZ

GPIO13

GPIO28

TXD

RXD

GPIO9

GPIO30

INTX3

CNTUP

LCX14

ICUUP

DTC114YKA

ENGWU

DTC114YKA

LCX14

PRTCWU

RESPCUN

LCX14

Communication

Signals

(UART)

Signals

(UART)

CMD

LCX14

STS

/SRDY

LCX14

/CRDY

DTC114YKA

LCX14

/POF

LCX14

244 (IC7)

Fan Power CN

(CN12)

SCLK

SEL

244

Buffer

(IC9-10)

SOR[76, 54, 32, 10]

SOG[76, 54, 32, 10]

SOB[76, 54, 32, 10]

Fan PWM

Scanner

Data

(8bit/color)

Data

(8bit/color)

LD_GT

Scanner Control

Signals

Signals

Scanner Clock

SCNIF

Slot

(CN8)

SCNIF

Board

Board

(N1521)

AR-C170M PRINTER CONTROLLER SECTION 14 - 9

5. Setting

A. Key operator program

(1) Printer setting

a. Basic setting

Basic setting modifies or cancels factory settings of various printer

functions according to the use conditions.

functions according to the use conditions.

1) Caution notice page output inhibition

This program is set when inhibiting print of the caution notice

page.

page.

2) Test page output inhibition

Used to inhibit printing of the test page.

When this is set, the printer test page (Test page print) cannot be

printed by the user setting.

printed by the user setting.

3) A4/Letter size auto conversion

This setting allows printing on A4 size paper when letter size is

requested but there is no letter size paper.

requested but there is no letter size paper.

∗

Printing on letter size paper when there is no A4 size is not

allowed.

allowed.

4) Hold data delete

This program is used to delete all data manually from the hard

disk.

disk.

5) Output method when built-in memory is full

When the built-in memory is full of printer data, further printing

cannot be made. Therefore, the contents stored in the memory are

printed. This program sets the print conditions. Factory setting is

"1 set."

cannot be made. Therefore, the contents stored in the memory are

printed. This program sets the print conditions. Factory setting is

"1 set."

6) Default paper type for bypass tray

This program is used to set the default paper type for paper

loaded in the bypass tray in printer mode. "NONE" (a default paper

type is not selected), "PLAIN", "HEAVY PAPER", or ''TRANSPAR-

ENCY" can be selected. If "HEAVY PAPER" is selected, select

"HEAVY PAPER 1" or "HEAVY PAPER 2". If "TRANSPARENCY"

is selected, select "SPEED MODE" or "QUALITY MODE".

loaded in the bypass tray in printer mode. "NONE" (a default paper

type is not selected), "PLAIN", "HEAVY PAPER", or ''TRANSPAR-

ENCY" can be selected. If "HEAVY PAPER" is selected, select

"HEAVY PAPER 1" or "HEAVY PAPER 2". If "TRANSPARENCY"

is selected, select "SPEED MODE" or "QUALITY MODE".

The factory default setting is "NONE".

b. Interface setting

The interface setting is used to set data monitoring and control of

data sent to the machine parallel port and network port.

data sent to the machine parallel port and network port.

1) Port select method

Used to select the parallel port and the network port of the

machine.

machine.

2) Parallel port enable setting

This program is used to set Enable/Disable of printing from the

parallel port.

parallel port.

3) USB port enable setting

This program is used to set Enable/Disable of printing from the

USB port.

USB port.

4) Network port enable setting

This program is used to set Enable/Disable of printing from the

network port.

network port.

Basic setting

Interface setting

Network setting

Color adjustments

Caution notice page output inhibition

Test page output inhibition

A4/Letter size auto conversion

Hold data delete

Output method when built-in memory is full

Port select method

Parallel port enable setting

Parallel port enable setting

USB port enable setting

Network port enable setting

I/O tome-out time

IP address setting

TCP/IP Enable setting

Netware enable setting

NetBEUI enable setting

NIC reset

Auto color calibration

Printer setting store/recall

Factory setting reset

Current setting storage

Stored setting value recall

Printer setup

Network scanner setup

Printer Operation Manual

Network Scanner Operation Manual

Printer setting

Third level

Second level

First level

Key operator

code input

code input

Default paper type for bypass tray

Items to be set

Content of item

Changeover at job

end

end

After completion of printing, the port is

set to the auto selection.

set to the auto selection.

