Sharp AL-1255 (serv.man12) Service Manual ▷ View online

AL-1555 SIMULATION, TROUBLE CODES 10 - 13

50

10

Center offset adjustment

Used to adjust the copy image position on the copy paper and the center offset position when scanning a document.

(Operating procedure)

When this simulation is executed, the current setup value is displayed. Enter the adjustment value with the 10-key and press the PRINT

switch, and the entered value will be saved and a copy will be made. When the clear key is pressed, the entered value will be saved

and the simulation will be terminated. (When the setup value is increased by 1, shift is increased by 0.1mm.)

Used to adjust the copy image position on the copy paper and the center offset position when scanning a document.

(Operating procedure)

When this simulation is executed, the current setup value is displayed. Enter the adjustment value with the 10-key and press the PRINT

switch, and the entered value will be saved and a copy will be made. When the clear key is pressed, the entered value will be saved

and the simulation will be terminated. (When the setup value is increased by 1, shift is increased by 0.1mm.)

∗

When the setup value is too great, outside of the shading area may be read, and black streaks may be produced on the edges.

When the adjustment value is increased, the image is shifted to the left.

When the adjustment value is decreased, the image is shifted to the right.

When the adjustment value is increased, the image is shifted to the left.

When the adjustment value is decreased, the image is shifted to the right.

18

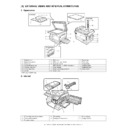

Memory reverse position adjustment in duplex copy

When this simulation is executed, the current setup value of correction is displayed. Enter the correction value with the 10-key and

press the PRINT switch, and the entered value will be saved. (Correction value 1 – 99, correction zero = 0, or 50) When the correction

value is set to 0, the correction value is written as 50.

Front surface printing in the S-D mode and printing on even pages in the D-S mode are reverse memory copy operations from the

document rear edge section.

When, therefore, the output image print position adjustment is required, adjust as follows:

In the reverse memory copy operation, if the document scan direction is in the direction of the arrow in the figure, the scan rear edge

section of the image is printed first.

When, therefore, the print lead edge is shifted, set the reference chart so that the reference position is in the rear edge section, and use

this simulation to adjust so that the print image lead edge comes to the lead edge.

Since printing is performed by processing the scanned image from the scan end position to the scan lead edge, the print lead edge

position adjustment is performed by changing the end data position stored in memory with the simulation setup value.

When this simulation is executed, the current setup value of correction is displayed. Enter the correction value with the 10-key and

press the PRINT switch, and the entered value will be saved. (Correction value 1 – 99, correction zero = 0, or 50) When the correction

value is set to 0, the correction value is written as 50.

Front surface printing in the S-D mode and printing on even pages in the D-S mode are reverse memory copy operations from the

document rear edge section.

When, therefore, the output image print position adjustment is required, adjust as follows:

In the reverse memory copy operation, if the document scan direction is in the direction of the arrow in the figure, the scan rear edge

section of the image is printed first.

When, therefore, the print lead edge is shifted, set the reference chart so that the reference position is in the rear edge section, and use

this simulation to adjust so that the print image lead edge comes to the lead edge.

Since printing is performed by processing the scanned image from the scan end position to the scan lead edge, the print lead edge

position adjustment is performed by changing the end data position stored in memory with the simulation setup value.

19

Duplex copy rear edge void adjustment

Used to adjust the rear edge void quantity in duplex copy.

(Operating procedure)

When this simulation is executed, the current setup value is displayed the current setup value is displayed in two digits. (Center value:

50 However, setup 50 = setup 0) When the correction value is set to 0, the correction value is written as 50. Press the copy mode select

key to select your desired copy mode, and the display will change. Enter the adjustment value with the 10-key and press the PRINT

switch, and the setup value will be saved and a copy will be made. (The paper information is cleared for every copying.) Press the clear

key to save the setup value and exit from the simulation mode. (Increasing the setup value by 1 increases the void quantity by about

0.1mm.)

Used to adjust the rear edge void quantity in duplex copy.

