Sharp R-874 (serv.man3) Service Manual ▷ View online

R-874M - 21

LSI(IXA094DR)

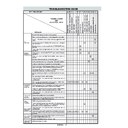

The I/O signal of the LSI(IXA094DR) are detailed in the following table.

The I/O signal of the LSI(IXA094DR) are detailed in the following table.

DESCRIPTION OF LSI

Pin No.

Signal

I/O

Description

Power output

ON time

OFF time

100 %

48 sec.

0 sec.

90 %

44 sec.

4 sec.

80 %

40 sec.

8 sec.

70 %

36 sec.

12 sec.

60 %

32 sec.

16 sec.

50 %

26 sec.

22 sec.

40 %

22 sec.

26 sec.

30 %

16 sec.

32 sec.

20 %

12 sec.

36 sec.

10 %

8 sec.

40 sec.

ON

OFF

During

cooking

L

GND

H.

(Convection or dual cooking)

ON

OFF

During cooking or for awhile after convection,

grill (top and bottom grill ) or dual.

grill (top and bottom grill ) or dual.

L

GND

H.

38

XIN

IN

Internal clock oscillation frequency input setting.

The internal clock frequency is set by inserting the ceramic filter oscillation circuit

with respect to XOUT terminal.

The internal clock frequency is set by inserting the ceramic filter oscillation circuit

with respect to XOUT terminal.

39

XOUT

OUT

Internal clock oscillation frequency control output.

Output to control oscillation input of XIN.

Output to control oscillation input of XIN.

40

VSS

IN

Power source voltage: -5V.

VC voltage of power source circuit input.

VC voltage of power source circuit input.

41

P27

OUT

Bottom heating element driving signal.

To turn on and off the relay (RY4). "L"

level during grill cooking, convection

cooking or dual cooking, "H" level

otherwise.

The heater relay turns on and off within

a 48 second time base in accordance

with the special program in LSI.

To turn on and off the relay (RY4). "L"

level during grill cooking, convection

cooking or dual cooking, "H" level

otherwise.

The heater relay turns on and off within

a 48 second time base in accordance

with the special program in LSI.

42

P26

OUT

Convection motor driving signal.

To turn on and off shut-off relay(RY7). "L"

level during convection or dual cooking "H"

level otherwise. (Relay RY7 does not turn on

at preheating mode.)

To turn on and off shut-off relay(RY7). "L"

level during convection or dual cooking "H"

level otherwise. (Relay RY7 does not turn on

at preheating mode.)

43

P25

OUT

Fan motor driving signal.

To turn on and off the fan motor relay RY6. "L"

level during cooking, or for a while after

convection, grill (top and bottom grill) or dual

cooking. "H" level otherwise.

To turn on and off the fan motor relay RY6. "L"

level during cooking, or for a while after

convection, grill (top and bottom grill) or dual

cooking. "H" level otherwise.

44

P24

OUT

Terminal not used.

45

P23

OUT

Touch control transformer driving signal.

To turn on and off the shut off relay (RY5). If the oven has not been used for more

than 3 minutes, the relay RY5 will be turned off. The relay RY5 will be turned on

when the oven door is opened and closed.

To turn on and off the shut off relay (RY5). If the oven has not been used for more

than 3 minutes, the relay RY5 will be turned off. The relay RY5 will be turned on

when the oven door is opened and closed.

46-48

P22-P20

OUT

Terminal not used.

49-50

P17-P16

IN

Terminal to change functions according to the model.

51-80

SEG39-SEG10

OUT

Segment data signal.

Connected to LCD.

The relation between signals are as follows:

Connected to LCD.

The relation between signals are as follows:

LSI signal (Pin No.)

LCD (Pin No.)

LSI signal (Pin No.) LCD (Pin No.)

SEG 0 (90) .................... SEG39 (51)

SEG21 (69) ................. SEG19 (19)

SEG 1 (89) .................... SEG38 (50)

SEG22 (68) ................. SEG18 (18)

SEG 2 (88) .................... SEG37 (49)

SEG23 (67) ................. SEG17 (17)

SEG 3 (87) .................... SEG36 (48)

SEG24 (66) ................. SEG16 (16)

SEG 4 (86) .................... SEG35 (47)

SEG25 (65) ................. SEG15 (15)

SEG 5 (85) .................... SEG34 (46)

SEG26 (64) ................. SEG14 (14)

SEG 6 (84) .................... SEG33 (45)

SEG27 (63) ................. SEG13 (13)

SEG 7 (83) .................... SEG32 (44)

SEG28 (62) ................. SEG12 (12)

SEG 8 (82) .................... SEG31 (43)

SEG29 (61) ................. SEG11 (11)

SEG10 (80) ................... SEG30 (30)