Changeover after I/O

time-out

time-out

When the time set with I/O time-out

time (item below) is reached, the port

is set to auto selection.

time (item below) is reached, the port

is set to auto selection.

AR-C170M PRINTER CONTROLLER SECTION 14 - 10

5) I/O tome-out time

This program is used to interrupt connection of the port when print

data are not sent for a certain time to the port which is in standby

for print data reception, and used to set auto selection of port or to

start the next print data in standby for printing.

data are not sent for a certain time to the port which is in standby

for print data reception, and used to set auto selection of port or to

start the next print data in standby for printing.

I/O time-out item means the time interval between print data

reception standby and I/O time-out.

reception standby and I/O time-out.

c. Network setting

This setting is used to use the printer as a network printer. [Net-

work setting] allows setting of the following items. After changing

the items, terminate the key operator program and turn off the

main switch. Then turn on the main switch again after a while to

enable the setting.

work setting] allows setting of the following items. After changing

the items, terminate the key operator program and turn off the

main switch. Then turn on the main switch again after a while to

enable the setting.

1) IP address setting

Used to set the IP address of this machine when is it used under

the network environment using the TCP/IP protocol. (IP address,

IP net mask, IP gateway)

the network environment using the TCP/IP protocol. (IP address,

IP net mask, IP gateway)

Factory setting is "IP address is automatically acquired (DHCP

Enable)."

Enable)."

When using under the TCP/IP protocol network environment,

[TCP/IP Enable] is set to Enable.

[TCP/IP Enable] is set to Enable.

2) TCP/IP Enable setting

This setting is used when the machine is used under the TCP/IP

protocol network environment.

protocol network environment.

3) Netware enable setting

This setting is used when the machine is used under the NetWare

protocol network environment.

protocol network environment.

4) NetBEUI enable setting

This setting is used when the machine is used under the NetBEUI

protocol network environment.

protocol network environment.

5) NIC reset

Used to reset all the setting items of NIC (Network Interface Card)

to the factory setting.

to the factory setting.

Terminate the key operator program and turn off the main switch.

Then turn on the main switch again after a while to enable the set-

ting.

Then turn on the main switch again after a while to enable the set-

ting.

d. Color adjustments

This program is used to automatically adjust the color tone of each

color (cyan, magenta, yellow, and black). None of these adjust-

ments affect black and white printing.

color (cyan, magenta, yellow, and black). None of these adjust-

ments affect black and white printing.

1) Auto color calibration

The auto color calibration program enables automatic color grada-

tion correction when the color is off.

tion correction when the color is off.

Note: The color gradation may not be sufficiently corrected after

one correction cycle. If so, execute the program again.

When the [AUTO COLOUR CALIBRATION] key is touched, the

following display will appear.

following display will appear.

After the [EXECUTE] key is touched and a test patch printed, a

message appears asking you to begin automatic adjustment.

Place the test patch on the document glass as shown below and

touch the [EXECUTE] key.

message appears asking you to begin automatic adjustment.

Place the test patch on the document glass as shown below and

touch the [EXECUTE] key.

Notes:

• Correct adjustment will not be possible if you use the test patch

that is printed for "Auto color calibration" for the copy function or

any other document. If you attempt to use the wrong test patch,

you will return to the message screen that asks you to begin

automatic adjustment. Be sure to place only the test patch

printed out above on the document glass.

any other document. If you attempt to use the wrong test patch,

you will return to the message screen that asks you to begin

automatic adjustment. Be sure to place only the test patch

printed out above on the document glass.