(Operating procedure)

When this simulation is executed, the current setup value is displayed the current setup value is displayed in two digits. (Center value:

50 However, setup 50 = setup 0) When the correction value is set to 0, the correction value is written as 50. Press the copy mode select

key to select your desired copy mode, and the display will change. Enter the adjustment value with the 10-key and press the PRINT

switch, and the setup value will be saved and a copy will be made. (The paper information is cleared for every copying.) Press the clear

key to save the setup value and exit from the simulation mode. (Increasing the setup value by 1 increases the void quantity by about

0.1mm.)

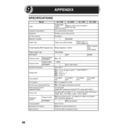

Main

code

code

Sub

code

Content

: Supported only for installing models, and skipped for not-installing models.

Adjustment mode

Lamp ON

Print center offset (Main cassette paper feed)

AE, main cassette lamp

Print center offset (2nd cassette paper feed)

AE, 2nd cassette lamp

Print center offset (Manual paper feed)

AE, manual paper feed lamp

OC/document center offset

AE, TEXT lamp

SPF/RSPF (front) document center offset

AE, TEXT, PHOTO lamp

Print lead edge

Lead edge void (1)

Print start position

Lead edge void (1)

Print start position

Rear edge void

Print rear edge

Print rear edge

Document transport direction

Scan lead edge

Scan end position

(Default: Scan cut by void (1))

(Default: Scan cut by void (1))

Scan direction

Scan rear edge

Paper transport direction

Adjustment mode

Lamp ON

Image cut rear edge void quantity (RSPF)

AE lamp

Paper rear edge void quantity

TEXT lamp

Print start position (Duplex back)

PHOTO lamp

RSPF (Back) original center offset

AE, TEXT, PHOTO lamps

AL-1555 SIMULATION, TROUBLE CODES 10 - 14

51

02

Resist quantity adjustment

Used to adjust the contact pressure of paper against the machine resist roller and the RSPF resist roller.

(Operating procedure)

When this simulation is executed, the current setup value is displayed.

Enter the adjustment value with the 10-key and press the PRINT switch, the entered set value will be saved and a copy will be made.

When the clear key is pressed, the entered value will be saved and the machine will exit from the simulation mode.

Used to adjust the contact pressure of paper against the machine resist roller and the RSPF resist roller.

(Operating procedure)

When this simulation is executed, the current setup value is displayed.

Enter the adjustment value with the 10-key and press the PRINT switch, the entered set value will be saved and a copy will be made.

When the clear key is pressed, the entered value will be saved and the machine will exit from the simulation mode.

53

08

SPF scan position automatic adjustment

Place a black chart so that it covers the SPF scan glass and the OC glass, and execute the simulation with the OC cover open, the

mirror unit scans from the home position to the SPF scan position to identify the SPF glass cover edge position by the difference in the

CCD output levels of the SPF glass cover edge and the OC side document glass.

Default is 50. Adjustment range is 0 – 99. Adjustment increment: 1 = about 0.127mm

If this adjustment is performed properly, the adjustment value is displayed. If it is abnormal, the jam lamp lights up. If the adjustment is

not made properly, “– –” is displayed.

Place a black chart so that it covers the SPF scan glass and the OC glass, and execute the simulation with the OC cover open, the

mirror unit scans from the home position to the SPF scan position to identify the SPF glass cover edge position by the difference in the

CCD output levels of the SPF glass cover edge and the OC side document glass.

Default is 50. Adjustment range is 0 – 99. Adjustment increment: 1 = about 0.127mm

If this adjustment is performed properly, the adjustment value is displayed. If it is abnormal, the jam lamp lights up. If the adjustment is

not made properly, “– –” is displayed.

61

03

Polygon motor check (HSYNC output check)

(Operation/Procedure)

When the START key is pressed, HSYNC is performed and the polygon motor is rotated for 30 sec.

At that time, the Zoom lamp is lit for 100msec for every 3 times that the HSYNC is detected.

(Operation/Procedure)

When the START key is pressed, HSYNC is performed and the polygon motor is rotated for 30 sec.

At that time, the Zoom lamp is lit for 100msec for every 3 times that the HSYNC is detected.

63

01

Shading check

Used to display the detection level of the white board for shading.

(Operating procedure)

When the PRINT switch is pressed, the mirror base unit moves to the white board for shading to light the copy lamp. Under this state,

the level of one pixel at the CCD center which is not corrected for 10sec in 1 sec, and the result is displayed on the value display

section.