SEG30 (60) ................. SEG10 (10)

SEG11 (79) ................... SEG29 (29)

SEG31 (59) ................... SEG 9 ( 9)

SEG12 (78) ................... SEG28 (28)

SEG32 (58) ................... SEG 8 ( 8)

SEG13 (77) ................... SEG27 (27)

SEG33 (57) ................... SEG 7 ( 7)

SEG14 (76) ................... SEG26 (26)

SEG34 (56) ................... SEG 6 ( 6)

SEG15 (75) ................... SEG25 (25)

SEG35 (55) ................... SEG 5 ( 5)

SEG16 (74) ................... SEG24 (24)

SEG36 (54) ................... SEG 4 ( 4)

SEG17 (73) ................... SEG23 (23)

SEG37 (53) ................... SEG 3 ( 3)

SEG18 (72) ................... SEG22 (22)

SEG38 (52) ................... SEG 2 ( 2)

SEG19 (71) ................... SEG21 (21)

SEG39 (51) ................... SEG 1 ( 1)

SEG20 (70) ................... SEG20 (20)

R-874 S/MANUAL

11/7/01, 10:59 am

21

R-874M - 22

Pin No.

Signal

I/O

Description

81

SEG9

OUT

Terminal not used.

82-90

SEG8-SEG0

OUT

Segment data signal.

Connected to LCD. Signal is similar to SEG39.

Connected to LCD. Signal is similar to SEG39.

91

VCC

IN

Connected to GND.

92

VREF

IN

Connected to GND.

93

AVSS

IN

Connected to VC.

94

COM3

OUT

Common data signal: COM3.

Connected to LCD (Pin No. 35).

Connected to LCD (Pin No. 35).

95

COM2

OUT

Common data signal: COM2.

Connected to LCD (Pin No. 34).

Connected to LCD (Pin No. 34).

96

COM1

OUT

Common data signal: COM1.

Connected to LCD (Pin No. 33).

Connected to LCD (Pin No. 33).

97

COM0

OUT

Terminal not used.

98-99

VL3-VL2

IN

Power source voltage input terminal.

Standard voltage for LCD.

Standard voltage for LCD.

100

C2

IN

Terminal not used.

LSI(IXA094DR)

The I/O signal of the LSI(IXA094DR) are detailed in the following table.

The I/O signal of the LSI(IXA094DR) are detailed in the following table.

DESCRIPTION OF LSI

R-874 S/MANUAL

11/7/01, 10:59 am

22

R-874M - 23

SERVICING

5) Re-connect the power supply cord after the outer

case is installed.

6) Run the oven and check all functions.

A.

On some models, the power supply cord between the

touch control panel and the oven itself is so short that

the two can't be separated.

the two can't be separated.

For those models, check and repair all the controls

(sensor-related ones included) of the touch control

panel while keeping it connected to the oven.

(sensor-related ones included) of the touch control

panel while keeping it connected to the oven.

B.

On some models, the power supply cord between the

touch control panel and the oven is long enough that

they may be separated from each other. For those

models, therefore, it is possible to check and repair the

controls of the touch control panel while keeping it apart

from the oven; in this case you must short both ends of

the door sensing switch (on PWB) of the touch control

panel with a jumper, which brings about an operational

state that is equivalent to the oven door being closed.

As for the sensor-related controls of the touch control

panel, checking them is possible if the dummy resistor(s)

with resistance equal to that of the controls are used.

they may be separated from each other. For those

models, therefore, it is possible to check and repair the

controls of the touch control panel while keeping it apart

from the oven; in this case you must short both ends of

the door sensing switch (on PWB) of the touch control

panel with a jumper, which brings about an operational

state that is equivalent to the oven door being closed.

As for the sensor-related controls of the touch control

panel, checking them is possible if the dummy resistor(s)

with resistance equal to that of the controls are used.

(2) Servicing the touch control panel with power

supply from an external power source:

Disconnect the touch control panel completely from

the oven, and short both ends of the door sensing

switch (on PWB) of the touch control panel, which

brings about an operational state that is equivalent to

the oven door being closed. Connect an external

power source to the power input terminal of the touch

control panel, then it is possible to check and repair the

controls of the touch control panel; it is also possible to

check the sensor-related controls of the touch control

panel by using the dummy resistor(s).

the oven, and short both ends of the door sensing

switch (on PWB) of the touch control panel, which

brings about an operational state that is equivalent to

the oven door being closed. Connect an external

power source to the power input terminal of the touch

control panel, then it is possible to check and repair the

controls of the touch control panel; it is also possible to

check the sensor-related controls of the touch control

panel by using the dummy resistor(s).

4. Servicing Tools

Tools required to service the touch control panel assem-

bly.

1) Soldering iron: 30W

bly.