• Lay approximately five sheets of copy paper that are the same

size as the test patch on top of the set test patch, and gently

close the original cover.

close the original cover.

When a message appears informing you that auto color calibration

is completed, touch the [OK] key to end the procedure.

is completed, touch the [OK] key to end the procedure.

Note: Before using this program, make sure that the registration is

correctly adjusted. If the registration is not correctly

adjusted, perform [AUTO ADJUSTMENT] in "Registration

adjustment".

adjusted, perform [AUTO ADJUSTMENT] in "Registration

adjustment".

e. Printer setting store/recall

This program is used to reset the environment setting and the key

operator program printer setting to the default setting and to store

the current setting contents. If the setting contents are changed,

the stored contents can be recalled to reset the machine to the

stored setting contents.

operator program printer setting to the default setting and to store

the current setting contents. If the setting contents are changed,

the stored contents can be recalled to reset the machine to the

stored setting contents.

1) Factory setting reset

This program is used to reset the environment setting and the key

operator program printer setting to the default setting. After execu-

tion of this program, terminate the key operator program and turn

off the main switch. Then turn on the main switch again after a

while to enable the setting.

operator program printer setting to the default setting. After execu-

tion of this program, terminate the key operator program and turn

off the main switch. Then turn on the main switch again after a

while to enable the setting.

2) Current setting storage

This program is used to store the environment setting and the key

operator program printer setting in the memory. The stored con-

tents are not deleted even the main switch is turned off. To recall

the stored contents, use [Stored setting value recall].

operator program printer setting in the memory. The stored con-

tents are not deleted even the main switch is turned off. To recall

the stored contents, use [Stored setting value recall].

3) Stored setting value recall

This program is used to recall the setting contents stored with the

program of [Current setting storage] and reset the machine to the

recalled setting.

program of [Current setting storage] and reset the machine to the

recalled setting.

(2) Jumper Setting

Configuration for 3-pin jumper is shown as follows.

a. Boot ROM Write Protect setting (JP1)

b. Battery setting (JP7)

KEY OPERATOR PROGRAMS

OK

AUTO COLOUR CALIBRATION

USE 11"X17" OR A3 PAPER FOR THIS ADJUSTMENT.

PRESS [EXECUTE] TO PRINT THE TEST PATCH.

PRESS [EXECUTE] TO PRINT THE TEST PATCH.

EXECUTE

Cyan

Magenta

Yellow

Black

Boot ROM Write Protect

JP1

Factory Default

Normal

1-2 Short

Write Protect

2-3 Short

←

Battery

JP7

Factory Default

ON

1-2 Short

←

OFF

2-3 Short

JP1

VCCWB

BOOT

3

1

L

⇔

H

JP7

BATTERY

1

OFF

⇔

ON

3

AR-C170M PRINTER CONTROLLER SECTION 14 - 11

6. Operation

A. Printer driver setting and operation

(1) Document mode and image process

Custom Setting dialog is automatically set with the Original Type as follows:

• When a user changes color dialog settings, "Original Type" is set Custom.

• When Original Type item is set to "Drawing (Thin line)", Screening item is set to "Automatic" on UI. However, in this case the drivers out-

put "Drawing" mode as PJL.

Color Mode

Color

Gray Scale

Automatic

Original

Type

Type

Standard

Graphics

Photo

Drawing

(Thin

line)

(Thin

line)

Web

Page

Page

Custom

Color Rendering

UCR Selection

Black Overprint

Screening

Pure Black Text

Original Type

Standard

SHARP Color

Standard

ON

Automatic

On

Graphics

Saturation Match

High Black

On

Text/Graphics

Off

Photo

Perceptual Match (Photo)

Low Black

Off

Photo

Off

Drawing (Thin line)

Saturation Match

High Black

On

Automatic

On

Web Page

Perceptual Match (Web)

Standard

Off

Automatic

On

Custom

No Change

No Change

No Change

No Change

No Change

Click on the first or last page to see other AR-C170 (serv.man31) service manuals if exist.