Used to display the detection level of the white board for shading.

(Operating procedure)

When the PRINT switch is pressed, the mirror base unit moves to the white board for shading to light the copy lamp. Under this state,

the level of one pixel at the CCD center which is not corrected for 10sec in 1 sec, and the result is displayed on the value display

section.

64

01

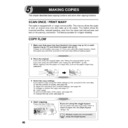

Self print

Print of one page is made regardless of the status of the optical system.

(Operating procedure)

When this simulation is executed, warm-up is performed and the ready lamp is lighted. Enter the code number with the 10-key, and

select the cassette with the cassette select key and press the PRINT switch, and paper feed operation will be made from the selected

cassette and printing of the selected pattern will be made. Printing is in 1by2 mode, or grid pattern.

Print of one page is made regardless of the status of the optical system.

(Operating procedure)

When this simulation is executed, warm-up is performed and the ready lamp is lighted. Enter the code number with the 10-key, and

select the cassette with the cassette select key and press the PRINT switch, and paper feed operation will be made from the selected

cassette and printing of the selected pattern will be made. Printing is in 1by2 mode, or grid pattern.

Main

code

code

Sub

code

Content

: Supported only for installing models, and skipped for not-installing models.

Adjustment mode

Lamp ON

Main cassette paper feed

AE, main cassette lamp

2nd cassette paper feed

AE, 2nd cassette lamp

Manual paper feed

AE, manual paper feed lamp

RSPF document feed (front)

AE, TEXT, PHOTO lamp

RSPF document feed (back)

AE, TEXT lamp

duplex back

TEXT, PHOTO lamp

∗

2 – 99: print in 1by2.

Code number

Pattern

0

1by2

1

Grid pattern

AL-1555 SIMULATION, TROUBLE CODES 10 - 15

4. Trouble codes

A. Trouble codes list

Main

code

code

Sub

code

Trouble content

Detail of trouble

E7

01

Duplex model memory

setup error, memory not-

detected error

setup error, memory not-

detected error

The memory is not set properly or the memory capacity is not set to the duplex setup (6M).

Cancel method: Set SIM 26-39 code number to 2.

Cancel method: Set SIM 26-39 code number to 2.

02

HSYNC not detected.

LSU (laser diode, reception element, APC circuit) trouble

LSU drive circuit (ASIC) trouble

LSU drive circuit (ASIC) trouble

10

CCD black level trouble

CCD drive circuit (CCD PWB, ASIC, harness) trouble

11

CCD white level trouble

CCD drive circuit (CCD PWB, ASIC harness) trouble

Copy lamp lighting trouble (Copy lamp, inverter PWB)

Copy lamp lighting trouble (Copy lamp, inverter PWB)

12

Shading trouble

(White correction)

(White correction)

Dirt on white plate for scanning white level

16

Laser output trouble

LSU (laser diode, reception element, APC circuit) trouble

LSU drive circuit (ASIC) trouble

LSU drive circuit (ASIC) trouble

F5

02

Copy lamp disconnection

trouble

trouble

Copy lamp or copy lamp drive circuit (inverter PWB) trouble

Copy lamp disconnection

Copy lamp disconnection

H2

00

Thermistor open detection The fusing thermistor is open.

H3

00

Heat roller abnormally high

temperature

temperature

The fusing temperature rises above 240° C.

H4

00

Heat roller abnormally low

temperature

temperature

The fusing temperature does not reach 185° C within 27 sec of turning on the power, or the fusing

temperature keeps at 140° C.

temperature keeps at 140° C.

L1

00

Feeding is not completed

within the specified time

after starting feeding.

(The scan head locking

switch is locked)

within the specified time

after starting feeding.

(The scan head locking

switch is locked)

The white area and the black marking on the shading plate are used to obtain the difference in the CCD

level values for judgment of lock. When the difference in the levels of which and black is small, it is judged

that the black mark could not be scanned by lock and the trouble code “L1” is displayed.

level values for judgment of lock. When the difference in the levels of which and black is small, it is judged

that the black mark could not be scanned by lock and the trouble code “L1” is displayed.

L3

00

Return is not completed

within the specified time.

within the specified time.