1) Soldering iron: 30W

(It is recommended to use a soldering iron with a

grounding terminal.)

grounding terminal.)

2) Oscilloscope: Single beam, frequency range: DC -

10MHz type or more advanced model.

3) Others: Hand tools

5. Other Precautions

1) Before turning on the power source of the control unit,

remove the aluminium foil applied for preventing static

electricity.

electricity.

2) Connect the connector of the key unit to the control unit

being sure that the lead wires are not twisted.

3) After aluminium foil is removed, be careful that abnor-

mal voltage due to static electricity etc. is not applied

to the input or output terminals.

to the input or output terminals.

4) Attach connectors, electrolytic capacitors, etc. to PWB,

making sure that all connections are tight.

5) Be sure to use specified components where high

precision is required.

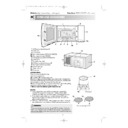

E

C B

Transistor

2SB1238

2SB1238

Transistor

KRC243M

KRC243M

E

C

B

1. Precautions for Handling Electronic Components

This unit uses CMOS LSI in the integral part of the circuits.

When handling these parts, the following precautions

should be strictly followed. CMOS LSI have extremely

high impedance at its input and output terminals. For this

reason, it is easily influenced by the surrounding high

voltage power source, static electricity charge in clothes,

etc., and sometimes it is not fully protected by the built-in

protection circuit.

In order to protect CMOS LSI.

1) When storing and transporting, thoroughly wrap them

When handling these parts, the following precautions

should be strictly followed. CMOS LSI have extremely

high impedance at its input and output terminals. For this

reason, it is easily influenced by the surrounding high

voltage power source, static electricity charge in clothes,

etc., and sometimes it is not fully protected by the built-in

protection circuit.

In order to protect CMOS LSI.

1) When storing and transporting, thoroughly wrap them

in aluminium foil. Also wrap PW boards containing

them in aluminium foil.

them in aluminium foil.

2) When soldering, ground the technician as shown in

the figure and use grounded soldering iron and work

table.

table.

approx. 1M ohm

2. Shapes of Electronic Components

3. Servicing of Touch Control Panel

We describe the procedures to permit servicing of the

touch control panel of the microwave oven and the pre-

cautions you must take when doing so.

To perform the servicing, power to the touch control panel

is available either from the power line of the oven itself or

from an external power source.

touch control panel of the microwave oven and the pre-

cautions you must take when doing so.

To perform the servicing, power to the touch control panel

is available either from the power line of the oven itself or

from an external power source.

(1) Servicing the touch control panel with power

supply of the oven :

CAUTION:

THE HIGH VOLTAGE TRANSFORMER OF THE

MICROWAVE OVEN IS STILL LIVE DURING

SERVICING AND PRESENTS A HAZARD .

THE HIGH VOLTAGE TRANSFORMER OF THE

MICROWAVE OVEN IS STILL LIVE DURING

SERVICING AND PRESENTS A HAZARD .

T

herefore, before checking the performance of the touch

control panel,

1) Disconnect the power supply cord, and then remove

1) Disconnect the power supply cord, and then remove

outer case.

2) Open the door and block it open.

3) Discharge high voltage capacitor.

4) Disconnect the leads to the primary of the power

3) Discharge high voltage capacitor.

4) Disconnect the leads to the primary of the power

transformer.

5) Ensure that these leads remain isolated from other

components and oven chassis by using insulation

tape.

tape.

6) After that procedure, re-connect the power supply

cord.

After checking the performance of the touch control

panel,

1) Disconnect the power supply cord.

2) Open the door and block it open.

3) Re-connect the leads to the primary of the power

2) Open the door and block it open.

3) Re-connect the leads to the primary of the power

transformer.

4) Re-install the outer case (cabinet).

R-874 S/MANUAL

11/7/01, 10:59 am

23

R-874M - 24

9. Discharge the H.V. capacitor before carrying out any

further work.

10.Do not operate the oven with the outer case removed.

N.B.; Step 1, 2 and 9 form the basis of the 3D checks.

N.B.; Step 1, 2 and 9 form the basis of the 3D checks.

CAUTION: DISCHARGE HIGH VOLTAGE CAPACI-

TOR BEFORE TOUCHING ANY OVEN

COMPONENT OR WIRING.

COMPONENT OR WIRING.

CAUTION: WHEN THE OUTER CASE CABINET IS

RE-INSTALLED, INSTALL IT BEFORE THE

BACK PLATE IS INSTALLED, OR THE

OUTER CASE CABINET WILL BE DE-

FORMED.

BACK PLATE IS INSTALLED, OR THE

OUTER CASE CABINET WILL BE DE-

FORMED.

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WARNING: Avoid possible exposure to microwave energy. Please follow the instructions below

before operating the oven.

1. Disconnect oven from power supply.

2. Make sure that a definite “click” can be heard when the

2. Make sure that a definite “click” can be heard when the

microwave oven door is unlatched. (Hold the door in a

closed position with one hand, then push the door open

button with the other, this causes the latch leads to rise,

it is then possible to hear a “click” as the door switches

operate.)

closed position with one hand, then push the door open

button with the other, this causes the latch leads to rise,

it is then possible to hear a “click” as the door switches

operate.)

3. Visually check the door and cavity face plate for dam-

age (dents, cracks, signs of arcing etc.).

Carry out any remedial work that is necessary before

operating the oven.

Do not operate the oven if any of the following conditions

exist;

operating the oven.

Do not operate the oven if any of the following conditions

exist;

1. Door does not close firmly.

2. Door hinge, support or latch hook is damaged.

3. The door gasket or seal or damaged.

4. The door is bent or warped.

5. There are defective parts in the door interlock system.

6. There are defective parts in the microwave generating

2. Door hinge, support or latch hook is damaged.

3. The door gasket or seal or damaged.

4. The door is bent or warped.

5. There are defective parts in the door interlock system.

6. There are defective parts in the microwave generating

and transmission assembly.

7. There is visible damage to the oven.

Do not operate the oven:

1. Without the RF gasket (Magnetron).

2. If the wave guide or oven cavity are not intact.

3. If the door is not closed.

4. If the outer case (cabinet) is not fitted.

1. Without the RF gasket (Magnetron).

2. If the wave guide or oven cavity are not intact.

3. If the door is not closed.

4. If the outer case (cabinet) is not fitted.

Please refer to ‘OVEN PARTS, CABINET PARTS, CONTROL PANEL PARTS, DOOR PARTS’, when carrying out any

of the following removal procedures:

of the following removal procedures:

WARNING FOR WIRING

To prevent an electric shock, take the following

manners.

1. Before wiring,

manners.

1. Before wiring,

1) Disconnect the power supply.

2) Open the door and wedge the door open.

3) Discharge the high voltage capacitor and wait for

2) Open the door and wedge the door open.

3) Discharge the high voltage capacitor and wait for

60 seconds.

2. Don't let the wire leads touch to the following parts;

1) High voltage parts:

Magnetron, High voltage transformer, High volt-

age capacitor and High voltage rectifier assem-

bly.

age capacitor and High voltage rectifier assem-

bly.

2) Hot parts:

Top heating element, Bottom heating element,

Oven lamp, Magnetron, High voltage transformer

and Oven cavity.

and Oven cavity.

3) Sharp edge:

Bottom plate, Oven cavity, Waveguide flange,

Chassis support and other metallic plate.

Chassis support and other metallic plate.

4) Movable parts (to prevent a fault)

Fan blade, Fan motor, Switch, Open lever, Open

button,Turntable motor, Convection motor.

button,Turntable motor, Convection motor.

3. Do not catch the wire leads in the outer case cabinet.

4. Insert the positive lock connector certainly until its pin

4. Insert the positive lock connector certainly until its pin

is locked. And make sure that the wire leads should

not come off even if the wire leads is pulled.

not come off even if the wire leads is pulled.

5. To prevent an error function, connect the wire leads

correctly, referring to the Pictorial Diagram.

voltage capacitor.

3. Disconnect the high voltage wire B from the magnetron.

4. Remove one (1) screw holding earth side terminal of

4. Remove one (1) screw holding earth side terminal of

the high voltage rectifier assembly.

OUTER CASE REMOVAL

To remove the outer case proceed as follows.

1. Disconnect oven from power supply.

2. Open the oven door and wedge it open.

3. Remove the two (2) screws holding the back plate to

1. Disconnect oven from power supply.

2. Open the oven door and wedge it open.

3. Remove the two (2) screws holding the back plate to

the oven cavity rear plate. Remove the back plate

4. Remove the one (1) screw holding the air duct assem-

bly to the oven cavity rear plate.

5. Remove the air duct assembly

6. Remove the eight (8) screws from rear and along the

6. Remove the eight (8) screws from rear and along the

side edge of case.

7. Slide the entire case back about 3 cm to free it from

retaining clips on the cavity face plate.

8. Lift the entire case from the oven.

HIGH VOLTAGE COMPONENTS REMOVAL

(HIGH VOLTAGE CAPACITOR AND HIGH VOLTAGE RECTIFIER ASSEMBLY)

To remove the components, proceed as follows.

1. CARRY OUT 3D CHECKS.

2. Disconnect the filament lead of the high voltage trans-

1. CARRY OUT 3D CHECKS.

2. Disconnect the filament lead of the high voltage trans-

former and the high voltage wire A from the high

R-874 S/MANUAL

11/7/01, 10:59 am

24