When the mirror base is returned for the specified time (6 sec) in mirror initializing after turning on the

power, the mirror home position sensor (MHPS) does not turn ON. Or when the mirror base is returned for

the specified time (about 6 sec) after start of copy return, the mirror home position sensor (MHPS) does not

turn ON.

power, the mirror home position sensor (MHPS) does not turn ON. Or when the mirror base is returned for

the specified time (about 6 sec) after start of copy return, the mirror home position sensor (MHPS) does not

turn ON.

L4

01

Main motor lock

When the main motor encoder pulse is not detected for 100 msec.

L6

10

Polygon motor lock

The lock signal (specified rpm signal) does not return within a certain time (about 20 sec) from starting the

polygon motor rotation

polygon motor rotation

U2

01

Counter sum check error

04

EEPROM serial

communication error

communication error

When a communication trouble occurs with the EEPROM.

AL-1555 SIMULATION, TROUBLE CODES 10 - 15

4. Trouble codes

A. Trouble codes list

Main

code

code

Sub

code

Trouble content

Detail of trouble

E7

01

Duplex model memory

setup error, memory not-

detected error

setup error, memory not-

detected error

The memory is not set properly or the memory capacity is not set to the duplex setup (6M).

Cancel method: Set SIM 26-39 code number to 2.

Cancel method: Set SIM 26-39 code number to 2.

02

HSYNC not detected.

LSU (laser diode, reception element, APC circuit) trouble

LSU drive circuit (ASIC) trouble

LSU drive circuit (ASIC) trouble

10

CCD black level trouble

CCD drive circuit (CCD PWB, ASIC, harness) trouble

11

CCD white level trouble

CCD drive circuit (CCD PWB, ASIC harness) trouble

Copy lamp lighting trouble (Copy lamp, inverter PWB)

Copy lamp lighting trouble (Copy lamp, inverter PWB)

12

Shading trouble

(White correction)

(White correction)

Dirt on white plate for scanning white level

16

Laser output trouble

LSU (laser diode, reception element, APC circuit) trouble

LSU drive circuit (ASIC) trouble

LSU drive circuit (ASIC) trouble

F5

02

Copy lamp disconnection

trouble

trouble

Copy lamp or copy lamp drive circuit (inverter PWB) trouble

Copy lamp disconnection

Copy lamp disconnection

H2

00

Thermistor open detection The fusing thermistor is open.

H3

00

Heat roller abnormally high

temperature

temperature

The fusing temperature rises above 240° C.

H4

00

Heat roller abnormally low

temperature

temperature

The fusing temperature does not reach 185° C within 27 sec of turning on the power, or the fusing

temperature keeps at 140° C.

temperature keeps at 140° C.

L1

00

Feeding is not completed

within the specified time

after starting feeding.

(The scan head locking

switch is locked)

within the specified time

after starting feeding.

(The scan head locking

switch is locked)

The white area and the black marking on the shading plate are used to obtain the difference in the CCD

level values for judgment of lock. When the difference in the levels of which and black is small, it is judged

that the black mark could not be scanned by lock and the trouble code “L1” is displayed.

level values for judgment of lock. When the difference in the levels of which and black is small, it is judged

that the black mark could not be scanned by lock and the trouble code “L1” is displayed.

L3

00

Return is not completed

within the specified time.

within the specified time.

When the mirror base is returned for the specified time (6 sec) in mirror initializing after turning on the

power, the mirror home position sensor (MHPS) does not turn ON. Or when the mirror base is returned for

the specified time (about 6 sec) after start of copy return, the mirror home position sensor (MHPS) does not

turn ON.

power, the mirror home position sensor (MHPS) does not turn ON. Or when the mirror base is returned for

the specified time (about 6 sec) after start of copy return, the mirror home position sensor (MHPS) does not

turn ON.

L4

01

Main motor lock

When the main motor encoder pulse is not detected for 100 msec.

L6

10

Polygon motor lock

The lock signal (specified rpm signal) does not return within a certain time (about 20 sec) from starting the

polygon motor rotation

polygon motor rotation

U2

01

Counter sum check error

04

EEPROM serial

communication error

communication error

When a communication trouble occurs with the EEPROM.